Oil supply and control device for hydraulic clutch

A technology of hydraulic clutches and control devices, applied in the direction of clutches, fluid-driven clutches, non-mechanical drive clutches, etc., to achieve the effects of ensuring stable meshing, improving pressure response speed, and stably transmitting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

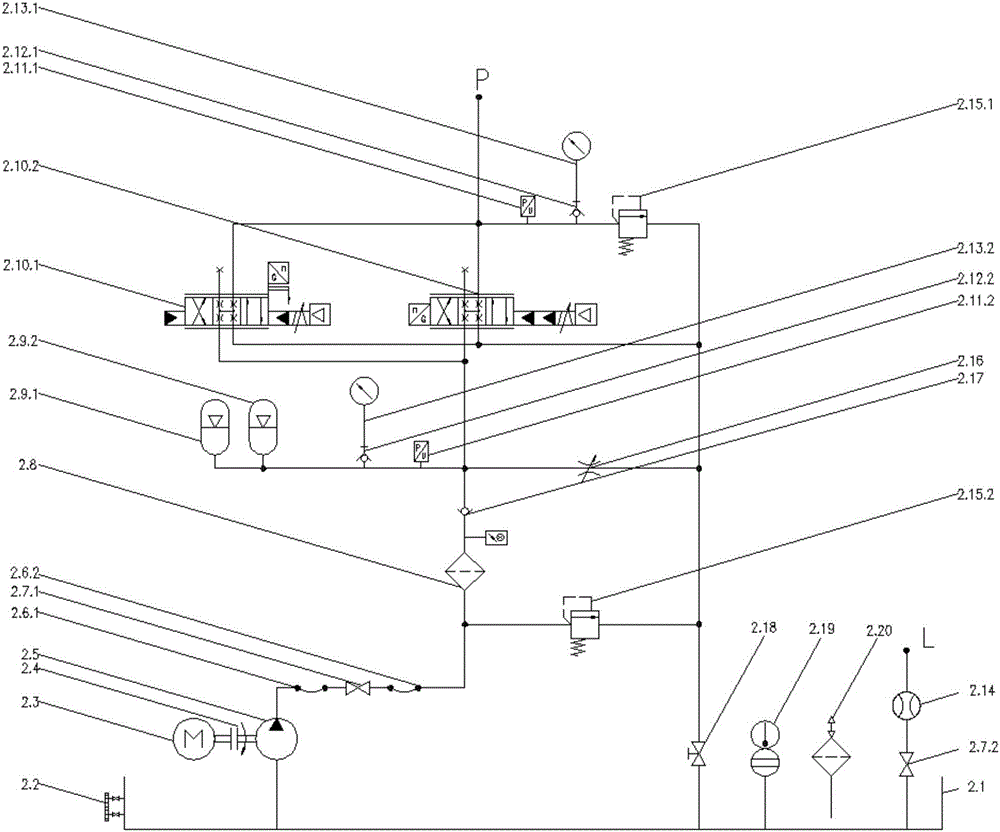

[0035] Embodiment 1: In this embodiment, the device includes a flow meter 2.14 installed on the second globe valve 2.7.2, a first accumulator 2.9.1, a second accumulator 2.9.2, and a second pressure sensor 2.11. 2. Second pressure measuring joint 2.12.2, second pressure gauge 2.13.2, throttle valve 2.16;

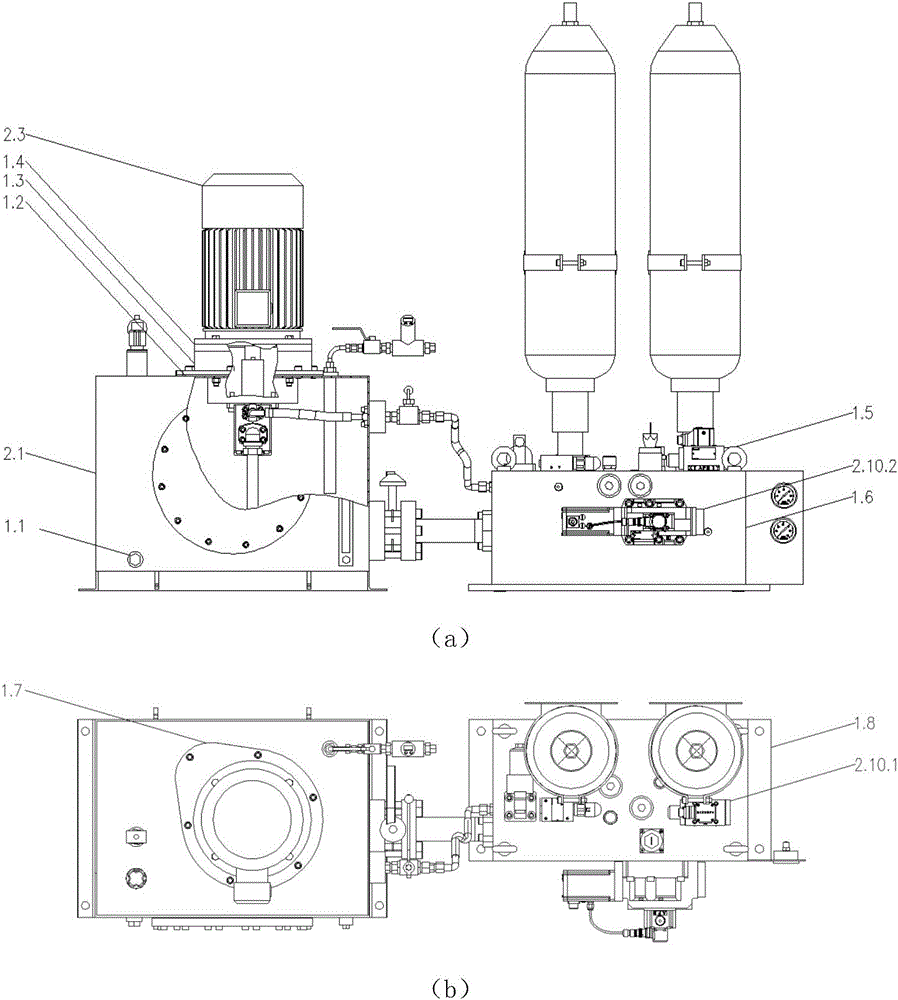

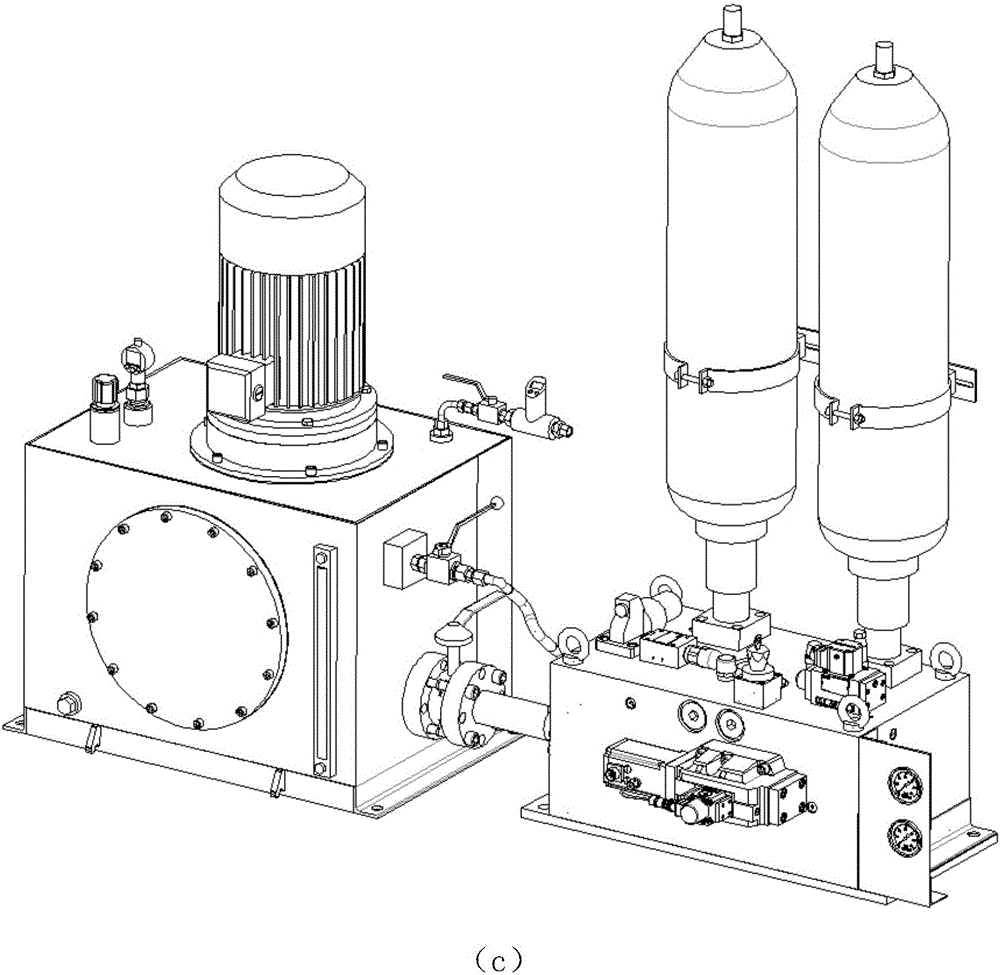

[0036] refer to figure 1 and figure 2 , when the device starts to work, the AC motor 2.3 starts to rotate, drives the hydraulic pump 2.5 to rotate, and the hydraulic pump 2.5 starts to supply oil, and the oil passes through the first hose 2.6.1, the first cut-off ball valve 2.7.1 and the second hose 2.6 .2 into the hydraulic control valve block. The oil is filtered through the filter 2.8, and then the first accumulator 2.9.1 and the second accumulator 2.9.2 are charged and pressure built up. The second overflow valve 2.15.2 is used to control the oil charging pressure of the accumulator, and the one-way valve 2.17 is used to prevent the return of pressure oil. The secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com