Patents

Literature

49results about How to "Control pressure stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

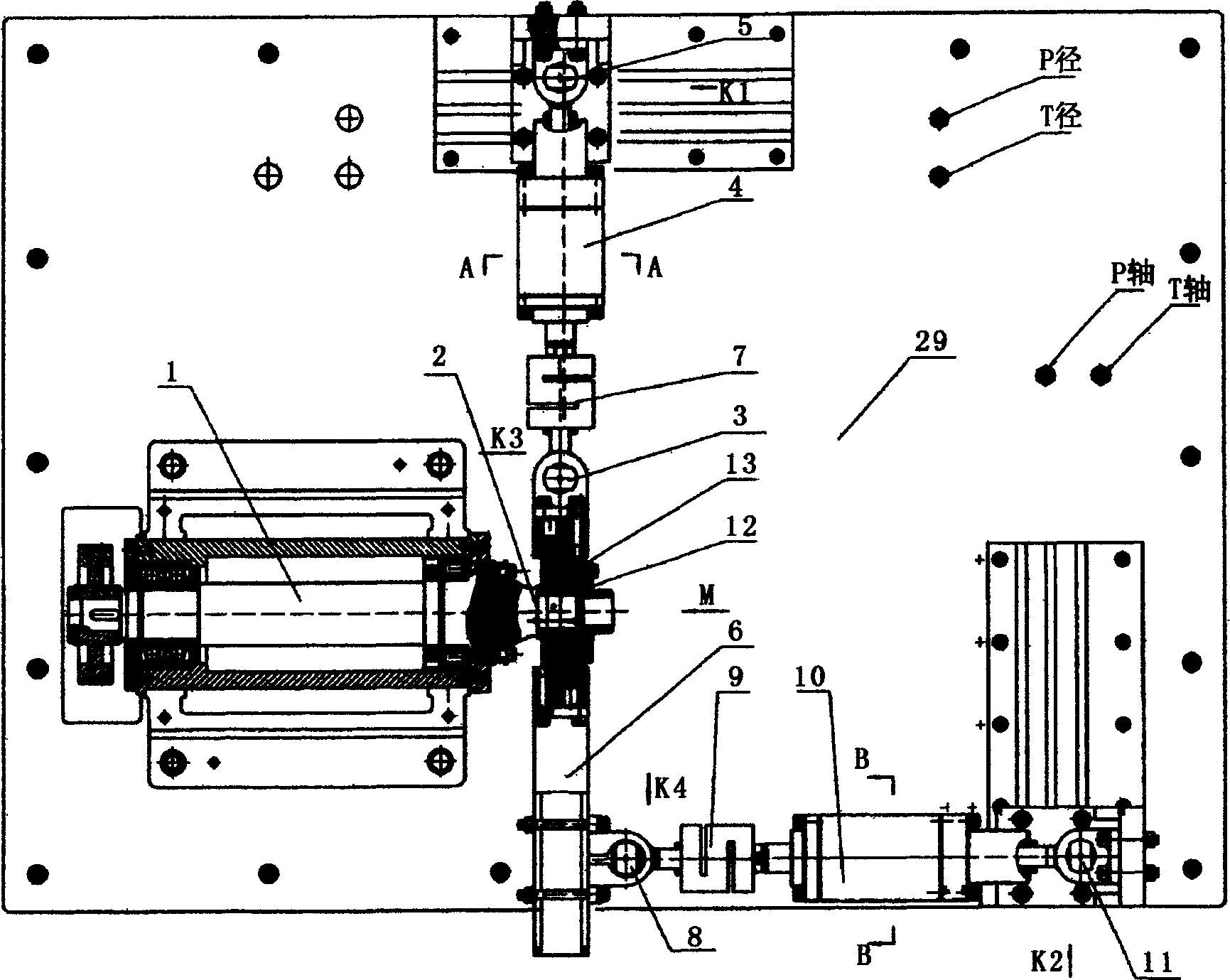

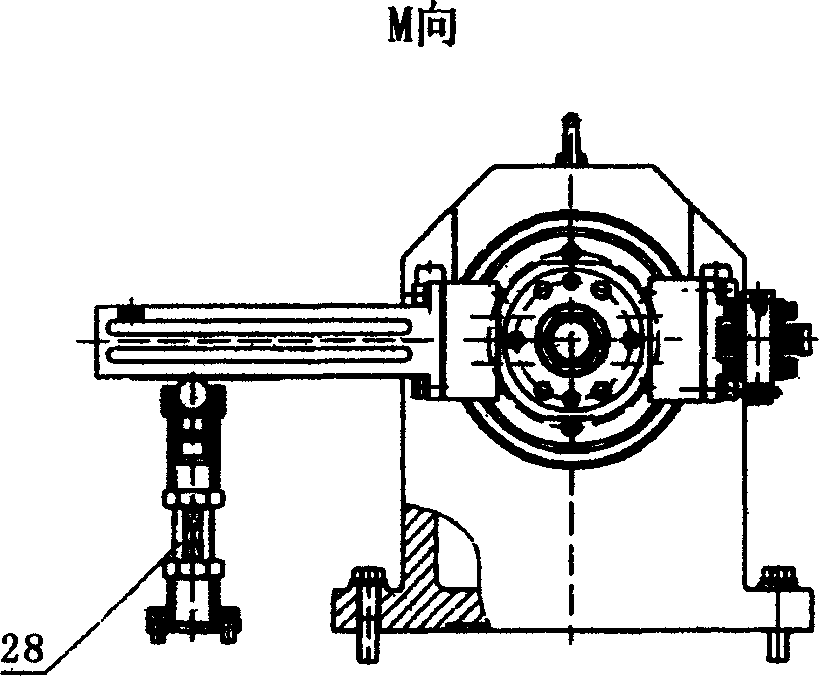

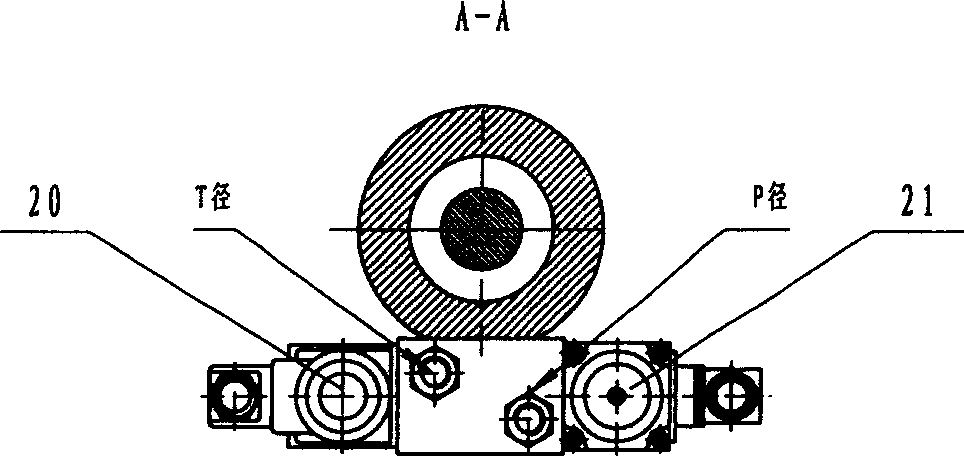

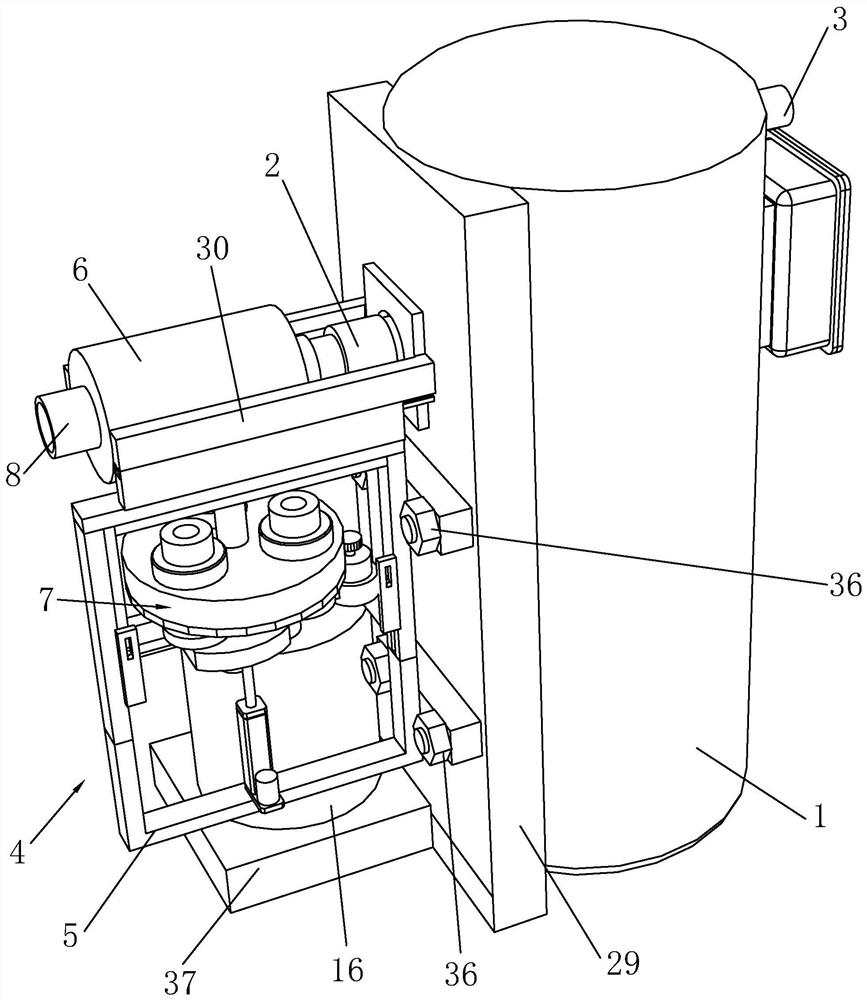

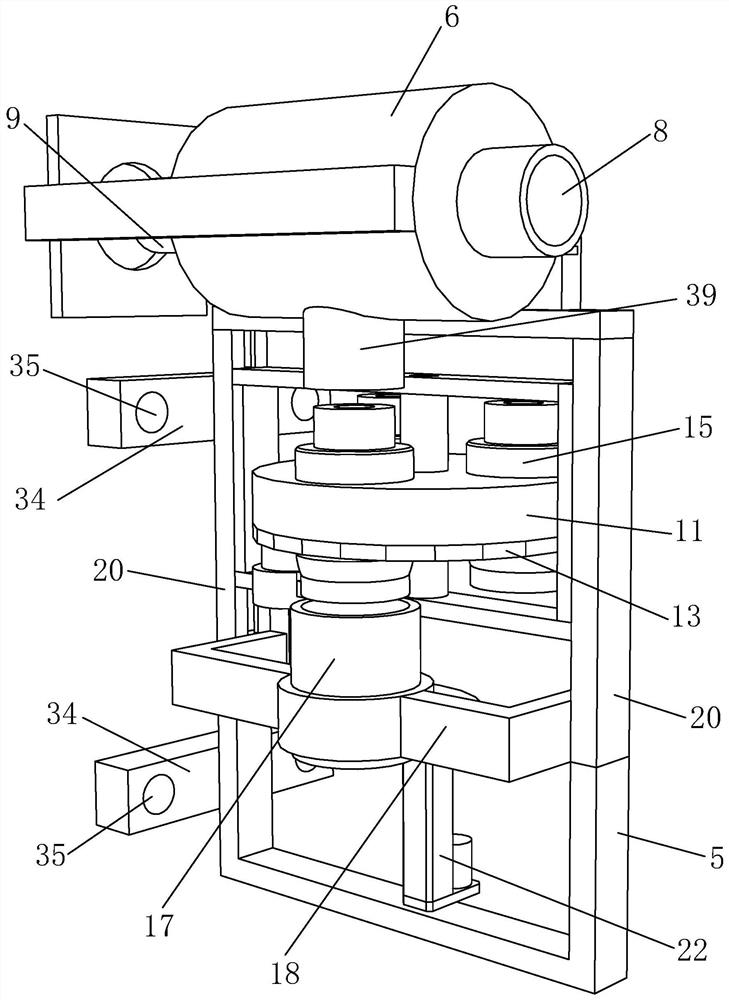

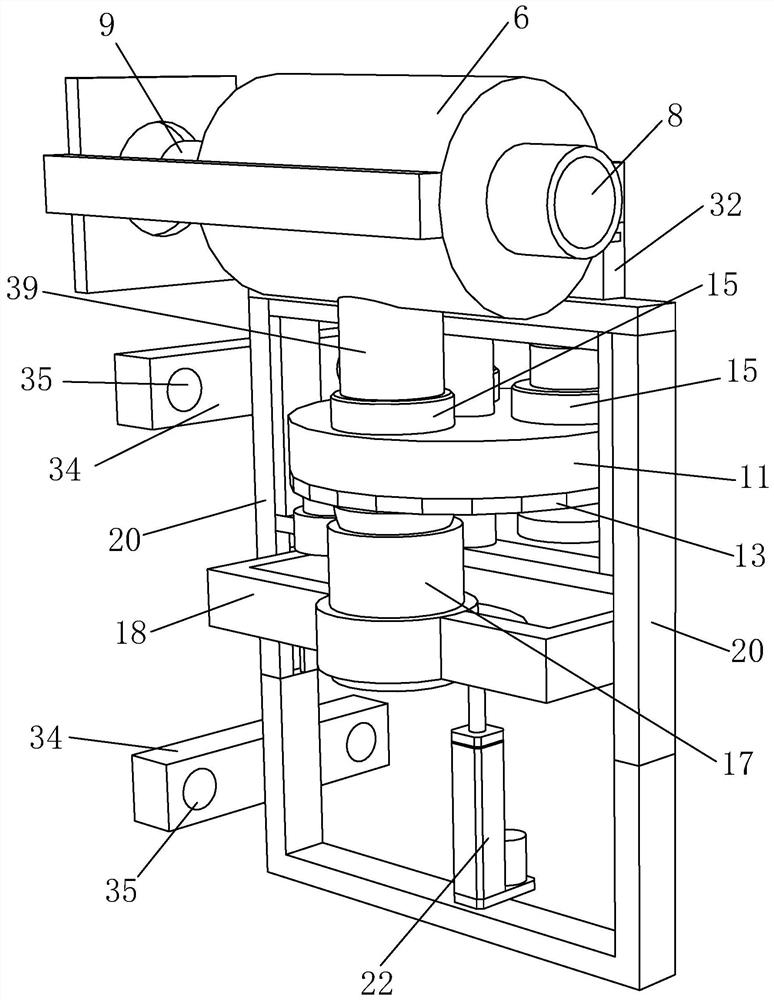

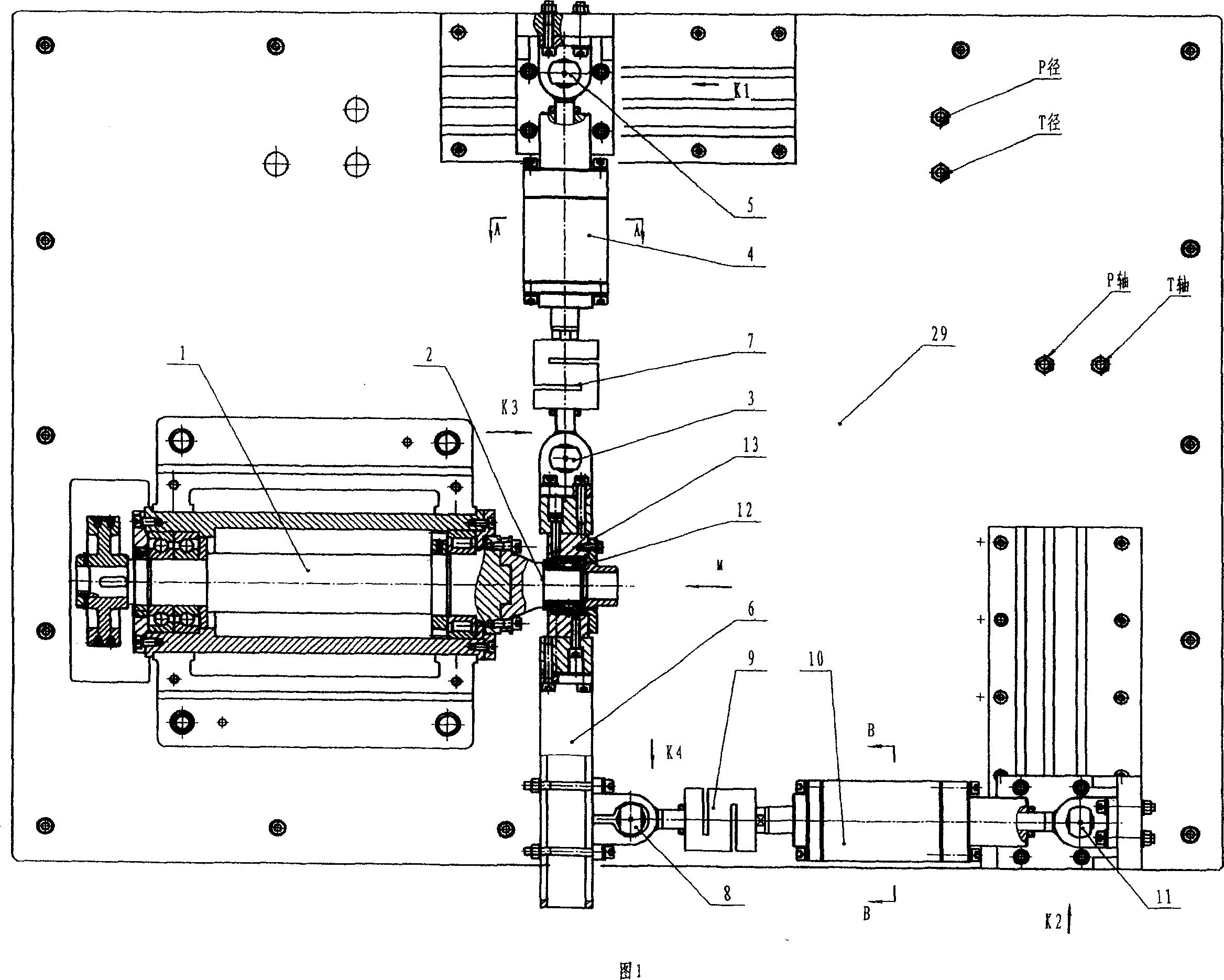

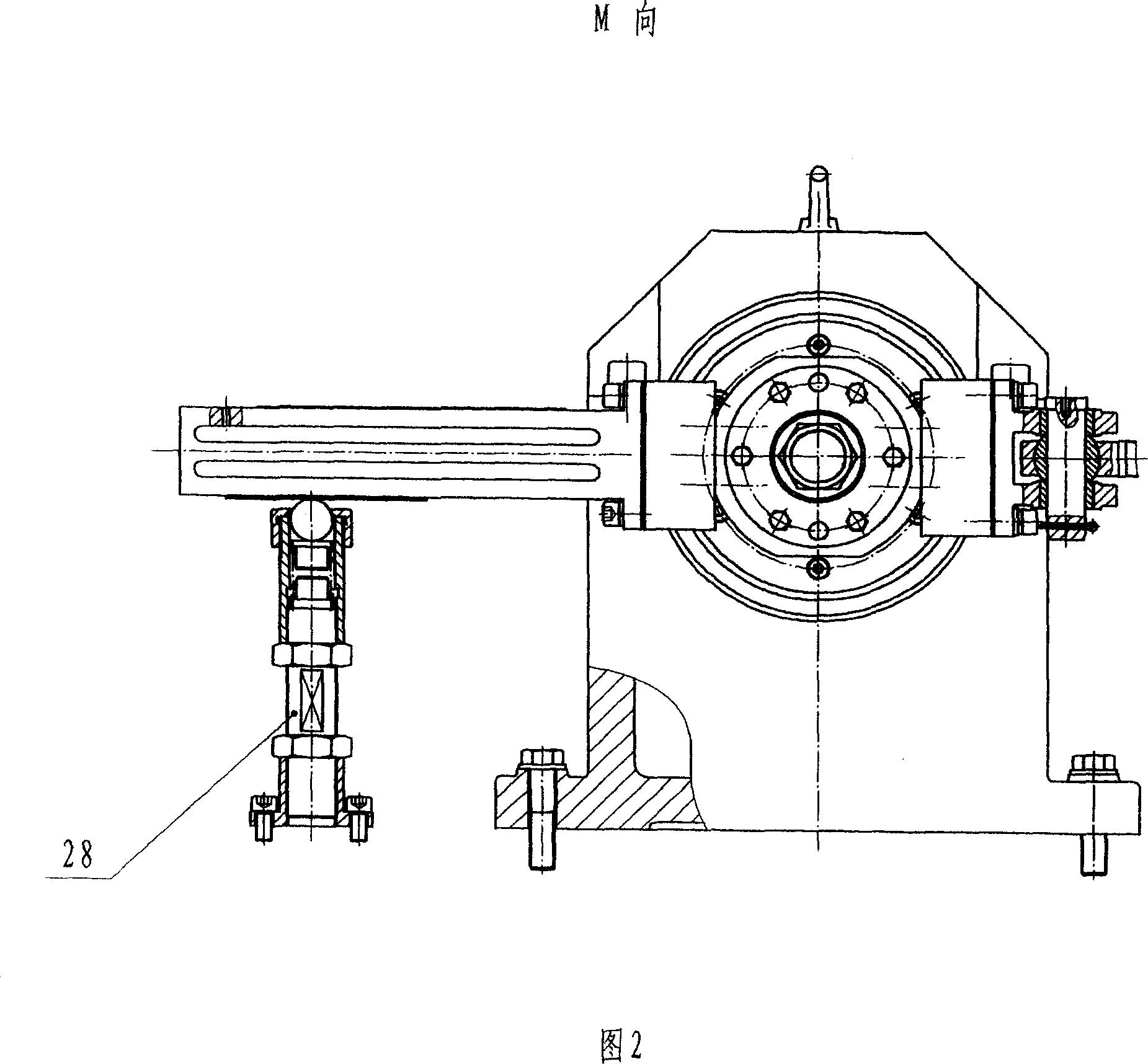

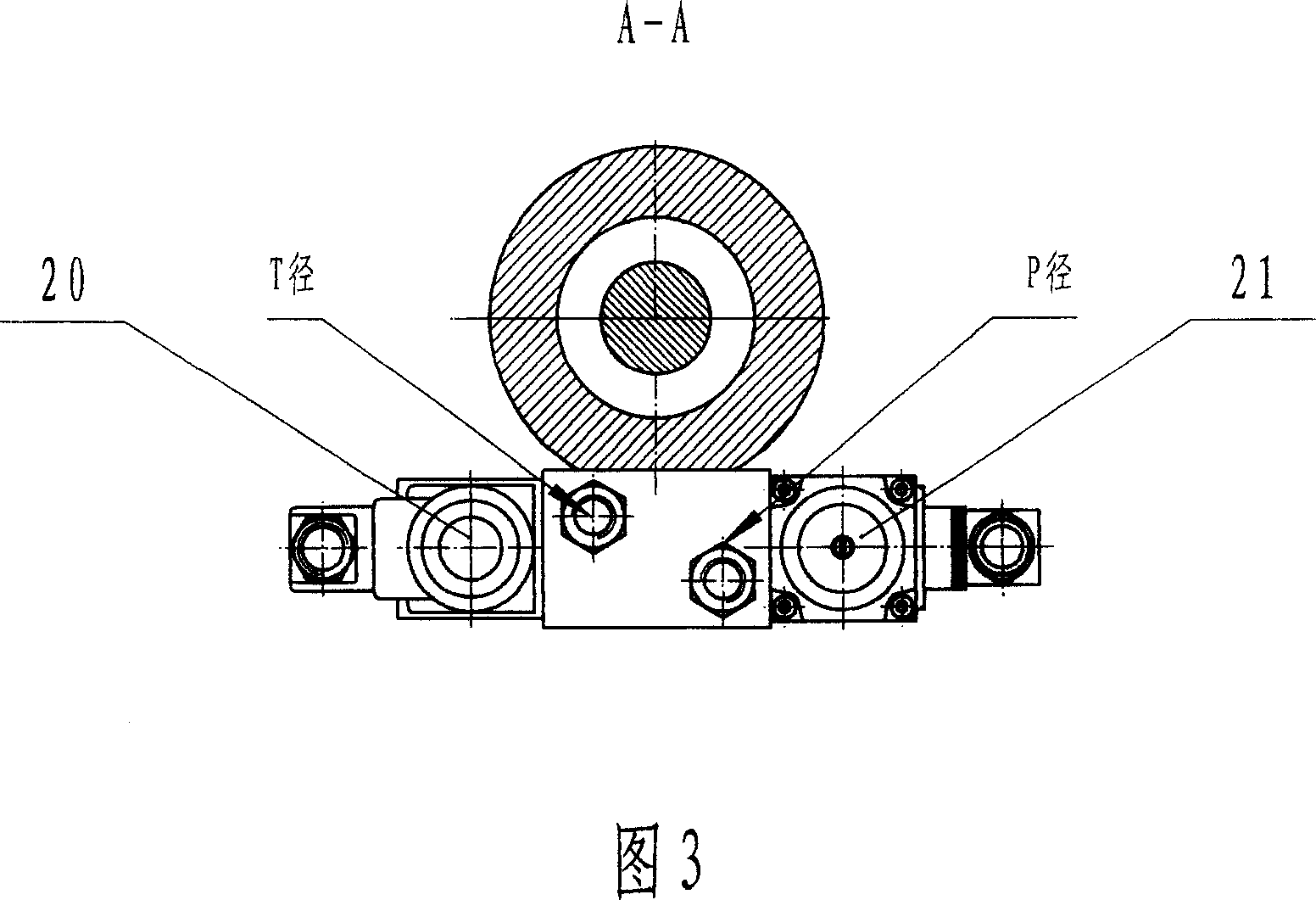

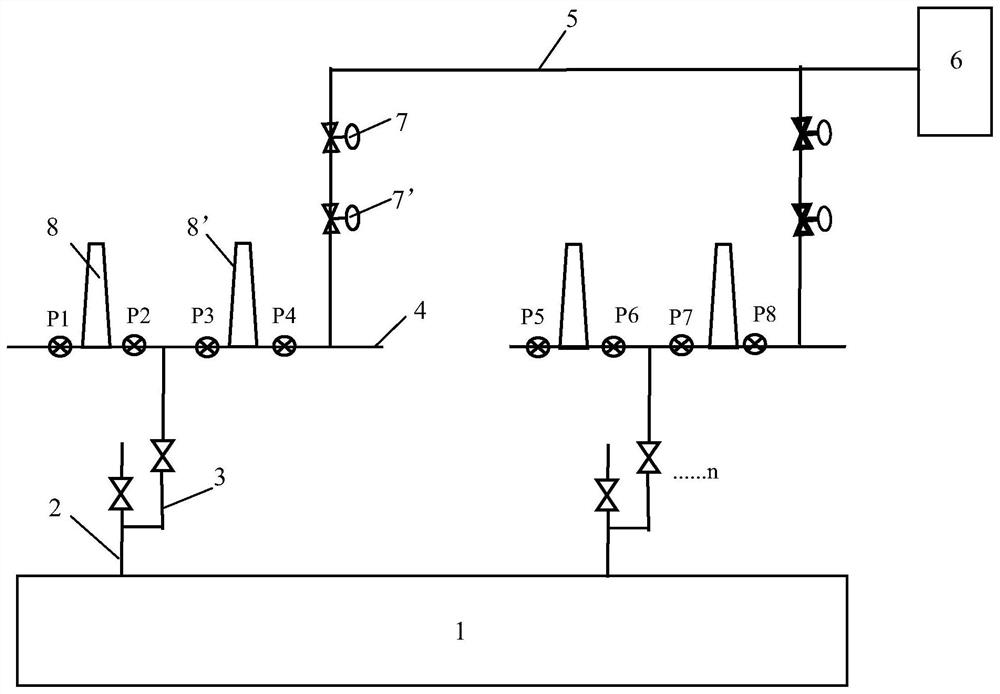

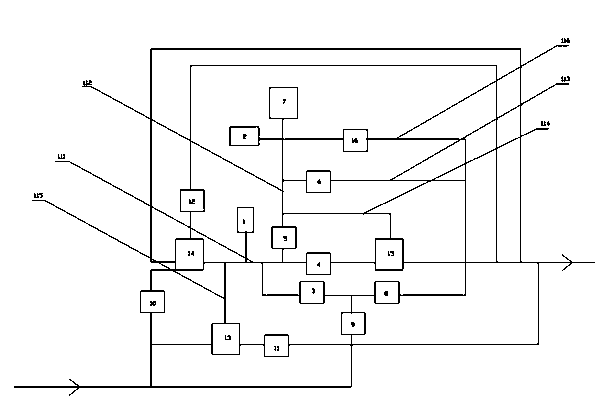

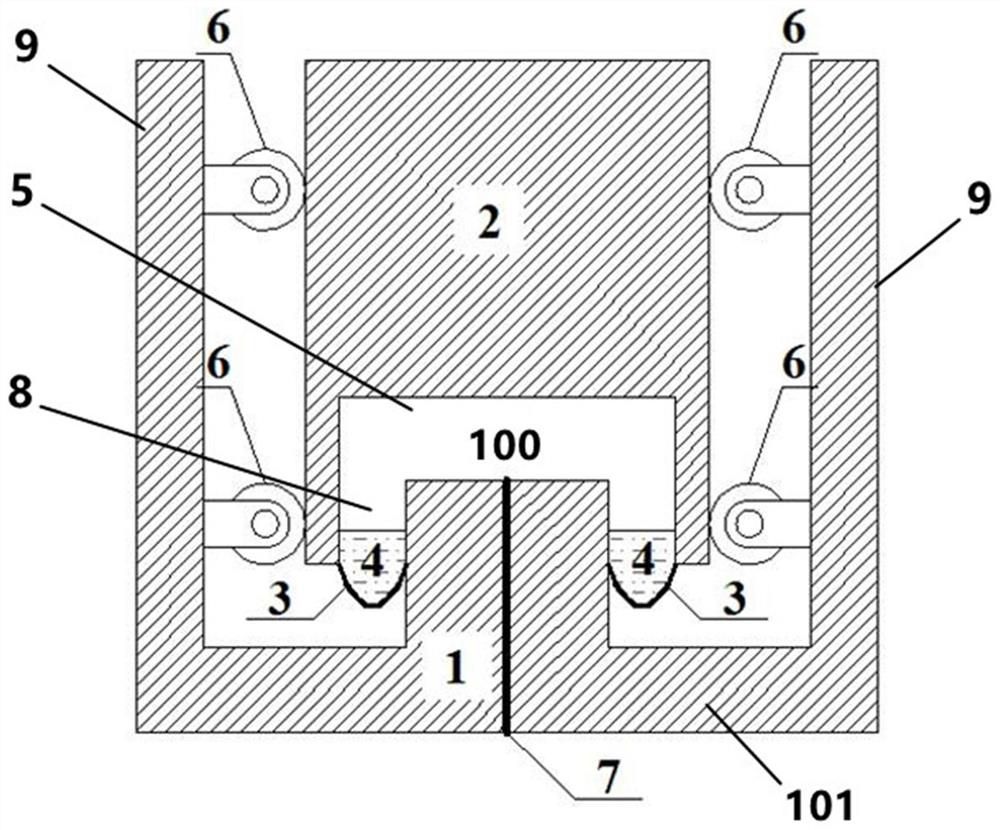

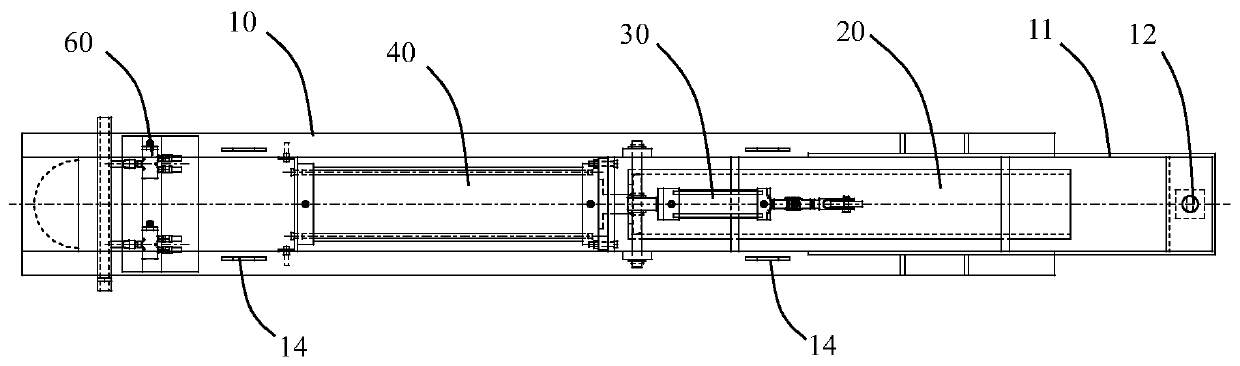

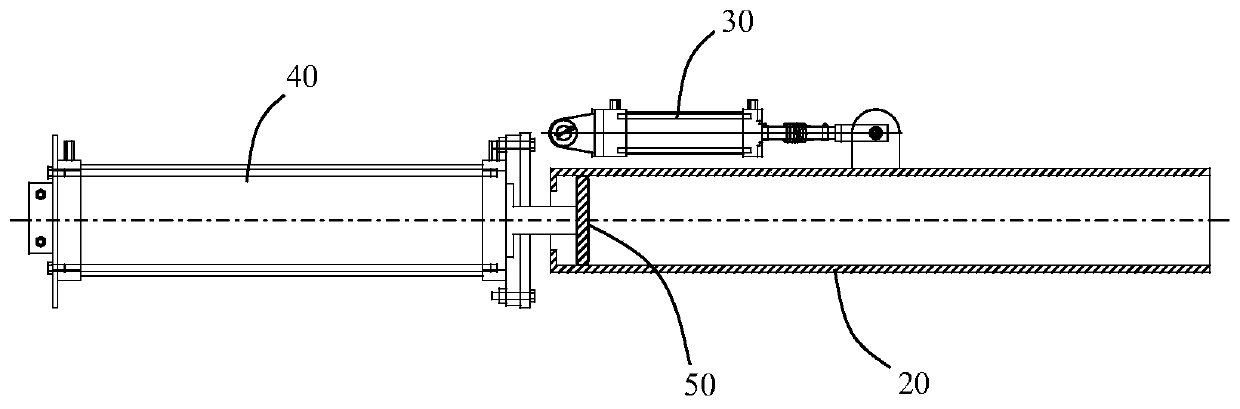

Simulation test loading device for automobile wheel hub bearing unit

InactiveCN1632503AControl pressure stabilityEasy to adjustVehicle testingMachine bearings testingEngineeringElectromagnetism

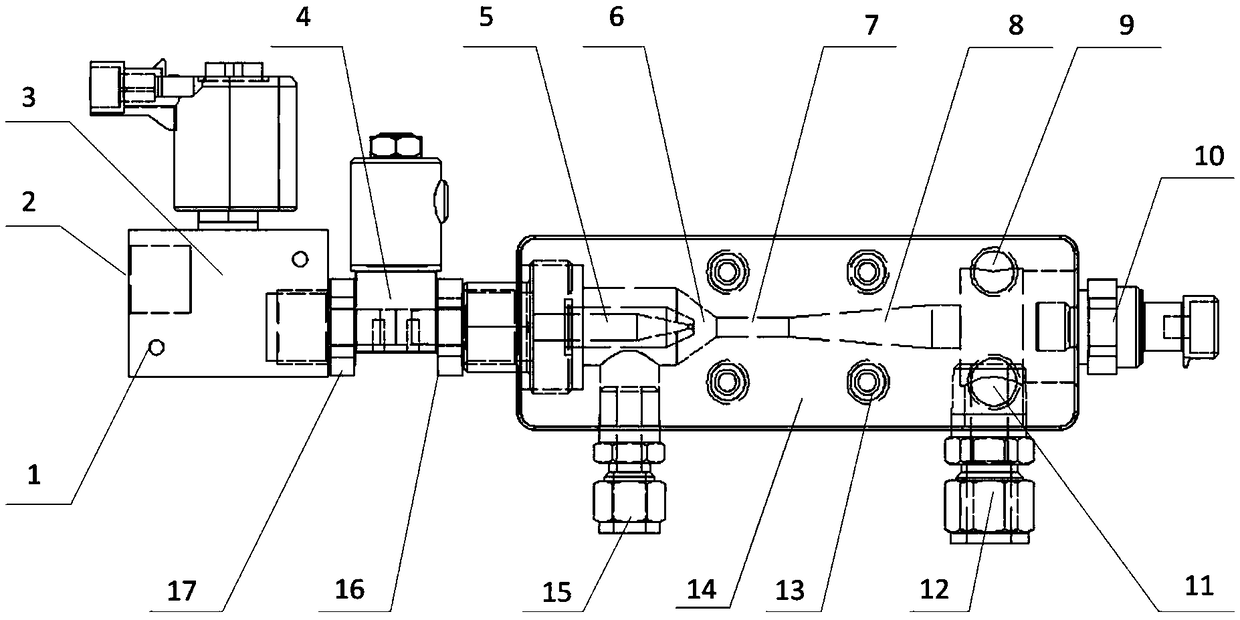

It is a car wheel bearing analogue test load device, which comprises drive main axis 1 and test main axis 2, test bearing supportive structure, radial and axis load cylinder structure. The connection end between radial load oil cylinder and frame is fixed with a ball socket bearing 5. The connection end between the axis bearing load oil cylinder and frame is fixed with ball socket bearing 11. Its radial load oil cylinder down part is directly fixed with proportion decompression valve 21 and electromagnetism switch valve 20. Its axis load oil cylinder down part is directly fixed with proportion decompression valve 15 and electromagnetism 14.

Owner:安徽徽熳动力机械制造有限公司

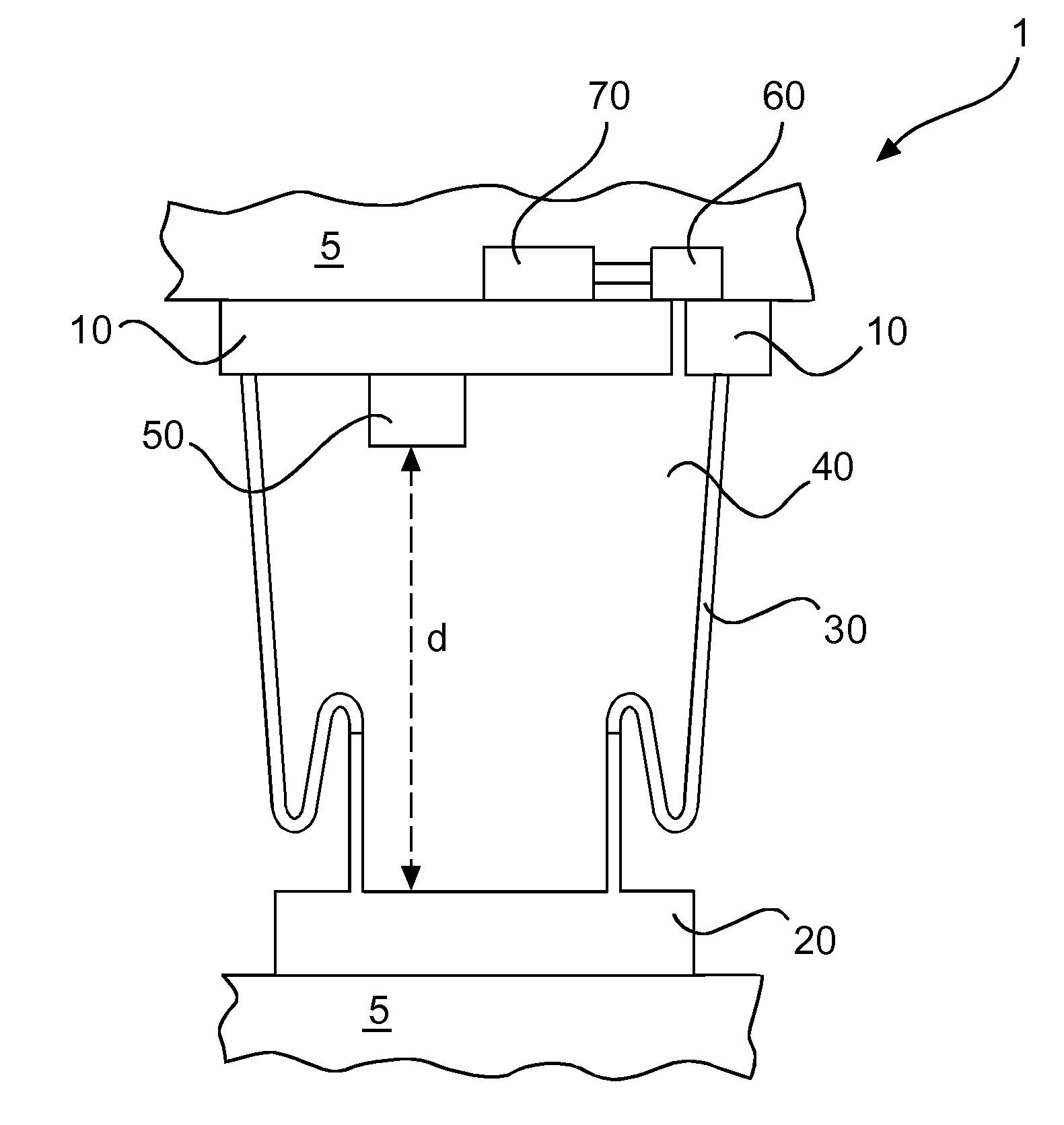

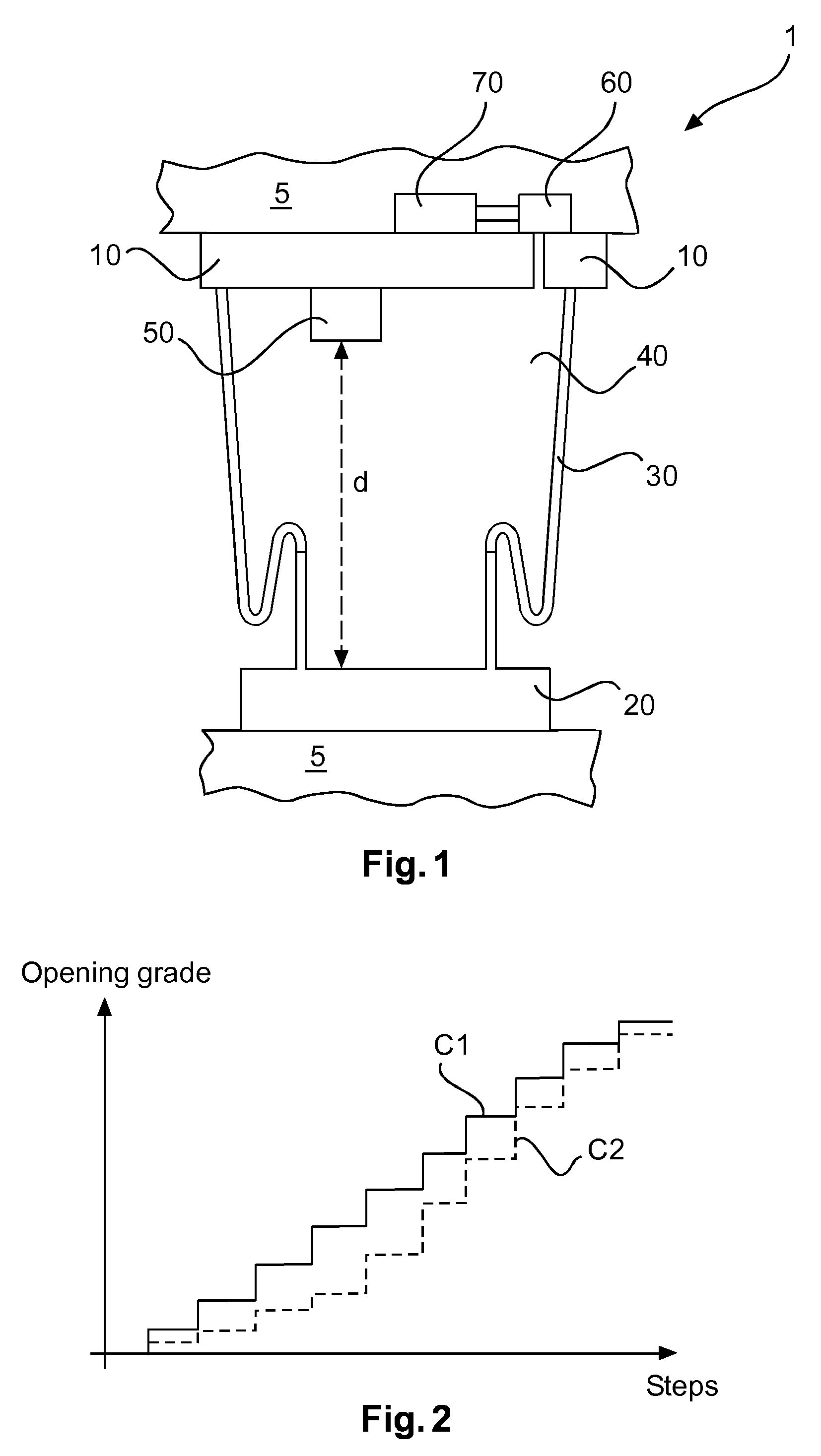

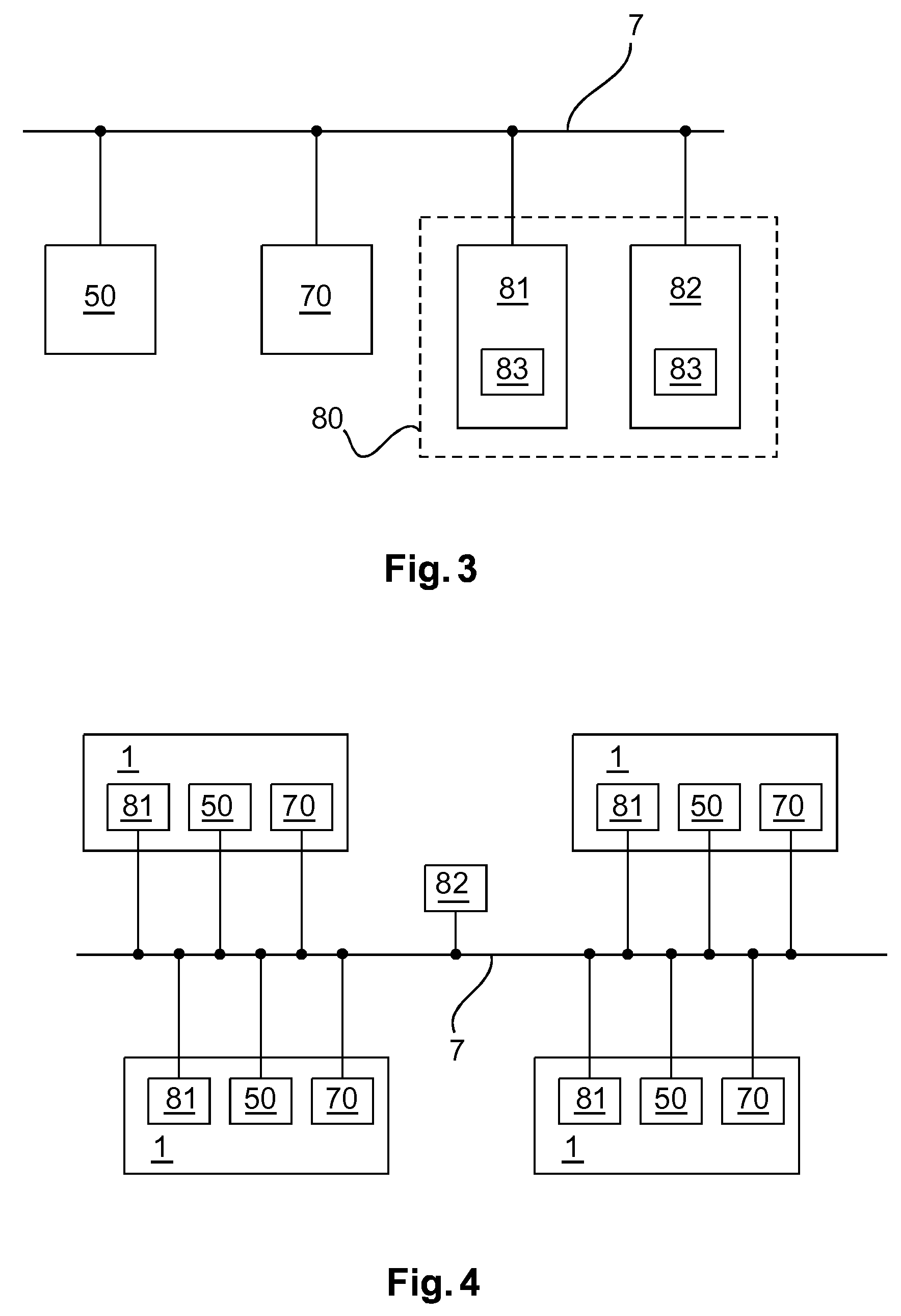

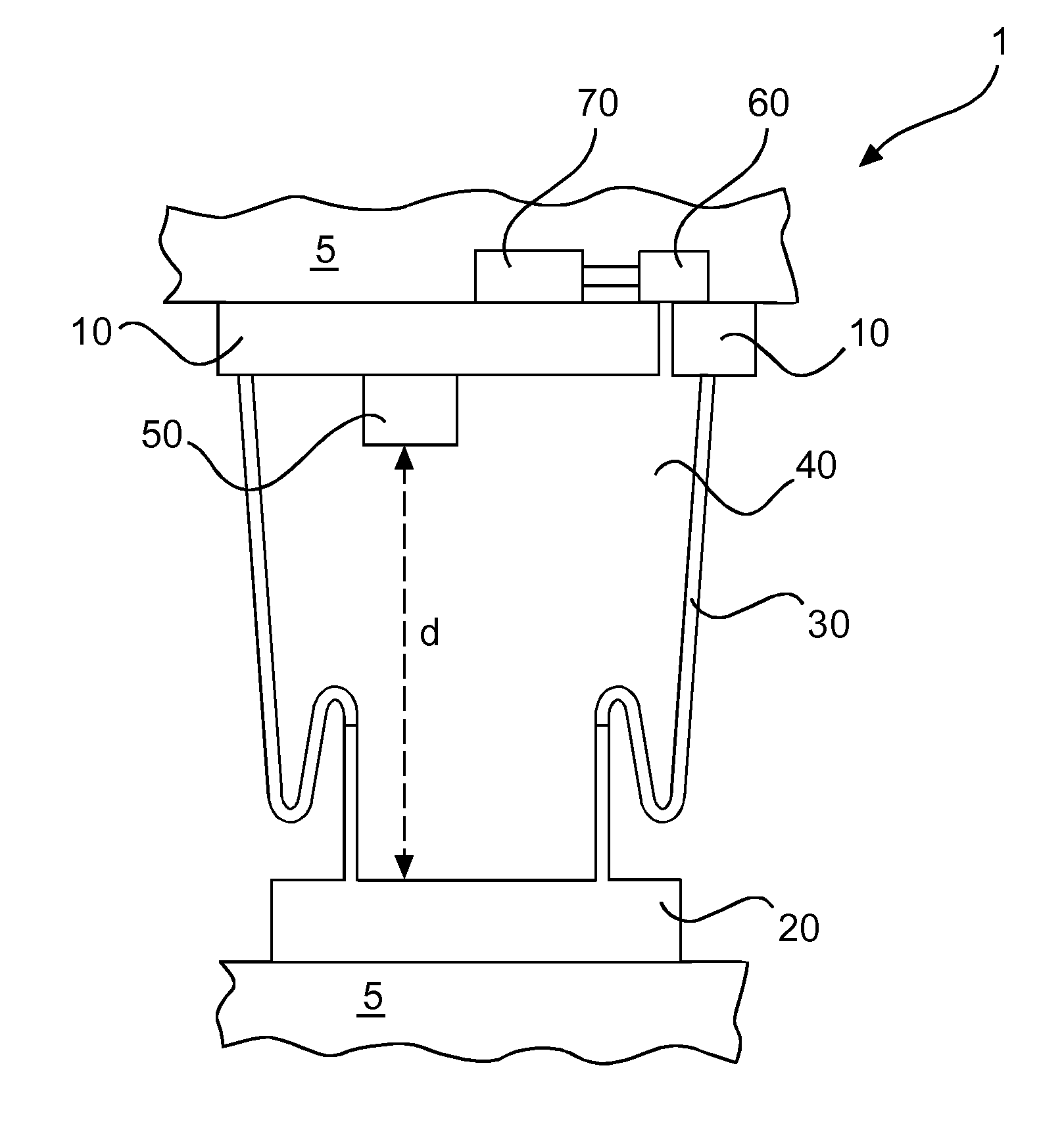

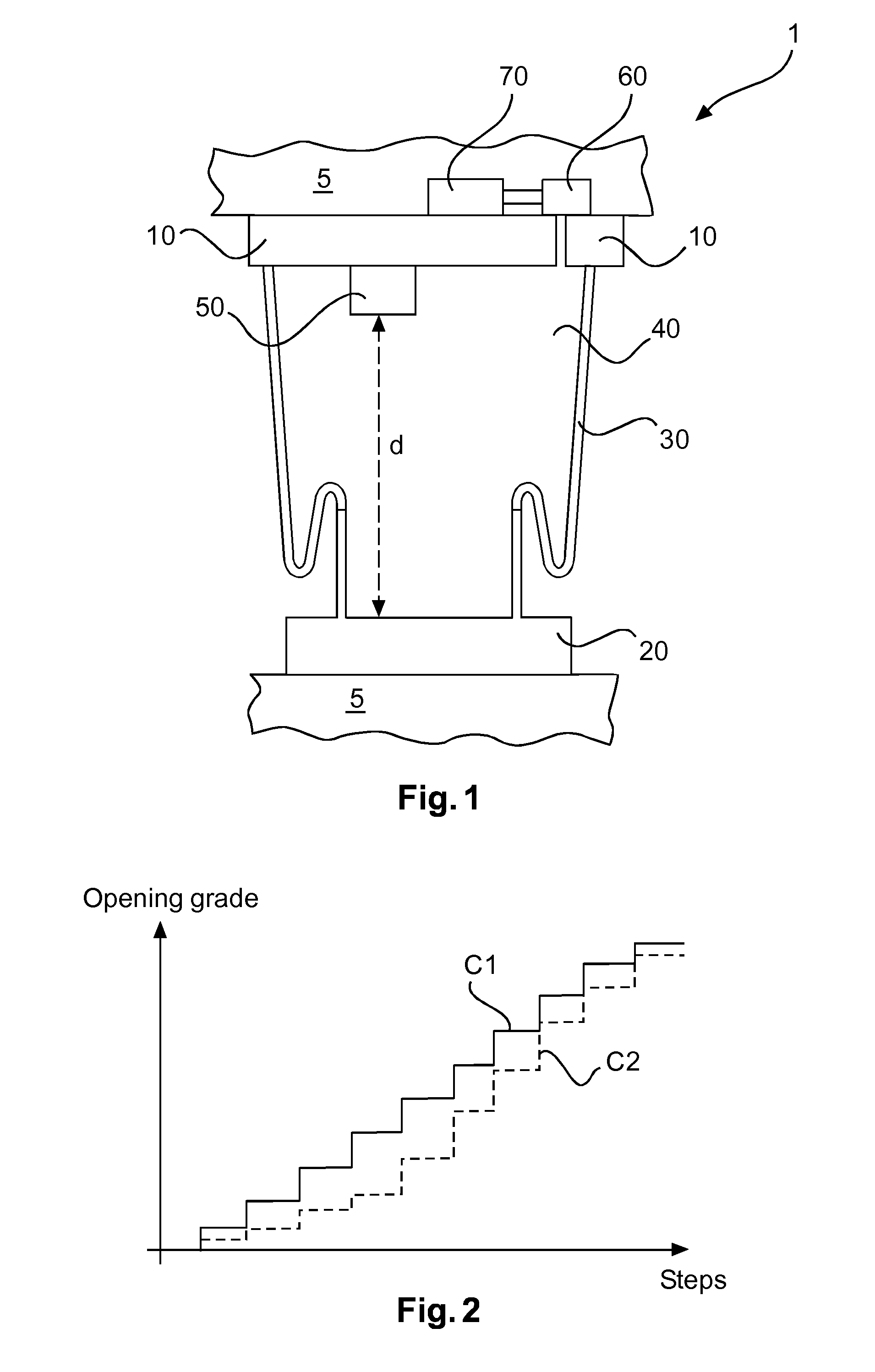

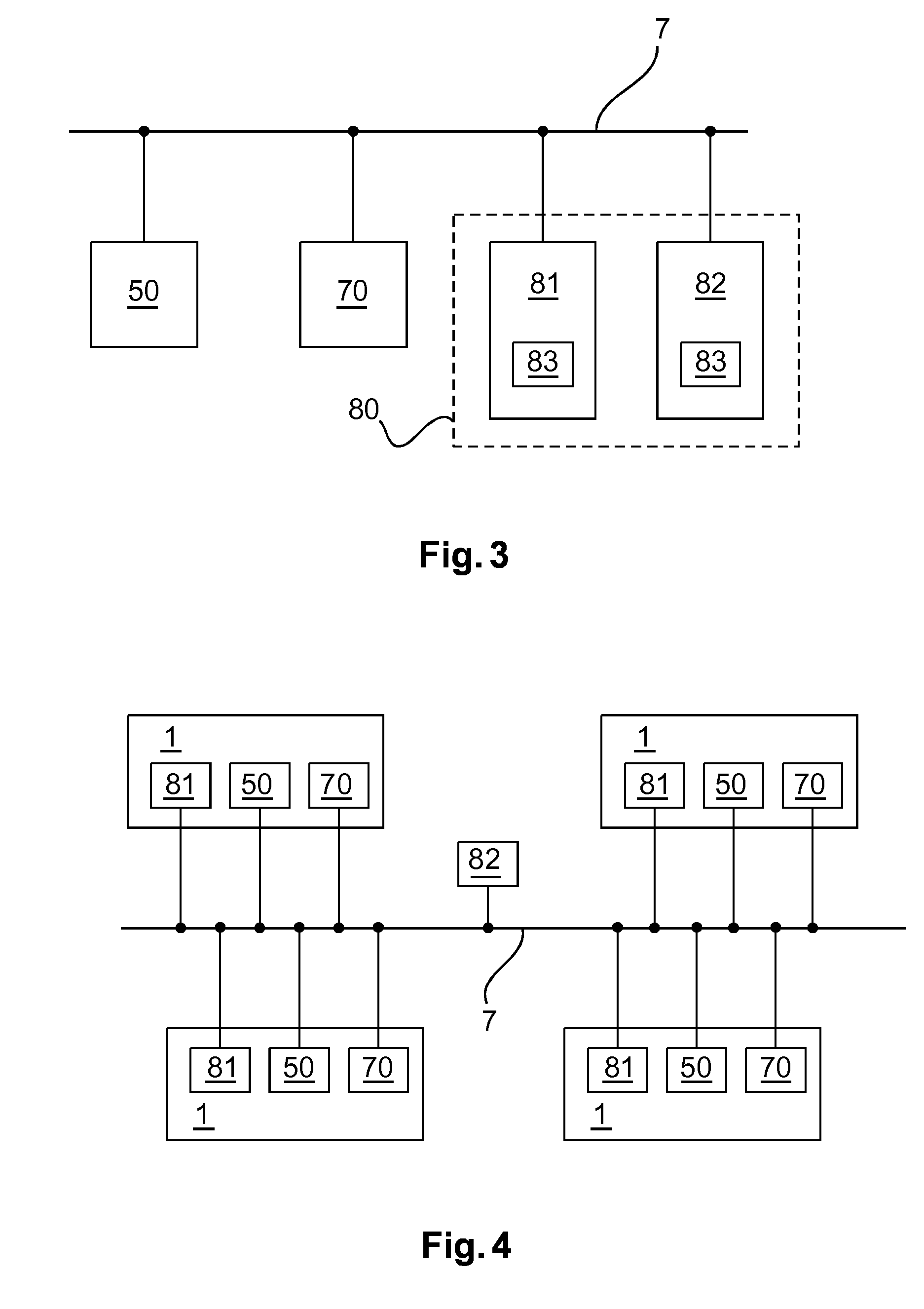

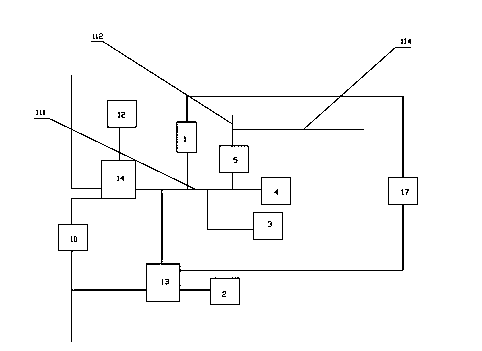

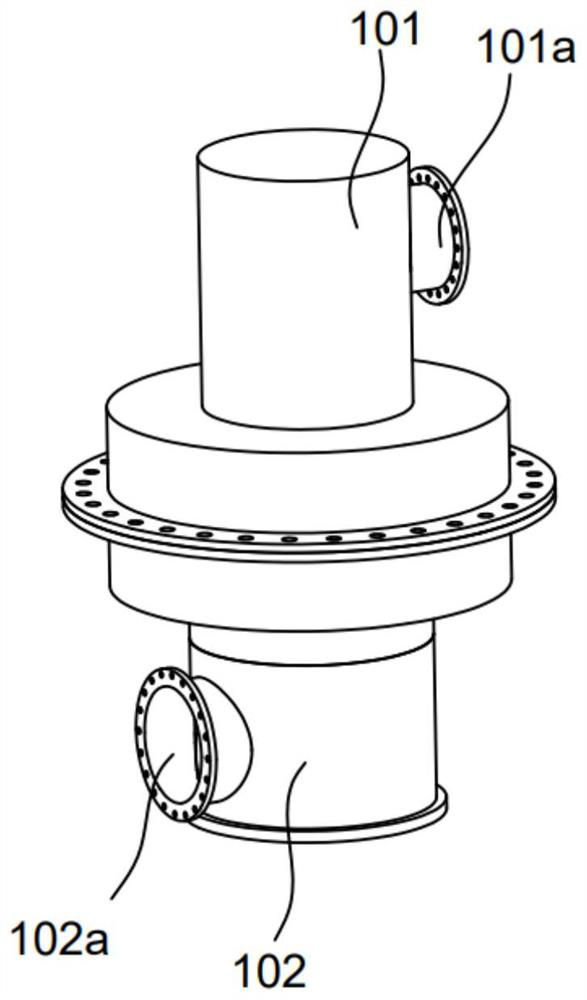

Air spring with stepper motor driven pneumatic valve

ActiveUS9211776B2Control pressure stabilityEasy to controlSpringsResilient suspensionsAir springPneumatic valve

The subject invention reveals an air spring arrangement comprising: a first mounting member, a second mounting member, an air spring volume, a height sensor, a controllable valve, a position controllable drive, wherein the first mounting member and the second mounting member are arranged so as to mount the air spring volume to corresponding vehicle members, wherein the height sensor is arranged so as to sense a distance between the first mounting member and the second mounting member, wherein the controllable valve is arranged so as to connect the inside of the air spring volume with the outside of the air spring volume, wherein the position controllable drive is arranged so as to drive the controllable valve with respect to an opening grade of the controllable valve, and wherein the position controllable drive is controlled based on the sensed distance between the first mounting member and the second mounting member.

Owner:INFINITY ENGINEERED PROD LLC

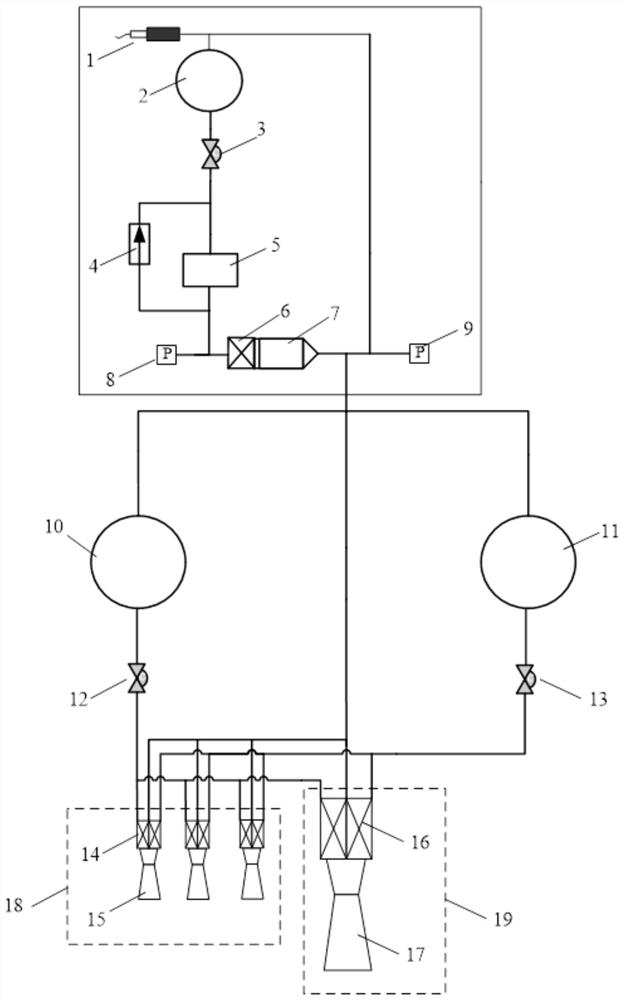

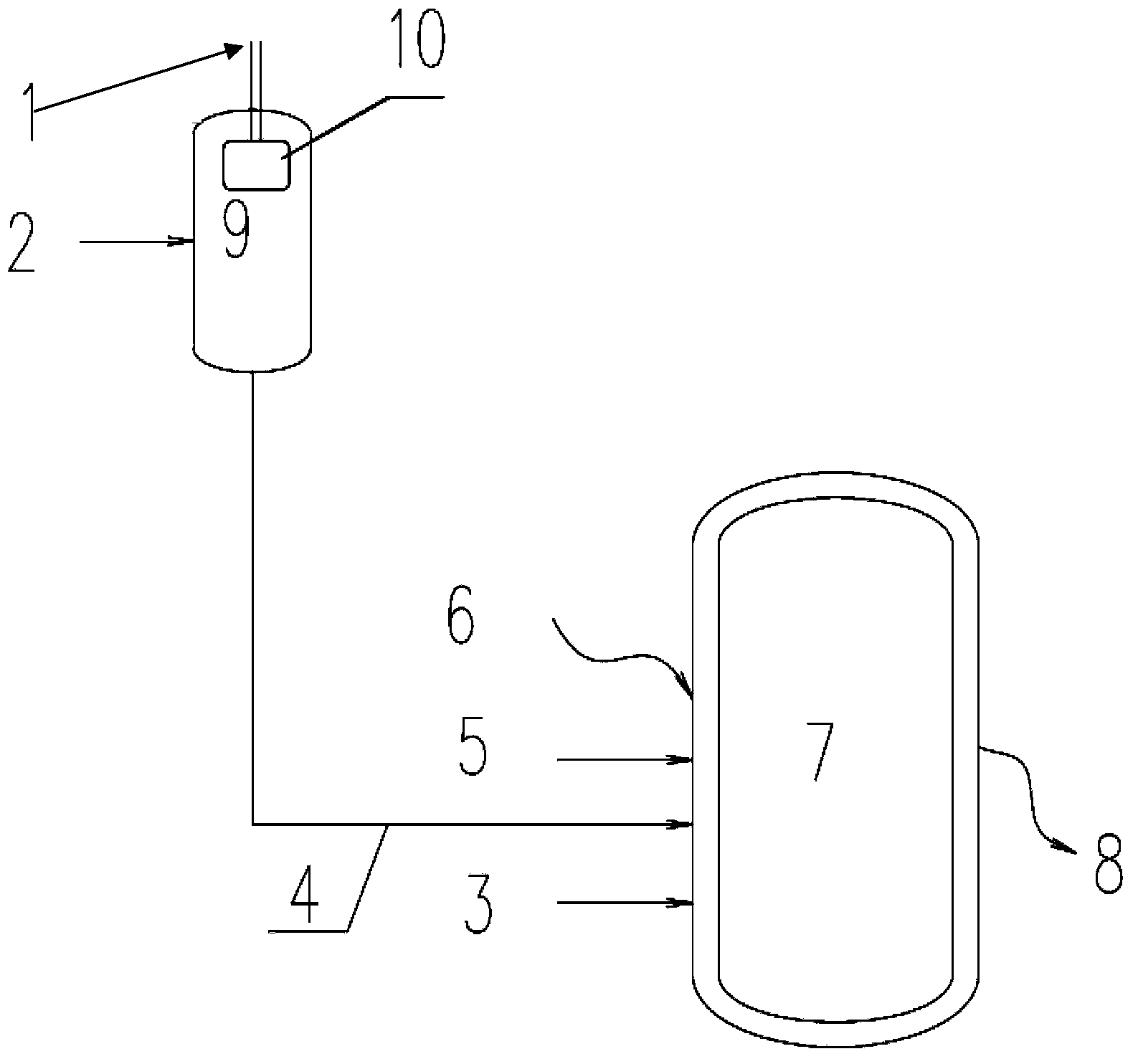

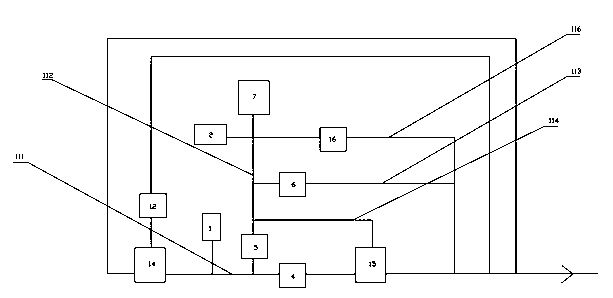

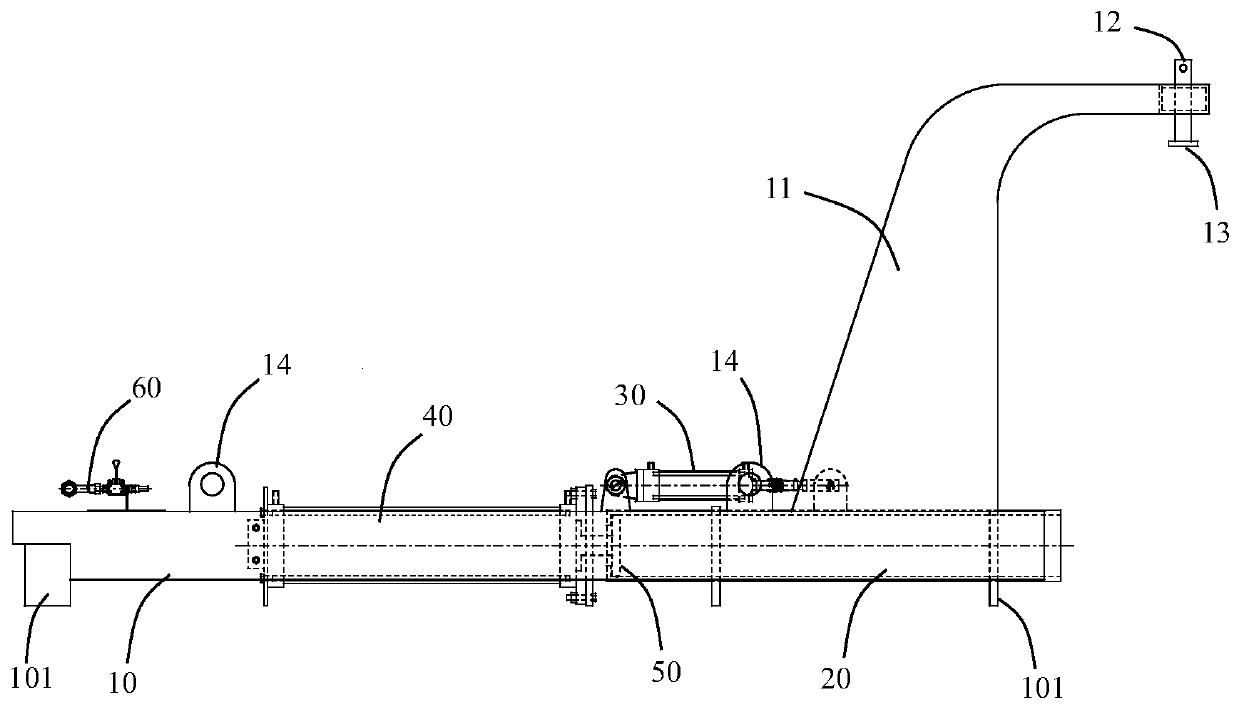

Fuel gas pressurization attitude and orbit control propulsion system based on electric pump

ActiveCN111946490AAvoid security issuesAvoid risk of leakageRocket engine plantsControl theoryOxidizing agent

The invention provides a fuel gas pressurization attitude and orbit control propulsion system based on an electric pump. The fuel gas pressurization attitude and orbit control propulsion system comprises a fuel gas generator pressurization module based on the electric pump, an oxidizing agent storage tank, a fuel storage tank, an orbit control engine, an attitude control engine and an electric explosion valve. The fuel gas generator pressurization module based on the electric pump is connected with an inlet of the oxidizing agent storage tank and an inlet of the fuel storage tank respectively;an outlet of the oxidizing agent storage tank is connected with the orbit control engine and the attitude control engine respectively after passing through the electric explosion valve; and an outletof the fuel storage tank is connected with the orbit control engine and the attitude control engine after passing through the electric explosion valve. Pressurized gas needed in the attitude and orbit control propulsion system is provided by the fuel gas generator pressurization module based on the electric pump, normal-pressure long-term storage of the pressurized gas can be achieved before thesystem does not work, and potential safety hazards and leakage risks existing in long-term storage of high-pressure gas are avoided.

Owner:SHANGHAI INST OF SPACE PROPULSION

Air spring with stepper motor driven pneumatic valve

ActiveUS20140225345A1Control pressure stabilityEasy to controlSpringsResilient suspensionsAir springAir suspension

The subject invention reveals an air spring arrangement comprising: a first mounting member, a second mounting member, an air spring volume, a height sensor, a controllable valve, a position controllable drive, wherein the first mounting member and the second mounting member are arranged so as to mount the air spring volume to corresponding vehicle members, wherein the height sensor is arranged so as to sense a distance between the first mounting member and the second mounting member, wherein the controllable valve is arranged so as to connect the inside of the air spring volume with the outside of the air spring volume, wherein the position controllable drive is arranged so as to drive the controllable valve with respect to an opening grade of the controllable valve, and wherein the position controllable drive is controlled based on the sensed distance between the first mounting member and the second mounting member.

Owner:INFINITY ENGINEERED PROD LLC

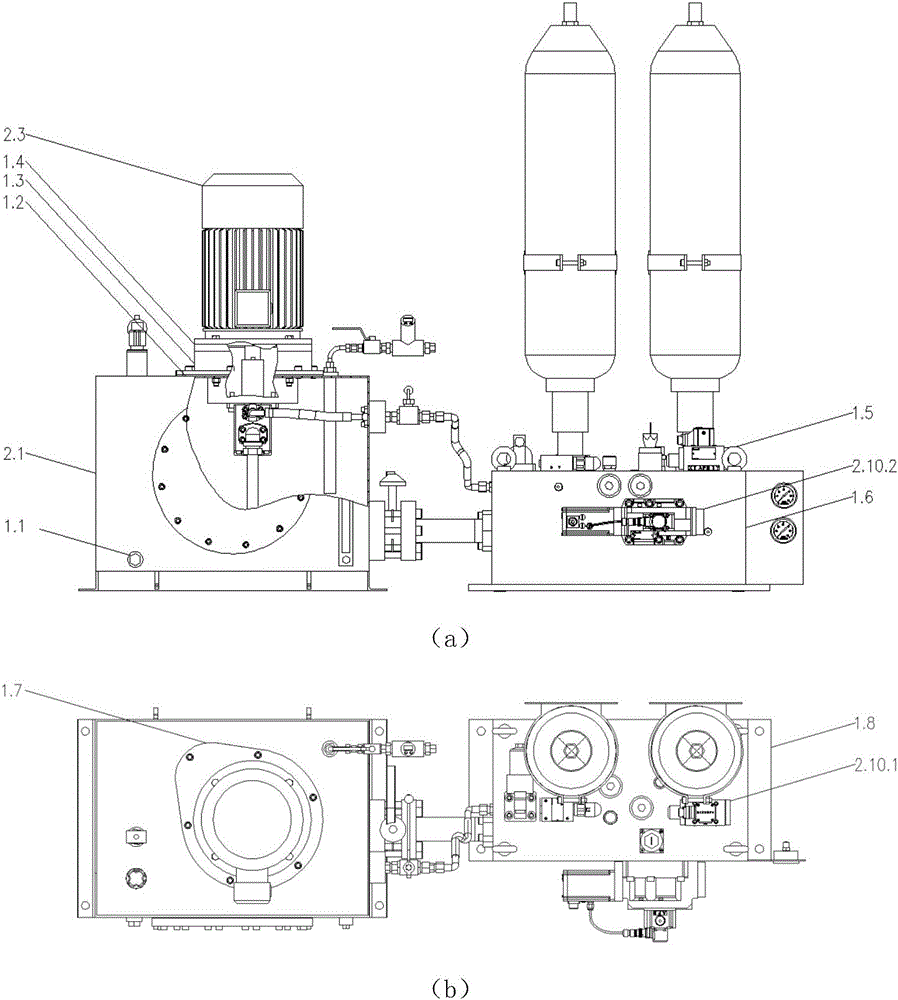

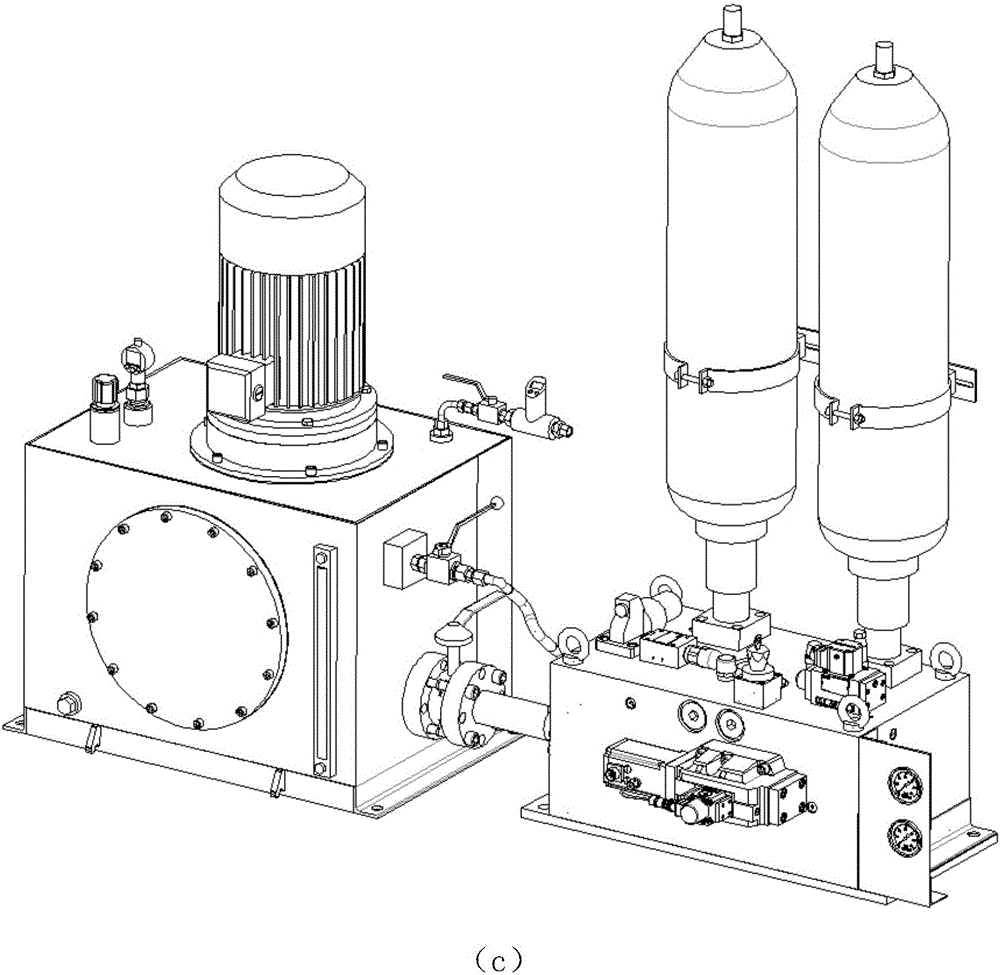

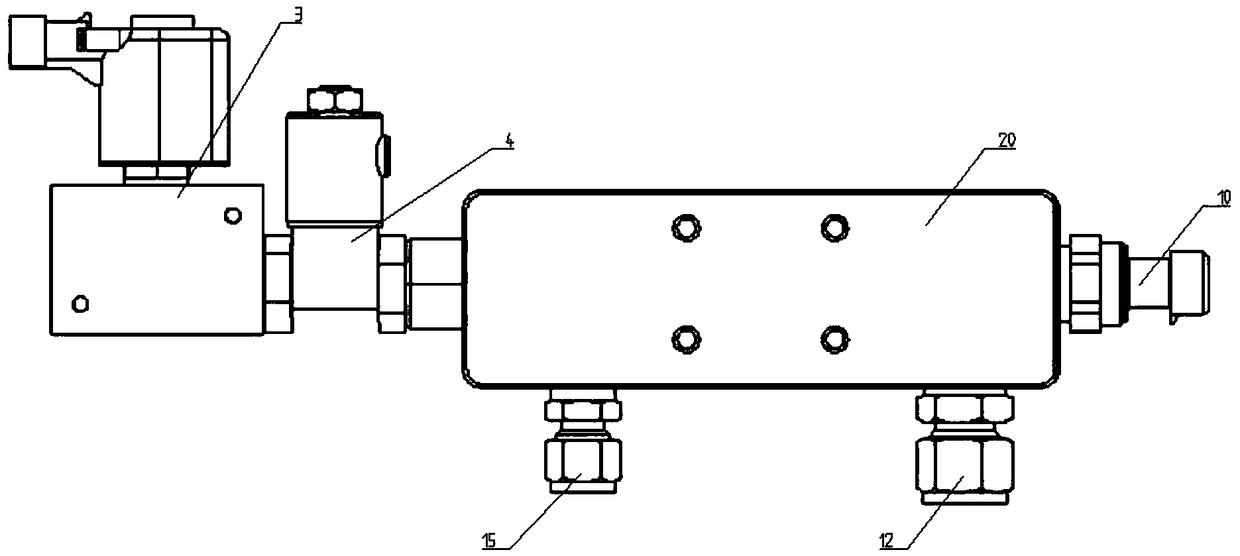

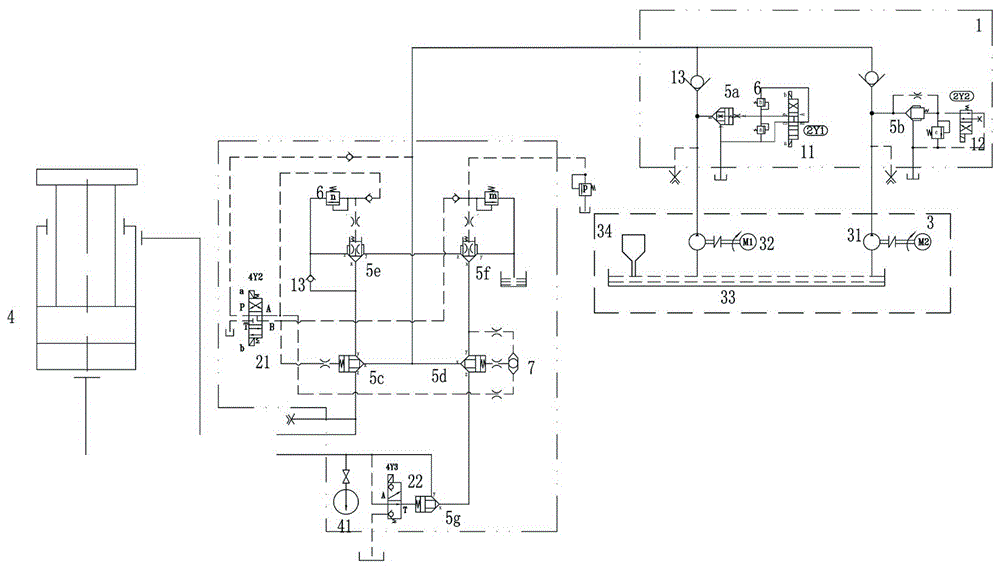

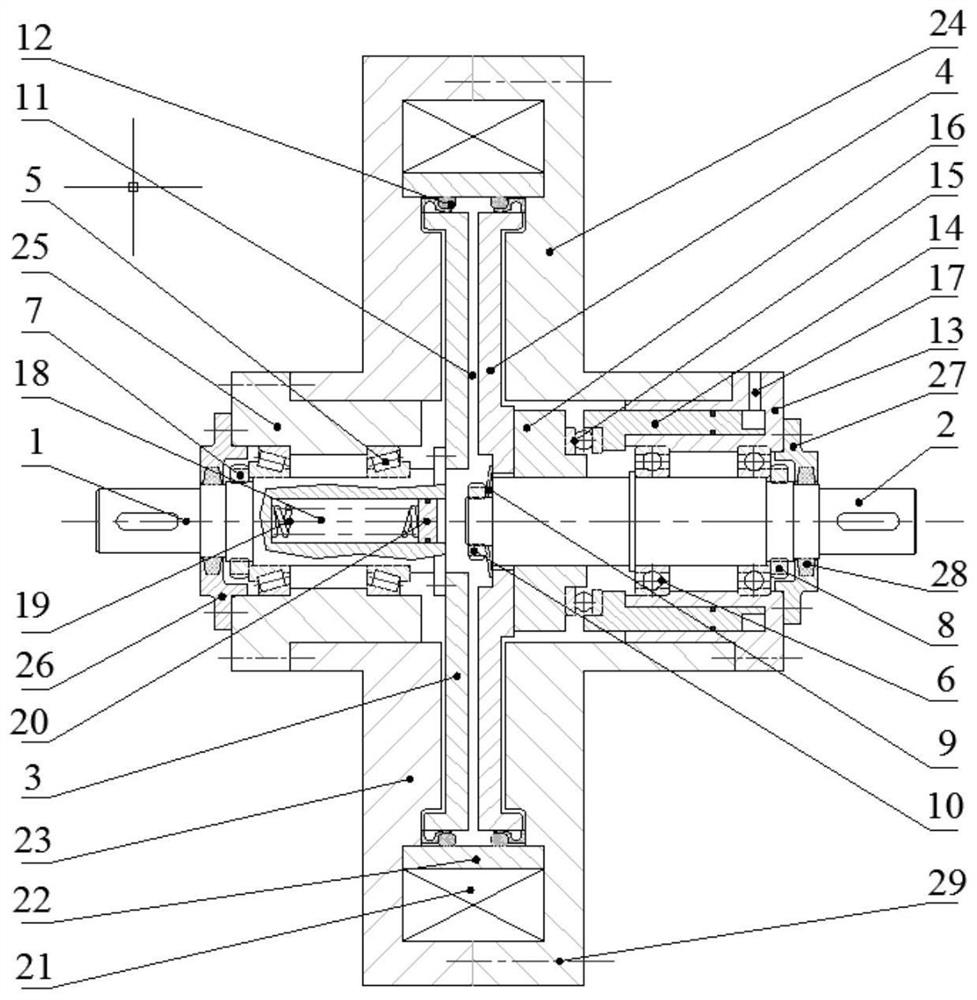

Oil supply and control device for hydraulic clutch

ActiveCN106523544AGuaranteed stable engagementImprove pressure response speedServomotorsFluid actuated clutchesClutchBall valve

The invention discloses an oil supply and control device for a hydraulic clutch. The oil supply and control device comprises a hydraulic pump station and a hydraulic control valve group. The hydraulic pump station comprises an oil tank, an alternating current motor, a hydraulic pump, an air filter, an electronic liquid level and temperature meter, an electronic liquid level meter, a liquid level and temperature meter, a liquid level meter, stop ball valves, a butterfly valve, a bell jar, a bell jaw gasket, a flange gasket, a damping ring, a coupler, a plug and hoses, wherein the bell jar, the bell jaw gasket, the flange gasket, the damping ring, the coupler, the plug and the hoses are used for connection. The hydraulic control valve group comprises a valve block, a valve block installation plate, a lifting lug bolt, a plug, a filter, a one-way valve, a servo valve, an overflow valve, a pressure measuring connector, an energy accumulator, a pressure sensor and a pressure gage. Rapid engagement and pressure control can be achieved for the hydraulic clutch by means of the oil supply and control device, and the oil supply and control device has the advantages of being large in instantaneous flow, accurate in pressure control and large in flow control range.

Owner:ZHEJIANG UNIV

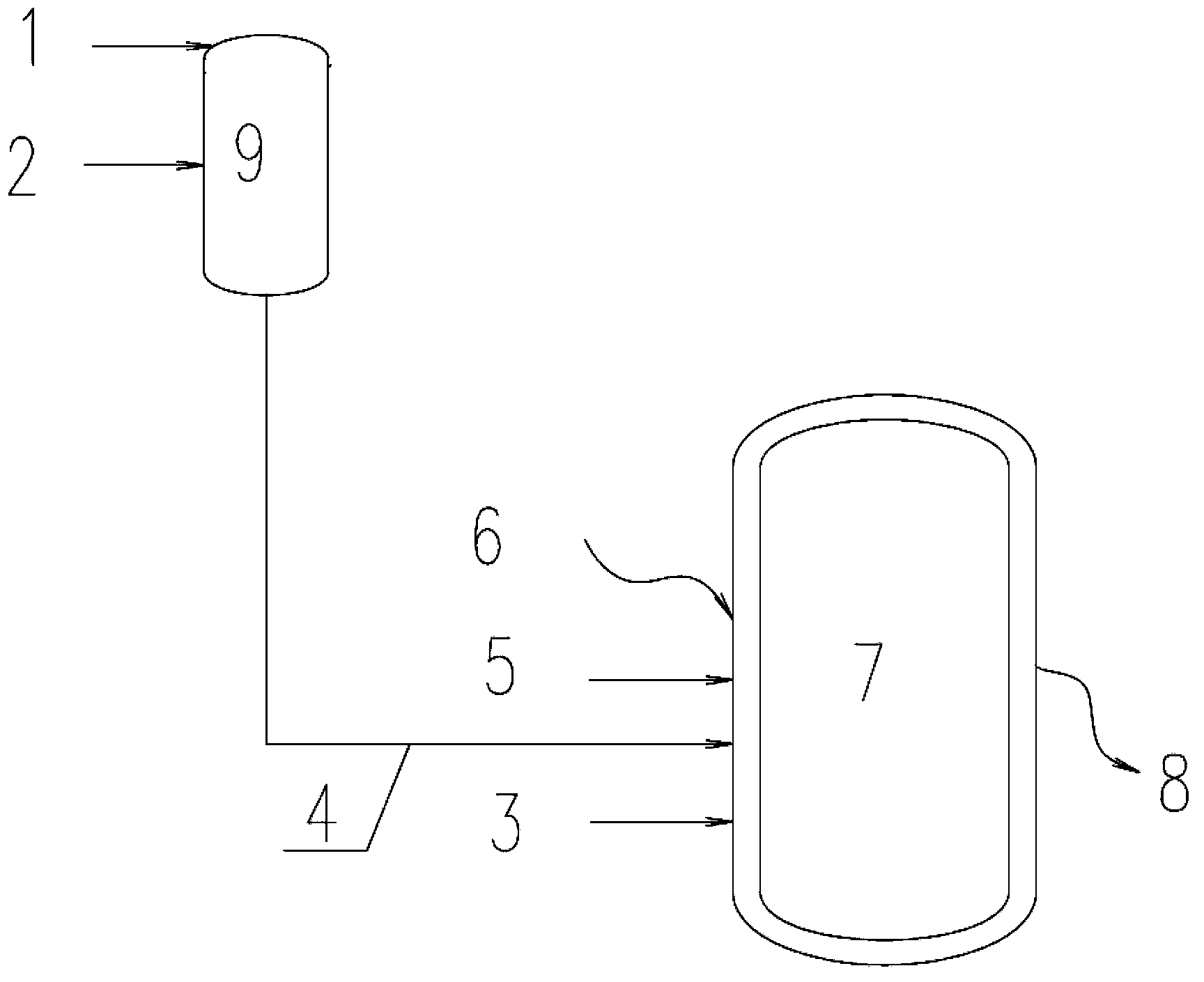

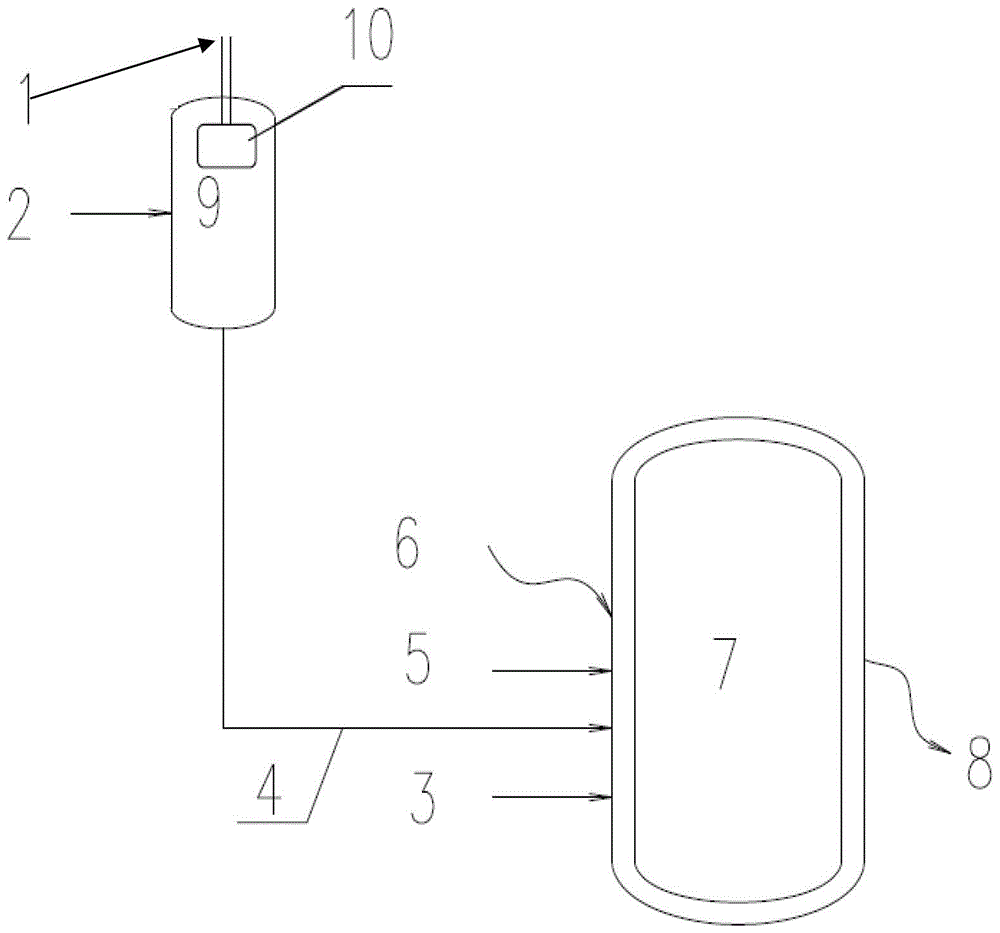

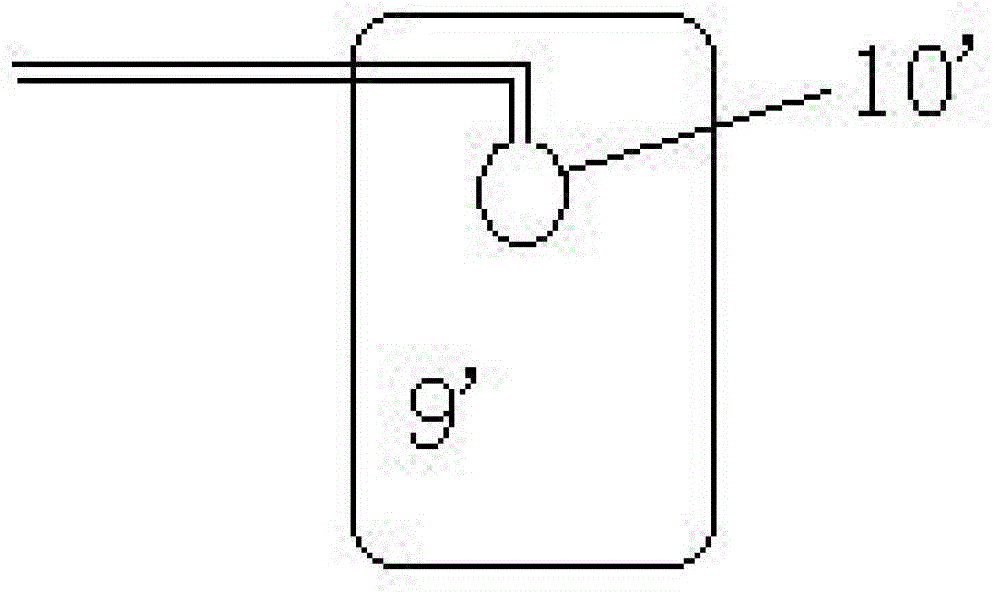

Method for producing alpha olefin through ethylene oligomerization

ActiveCN103896704AEasy to play in timeEasy to get stuckHydrocarbons from unsaturated hydrocarbon additionBulk chemical productionAlpha-olefinSolvent

The invention relates to a method for producing alpha olefin through ethylene oligomerization. The method comprises the steps of a) providing a reaction device in which an external container is connected with a loop reactor; b) pre-dissolving a catalyst component into a reaction solvent, and then continuously introducing the solution of the catalyst into the loop reactor; c) continuously introducing a part of supercharged ethylene monomer into the external container filled with the reaction solvent, pre-dissolving the ethylene monomer, and continuously introducing the reaction solvent dissolved with the ethylene monomer from the external container to the loop reactor; directly introducing the other part of supercharged ethylene monomer into the loop reactor filled with the reaction solvent; d) performing continuous oligomerization reaction on the ethylene monomer in the presence of a catalyst in the loop reactor, dissolving the alpha olefin obtained by the reaction into the reaction solvent, and discharging the solution through the outlet of the loop reactor. Compared with the prior art, the method has the advantages that the pressure control of the reactor is easy, the reactor is prevented from being blocked, the activity of the catalyst is high and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

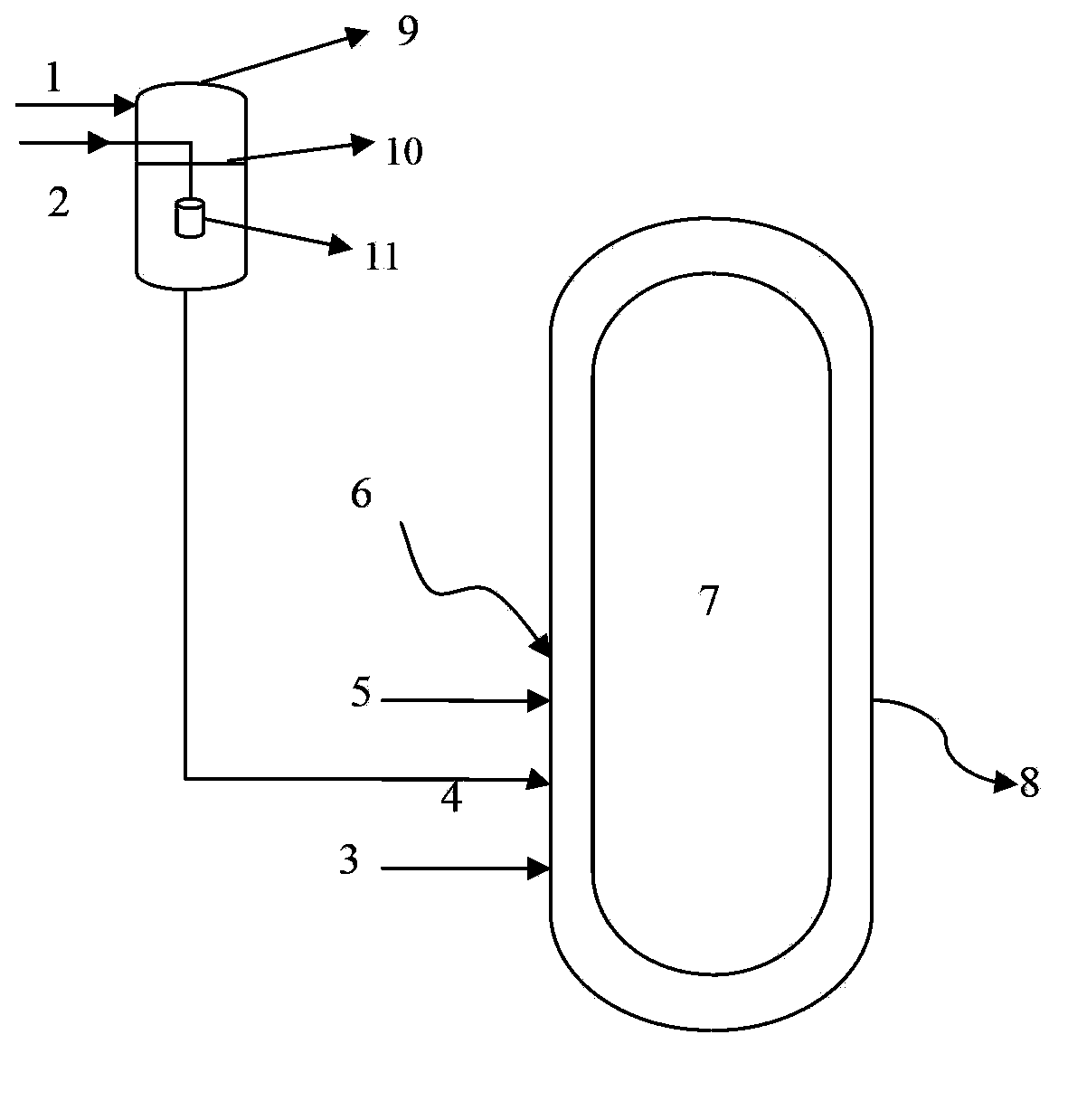

Method for oligomerization production of alpha olefin from ethylene

ActiveCN104086350AFast dissolutionIncrease concentrationHydrocarbons from unsaturated hydrocarbon additionSolventChemistry

The invention relates to a method for oligomerization production of alpha olefin from ethylene. The method provides a reaction device comprising an outer container connected to a circular pipe reactor, a gas distributor is arranged in the outer container, and a reaction solvent is fed into the outer container so that the reaction solvent contacts with a part or all the gas distributor and thus a vinyl monomer goes through a gas distributor and is fed into the solvent, mass transfer between the vinyl monomer and the reaction solvent is promoted and a dissolution amount of the vinyl monomer in the outer container is improved. Through contact between the vinyl monomer and the catalyst in the reactor, an olefin oligomerization reaction is induced fast. The method realizes high catalyst activity easily. Compared with the prior art, the method controls reactor pressure easily, avoids blocking of the reactor and has high catalyst activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

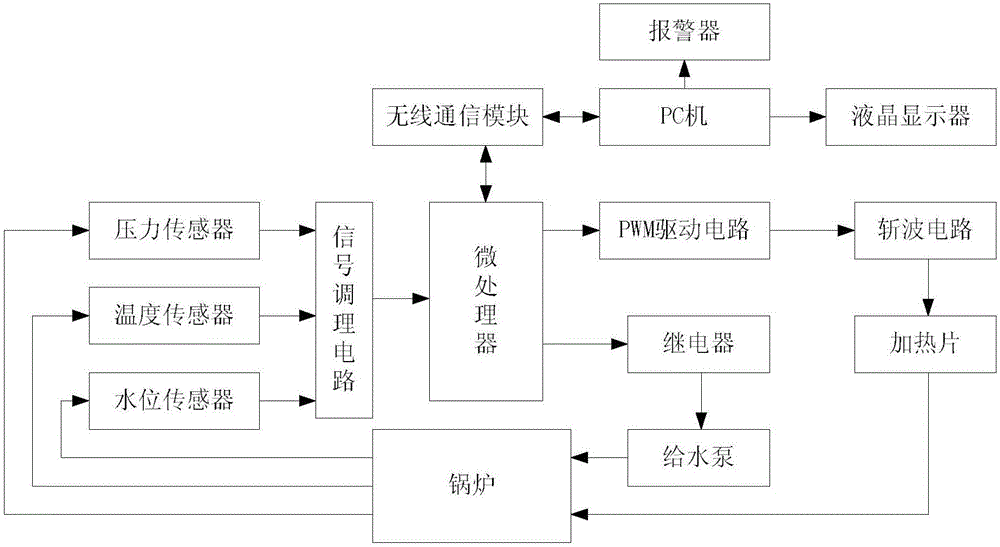

Automatic control device of steam generator

InactiveCN106764999AFast responseAutomatic control reachesSteam generation heating methodsBoiler controlAutomatic controlElectric heating

The invention discloses an automatic control device of a steam generator, and relates to the technical field of control over the steam generators for food processing. The automatic control device comprises a micro processor, a wireless communication module, a PC machine, a PWM driving circuit, a chopper circuit, a heating sheet, a boiler, a relay, a water feeding pump, a pressure sensor, a temperature sensor, a water level sensor and a signal conditioning circuit. The control device disclosed by the invention collects temperature, water level and pressure signals of the boiler through the sensors and transmits the signals to the micro processor; the micro processor controls the PWM driving circuit and the chopper circuit to heat water in the boiler through the electric heating sheet; the micro processor controls the relay and the water feeding pump to supply water to the boiler, so as to realize automatic control over the steam generator; the control device is high in reaction speed; and by the adoption of two-stage control of the micro processor and the PC machine, the steam pressure can be stably controlled.

Owner:ANHUI YICHENG FOOD

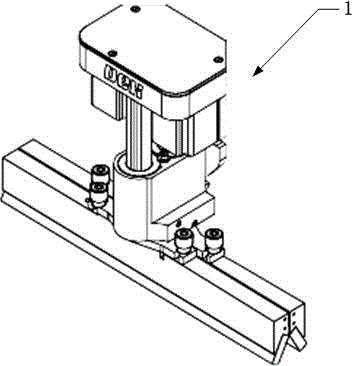

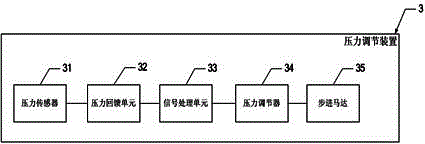

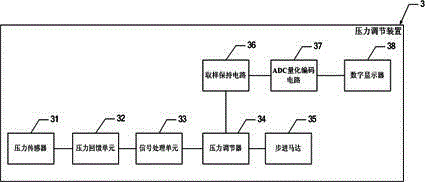

Scraper pressure control system for semiconductor packaging

ActiveCN105280516AControl pressure stabilitySemiconductor/solid-state device manufacturingControl systemPressure sense

The invention provides a scraper pressure control system for semiconductor packaging, which comprises a scraper and a screen plate, and is characterized in that the screen plate is controlled to move through an electromagnetic valve; and the scraper is electrically connected to a pressure regulating device. The pressure regulating device comprises a pressure sensor, a pressure feedback unit, a signal processing unit, pressure regulators and a stepping motor, wherein the pressure sensor is used for detecting pressure of the scraper and generating pressure sensing signals; the pressure feedback unit is used for receiving the pressure sensing signals, and generating and outputting pressure feedback signals according to the pressure sensing signals; the signal processing unit is used for receiving the pressure feedback signals, calculating an actual pressure value according to the pressure feedback signals, comparing the actual pressure value with a preset rated pressure value, and outputting triggering signals when the actual pressure value is inconsistent with the rated pressure value; the pressure regulators are used for outputting pressure regulating signals when receiving the triggering signals; and the stepping motor is used for receiving the pressure regulating signals and carrying out pressure regulation control on the scraper according to the pressure regulating signals, thereby realizing stable control for the scraper pressure.

Owner:HITECH SEMICON WUXI

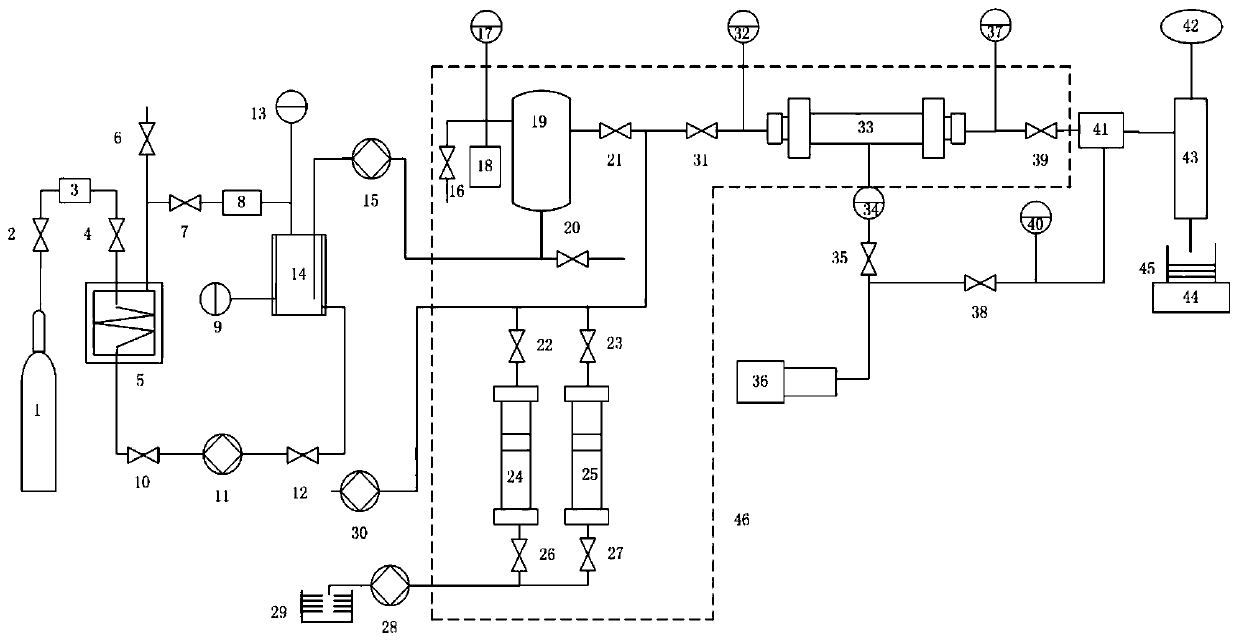

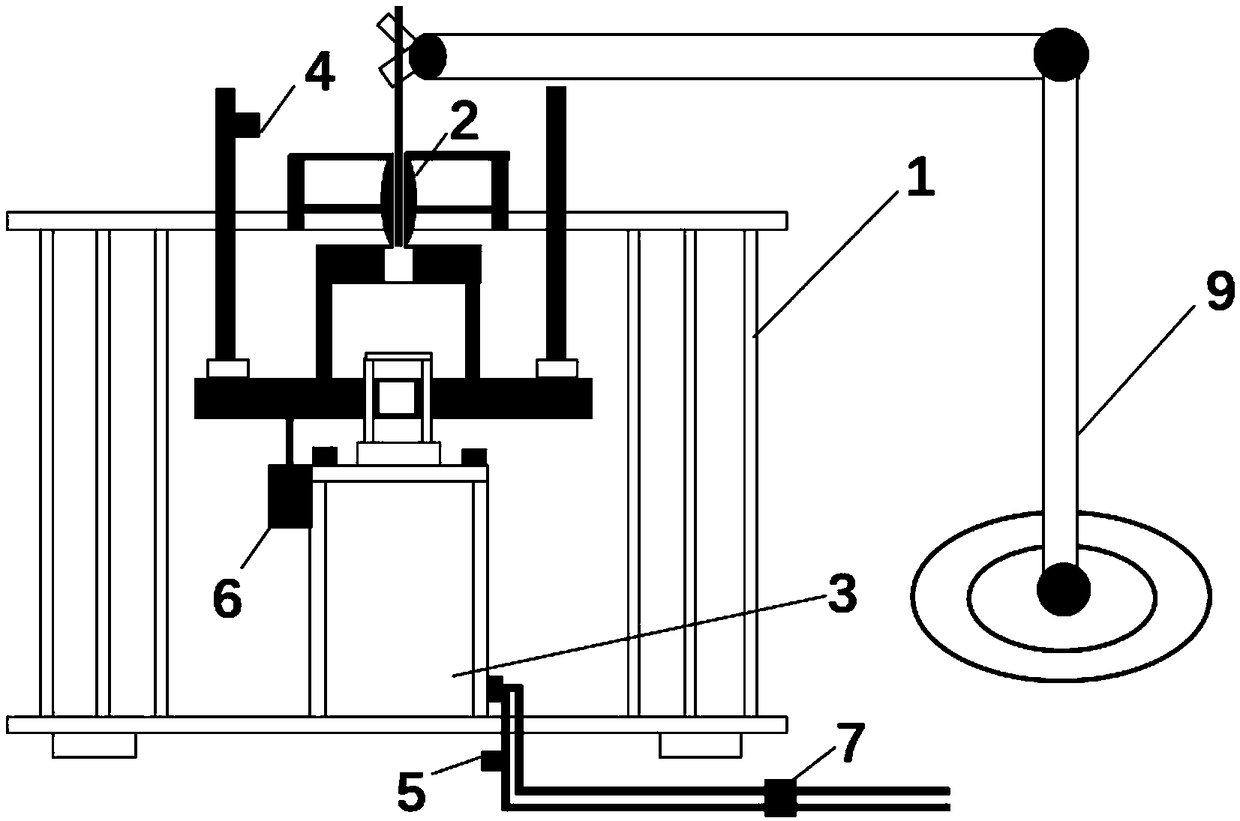

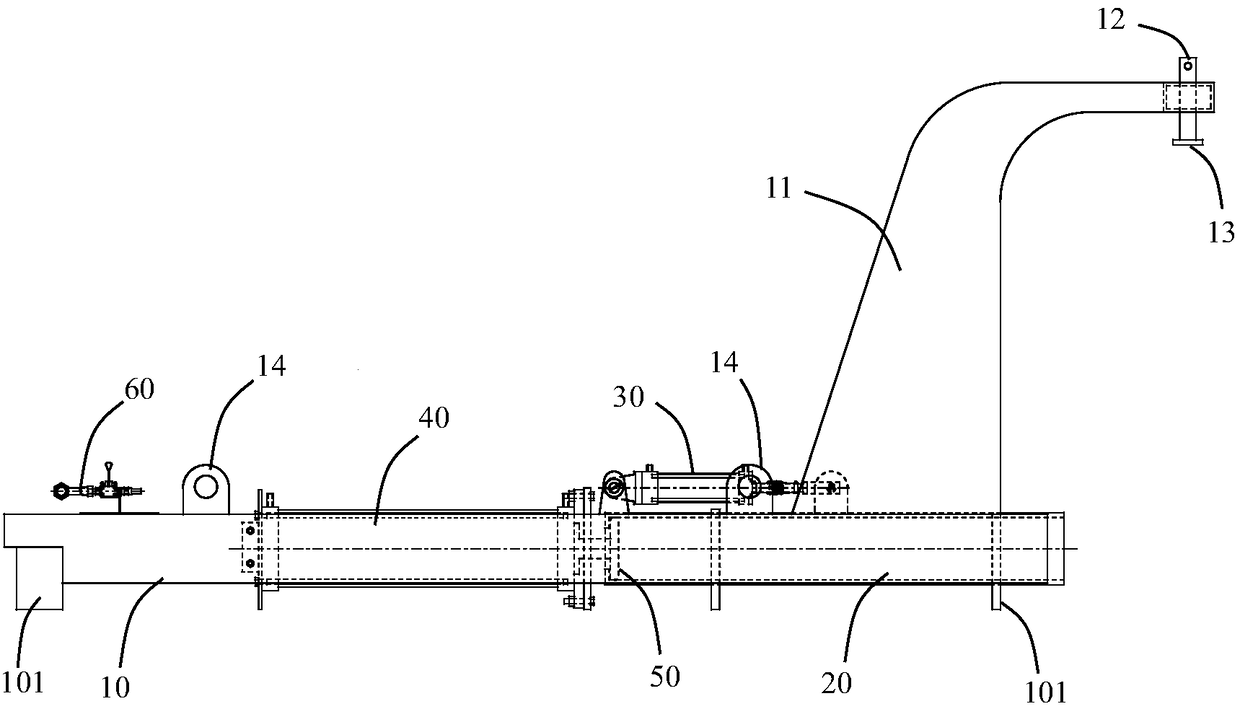

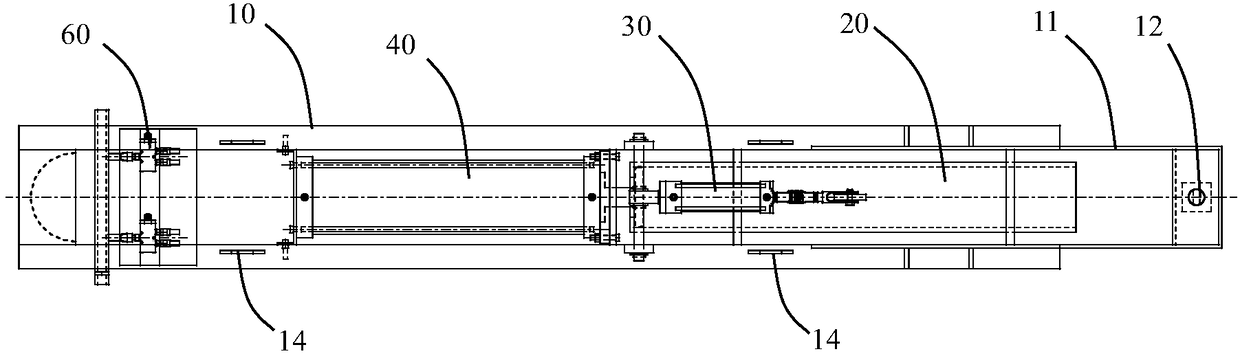

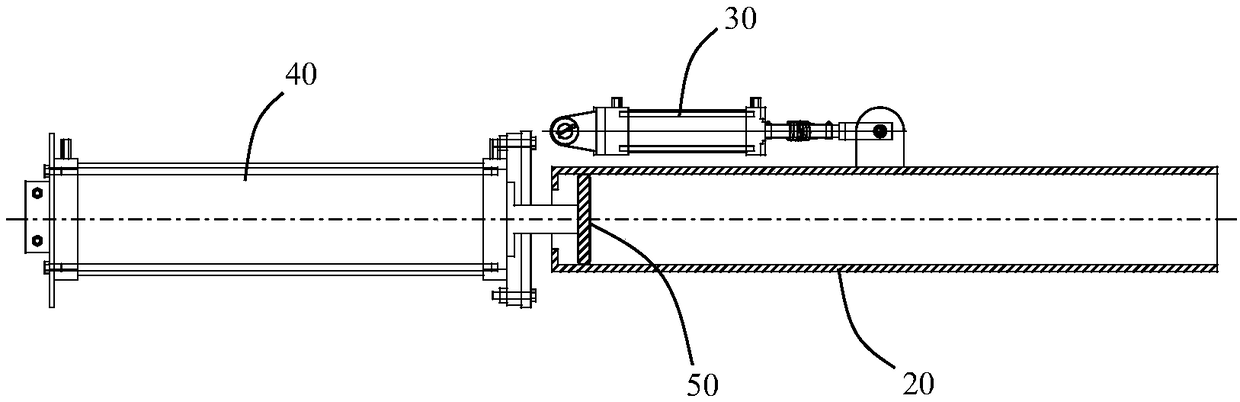

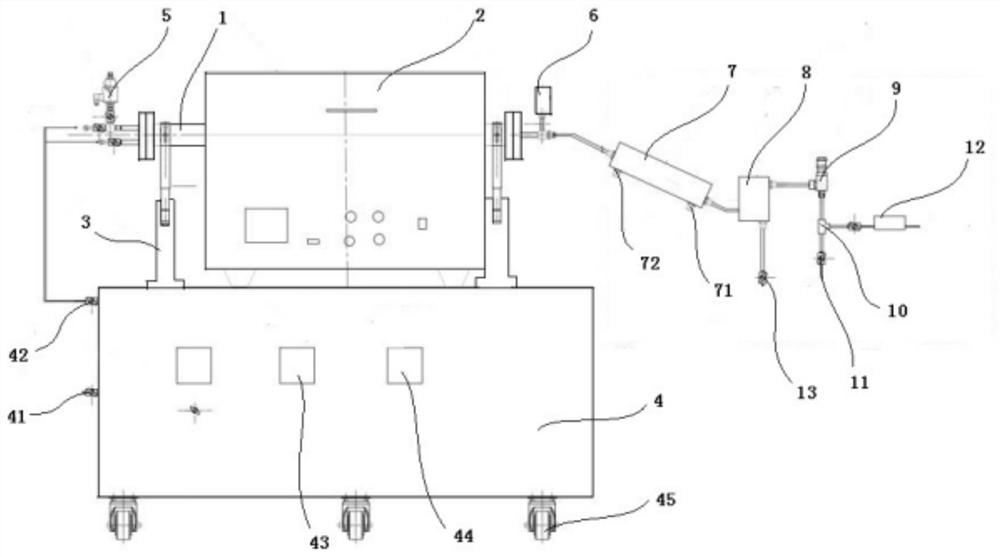

CO2 displacement experimental system and experimental method

PendingCN109932272AControl pressure stabilityEasy to operateWeighing by absorbing componentCarbon dioxideWater saturation

The invention discloses a CO2 displacement experimental system and experimental method. The system comprises a gas refrigeration system, a gas injection system, a liquid injection system and a core clamping system. The gas refrigeration system is composed of a gas cylinder filled with CO2, a purifier, a refrigeration water bath, a first CO2 pump and a storage tank, wherein the gas cylinder filledwith CO2, the purifier, the refrigeration water bath, the first CO2 pump and the storage tank are sequentially connected. The gas injection system is sequentially connected with a second CO2 pump anda buffer tank through the storage tank. The liquid injection system comprises two branches connected in parallel. The first branch comprises a first piston container. The second branch comprises a second piston container. The inlet of the liquid injection system is sequentially connected with a liquid injection pump and a first container. The outlet is connected with the buffer tank. The core clamping system comprises a core holder. The core holder is connected with the gas injection system and the liquid injection system. The device provided by the invention can simulate and test the displacement process of carbon dioxide or an aqueous solution to the reservoir core under different displacements, different temperatures, different pressures and different solution ratios, and calculates residual water saturation or residual CO2 saturation.

Owner:CHINA HUANENG GRP CO LTD +1

Method for oligomerization production of alpha olefin from ethylene

ActiveCN104086349AEasy to play in timeEasy to get stuckHydrocarbonsChemical recyclingDissolutionSolvent

The invention relates to a method for oligomerization production of alpha olefin from ethylene. The method comprises the following steps of a, providing a reaction device comprising an outer container connected to a circular pipe reactor, wherein the top of the outer container is provided with a liquid distributor and the liquid distributor has the effect of liquid dispersion, b, pre-dissolving a catalyst ingredient in a reaction solvent and continuously introducing the catalyst solution into the circular pipe reactor, c, continuously feeding one part of a vinyl monomer subjected to pressurization into the outer container with the reaction solvent for pre-dissolution, continuously feeding the reaction solvent containing the vinyl monomer into the circular pipe reactor from the outer container, and directly feeding the other part of the vinyl monomer subjected to pressurization into the circular pipe reactor with the reaction solvent, and d, carrying out continuous oligomerization reaction process on the vinyl monomer under the action of the catalyst in the circular pipe reactor, and discharging the produced alpha olefin dissolved in the reaction solvent from the outlet of the circular pipe reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

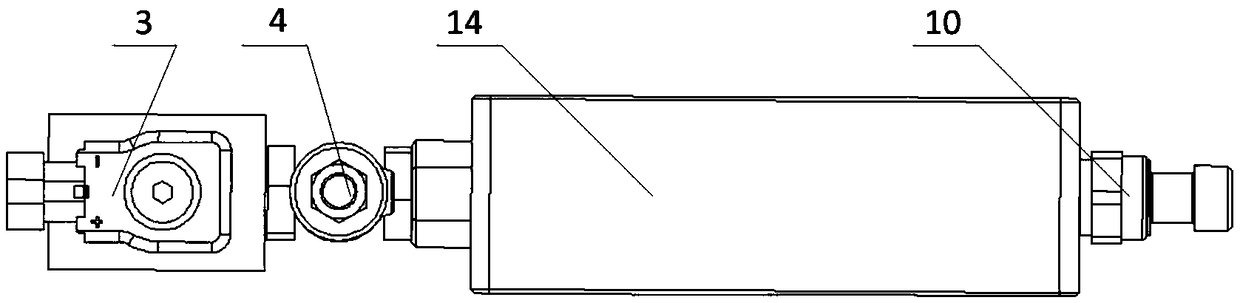

A hydrogen supply and hydrogen return pressure-stabilizing device of a fuel cell automobile power system

PendingCN109004247AStable hydrogen supply pressureImprove securityReactant parameters controlMotive system fuel cellsRefluxSpray nozzle

The invention discloses a hydrogen supply and hydrogen return pressure-stabilizing device of a fuel cell automobile power system, and the device comprises an electromagnetic valve, a proportional valve, an ejector nozzle, an ejector cavity and a hydrogen return ejector port; the electromagnetic valve, the proportional valve, the ejector nozzle and the ejector cavity are sequentially connected in series, the inlet of the electromagnetic valve is connected with a hydrogen storage system of a fuel cell, and the outlet of the ejector cavity is connected with the inlet of a fuel cell stack; the ejector cavity includes an ejector cavity reduction chamber, an ejector cavity mixing chamber and an ejector cavity diffusion chamber in sequence from the inlet to the outlet, wherein the ejector cavityreduction chamber is provided with a hydrogen return ejector port which is connected with the fuel cell stack outlet, and the proportional valve opening control stability is utilized to realize the stable control of hydrogen supply pressure of the fuel cell system; and a relatively high ejection ratio is maintained in a relatively large flow range, and through the ejection reflux effect of the ejection nozzle, the utilization rate of hydrogen is increased, and the hydrogen equivalent ratio of the anode side is improved.

Owner:德燃(浙江)动力科技有限公司

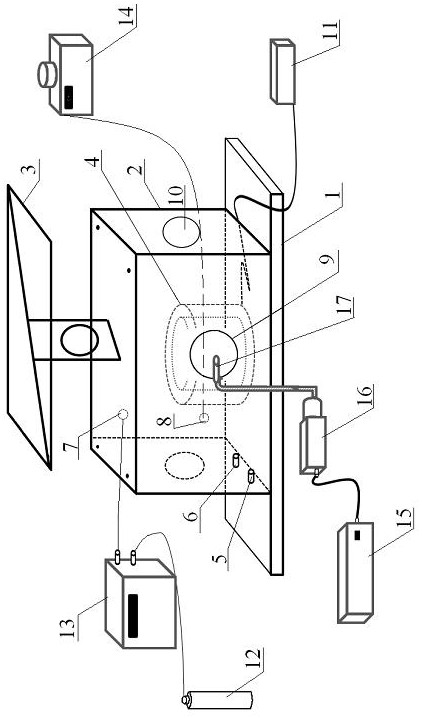

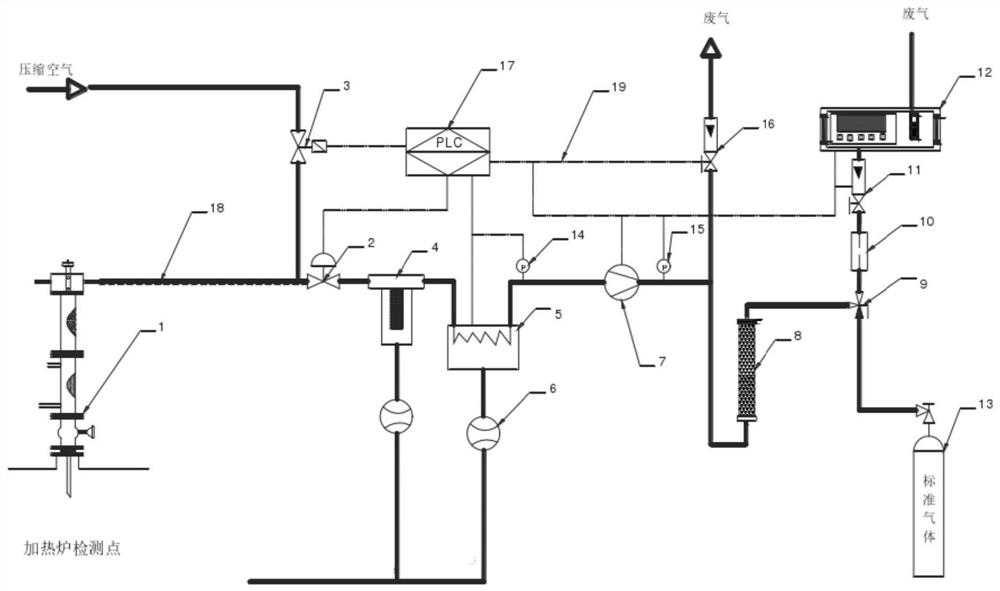

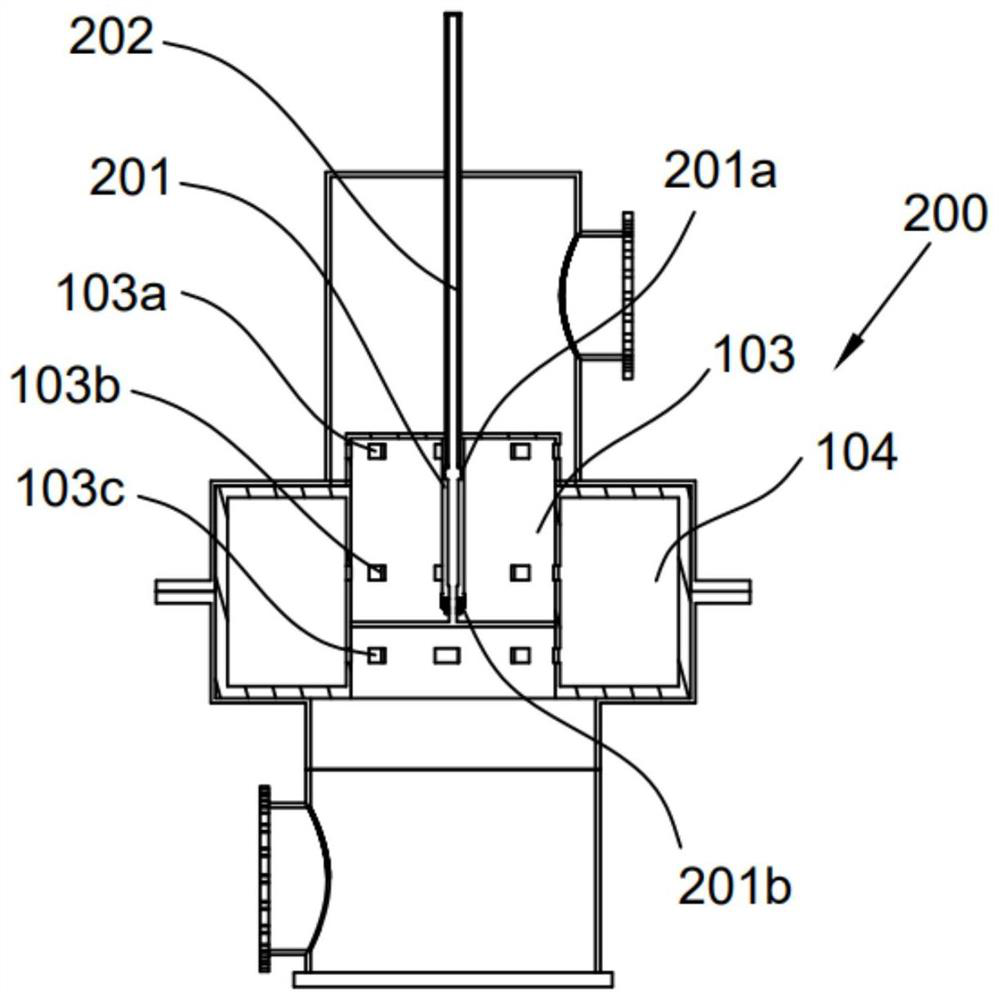

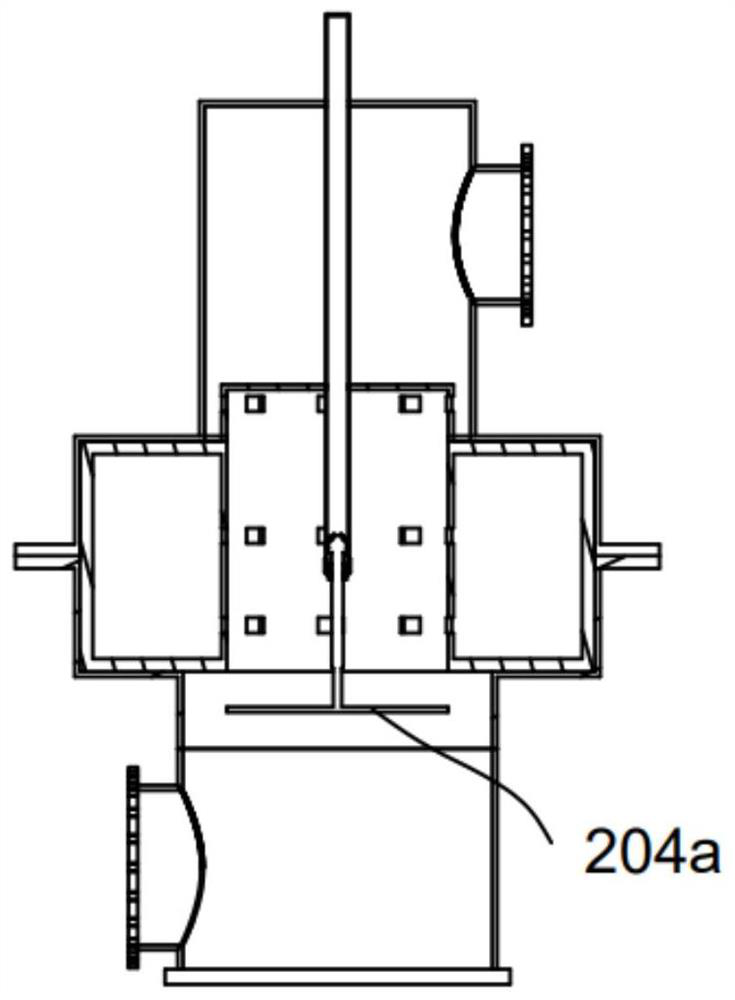

Photocatalytic material in-situ infrared cell system

PendingCN113624708AReal-timeAchieve representationChemical analysis using catalysisAnalysis by subjecting material to chemical reactionGas cylinderOptical spectrometer

The invention relates to a photocatalytic material in-situ infrared cell system. The system comprises an in-situ infrared sample transmission cell arranged on a base in a sample chamber of a Fourier transform infrared spectrometer, an external light source, and a gas control system. The in-situ infrared sample transmission cell comprises a cell body, a sample bracket and a heating coil. The sample bracket is arranged in the heating coil. The cell body is provided with a cooling water inlet and a cooling water outlet which are connected with a water cooler. The cooling water inlet and the cooling water outlet are connected together through a condensing coil. A reaction gas inlet and a reaction gas outlet which are connected together through the gas control system are formed in the rear wall of the cell body. An illumination window is arranged on the front wall of the cell body. Transmission windows are symmetrically arranged in the side walls of the cell body. The gas control system comprises a gas distribution system connected with a gas cylinder and a mechanical pump connected with a vacuum tube. The external light source comprises a light source controller, a light source generator and an ultraviolet lamp light source probe. The ultraviolet lamp light source probe is arranged on the illumination window. According to the invention, real-time illumination monitoring can be realized.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

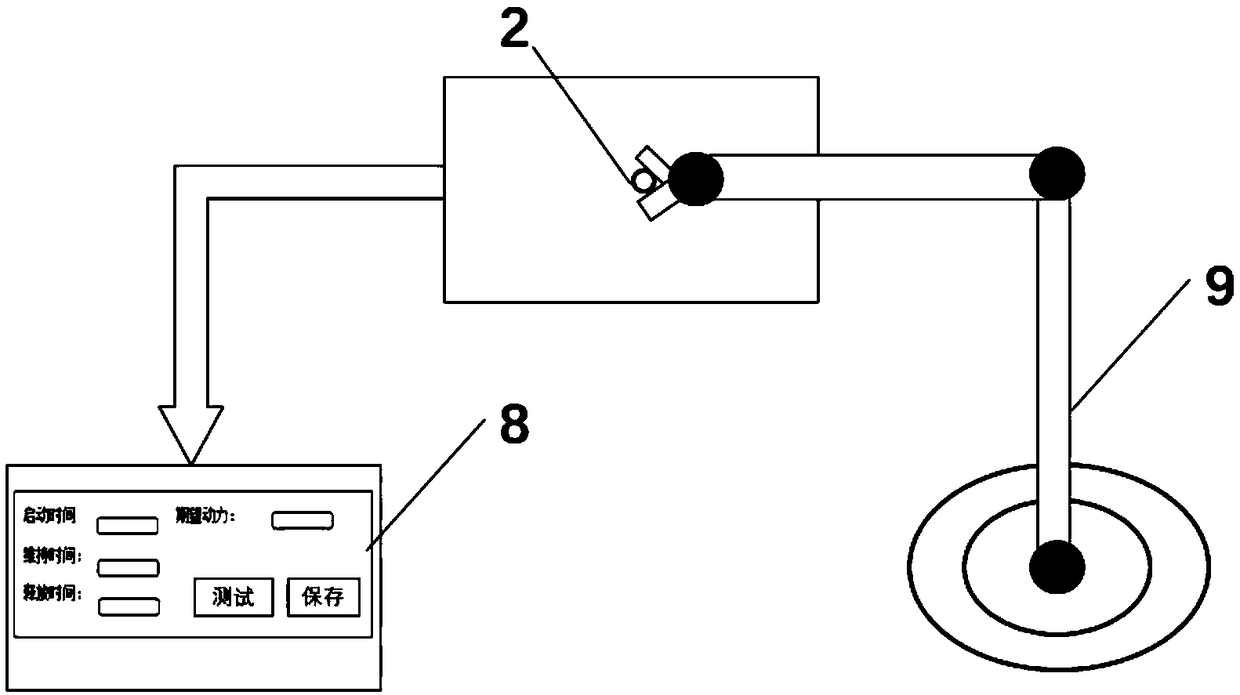

Control system for pressure joint process of detonating cord

InactiveCN109433939AReduce investmentImprove work efficiencyProgramme control in sequence/logic controllersControl systemControl engineering

The invention provides a control system for the pressure joint process of a detonating cord, and aims at solving the situation that in the current manufacturing link pressure joint process of initiating explosive devices, labor intensity is large, and efficiency is low. According to the scheme, the control system comprises the following steps that S1, the information of the detonating cord is scanned through a scanner, and a result is stored to a computer; S2, a metal sleeve of the detonating cord is manually mounted and is fed onto a machine claw of a four-freedom-degree feeding robot; S3, anoperation platform is started by a worker, the four-freedom-degree feeding robot tightens the machine claw, and the metal sleeve end of the detonating cord is fed into a pressure joint opening downwards through operations of ascending, rotating, leftward movement and descending successively; and S4, after ascending, a pressure joint execution mechanism executes pressure joint operation, after operation is completed, the pressure joint execution mechanism returns to the initial position, the machine claw is loosened, and the detonating cord is taken out manually. The pressure joint process ismainly divided into a detonating cord feeding and locating process and a pressure joint process, and the production efficiency and operation safety are greatly improved.

Owner:CHONGQING UNIV

Scroll compressor with pressure regulating device and assembling method thereof

PendingCN111963426AGuaranteed installation accuracyGuaranteed uptimeRotary piston pumpsRotary piston liquid enginesPressure stabilizationEngineering

The invention discloses a scroll compressor with a pressure regulating device and an assembling method thereof. The scroll compressor comprises a compressor body, wherein the compressor body is provided with an air inlet and an air outlet; the air inlet is provided with the pressure adjusting mechanism; the pressure adjusting mechanism comprises a supporting frame, a pressure reducing cylinder anda pressure limiting assembly; the pressure reducing cylinder and the pressure limiting assembly are both arranged on the supporting frame; the supporting frame is arranged on the compressor body; thepressure reducing cylinder is provided with an air inlet pipe and an air outlet pipe; the air outlet pipe is connected with the air inlet; the pressure reducing cylinder is provided with a pressure reducing pipe; the pressure reducing pipe communicates with the pressure reducing cylinder; and the pressure limiting assembly communicates with the pressure reducing pipe. The method comprises the steps of a, preparing and inspecting each component; b, assembling the pressure limiting assembly; c, installing a connecting pipe; d, connecting an air storage tank; and e, fixing the supporting frame.According to the scroll compressor with the pressure regulating device and the assembling method thereof, the inlet pressure of the scroll compressor can be stably controlled, the pressure fluctuationamplitude is reduced, the pressure is stable, and the stable operation of the compressor is ensured; and the method is simple in steps and easy to implement, and connecting and assembling are convenient.

Owner:浙江大明制冷科技有限公司

Simulation test loading device for automobile wheel hub bearing unit

InactiveCN100350233CAchieve free orientationControl pressure stabilityVehicle testingMachine bearings testingHydraulic circuitEngineering

It is a car wheel bearing analogue test load device, which comprises drive main axis 1 and test main axis 2, test bearing supportive structure, radial and axis load cylinder structure. The connection end between radial load oil cylinder and frame is fixed with a ball socket bearing 5. The connection end between the axis bearing load oil cylinder and frame is fixed with ball socket bearing 11. Its radial load oil cylinder down part is directly fixed with proportion decompression valve 21 and electromagnetism switch valve 20. Its axis load oil cylinder down part is directly fixed with proportion decompression valve 15 and electromagnetism 14.

Owner:安徽徽熳动力机械制造有限公司

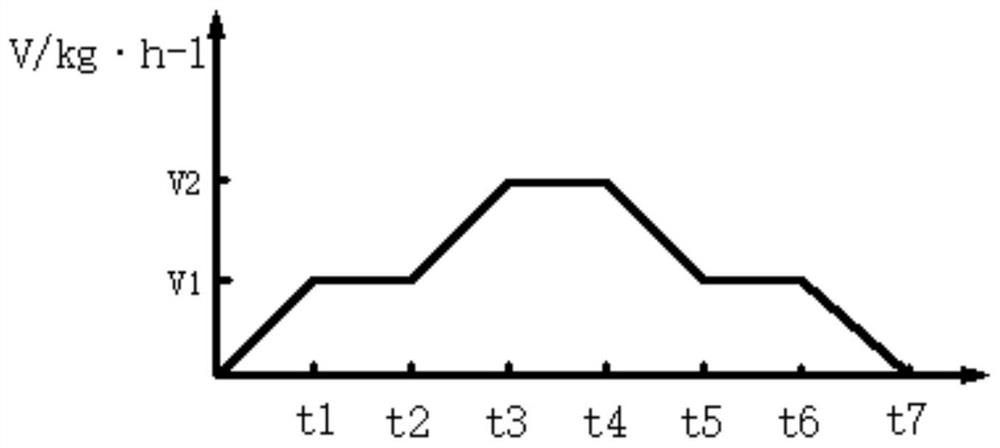

Pressure stabilization adjusting method for gas collecting pipe of coke oven

ActiveCN113736494AControl pressure stabilityAvoid the problem of a large amount of gas being released in the wastelandCoke oven safety devicesDistillation gas withdrawalThermodynamicsPressure stabilization

The invention provides a pressure stabilization adjusting method for a gas collecting pipe of a coke oven. The method comprises the following steps: 1) adjusting double turning plates of a gas suction pipe; 2) ignition diffusion system control: controlling the pressure change rate V of a gas collecting pipe, V = delta P / T; (3) riser pipe cover control: when the bridge pipe turning plate is in an open state, the riser pipe cover is in an open signal, and the system makes a riser pipe cover closing action until a riser pipe cover closing signal appears; and if the closing signal of the riser tube cover cannot be received, outputting an alarm and instructing post personnel to process on site. The pressure fluctuation of the gas collecting pipe under the normal production condition can be effectively controlled, the diffusion of a large amount of raw gas caused by the pressure surge of the gas collecting pipe and the carbonization chamber under the sudden abnormal condition of the gas exhaust fan is avoided, the visible pollution and the VOCs emission are reduced, and the coke oven operation environment is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

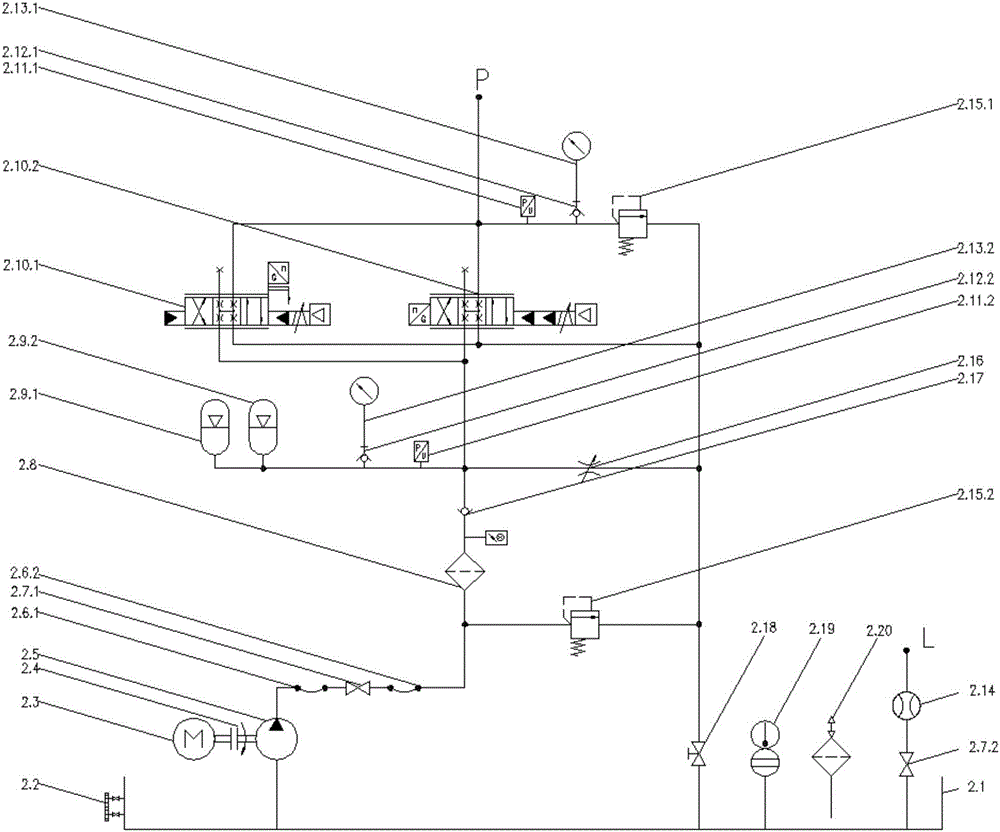

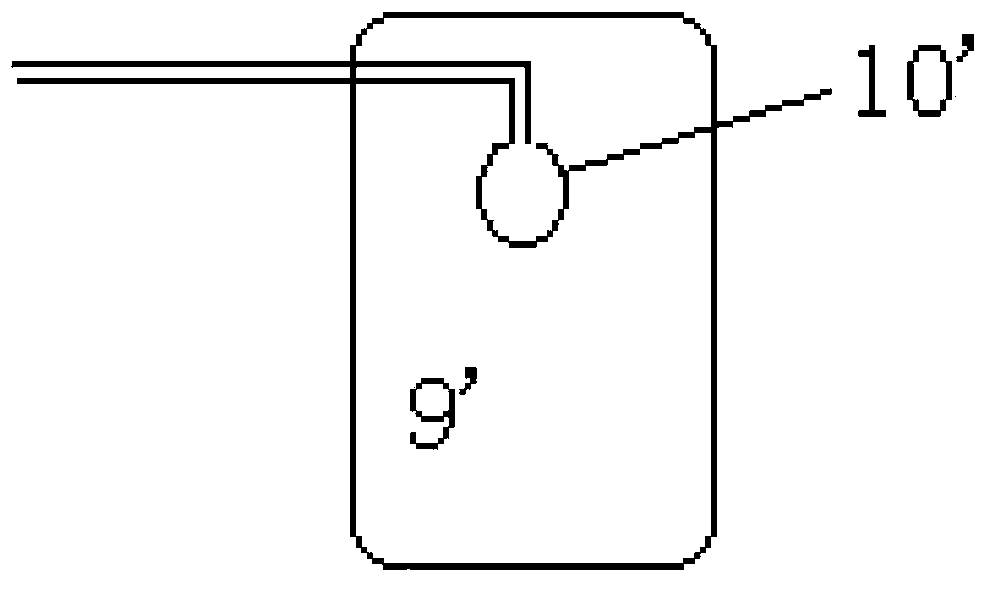

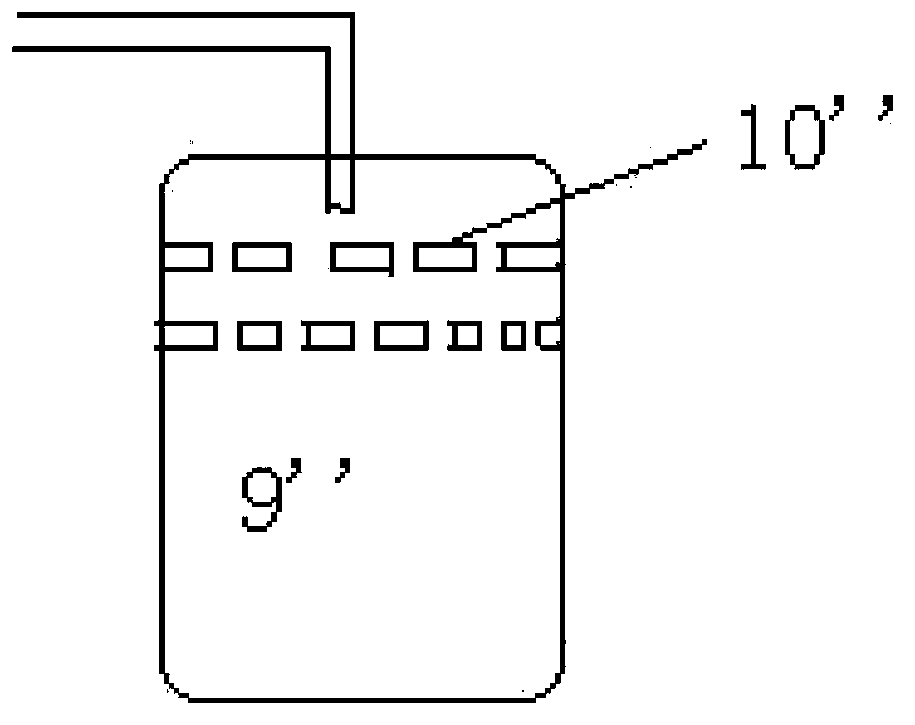

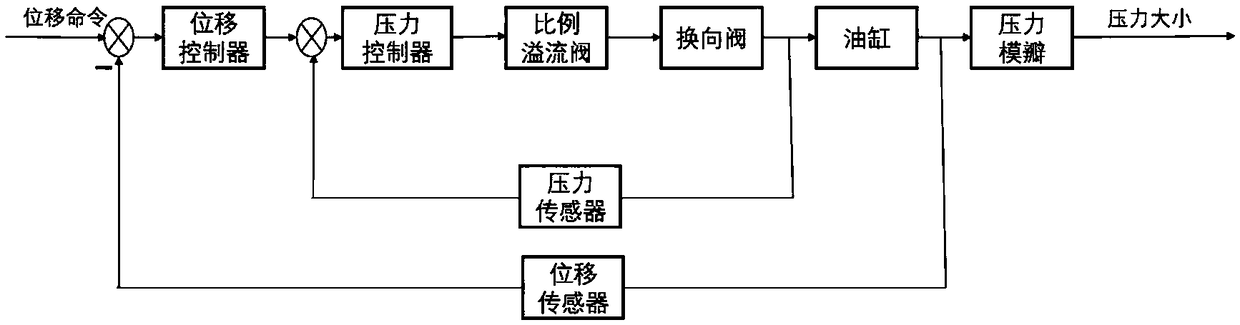

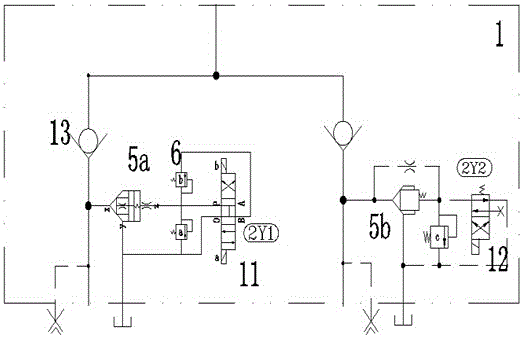

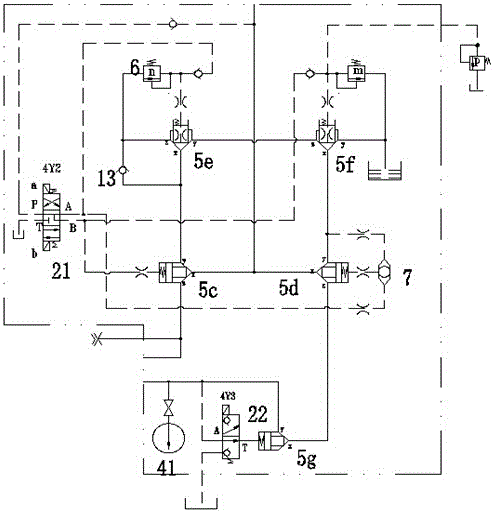

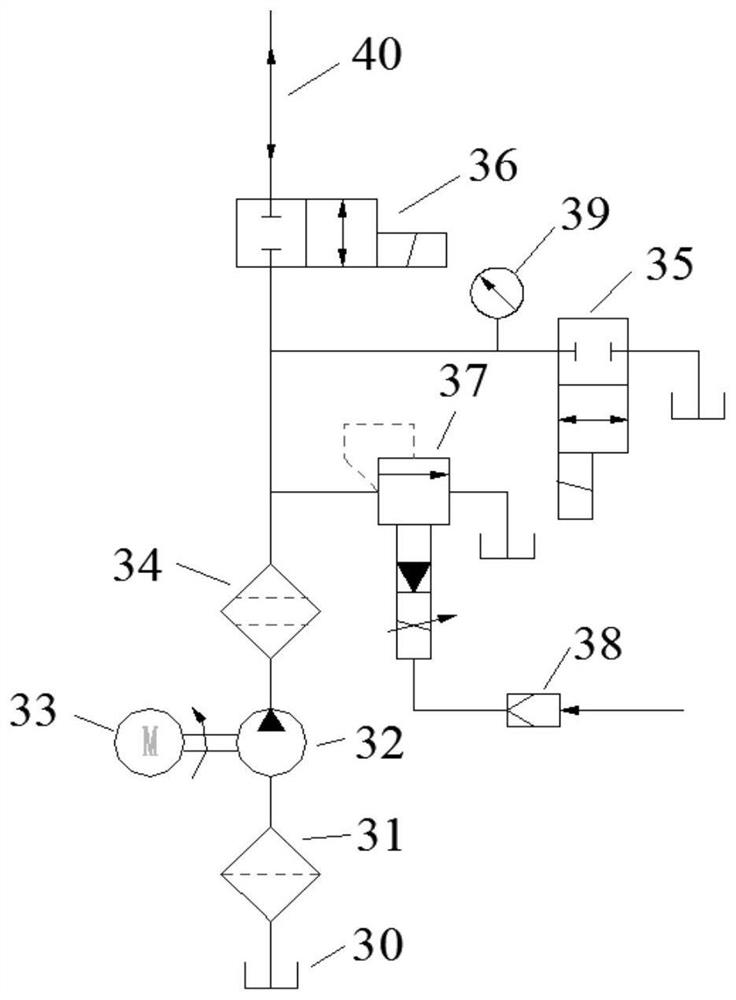

Jacking cylinder control hydraulic system

InactiveCN106438524AControl pressure stabilityContinuous pressure monitoringServomotor componentsServomotorsAir filterConstant stress

The invention relates to a jacking cylinder control hydraulic system. The hydraulic system comprises a power control valve block, a jacking cylinder control valve block, a foundation device and a jacking cylinder; the foundation device, the power control valve block, the jacking cylinder control valve block and the jacking cylinder are serially connected in sequence; a pressure gauge is arranged in the connecting place between the jacking cylinder and a y oil port of an insertion piece g for continuously monitoring the port pressure of the whole jacking cylinder to control the pressure stability of the jacking cylinder; an air filter is arranged on an oil tank of the foundation device for reducing the probability of feeding dust or impurities in air into the oil tank to prevent the conditions of pipe blockage and unstable pressure caused by a lot of dust entering the oil tank; and through simple connection between control valves and pipes, the pressure control of the jacking cylinder is realized, the uniform pressure distribution can be continuously and stably provided, and the pressure testing data is more precise.

Owner:NANTONG GAOYE HEAVY IND CO LTD

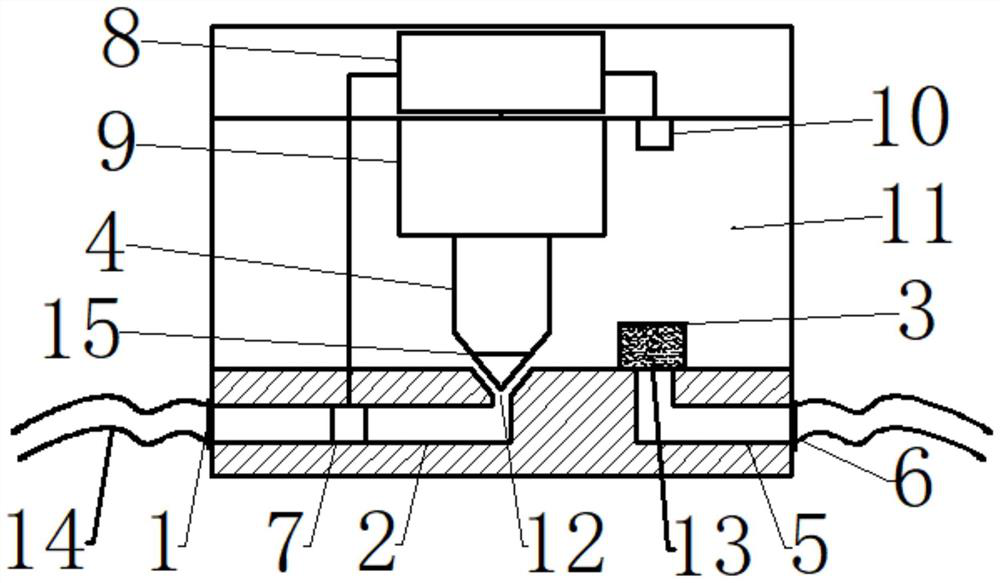

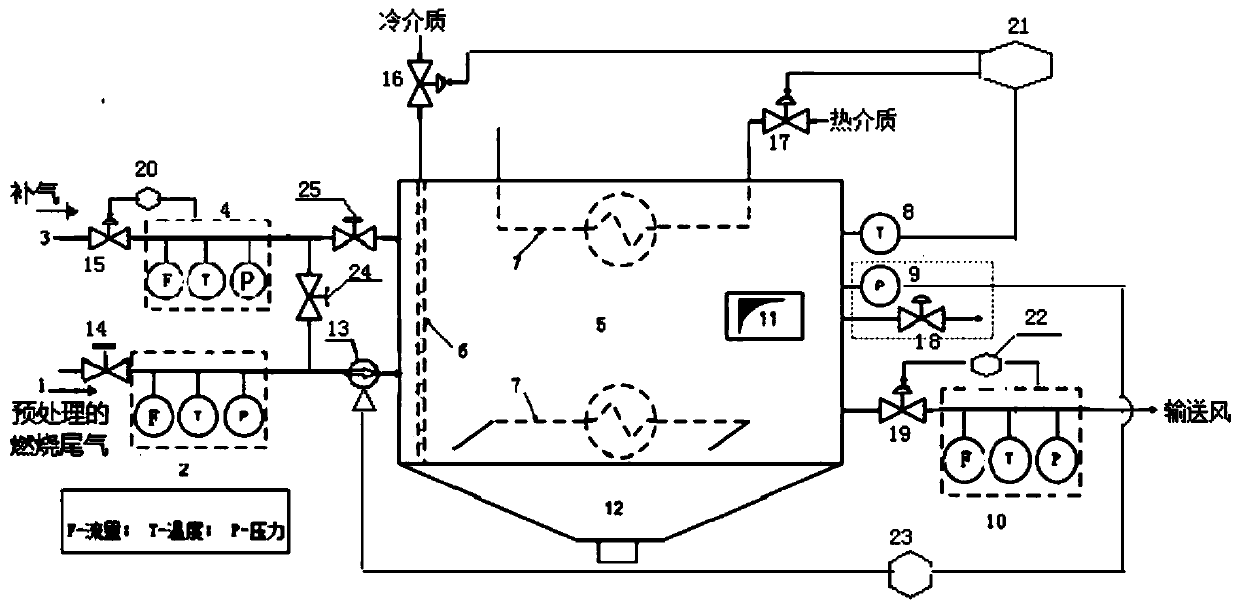

Furnace combustion flue gas online monitoring system and monitoring method

ActiveCN111912942AIncrease flow rateGuaranteed analytical accuracyWithdrawing sample devicesCleaning using gasesThermodynamicsFlue gas

The invention discloses a furnace combustion flue gas online monitoring system and monitoring method, and belongs to the field of flue gas monitoring. The system comprises a sampling unit, a processing unit, a vacuum pump, an analysis unit, an analysis flow controller, a behind-pump positive pressure meter, a diffusion flow controller and an electronic control device. The vacuum pump is connectedwith the analysis unit. The behind-pump positive pressure meter is installed behind an air outlet of the vacuum pump, the analysis flow controller is installed on a pipeline at an air inlet of the analysis unit, and an air inlet of the diffusion flow controller is communicated with a pipeline between the vacuum pump and the analysis unit. The electronic control device is electrically connected with the vacuum pump, the analysis flow controller, the behind-pump positive pressure meter and the diffusion flow controller. According to the method, the furnace combustion flue gas online monitoring system is adopted for flue gas online detection. According to the invention, the discharge condition of the sampled flue gas can be adjusted in real time according to the flue gas condition in the pipeline, the system is ensured to be in a stable-pressure and stable-flow state, and the detection precision of the flue gas is high.

Owner:MAANSHAN IRON & STEEL CO LTD

Reactor pressure stability control device and method

ActiveCN112578824AControl pressure stabilityReduce production accidentsFluid pressure control using electric meansPressure stabilizationThermodynamics

The invention discloses a reactor pressure stability control device and method, belongs to the technical field of metallurgical production, and solves the problems that in the process of generating titanium sponge by a magnesiothermy method, the pressure of a reactor cannot be stably controlled, the pressure is too high, the pressure relief is too fast, low-valence titanium powder blocks a pipeline, and the safety of field staff cannot be guaranteed, and stable operation and production efficiency of production are influenced. The device comprises an air chamber, an air inlet is formed in the air chamber and communicated with an air inlet pipeline, a driving device is connected with an ejector pin, the ejector pin is matched with the air inlet, a first pressure sensor is arranged in the airinlet pipeline and connected with a PLC, the PLC is connected with the driving device, the air chamber is further provided with an air outlet, and the air outlet is communicated with an exhaust pipeline. The PLC is externally connected with a main console, and the PLC is in communication connection with the main console. According to the present invention, the opening degree of the gas inlet is precisely regulated and controlled to control the pressure in the reactor so as to achieve the purpose of stable control of the pressure value required by the reactor at each production stage.

Owner:云南国钛金属股份有限公司

Residual iron hole plugging device

ActiveCN109306389AEasy to operateShorten the timeBlast furnace componentsBlast furnace detailsEngineeringUltimate tensile strength

The invention discloses a residual iron hole plugging device which comprises a body frame, a mud making barrel, a pressure keeping air cylinder and a mud making air cylinder. The mud making barrel isarranged in the body frame and can move front and back relative to the body frame. A mud making disc is arranged in the mud making barrel, the mud making disc is fixed to the end part of a piston rodof the mud making air cylinder, a cylinder body of the mud making air cylinder is fixed in the body frame, and the mud making air cylinder can drive the mud making disc to move relative to the mud making barrel; and a cylinder body of the pressure keeping air cylinder is fixedly connected to the body frame, a piston rod of the pressure keeping air cylinder is fixedly connected to the mud making barrel, and the pressure keeping air cylinder can drive the mud making barrel to move front and back relative to the body frame. The residual iron hole plugging device disclosed by the invention is simple to operate, saves time and reduces the labor intensity and the operational safety risk.

Owner:BAOSHAN IRON & STEEL CO LTD

Constant voltage pressure control method used for oil well cement curing kettle

ActiveCN103324214AControl pressure fluctuationsControl pressure stabilityFluid pressure control using electric meansOil wellElectromagnetic valve

The invention discloses a constant voltage pressure control method used for an oil well cement curing kettle. The constant voltage pressure control method sequentially comprises the following steps of: constant voltage heating, constant voltage constant temperature and constant voltage cooling. A conventional pressurization method in which an air compressor, a hydraulic pump, an electromagnetic valve, a buffer tank and the like are used is replaced by the constant voltage pressure control method, pressure surges can be accurately controlled, and the pressure is controlled in an automatic and stable manner. The pressure surges in GB10238-2005 is + / -0.345MPa, and the actual control precision of the constant voltage pressure control method can reach + / -0.25MPa and reaches the technical level which technologies, such as the conventional electromagnetic valve technology in the prior art can not reach.

Owner:JIAHUA SPECIAL CEMENT

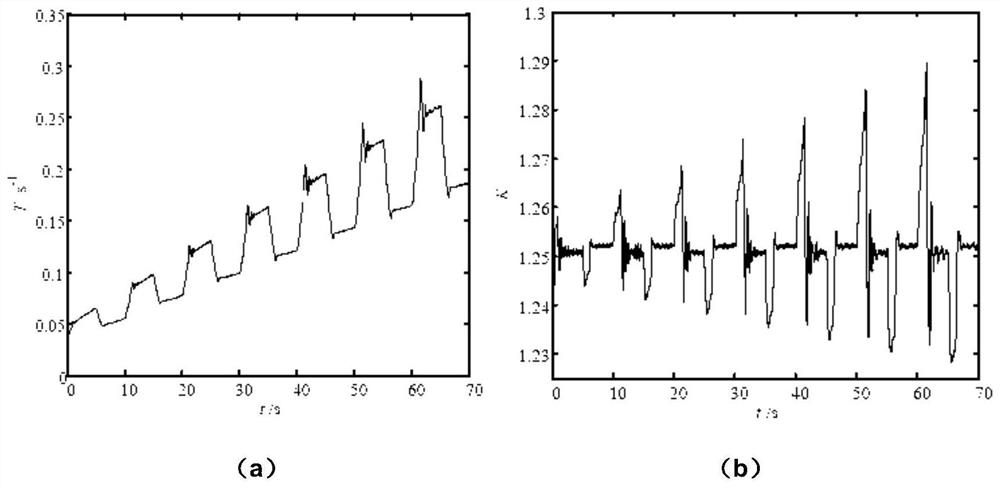

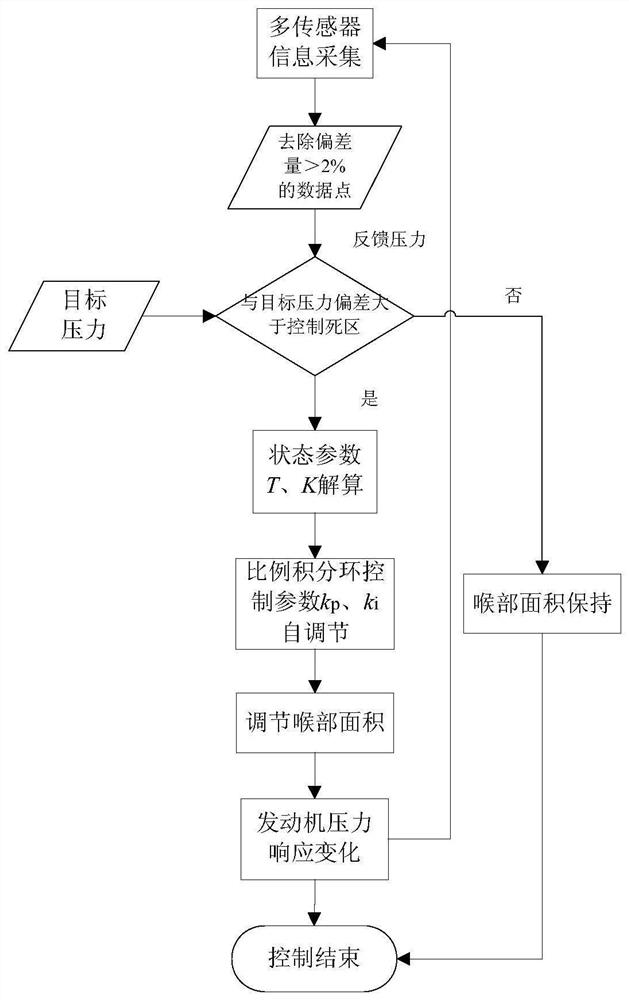

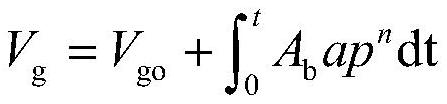

A Self-tuning Method for Pressure Feedback Control Parameters of Variable Thrust Engine

ActiveCN113236443BHigh structural reliabilityWorking pressure real-time feedback controlRocket engine plantsCombustion chamberPressure stabilization

Owner:SHANGHAI XINLI POWER EQUIP RES INST

Constant-pressure type gas storage

PendingCN113048385AAvoid pressure fluctuationsConvenience to workVariable capacity gas holdersEngineeringAir line

The invention relates to the technical field of pressure containers and energy storage, in particular to a constant-pressure type gas storage which comprises an air pipeline and a boss, a constant-pressure body capable of moving up and down is arranged above the boss, a groove is formed in the bottom of the constant-pressure body, and the constant-pressure body is meshed with the boss downwards through the groove. A gap is formed between the inner wall of the groove and the outer wall of the boss, a flexible film is arranged on the gap in a sealed mode, sealing liquid is loaded on the flexible film, and the air pipeline communicates with the groove from the outside. According to the constant-pressure type gas storage, the problems of pressure fluctuation and low volume efficiency of a gas storage in the prior art can be solved, the problem that the gas storage is prone to gas leakage in the high-pressure state can be effectively solved, and it is ensured that the gas storage can store gas at the constant pressure in the high-pressure state.

Owner:TSINGHUA UNIV +2

A plugging device for residual iron eye

ActiveCN109306389BEasy to operateShorten the timeBlast furnace componentsBlast furnace detailsCircular discEngineering

The invention discloses a residual iron hole plugging device which comprises a body frame, a mud making barrel, a pressure keeping air cylinder and a mud making air cylinder. The mud making barrel isarranged in the body frame and can move front and back relative to the body frame. A mud making disc is arranged in the mud making barrel, the mud making disc is fixed to the end part of a piston rodof the mud making air cylinder, a cylinder body of the mud making air cylinder is fixed in the body frame, and the mud making air cylinder can drive the mud making disc to move relative to the mud making barrel; and a cylinder body of the pressure keeping air cylinder is fixedly connected to the body frame, a piston rod of the pressure keeping air cylinder is fixedly connected to the mud making barrel, and the pressure keeping air cylinder can drive the mud making barrel to move front and back relative to the body frame. The residual iron hole plugging device disclosed by the invention is simple to operate, saves time and reduces the labor intensity and the operational safety risk.

Owner:BAOSHAN IRON & STEEL CO LTD

An automatic constant temperature and pressure device in a gas environment

ActiveCN108816165BImprove securityStable reaction temperatureChemical/physical/physico-chemical processesTemperature controlReaction system

The invention discloses an automatic constant temperature and pressure device in a gas environment, which includes a high temperature acquisition structure, a constant pressure structure, and a product collection structure. The high temperature acquisition structure includes a reactor, a constant temperature control cabinet installed on the reactor, and a The reactor brackets at both ends of the reactor; the constant pressure structure includes: a constant pressure control cabinet, the first constant pressure fitting, and the second constant pressure fitting; the product collection structure includes: a condenser, a gas-liquid separation tank, and an exhaust gas treatment device. One end of the tank is connected to the second constant pressure fitting, and the other end is connected to the gas-liquid separation tank; one end of the gas-liquid separation tank is connected to the condenser, and the upper wall of the other end is connected to the tail gas treatment device; the tail gas treatment device is connected through a three-way pipe joint There are exhaust ports and gas collection ports. The invention realizes the constant temperature and constant pressure adjustment of the reaction system, and the reaction tail gas is discharged and collected after purification treatment, the reaction temperature and pressure are controlled stably, manpower and material resources are saved, the safety factor is high, and the production efficiency is improved.

Owner:安徽科幂仪器有限公司

Hydraulic extrusion type magnetorheological fluid clutch

PendingCN111810556AHigh precisionControl pressure stabilityServomotor componentsServomotorsPhysicsElectromagnetic valve

The invention discloses a hydraulic extrusion type magnetorheological fluid clutch, and belongs to the technical field of mechanical transmission. The hydraulic extrusion type magnetorheological fluidclutch comprises a mechanical structure part and a hydraulic control part. The mechanical part comprises a shell, a driving assembly, a driven assembly, a magnetorheological fluid, a magnetorheological fluid extrusion device, a volume fine adjustment device and a magnetic field generation device. The hydraulic control part comprises a motor, an oil pump, a two-position two-way electromagnetic valve and an electro-hydraulic proportional overflow valve, and is used for controlling the axial extrusion force of the magnetorheological fluid. The working mode of a traditional magnetorheological fluid clutch based on single shear flow is changed, on the basis that the size of a mechanical structure device of the clutch is not increased, the torque transmission capacity is greatly improved, and the torque / volume ratio or the torque / mass ratio several times larger than that of a common magnetorheological fluid clutch is achieved.

Owner:CHINA UNIV OF MINING & TECH +1

A tail gas treatment device for providing solid fuel conveying air

ActiveCN109268845BMake up for the impactStable controlIncinerator apparatusPetroleum cokePressure detection

The invention discloses a tail gas treatment device used for providing solid fuel conveying air. The tail gas treatment device comprises a tail gas adjusting room, a tail gas input pipeline, an air supplementing pipeline and a conveying air pipeline outlet, wherein the tail gas adjusting room comprises a conveying air automatic temperature adjustment control system and a pressure automatic adjustment control system. The conveying air automatic temperature adjustment control system comprises a temperature detection device, a temperature adjustment device and a temperature controller; the pressure automatic adjustment control system comprises a pressure detection device, a pressure adjustment device and a pressure controller. With the tail gas treatment device, constant-temperature and constant-pressure control over conveying air is realized, the stability of the conveying air is guaranteed sufficiently, volume changes caused by temperature fluctuation are prevented from generating negative effects on the stability of gas and solid two-phase flows, and the tail gas treatment device is suitable for a high-temperature industrial boiler with petroleum coke powder or pulverized coal or other solid fuel being fuel and particularly suitable for a high-temperature industrial boiler combusting pure oxygen-solid fuel, and can be applied to the manufacturing fields of glass, metallurgy, cement, ceramic and others.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Method for producing alpha olefins by oligomerization of ethylene

ActiveCN104086349BStable pressureControl pressure stabilityHydrocarbonsChemical recyclingAlpha-olefinSolvent

The present invention relates to a method for producing alpha olefins by oligomerization of ethylene. The method a) provides a reaction device in which an external vessel is connected to a loop reactor, wherein a liquid distributor is provided on the top of the external vessel, and the liquid distributor It has the effect of dispersing the liquid; b) pre-dissolving the catalyst components in the reaction solvent, and then continuously introducing the catalyst solution into the loop reactor; c) continuously introducing a part of the pressurized ethylene monomer into the After pre-dissolving in the external container containing the reaction solvent, the reaction solvent dissolved in the ethylene monomer is continuously passed into the loop reactor from the external container; the other part of the pressurized ethylene monomer is directly passed into the container. In a loop reactor with a reaction solvent; d) In the loop reactor, the ethylene monomer is continuously oligomerized under the action of a catalyst, and the alpha olefin obtained by the reaction is dissolved in the reaction solvent and passed through the loop reactor. outflow.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pressure-controllable pipeline pressure regulating device

ActiveCN113932053AFast water flowControl pressure stabilityEqualizing valvesHydro energy generationWater flowEngineering

The invention provides a pressure-controllable pipeline pressure regulating device. The device comprises an upper water passing body, a lower water passing body, a pressure regulating module, wherein a guide cylinder communicating with the upper water passing body and the lower water passing body is arranged between the upper water passing body and the lower water passing body; the pressure regulating module comprises a sliding channel arranged in the guide cylinder, a connecting shaft is arranged in the sliding channel, a fixing piece is connected to the lower portion of the connecting shaft, a plurality of blades uniformly distributed in the circumferential direction are arranged on the fixing piece, the blades are rotationally connected with the fixing piece, the blades are spliced into a complete circular plate in the horizontal state, and the diameter of the circular plate is equal to the inner diameter of the guide cylinder; a sealing plate is extruded through the pressure difference between the interior and the exterior of a pipeline, so that water flow is automatically controlled to flow out or flow in, the pressure in the pipeline is controlled to be always kept within a proper range, the structure of the upper and lower water passing bodies enables the water passing speed to be fast, the control pressure is more stable, and bidirectional pressure adjusting operation can be well completed; and meanwhile, the manufacturing process requirement is not high, and the cost can be well saved.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com