A textile washing device

A flushing device and a technology for textile fabrics, which are applied in the processing of textile material equipment configuration, spray/jet textile material treatment, etc., can solve the problems affecting the surface quality and use texture of the fabric, cannot clean the fabric, and affect the fiber structure of the fabric, etc., to achieve Prevent damage to the fiber structure of the fabric, avoid cleaning uncleanness, and reduce the effect of equipment vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

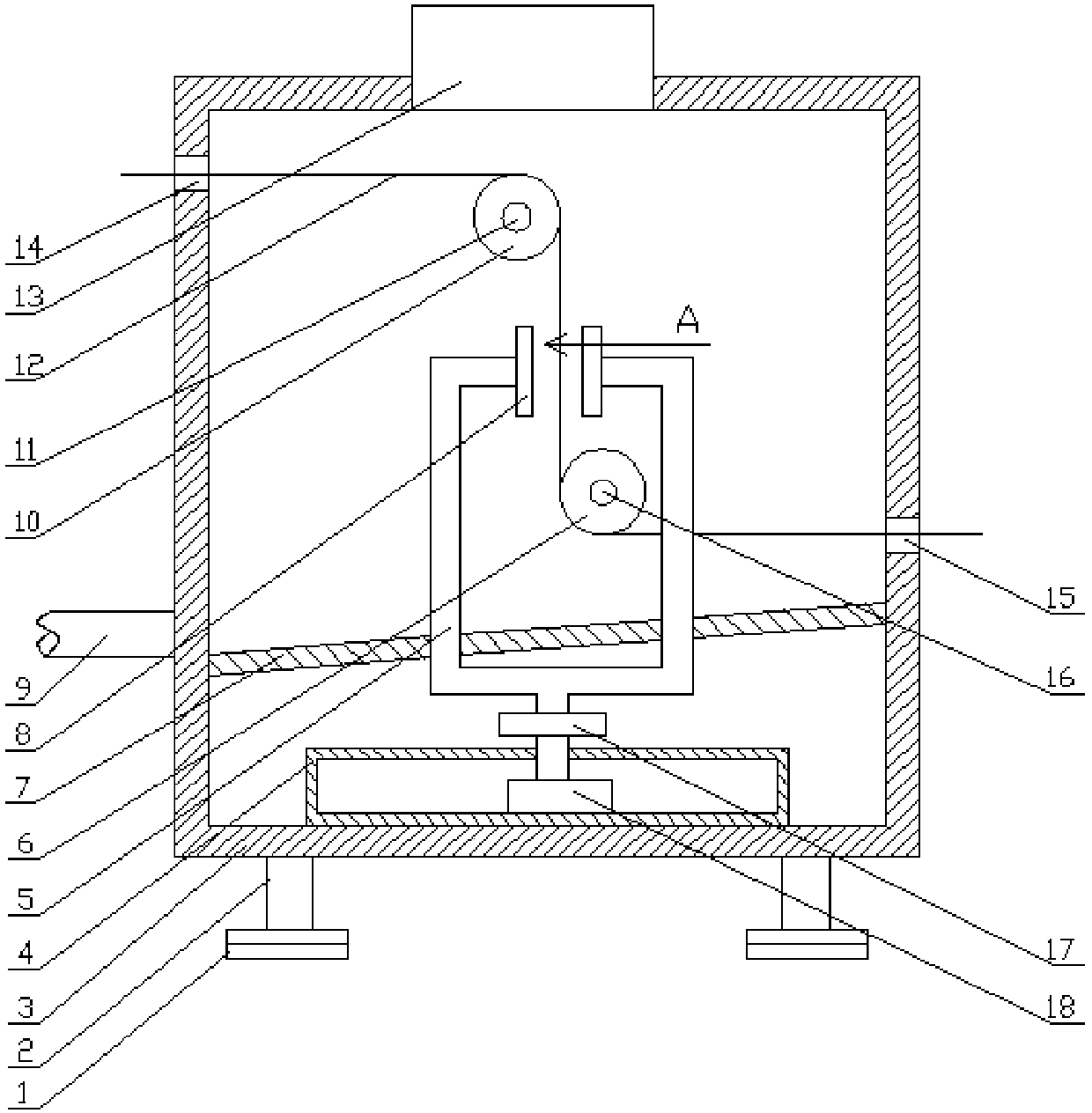

[0025] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention;

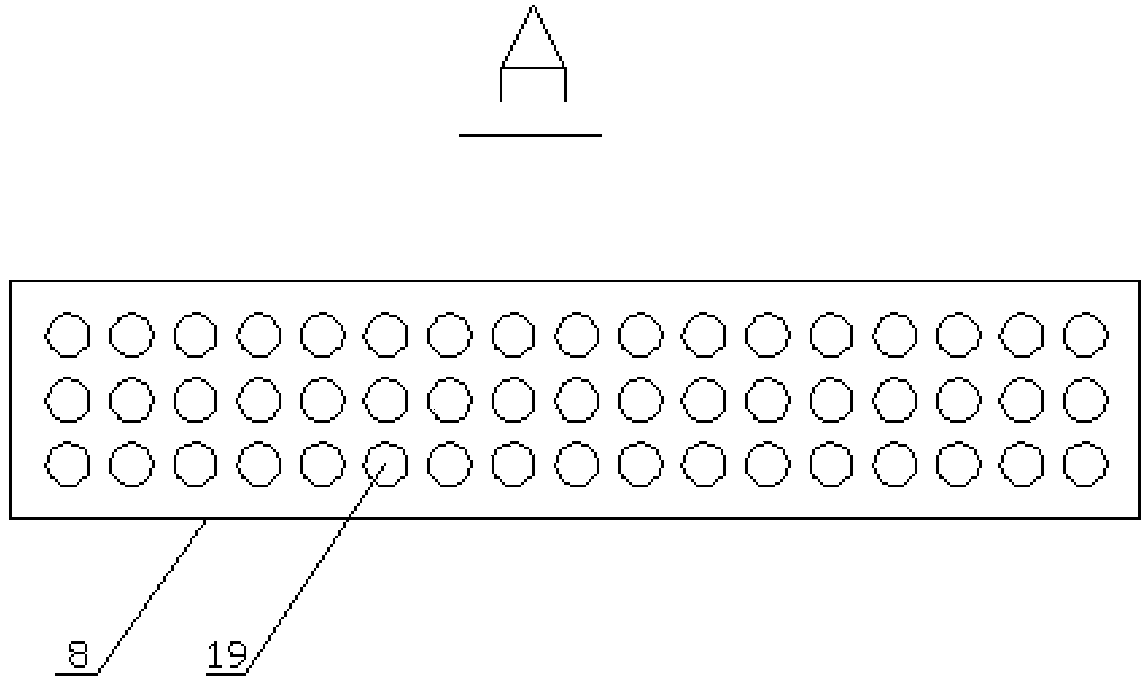

[0026] like figure 1 , figure 2 As shown, the textile cloth flushing device has a structure comprising a box body 3, which is a cuboid hollow structure. When in use, the box body 3 is used to support the parts of the device and restrict the flow direction of the cleaning liquid at the same time; the box body 3 is provided with a partition 7, which partitions the box 3 into two spaces, and the partition 7 is placed obliquely. When in use, the partition 7 is used to divide the box 3 into two spaces, dry and wet; The side wall of the box body 3 is provided with a drainpipe 9, which communicates with the inside of the box body 3, and the drainpipe 9 is located above the partition plate 7, and the drainpipe 9 is used to discharge the cleaning liquid from the box body 3 during use.

[0027] In the above embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com