Flexible grinding mechanism

A flexible mechanism and pin technology, applied in the field of grinding tools, can solve the problems of high hardness of pouring risers, damage to tools and robots, inconsistent dimensions and burrs, etc., to avoid rigid contact and improve yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

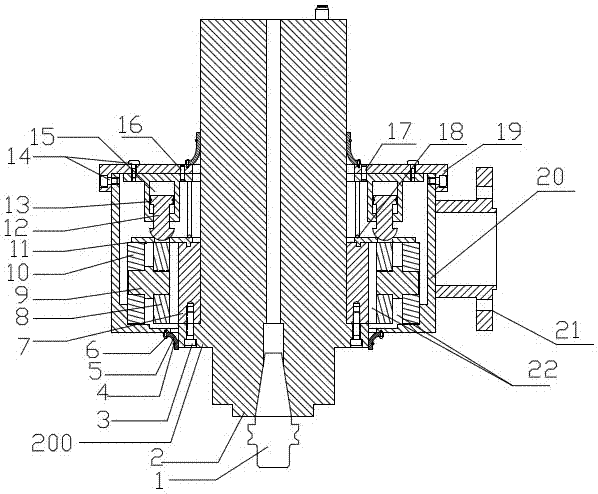

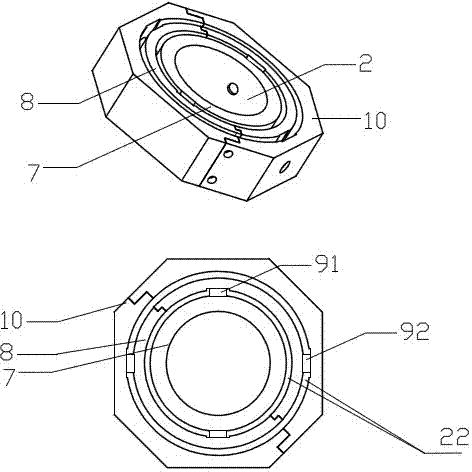

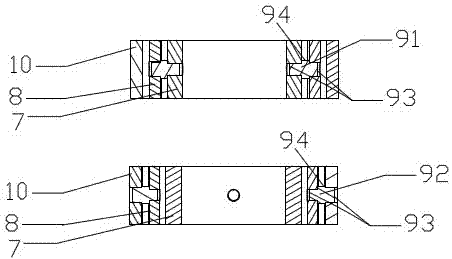

[0024] Such as figure 1 Shown is a schematic diagram of a preferred embodiment of the flexible grinding mechanism of the present invention. The flexible grinding mechanism includes a knife handle 1, an electric spindle 2, an inner cylinder sleeve 7, an outer cylinder sleeve 8, a copper pin 9, an anti-rotation cylinder 10, Pressing plate 11, annular cylinder group 15, travel switch 18, upper cover 19 and shell 20.

[0025] combine Figure 1 to Figure 3 As shown, the tool handle 1 is fixed in the chuck at the lower end of the electric spindle 2 . The electric spindle 2 is radially provided with a convex circle 200 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com