Worm gear-worm pair backlash eliminating device adopting enveloping worm

A toroidal worm, worm gear and worm technology, used in hoisting devices, portable lifting devices, components with teeth, etc., can solve the problems of long transmission chain, easy wear, and many transmission components, to prevent rigid contact, reduce Manufacturing cost, effect of preventing worm movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

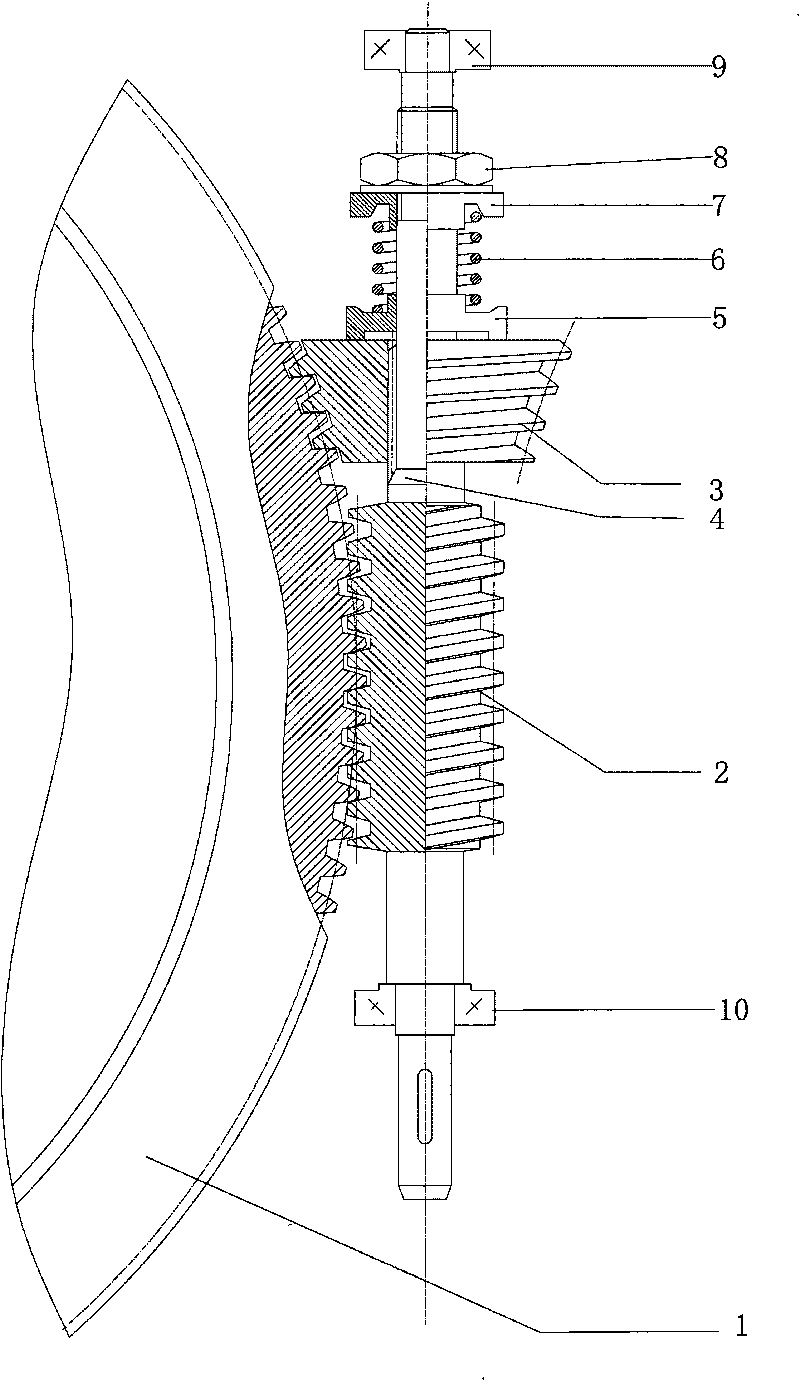

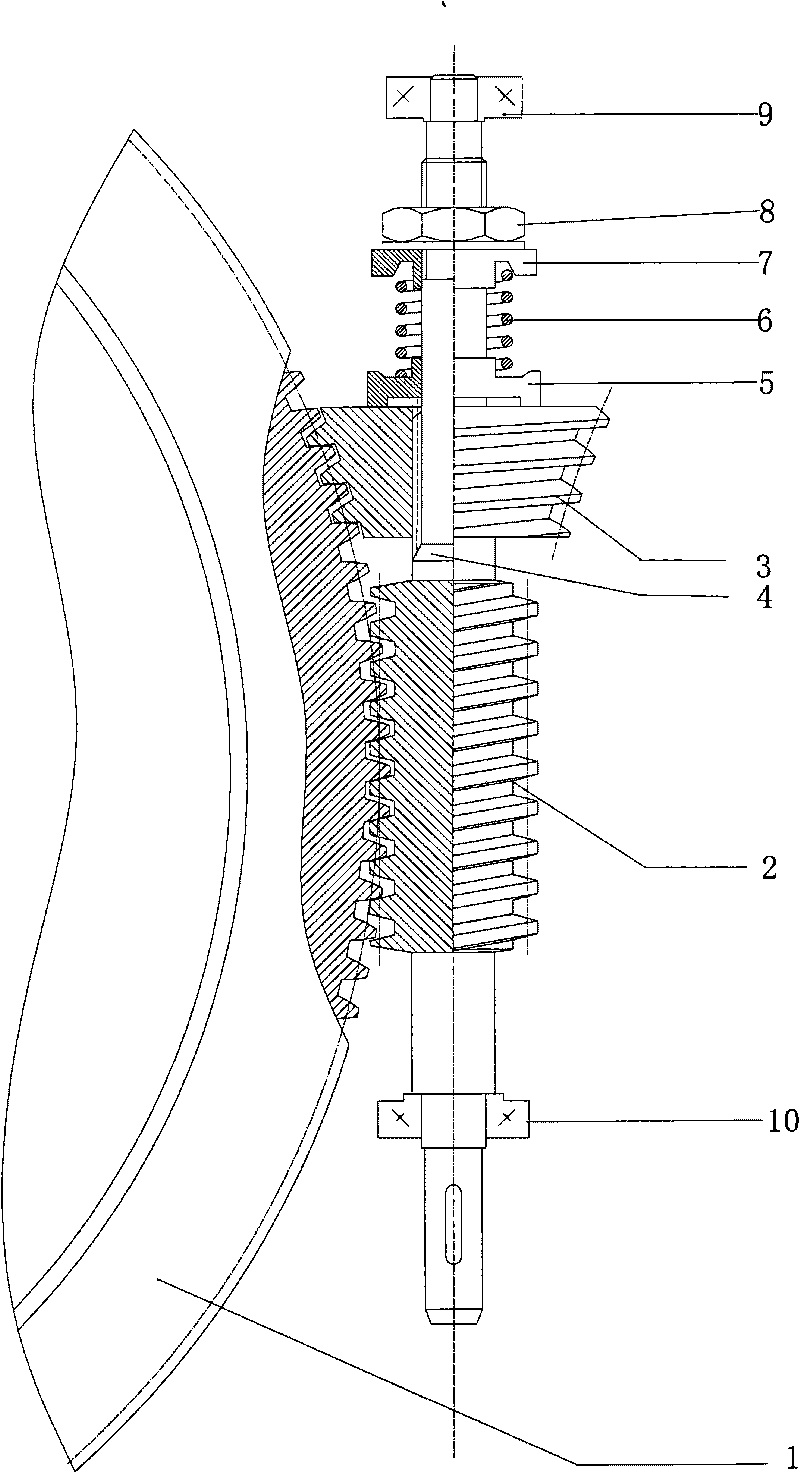

[0020] Such as figure 1 Shown is the structural diagram of the worm gear and worm pair anti-backlash device that adopts the toroidal worm. The main structure of the worm gear and worm pair anti-backlash device proposed by the present invention includes a worm wheel 1, a cylindrical worm 2 that provides an indexing function, and is assembled on the The toroidal worm 3 acting as resistance on the indexing worm 2 shaft, the right sleeve 5, the preload spring 6 and the left sleeve 7 form a preloading device that provides preloading force, and axially preloads the toroidal worm 3 Adjusting nut 8 for power adjustment and shaft end left bearing 9 and right bearing 10. The toroidal worm 3 is assembled between the elastic pretensioning device and the indexing worm 2 through the spline 4 .

[0021] During the assembly process, first adjust the positions of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com