Perforating device

A punching device and frame technology, applied in boring/drilling, drilling/drilling equipment, metal processing, etc., can solve problems such as potential safety hazards, single-aperture drilling, etc., to save the grinding process, Avoid potential safety hazards and adjust accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

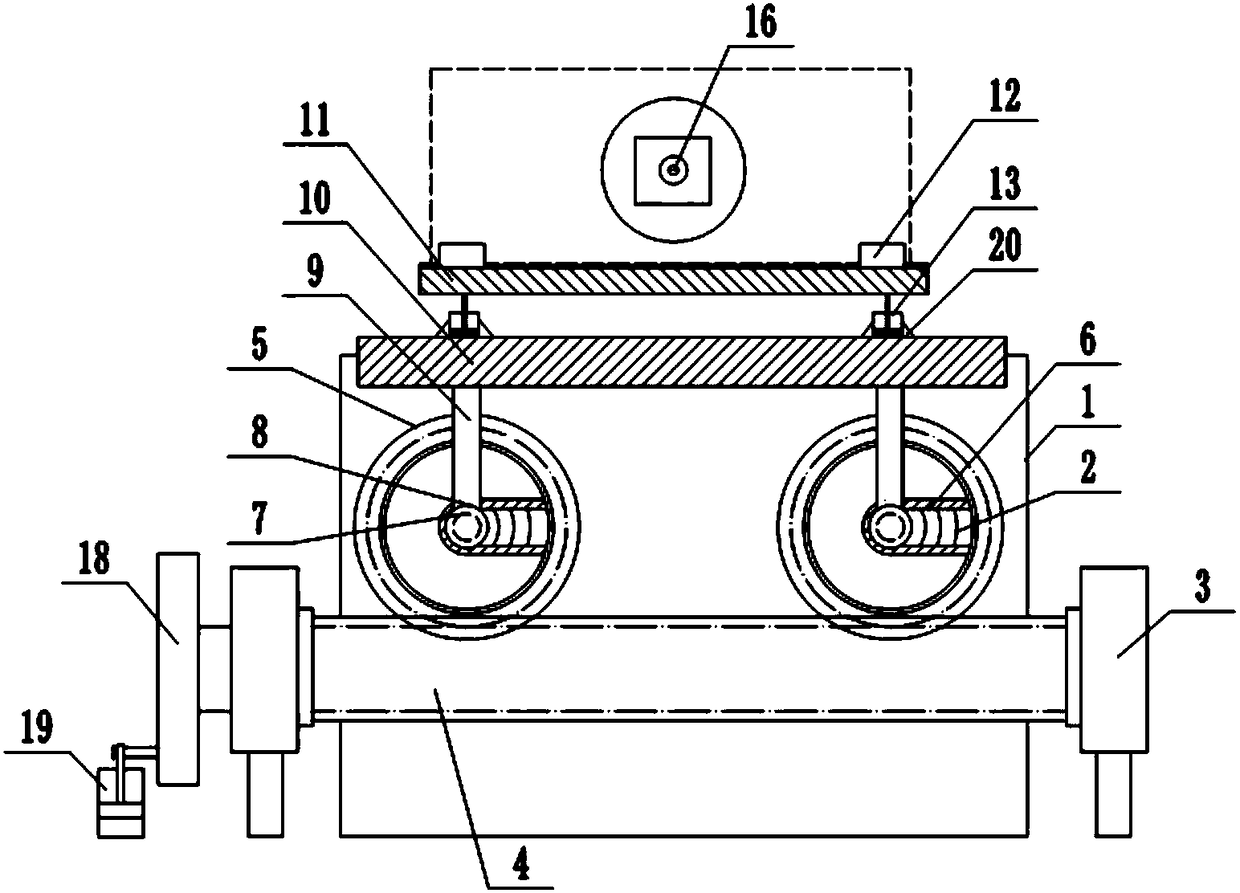

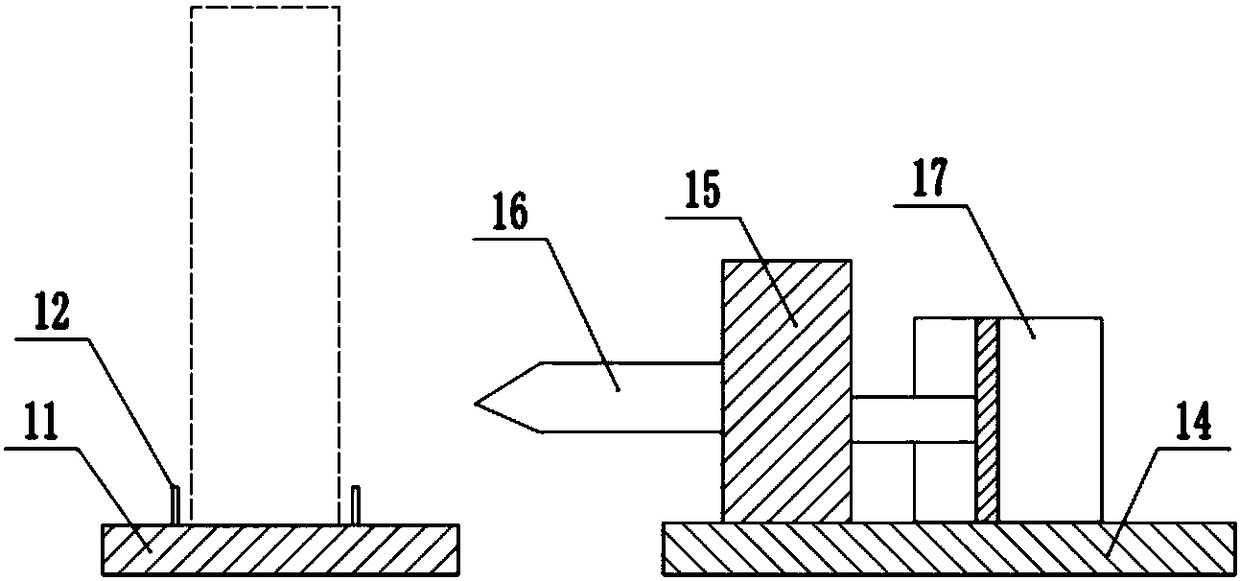

[0019] The reference signs in the drawings of the description include: frame 1, circular slideway 2, support table 3, threaded rod 4, drive gear 5, through hole 6, moving rod 7, limit plate 8, support rod 9, support Plate 10, operating panel 11, fixed block 12, first cylinder 13, drilling platform 14, push seat 15, drill bit 16, second cylinder 17, rotating disk 18, third cylinder 19, block 20.

[0020] The embodiment is basically as attached figure 1 Shown: The punching device includes a frame 1, and there are two sets of two circular slides on the frame 1, and the two sets of circular slides include multiple concentric circular slides with radii from small to large. 2. A plurality of circular slides 2 are provided with communicating grooves; one side of the frame 1 is provided with a driving mechanism, and the other side of the frame 1 is provided with a drilling mechanism, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com