A Self-tuning Method for Pressure Feedback Control Parameters of Variable Thrust Engine

A parameter self-tuning and feedback control technology, which is applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve the problem that the thrust, pressure dynamic oscillation and steady-state control error vary greatly, and it is difficult to meet the safety and reliability of the weapon system. Requirements, adjustment performance, large changes in engine working status, etc., to achieve follow-up adjustment, overcome pressure adjustment quality changes, and increase the accuracy of interpretation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

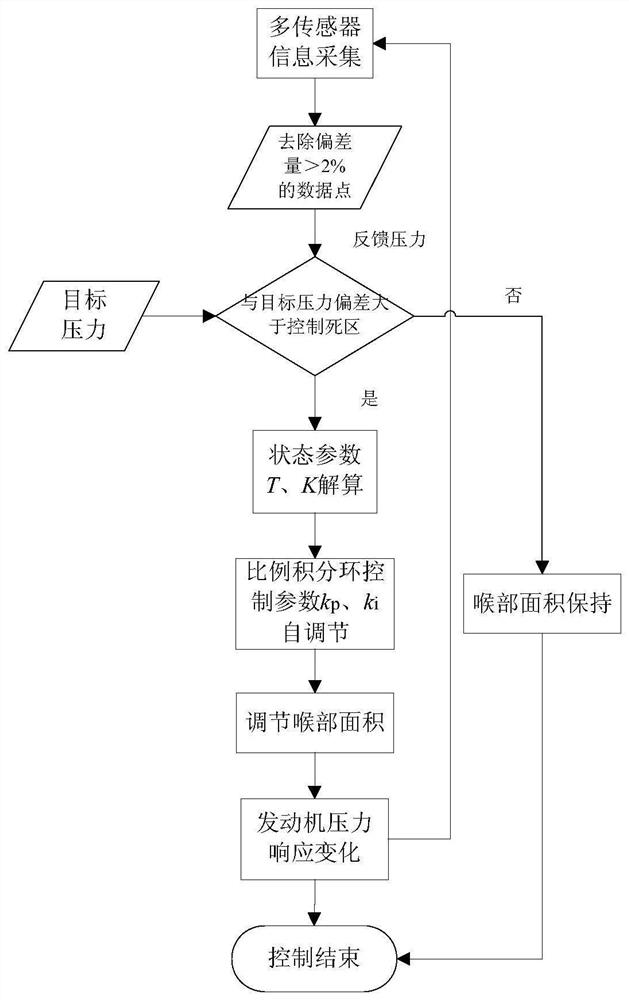

[0048] A pressure feedback control parameter self-tuning method of a variable thrust engine according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

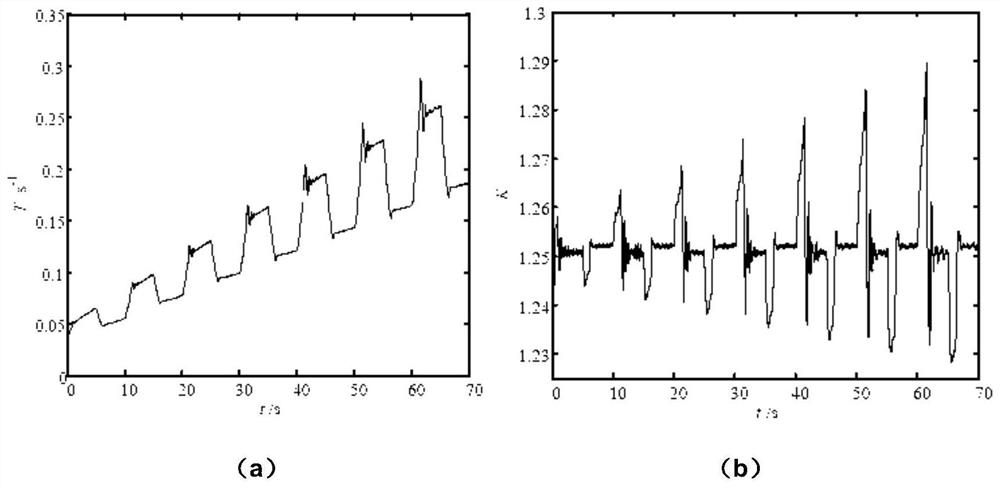

[0049] Such as figure 2 As shown, the present invention provides a pressure feedback control parameter self-tuning method of a variable thrust engine, and the feedback control parameter adjustment method includes the following main steps:

[0050] (1) Formulate the interpretation method of engine feedback pressure:

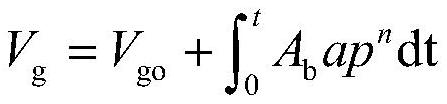

[0051]Set the maximum adjustment pressure and corresponding thrust of the variable thrust engine, select the sensor with range coverage according to the maximum working pressure of the engine design, use multiple sensors and multiple measurement points to redundantly measure the working pressure of the engine, and select some data with a difference of less than 2% in the test data , remove the rest of the data, and take the test average value as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com