Cloth cleaning device for textile processing

A cleaning device and cloth technology, which is applied in the processing of textile material equipment configuration, textile material processing, spray/jet textile material processing, etc., can solve the problems of reducing performance, workshop environment impact, textile cloth deformation, etc., and achieve not easy deformation or damage, avoid rigid contact, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

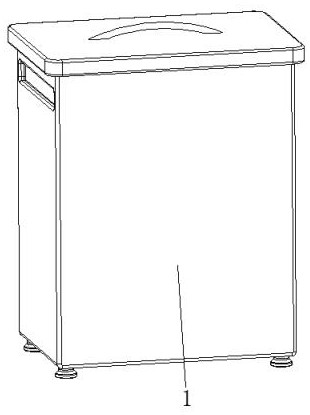

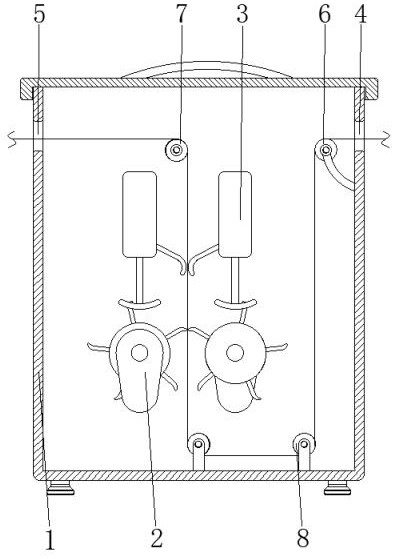

[0033] see Figure 1-7 , the present invention provides a technical solution: a cloth cleaning device for textile processing, including a box body 1, a flexible cleaning device 2, and a water removal device 3, and the flexible cleaning device 2 is arranged at the inner center of the box body 1 and near the bottom position , the dewatering device 3 is arranged inside the box body 1 and located above the flexible cleaning device 2, and the flexible cleaning device 2 is connected with the dewatering device 3;

[0034] The top side of the surface of the box body 1 is provided with a feed port 4, and the top surface of the box body 1 and the side away from the feed port 4 is provided with a discharge port 5, and the inner wall of the box body 1 is close to the position of the feed port 4 A support roller 6 is provided, an upper guide roller 7 is arranged inside the box body 1 and near the top of the dewatering device 3, and a lower guide roller 8 is arranged at the bottom of the in...

Embodiment example 2

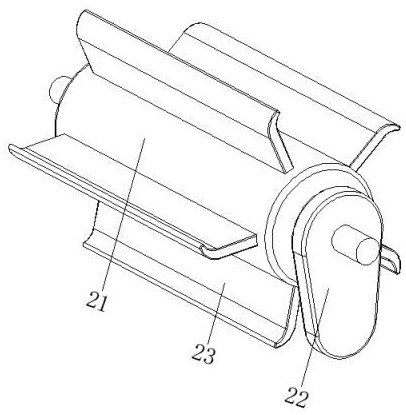

[0036] The flexible cleaning device 2 is provided with a driving roller 21, a cam 22, and a scrubbing device 23. The driving roller 21 is rotatably connected between the two sides corresponding to the inner wall of the casing 1. The cam 22 is arranged on one end of the driving roller 21, and the scrubbing device 23 is arranged on the The inside of the driving roller 21 is located on the surface, and the brushing device 23 is connected with the driving roller 21 .

[0037] The scrubbing device 23 is provided with a scraper device 231, an arc-shaped elastic member 232, an elastic water bag 233, and a scrubbing layer 234. The scraper device 231 is slidably connected to the inside of the drive roller 21 and is positioned on the surface, and the arc-shaped elastic member 232 is arranged on the scraper. Between the end of the body device 231 and the two sides corresponding to the inside of the drive roller 21, the elastic water bag 233 is arranged between the end of the scraper devic...

Embodiment example 3

[0039] The scraper device 231 is provided with a T-shaped base 2311, an arc-shaped scraper 2312, and a water spray channel 2313. One end of the T-shaped base 2311 is slidingly connected to the inside of the driving roller 21, and the arc-shaped scraper 2312 is arranged on the T-shaped base 2311. One end away from the driving roller 21, the water spray channel 2313 is opened in the inside of the T-shaped base body 2311, and the water spray channel 2313 communicates with the elastic water bag 233. Under the elastic force of the arc-shaped elastic member 232, it elastically shrinks to the inside of the driving roller 21, and presses the elastic water bag 233, and the compressed elastic water bag 233 sprays the cleaning liquid inside from the water spray channel 2313 to the cloth. In this way, water is sprayed while brushing, and after the T-shaped bases 2311 on both sides are separated from each other, under the elastic force of the arc-shaped elastic member 232, the T-shaped base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com