Curved surface grabbing mechanism

A grasping mechanism and curved surface technology, which is applied in the field of automation equipment, can solve the problems of pinched products, product falling, and increased scrapping rate of pinched products, so as to achieve the effect of stable grasping and avoiding rigid contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

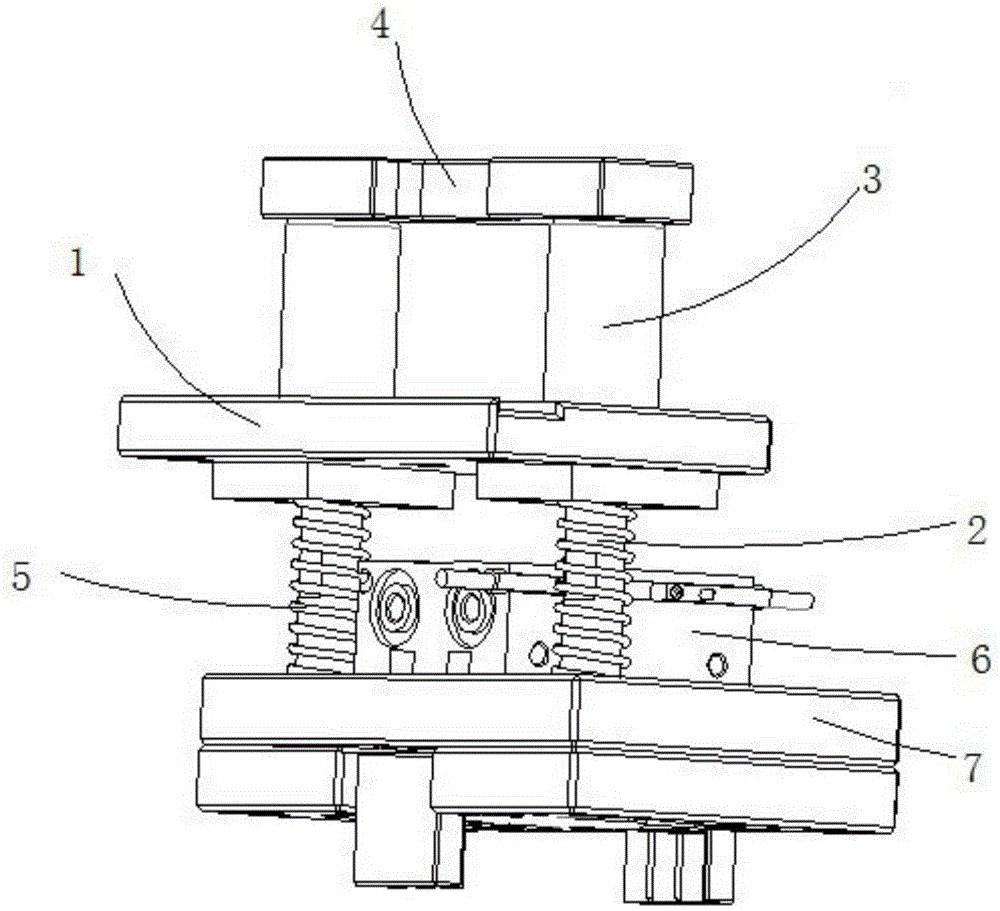

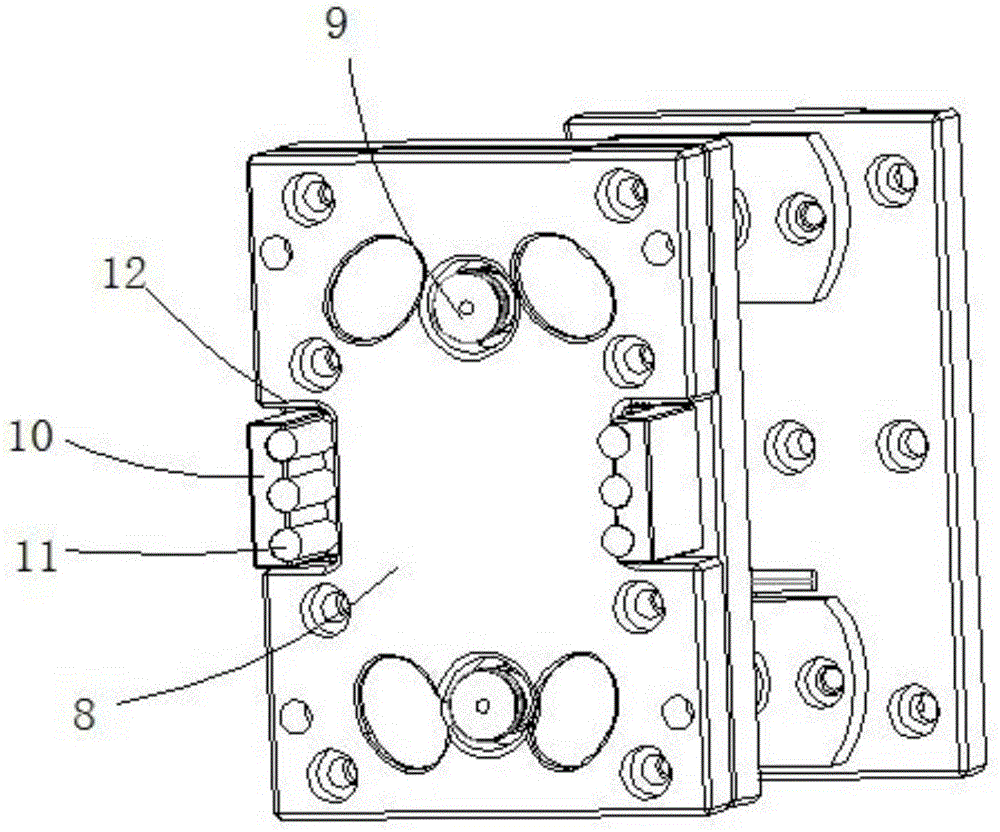

[0017] See Figure 1 to Figure 2 , Curved surface grabbing mechanism, including a mounting plate 1, a guide sleeve 3 fixed on the mounting plate 1, a guide rod 2 sliding along the guide sleeve 3, the two ends of the guide rod 2 are respectively connected with a guide rod connecting plate 4 and a cylinder fixing plate 7. The guide rod 2 is partially located in the guide sleeve 3. The guide rod connecting plate 4 and the cylinder fixing plate 7 are respectively located on both sides of the mounting plate 1. The mounting plate 1, the guide rod connecting plate 4 and the cylinder fixing plate 7 are parallel to each other, and the guide sleeve 3 is located between the mounting plate 1 and the guide rod connecting plate 4, the guide sleeve 3 is perpendicular to the mounting plate 1, the guide rod 2 is perpendicular to the mounting plate 1 and penetrates the mounting plate 1, and there is elasticity between the mounting plate 1 and the cylinder fixing 7. Part 5: In this embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com