Patents

Literature

32results about How to "Stable transmission torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

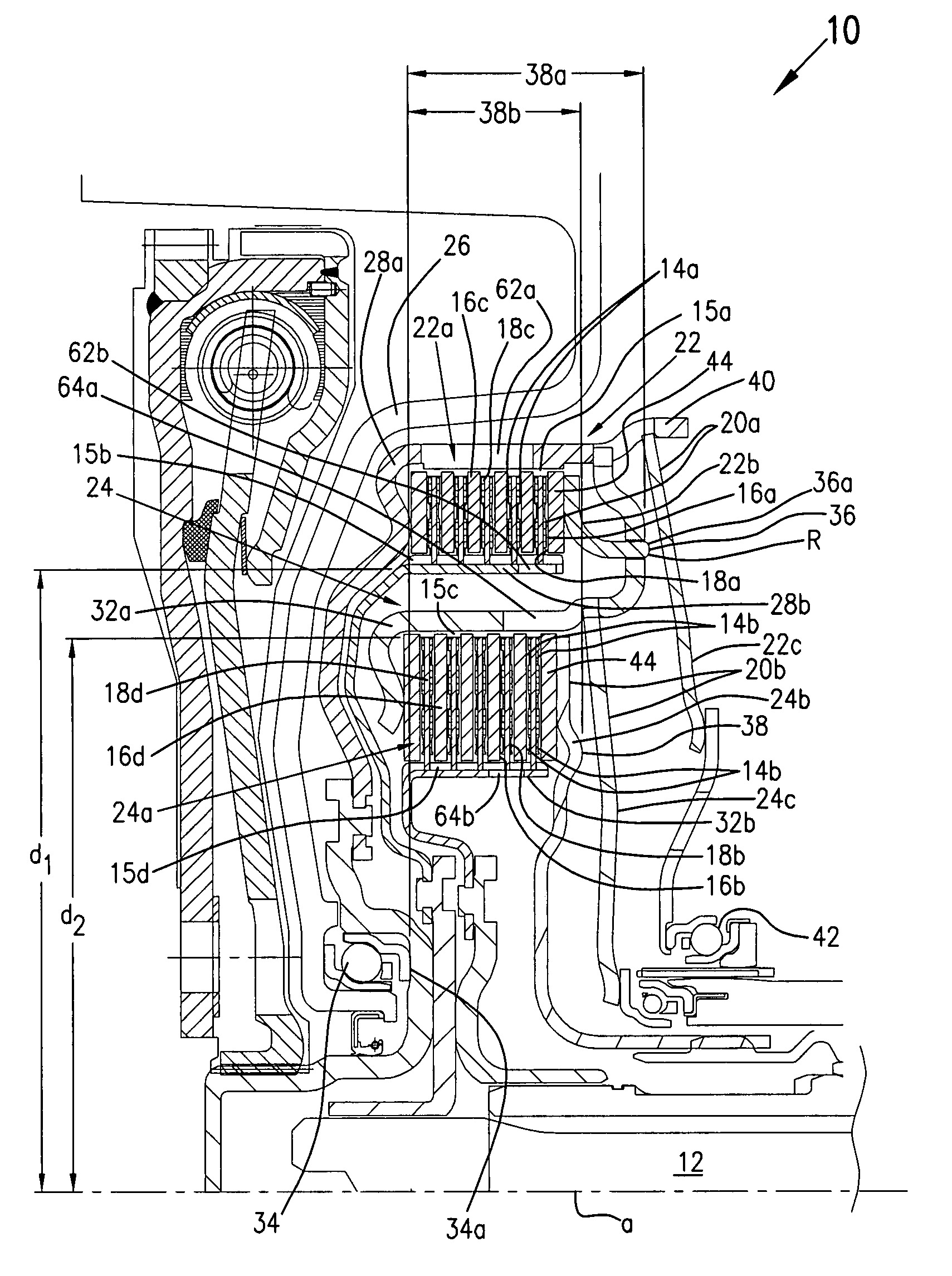

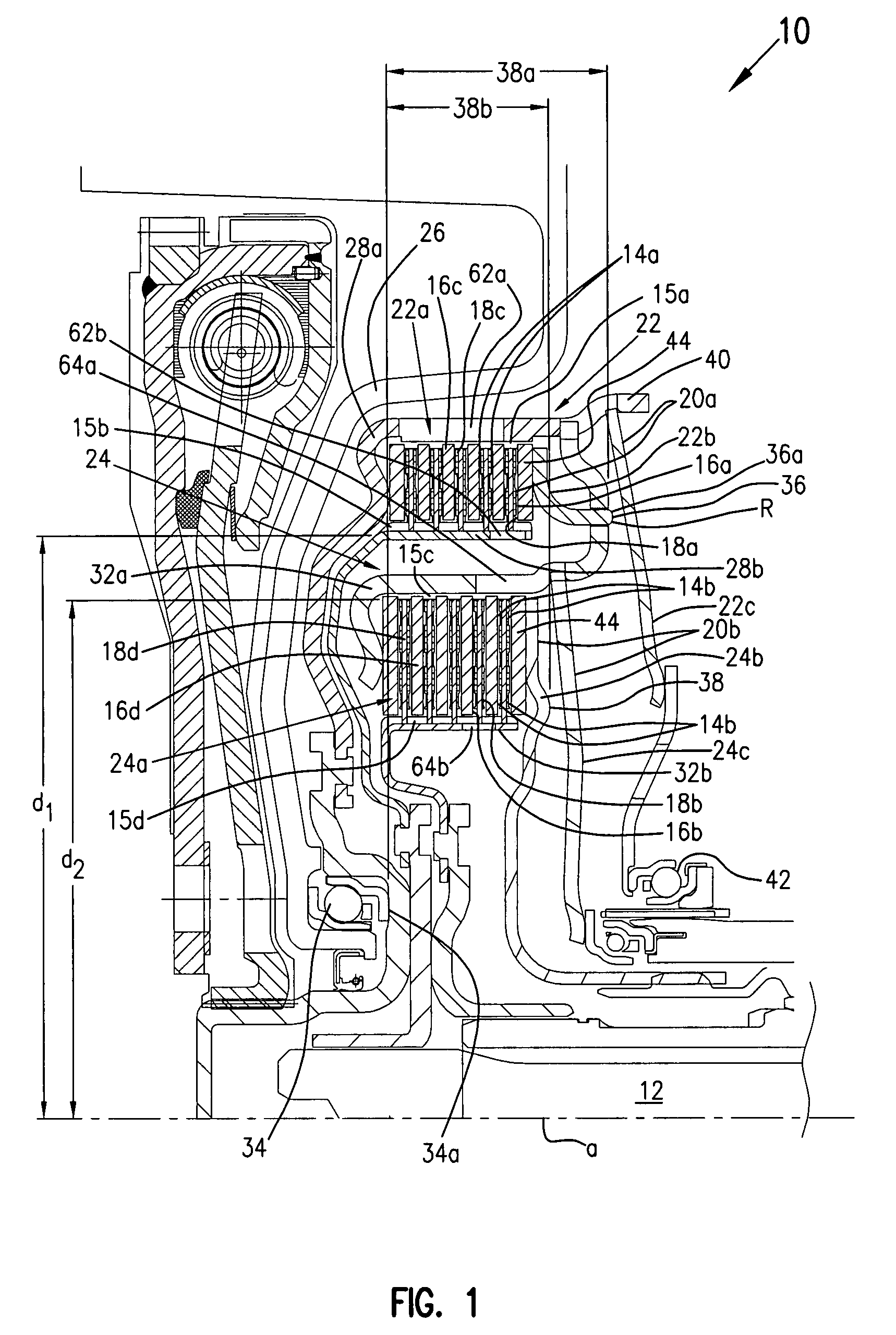

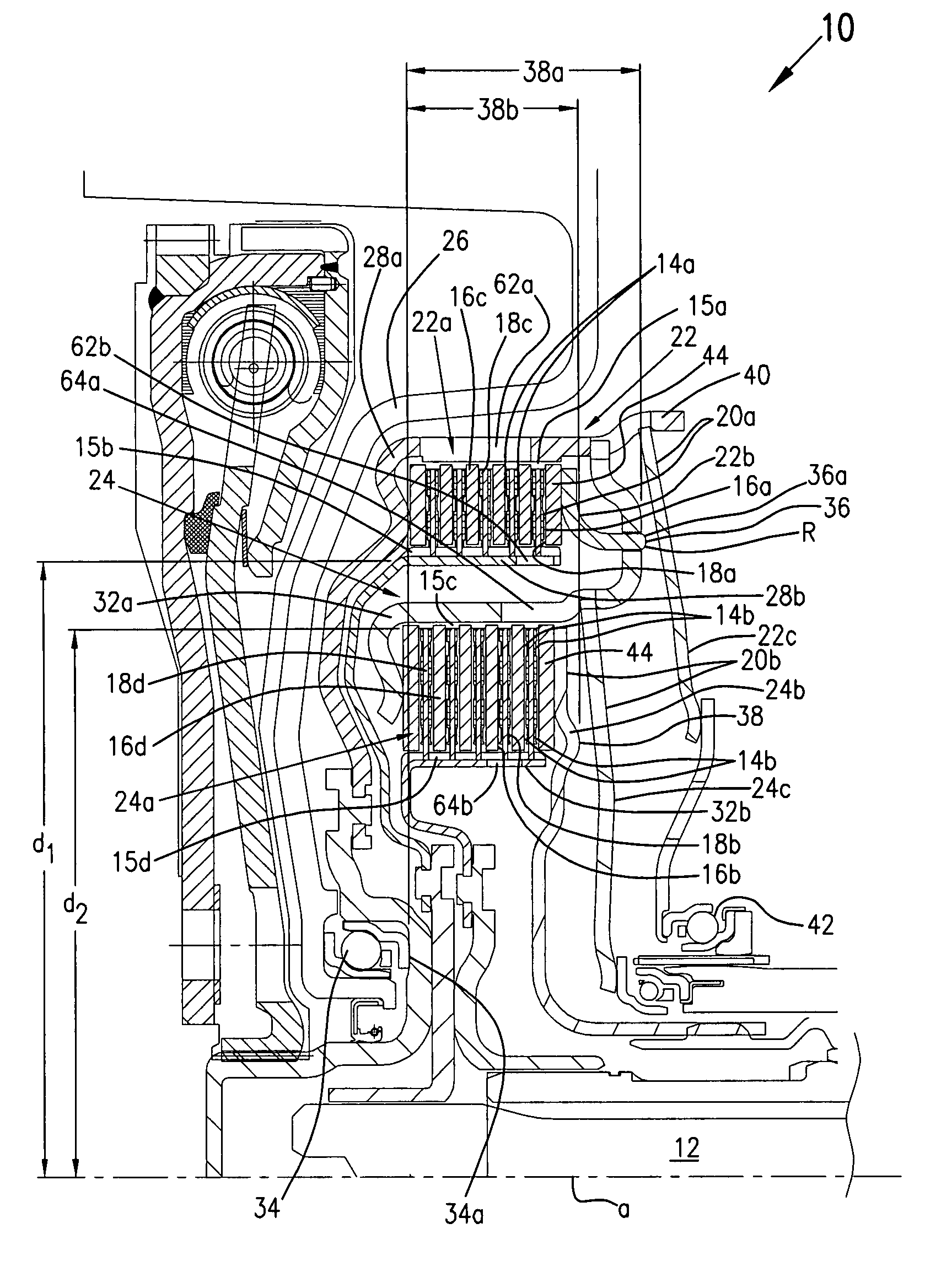

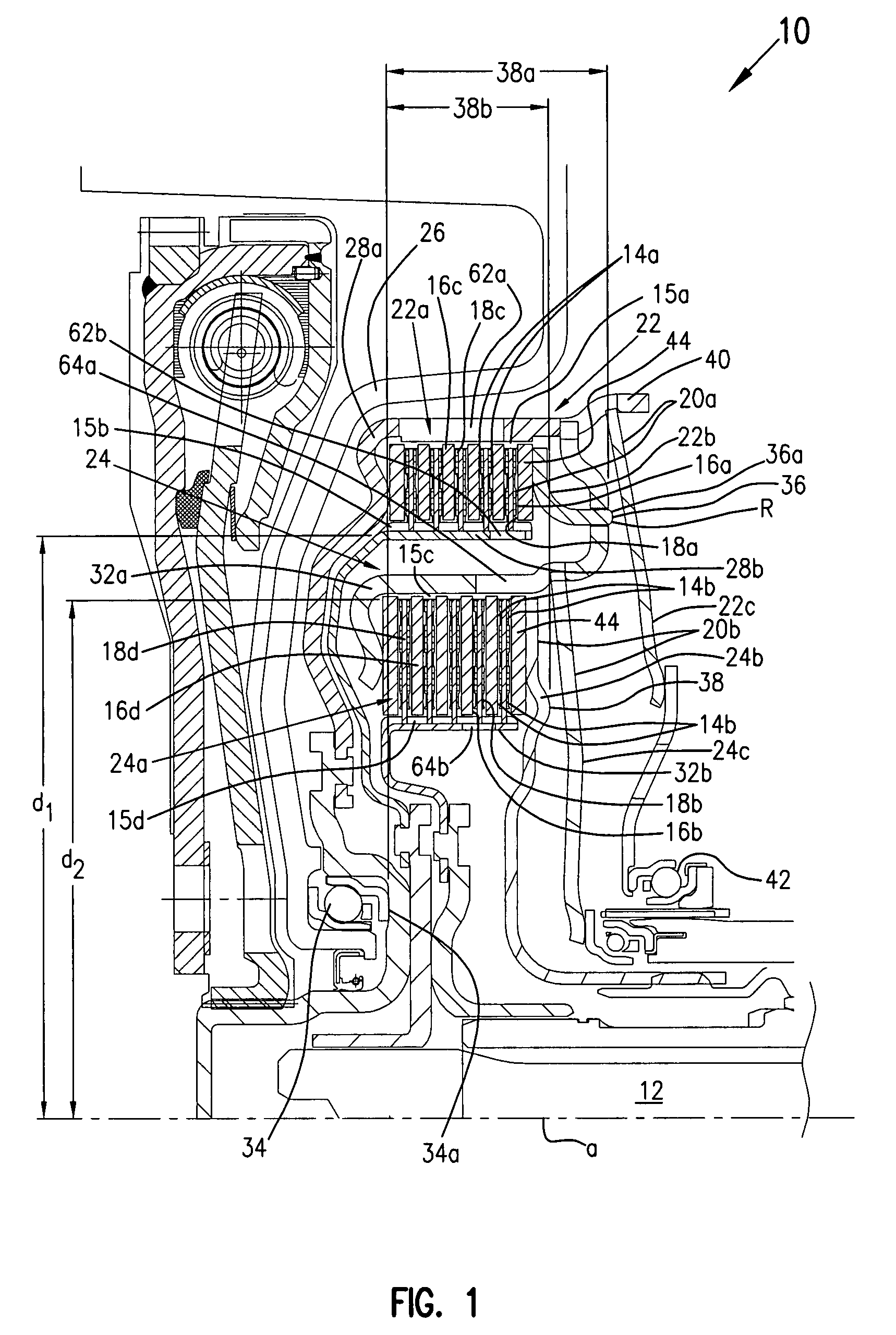

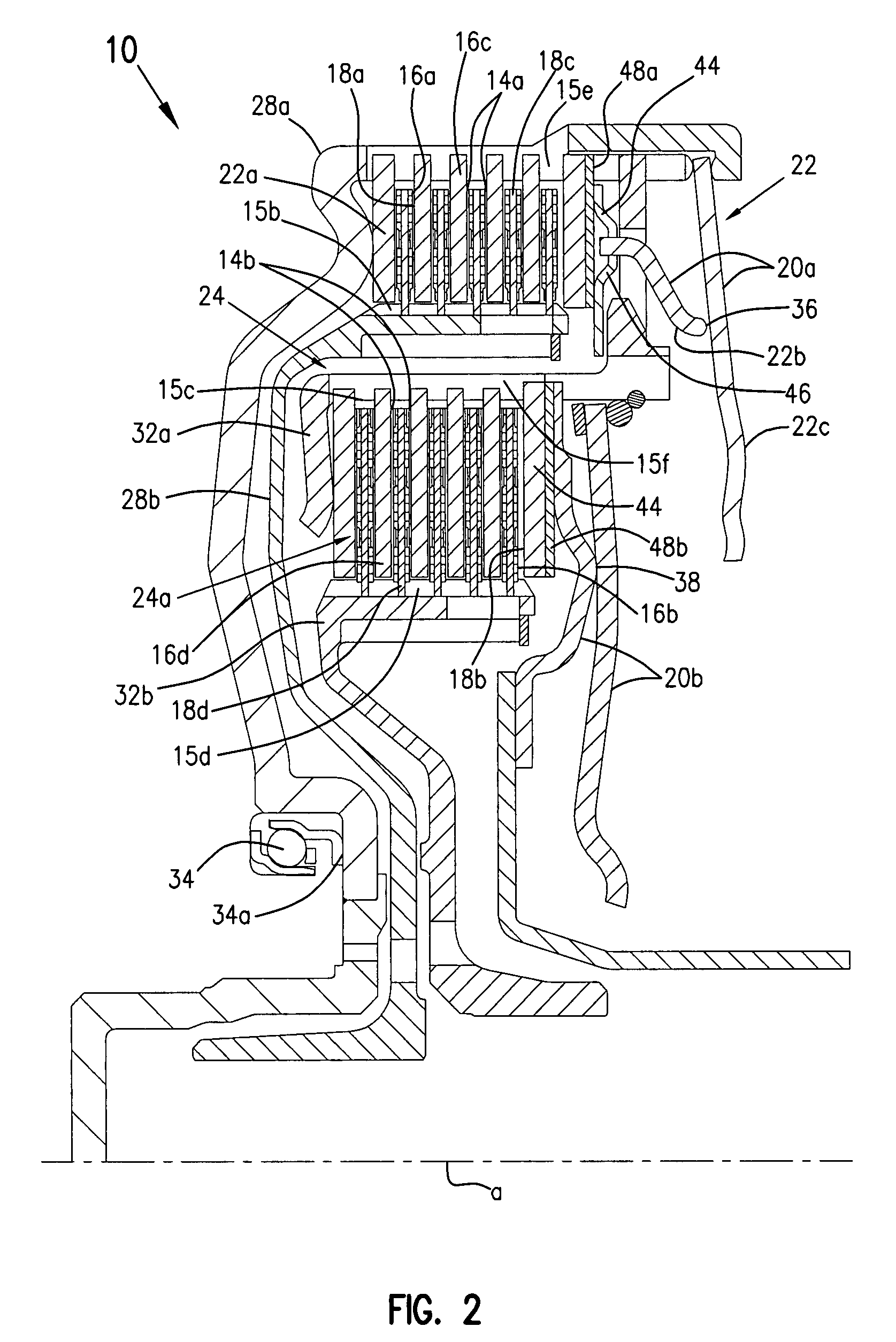

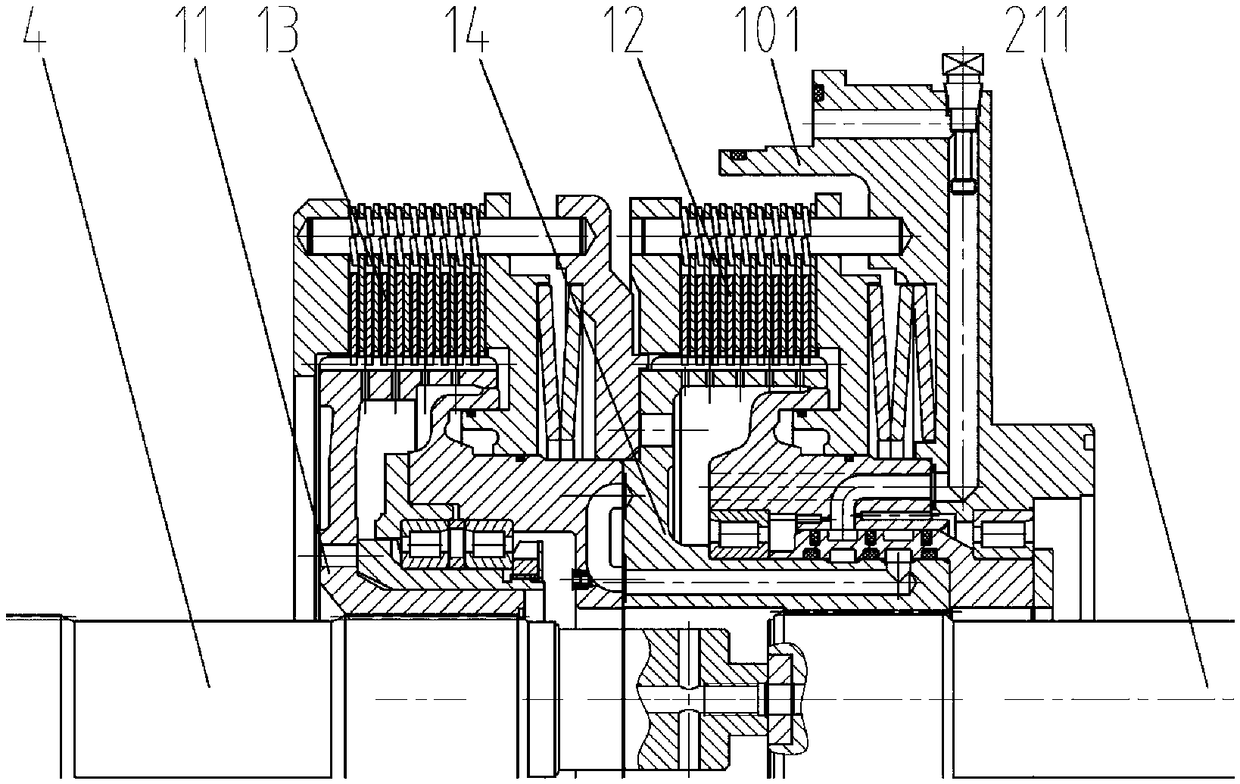

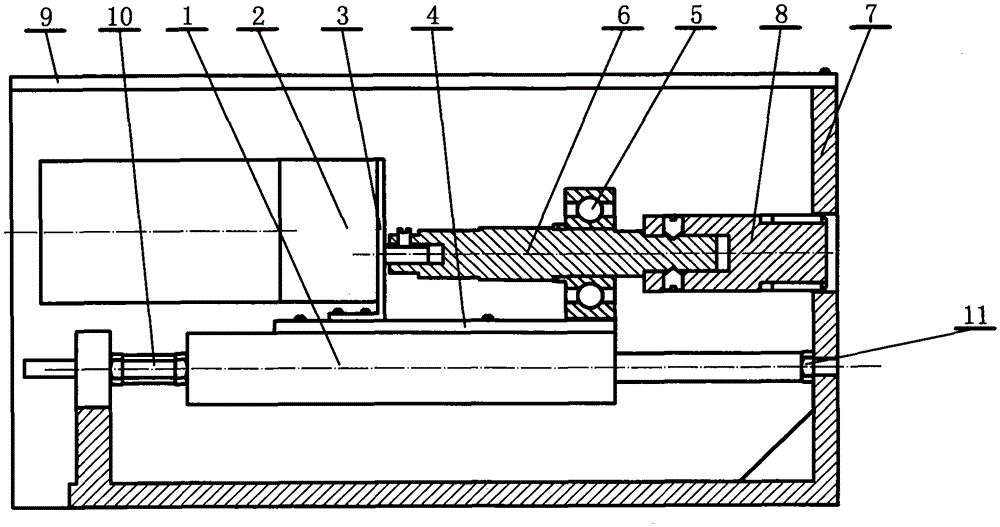

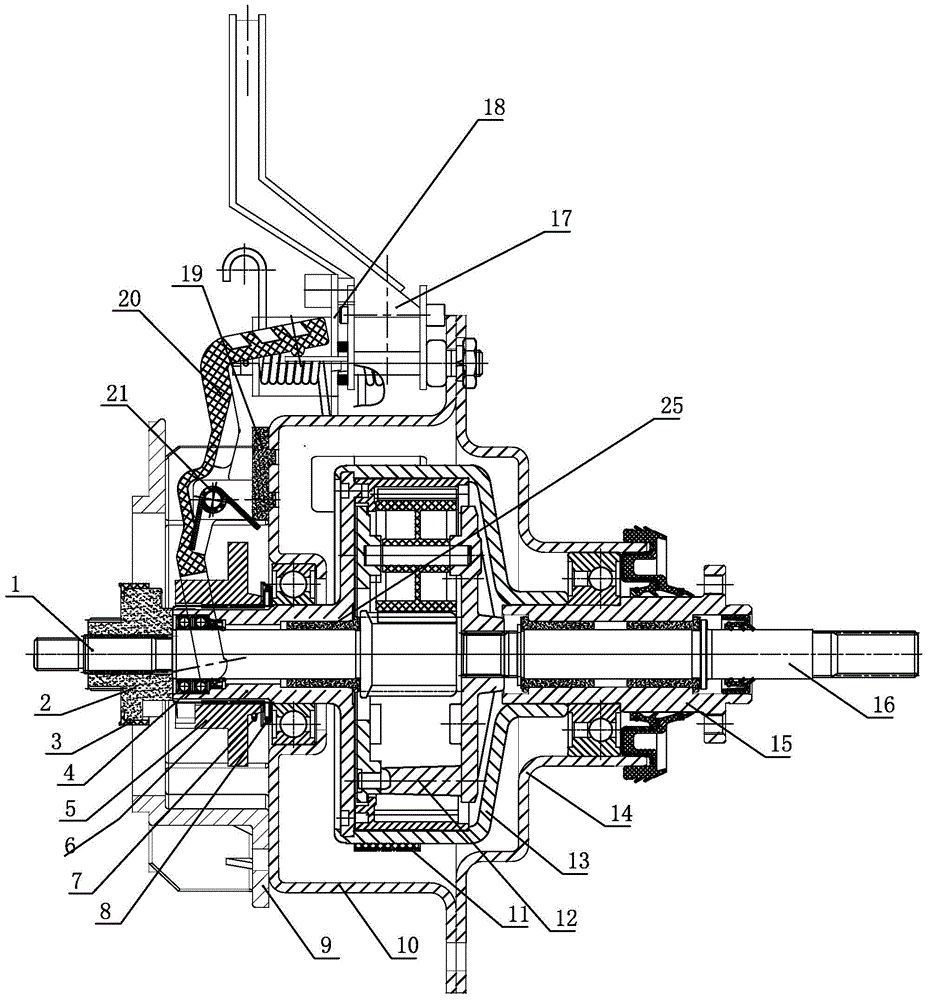

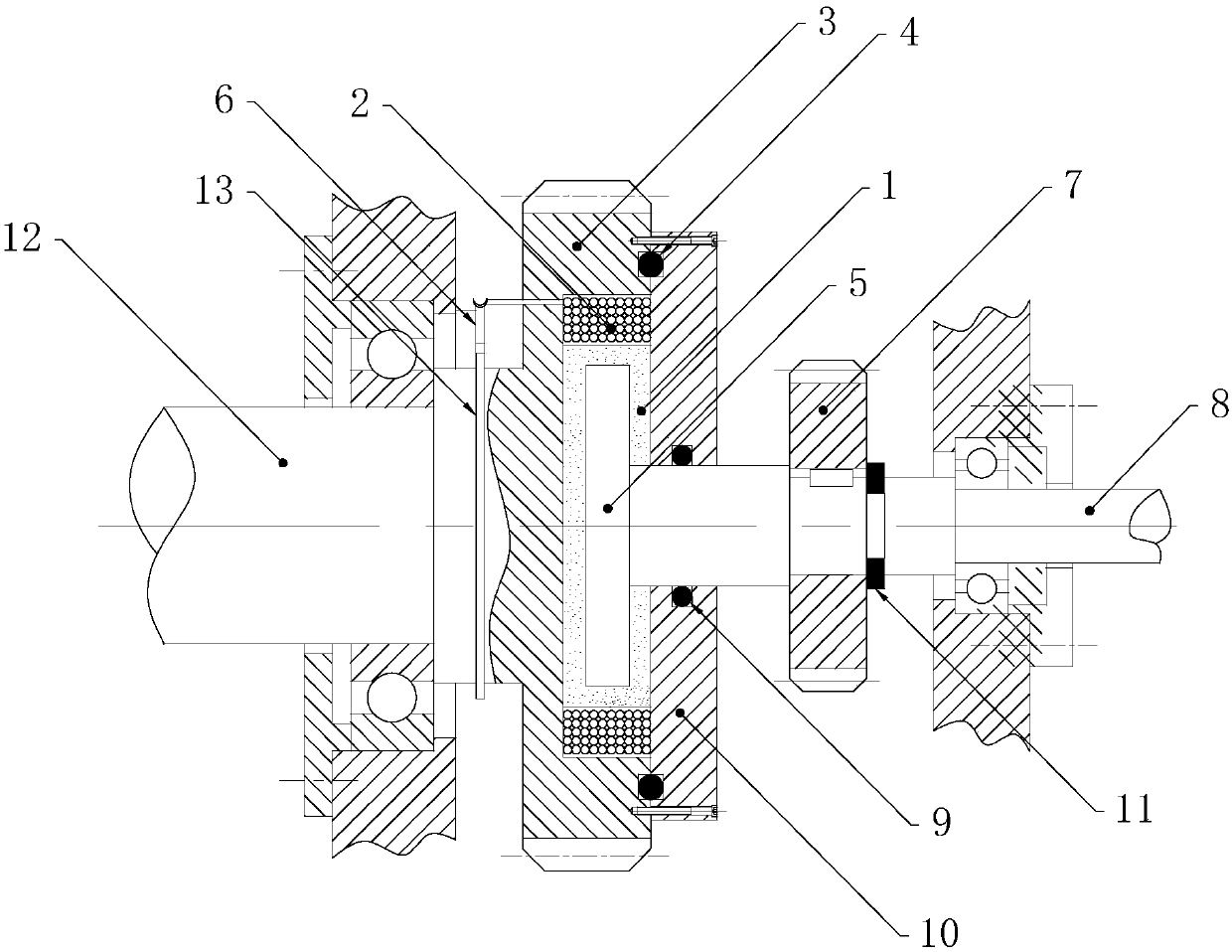

Dual clutch pack dual operating clutch and method for adjusting same

InactiveUS20070193843A1Smoothly transferring torqueReduce wear and degradationFluid actuated clutchesAssembly machinesClutchEngineering

A dual automatic mechanically actuated wet clutch device, for operation within a fluid tight housing, for a dual input shaft transmission that includes tightly specified average spacing between friction plate surfaces where the average spacing is selected from between about 0.05 mm to about 0.25 mm in an open position. The clutch has at least first and second independently actuatable clutch portions, and at least one clutch pack in the first or second clutch portion; and mechanical apparatus provided to move friction plates in at least one of the clutch portions toward each other so that they engage. The invention also includes apparatus and methods for adjusting and maintaining the spacing between the friction plate surfaces.

Owner:SCHAEFFLER TECH AG & CO KG

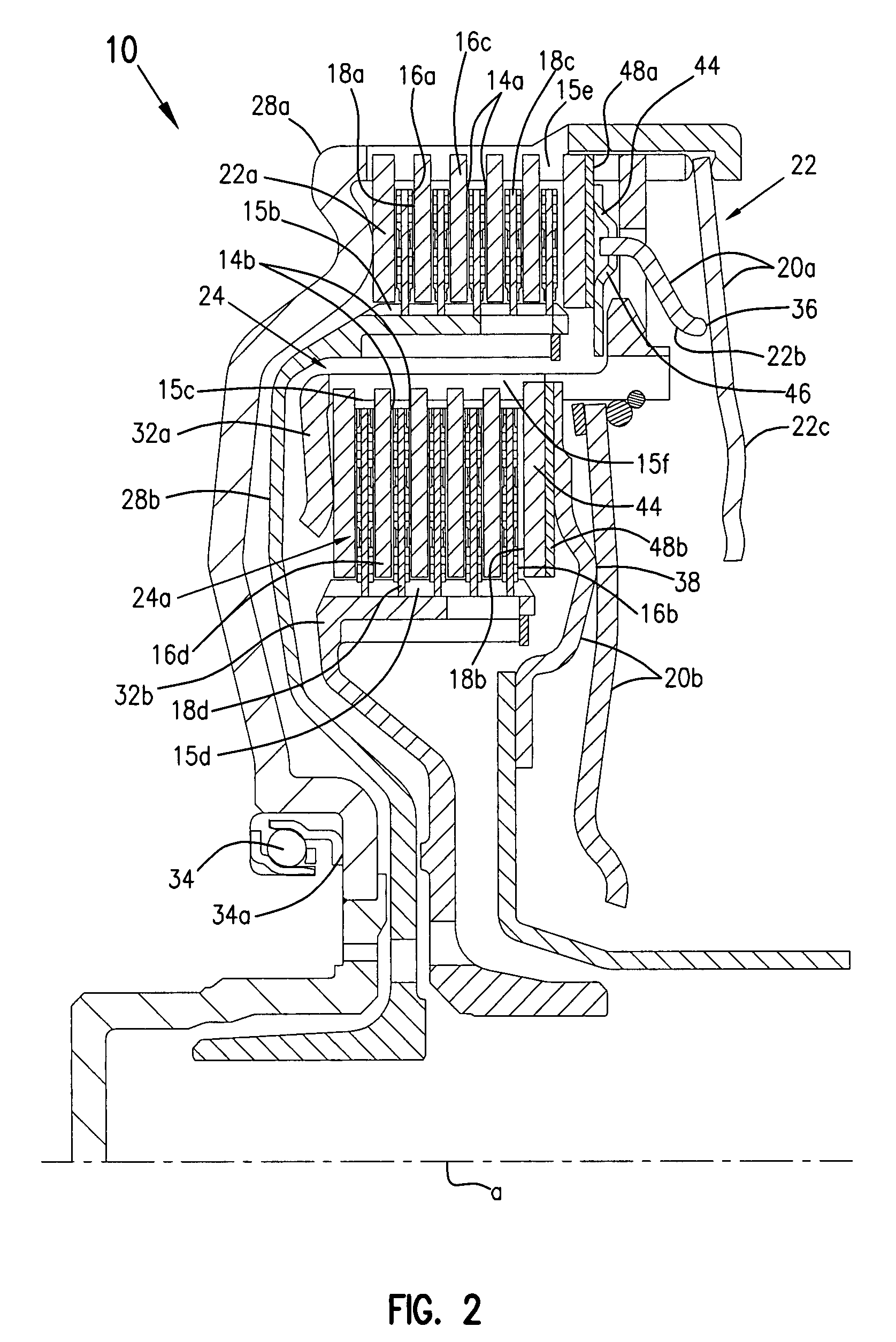

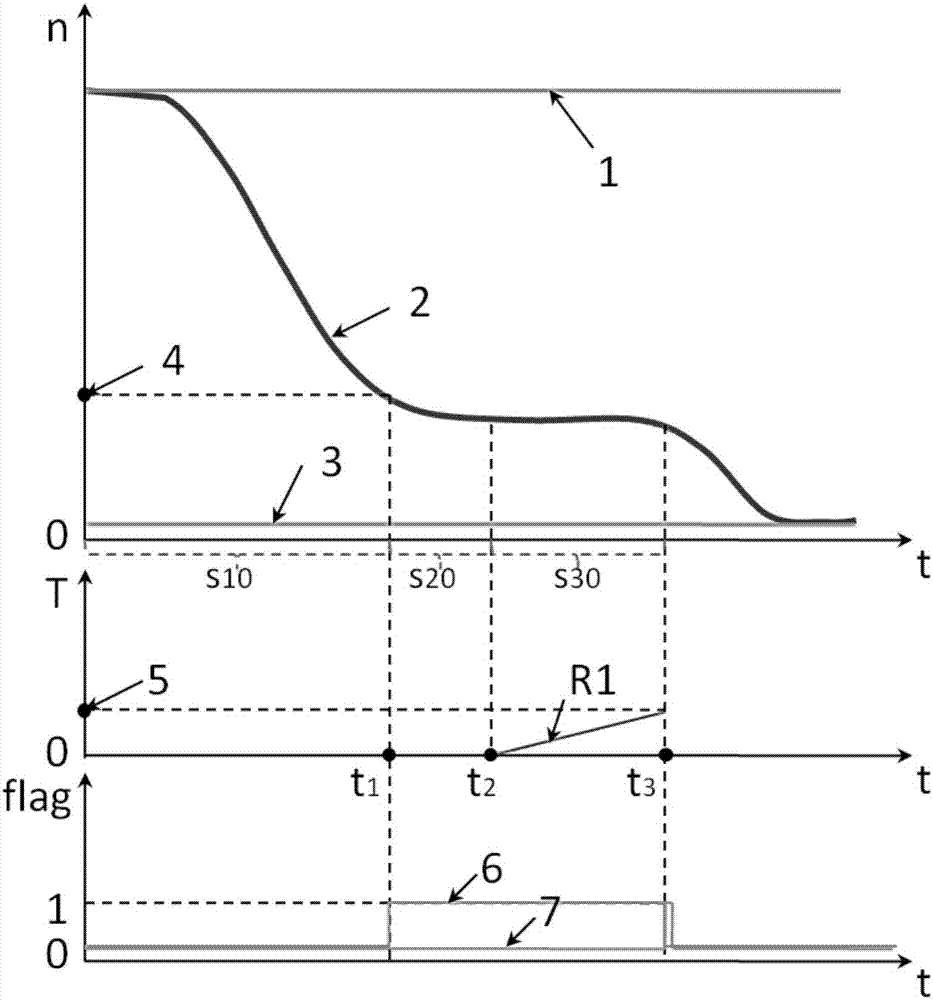

Self-learning optimization method and system for half-engagement point of wet double clutch

ActiveCN107100947AImprove robustnessEliminate the detrimental effects of precise torque controlClutchesLow speedFlywheel

The invention discloses a self-learning optimization method and system for a half-engagement point of a wet double clutch. The rotating speed of an engine flywheel is monitored in real time in the accelerator-free upshift working condition, the value of a clutch target current corresponding to the change inflection point moment of the engine flywheel is recorded, then the value of the difference between the clutch target current and the previous self-learning inflection point current is calculated, the obtained difference value is used for correcting the current value, corresponding to the half-engagement joint of the clutch, of an electromagnetic valve of the clutch, further the pressure, corresponding to the half-engagement point, between friction plates of the clutch is changed, and therefore adverse effects of abrasion on low-speed torque control of the clutch are eliminated or weakened.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

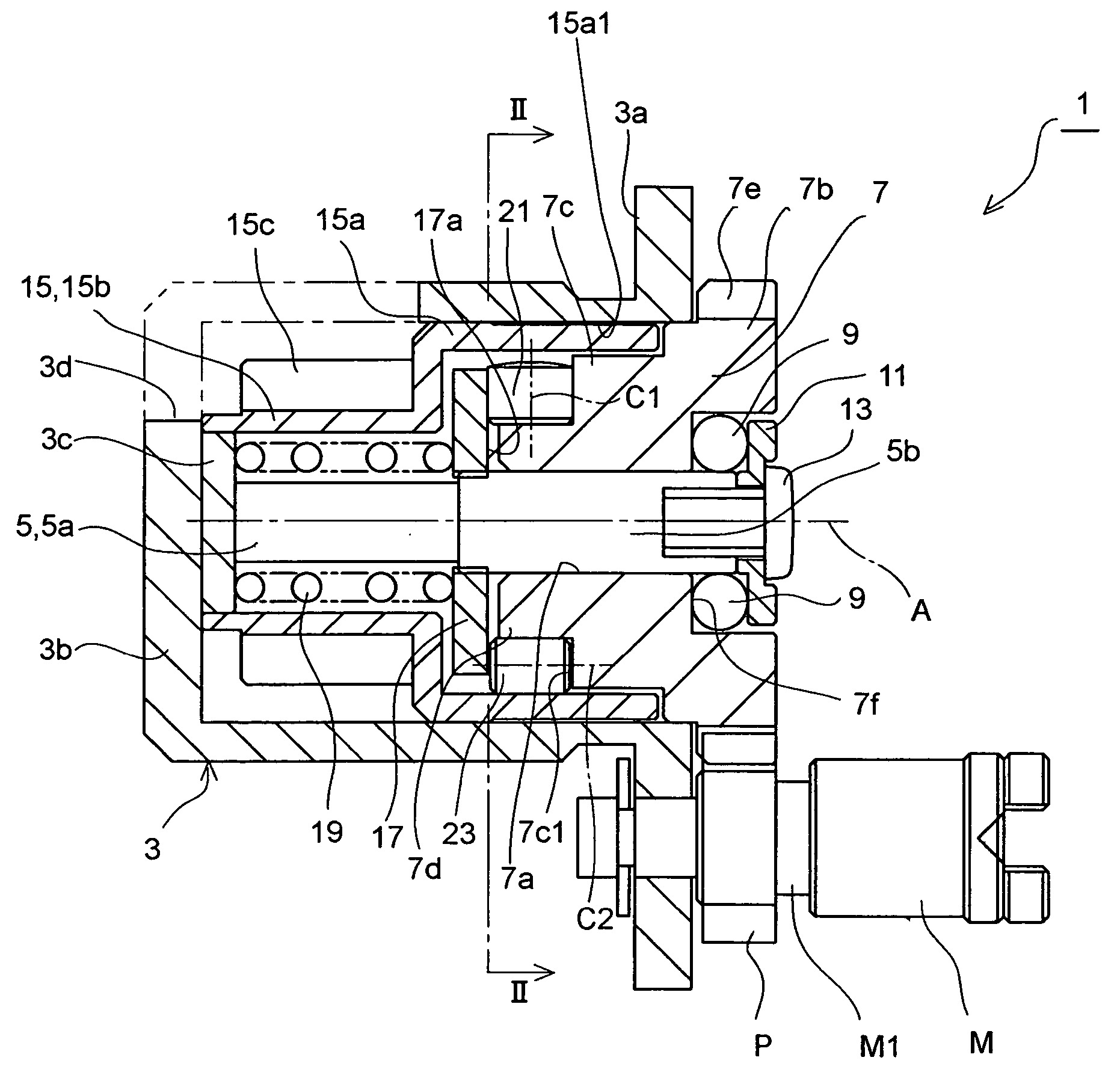

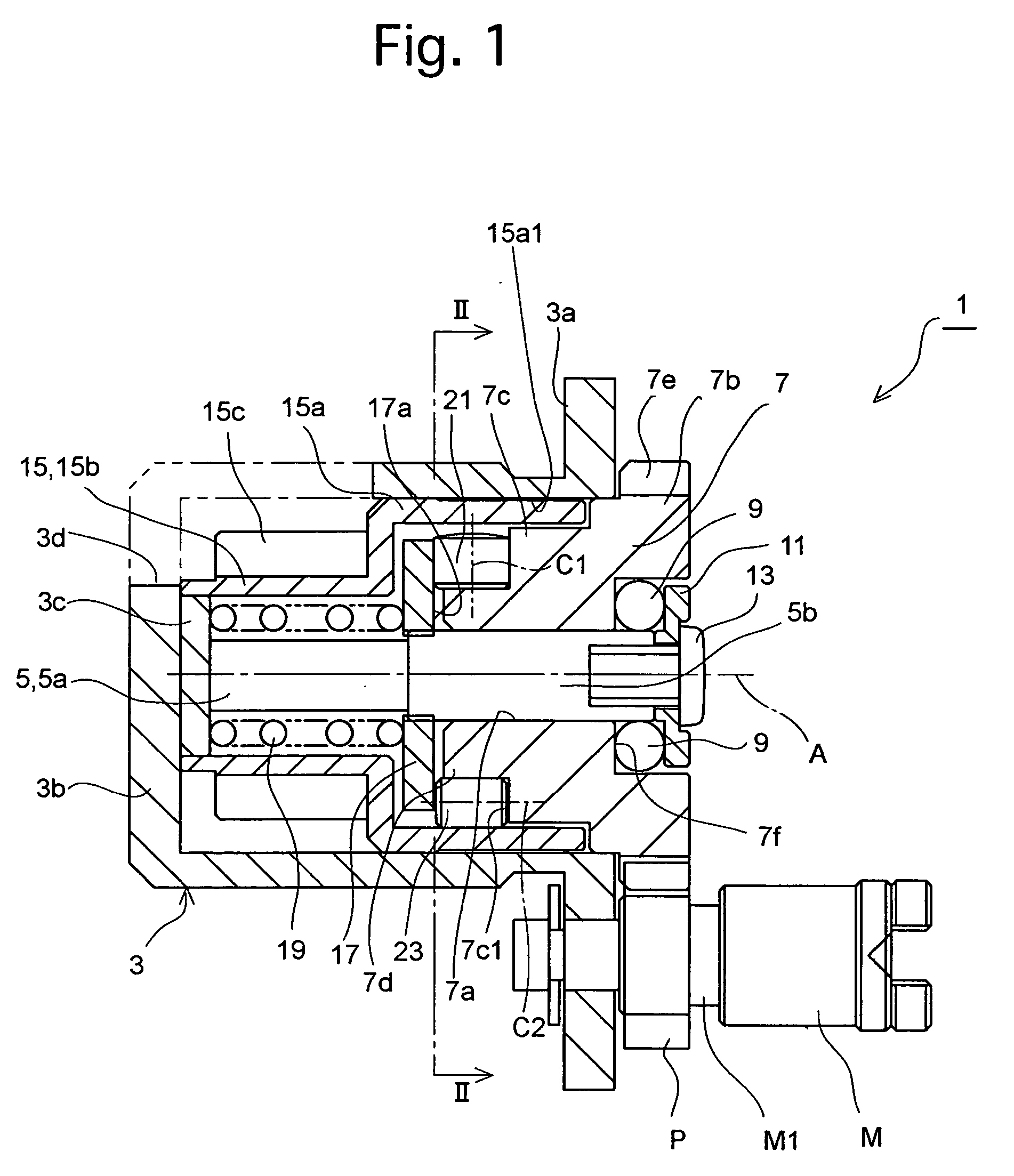

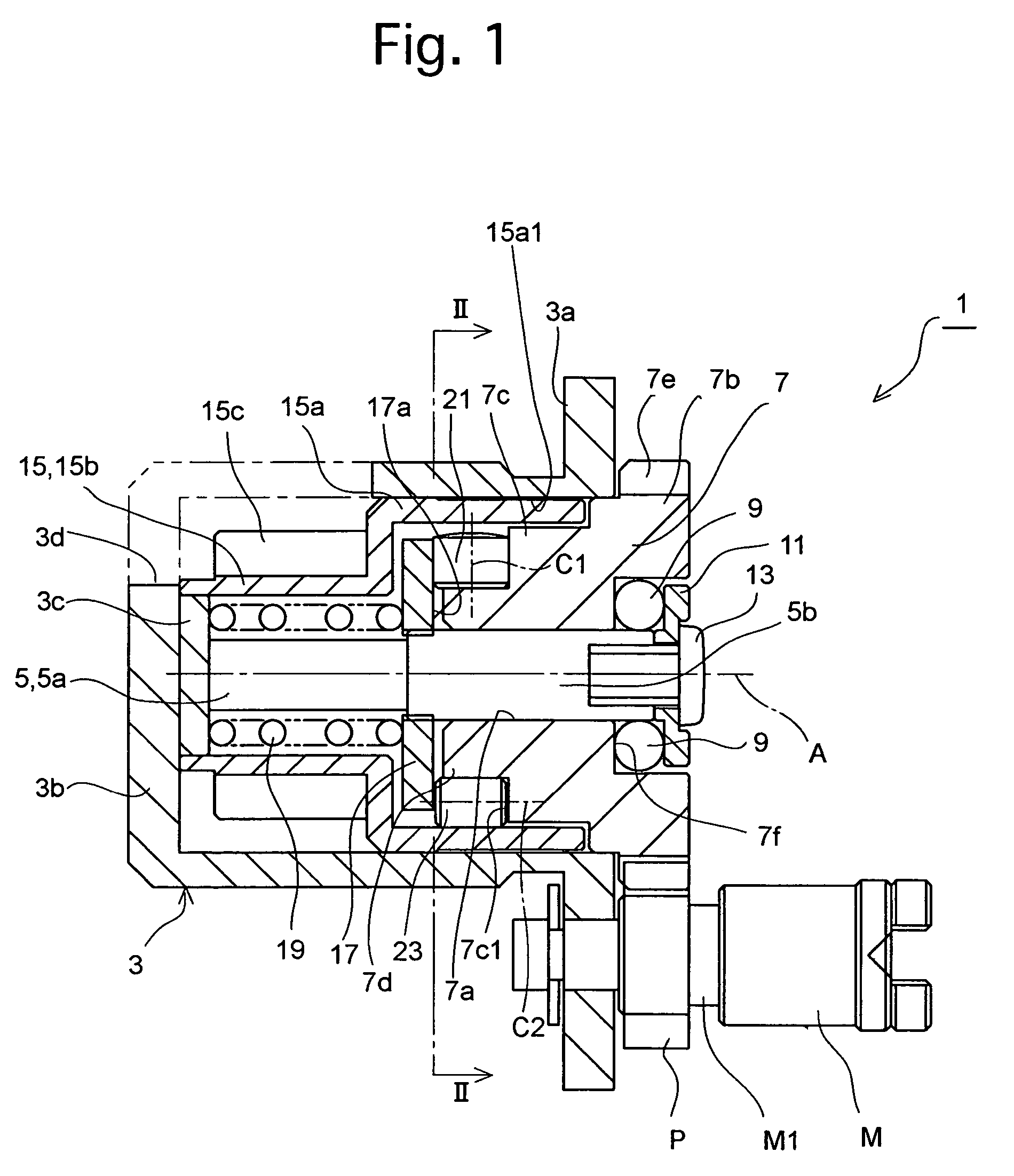

Dual clutch pack dual operating clutch and method for adjusting same

InactiveUS7823711B2Stable transmission torqueReduce degradationFluid actuated clutchesAssembly machinesClutchPhysics

A dual automatic mechanically actuated wet clutch device, for operation within a fluid tight housing, for a dual input shaft transmission that includes tightly specified average spacing between friction plate surfaces where the average spacing is selected from between about 0.05 mm to about 0.25 mm in an open position. The clutch has at least first and second independently actuatable clutch portions, and at least one clutch pack in the first or second clutch portion; and mechanical apparatus provided to move friction plates in at least one of the clutch portions toward each other so that they engage. The invention also includes apparatus and methods for adjusting and maintaining the spacing between the friction plate surfaces.

Owner:SCHAEFFLER TECH AG & CO KG

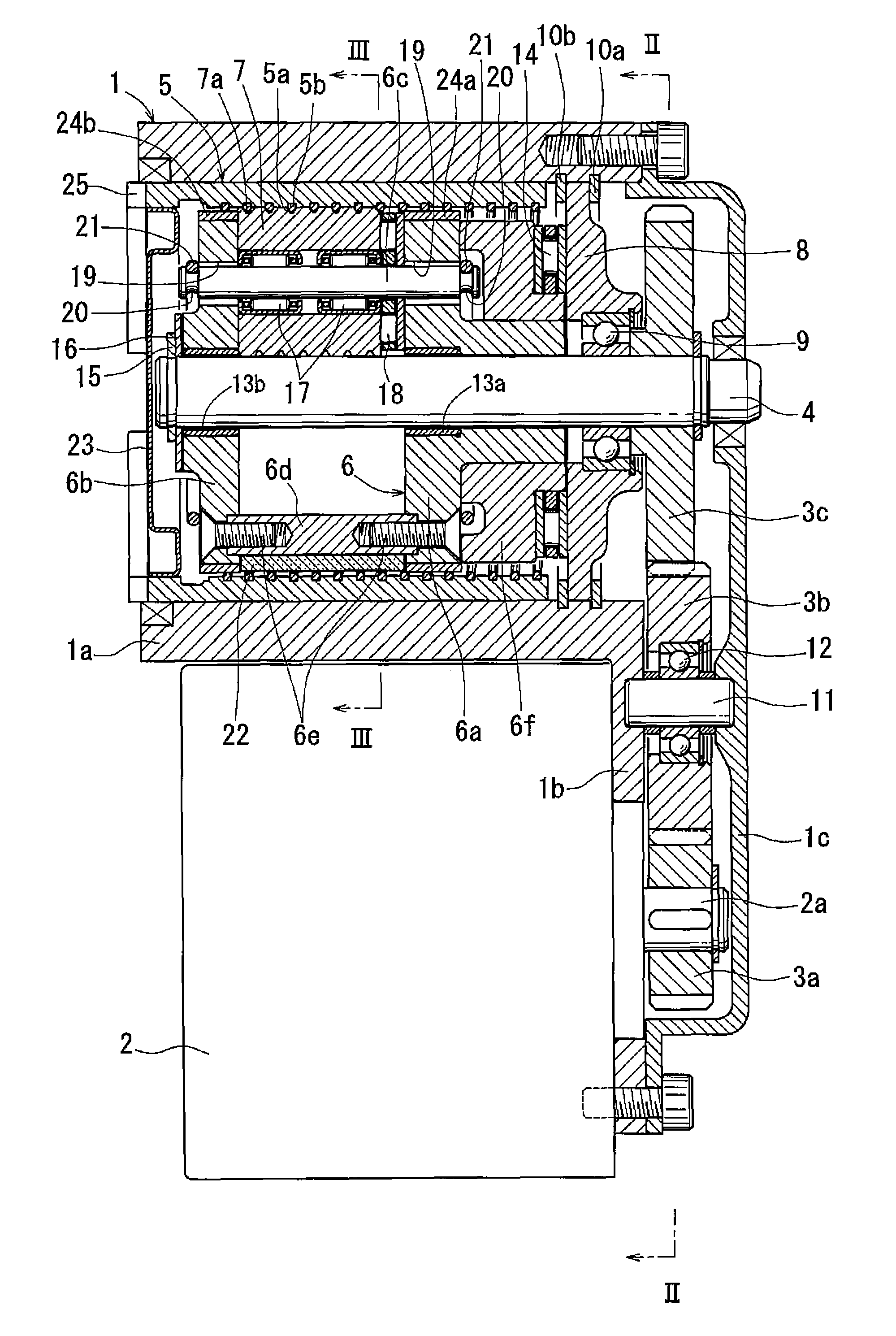

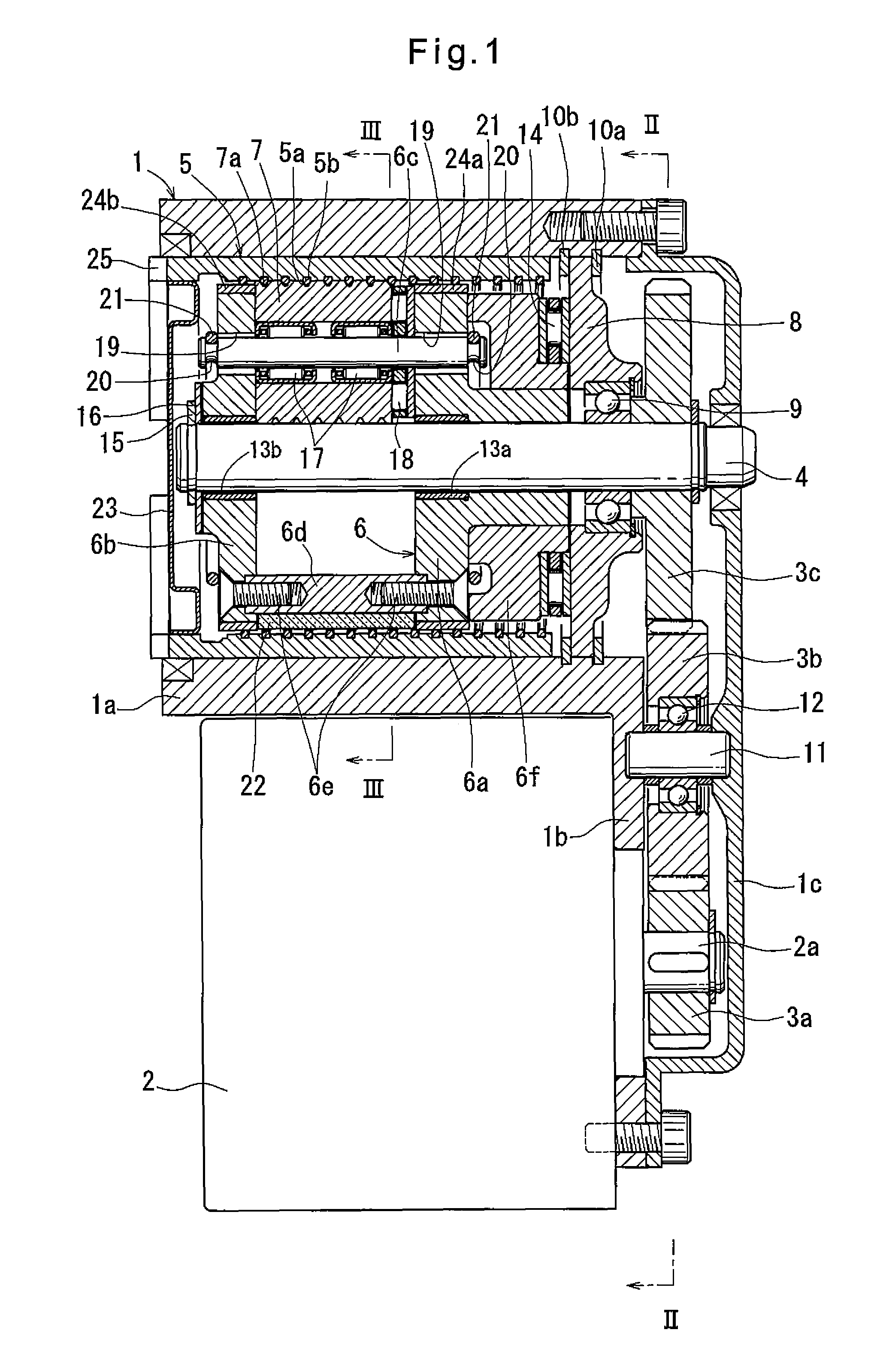

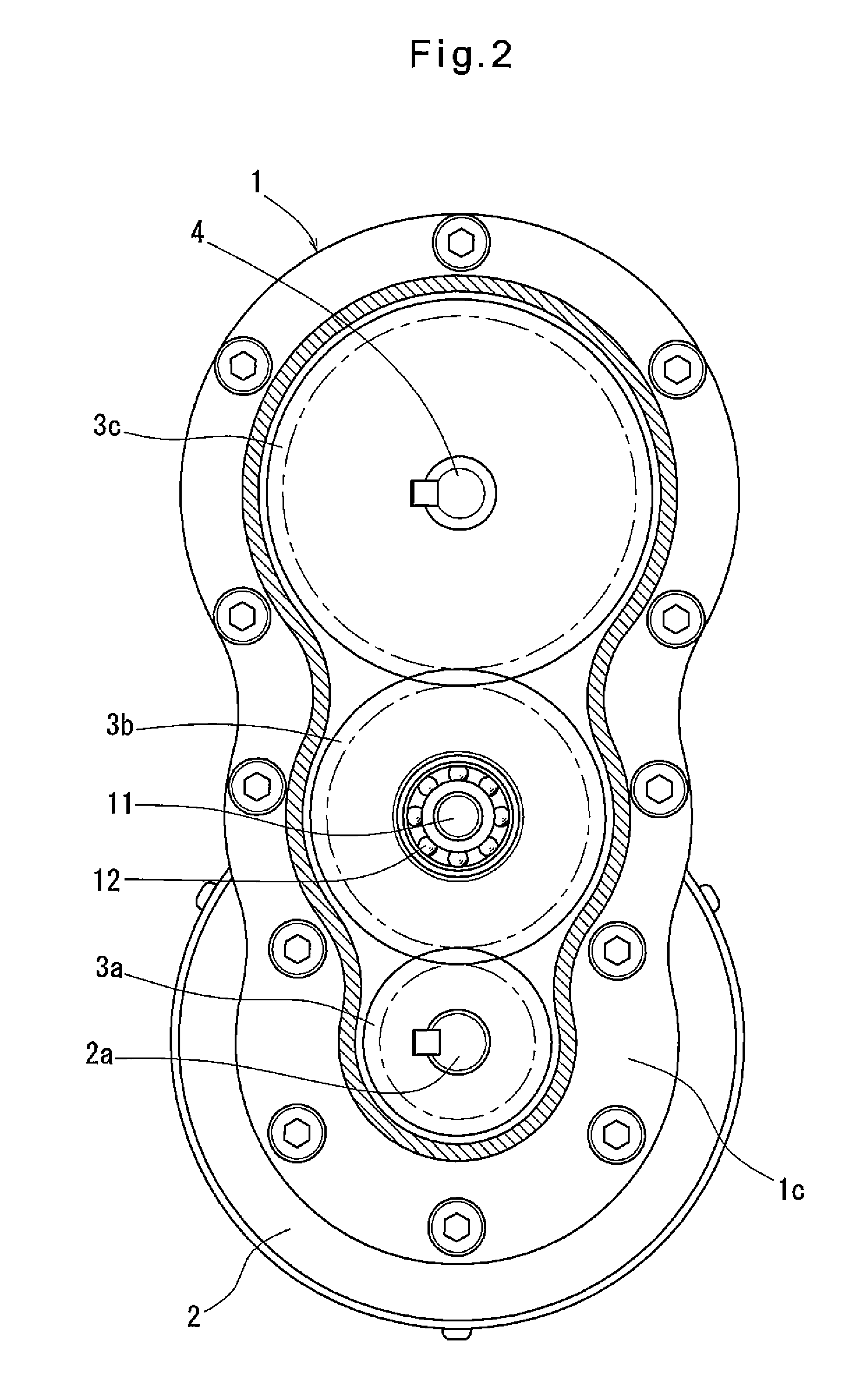

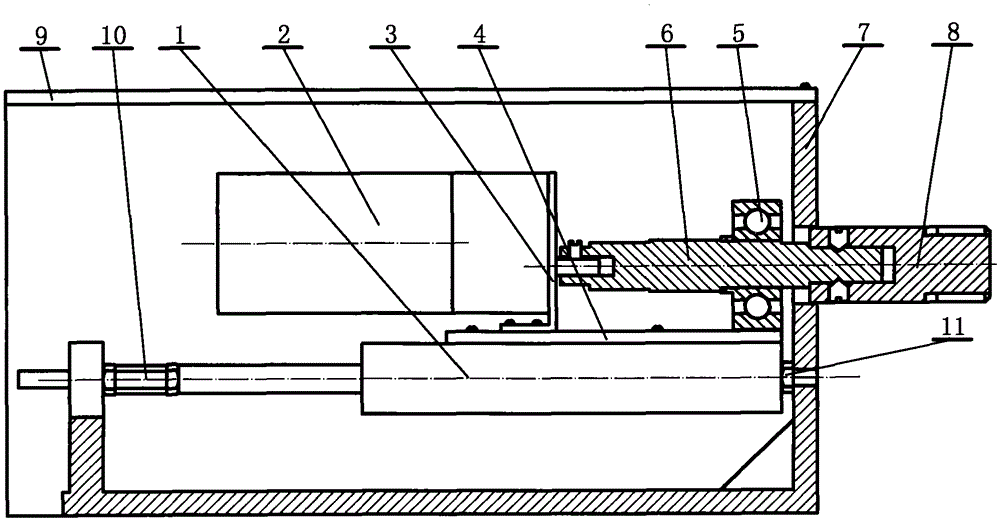

Electric linear motion actuator and electric brake system

ActiveUS8579090B2Stable transmission torqueMechanically actuated brakesElectrodynamic brake systemsLinear motionEngineering

In an electric linear motion actuator for transmitting torque of a rotary shaft (4) to planetary rollers (7) and thus to a linearly driven output member constituted by an outer race member (5), axial movement of a carrier (6) supporting the planetary rollers (7) is restricted, and the outer race member (5) is axially slidably fitted in a radially inner surface of a cylindrical portion (1a) of a housing (1) and is rotationally fixedly coupled to an object to be driven via keys (25) The planetary rollers (7) have their radially inner surfaces rotatably supported on respective support pins (6c) of the carrier (6), and are radially inwardly biased by radial compression ring springs (21) wound around the support pins (6c) so as to envelop the support pins. The planetary rollers (7) are thus pressed against the radially outer surface of the rotary shaft (4).

Owner:NTN CORP

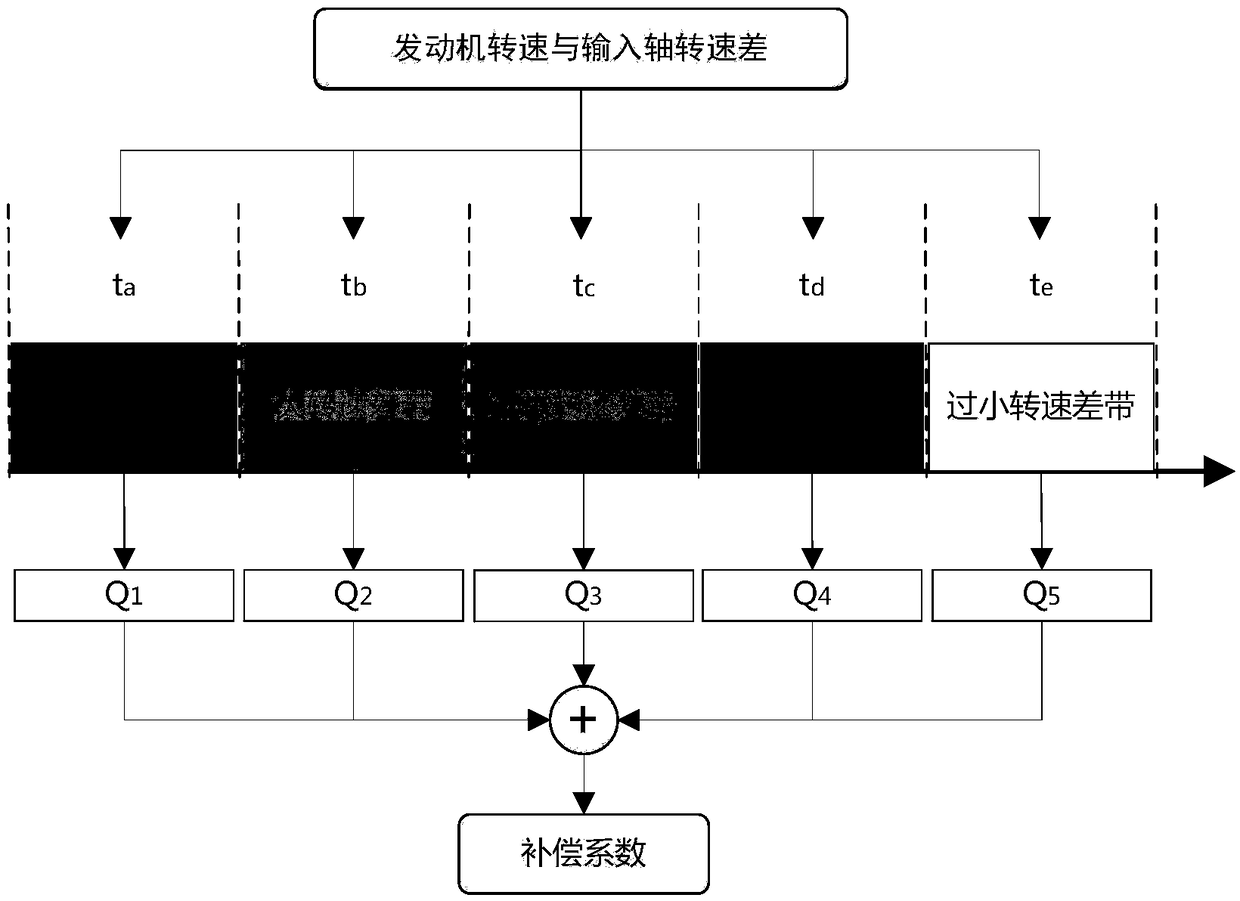

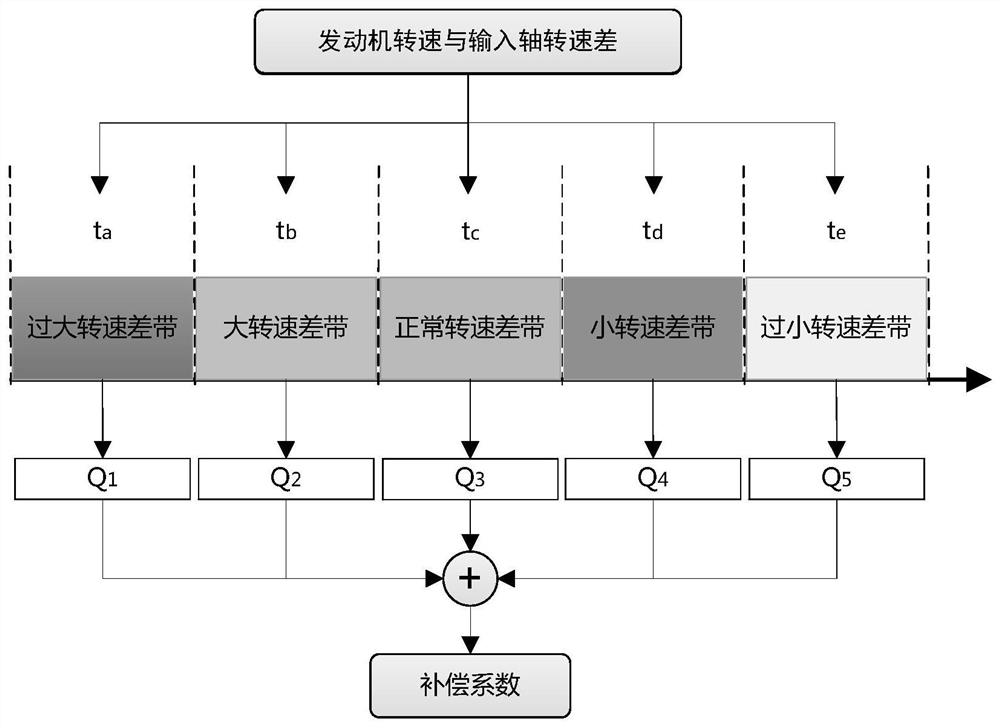

Clutch combined with self-adaption control method based on statistics principle

ActiveCN108869574AStable transmission torqueGuaranteed smoothnessClutchesRotation velocityEngineering

The invention relates to a clutch combined with self-adaption control method based on a statistics principle. The clutch combined with self-adaption control method comprises the steps that at each clutch combination stage, the difference between the rotation velocity of an engine and the rotation velocity of the input shaft of a gearbox is divided to be five rotation velocity difference ranges; the time from a clutch be in contact firstly to the rotation velocity of the input shaft of the gearbox being synchronous with the rotation velocity of the engine is recorded; the percentage of the timeof the difference between the rotation velocity of the engine and the rotation velocity of the input shaft of the gearbox in each rotation velocity difference range accounting for the time from the clutch being in contact firstly to the rotation velocity of the input shaft of the gearbox being synchronous with the rotation velocity of the engine is counted; and the compensation factor of clutch combined control in the next clutch combination stage is obtained. The compensation factor of the next clutch combined control is obtained through the difference between the rotation velocity of the engine and the rotation velocity of the gearbox in each clutch combination stage, the change of clutch transmission torque feature is automatically adapted, stable and smooth clutch transmission torqueis ensured, so that the torque of the engine is matched with the clutch transmission torque, and the riding comfort of vehicle starting and gear shifting is guaranteed.

Owner:FAW JIEFANG AUTOMOTIVE CO

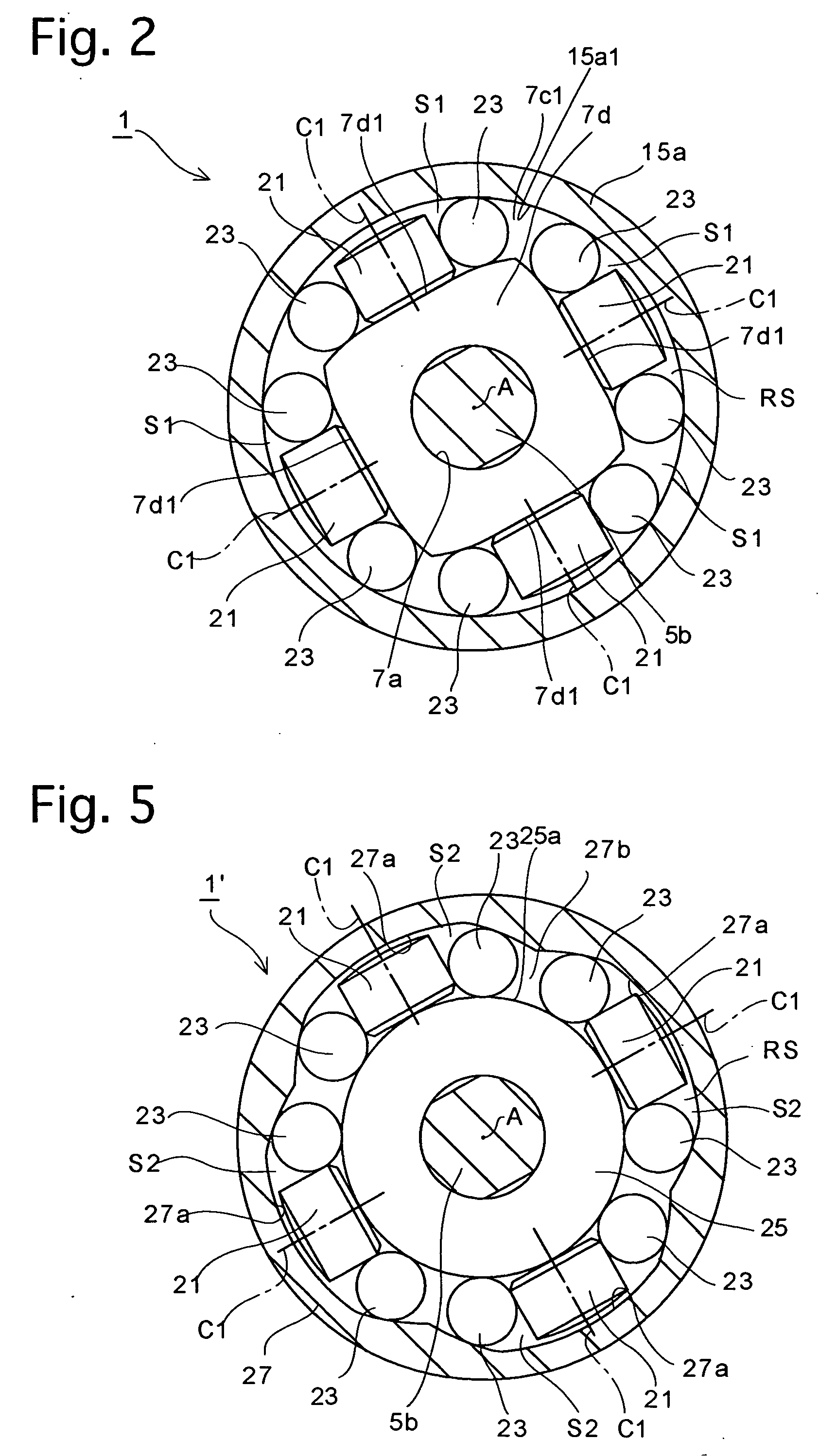

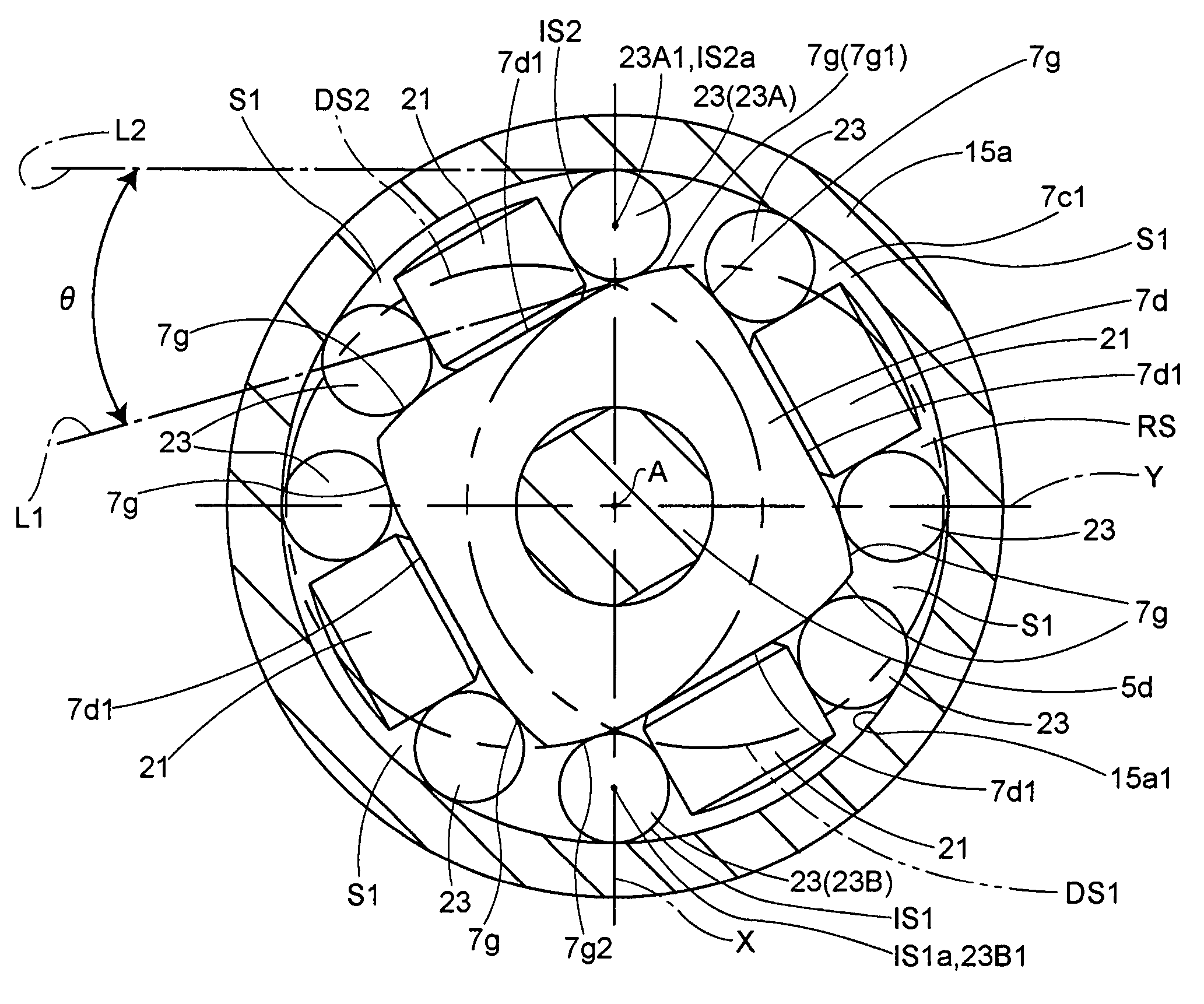

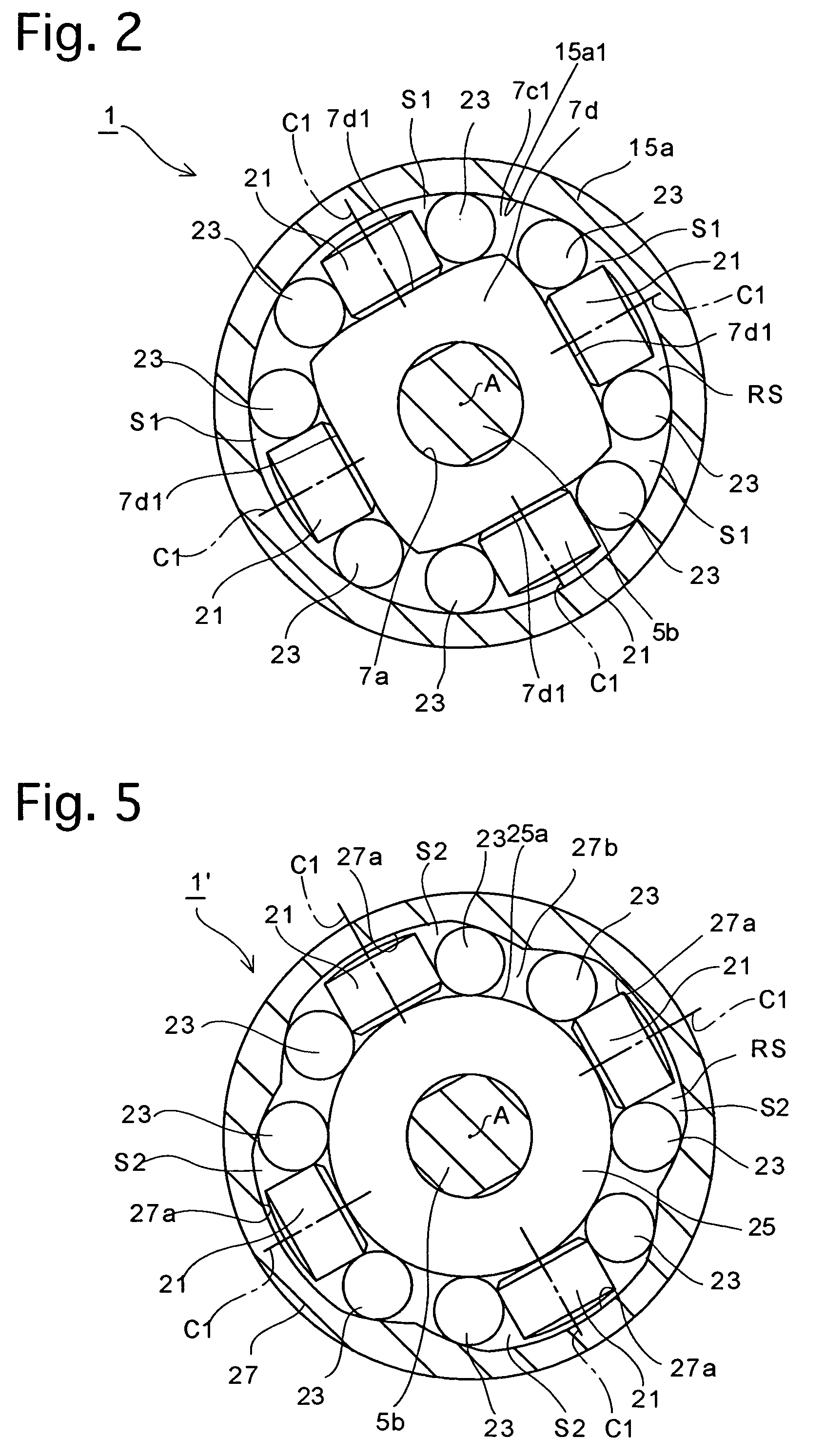

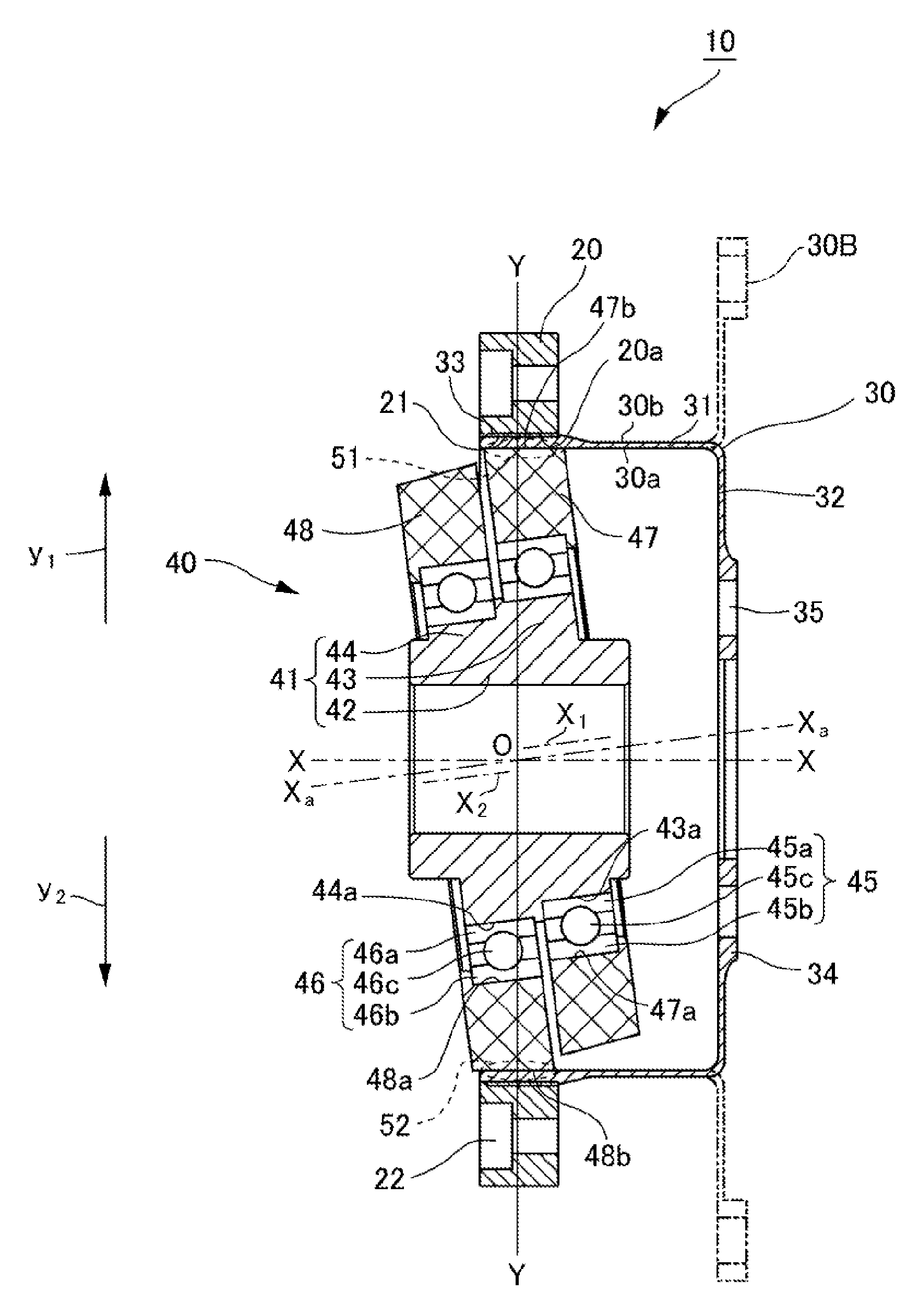

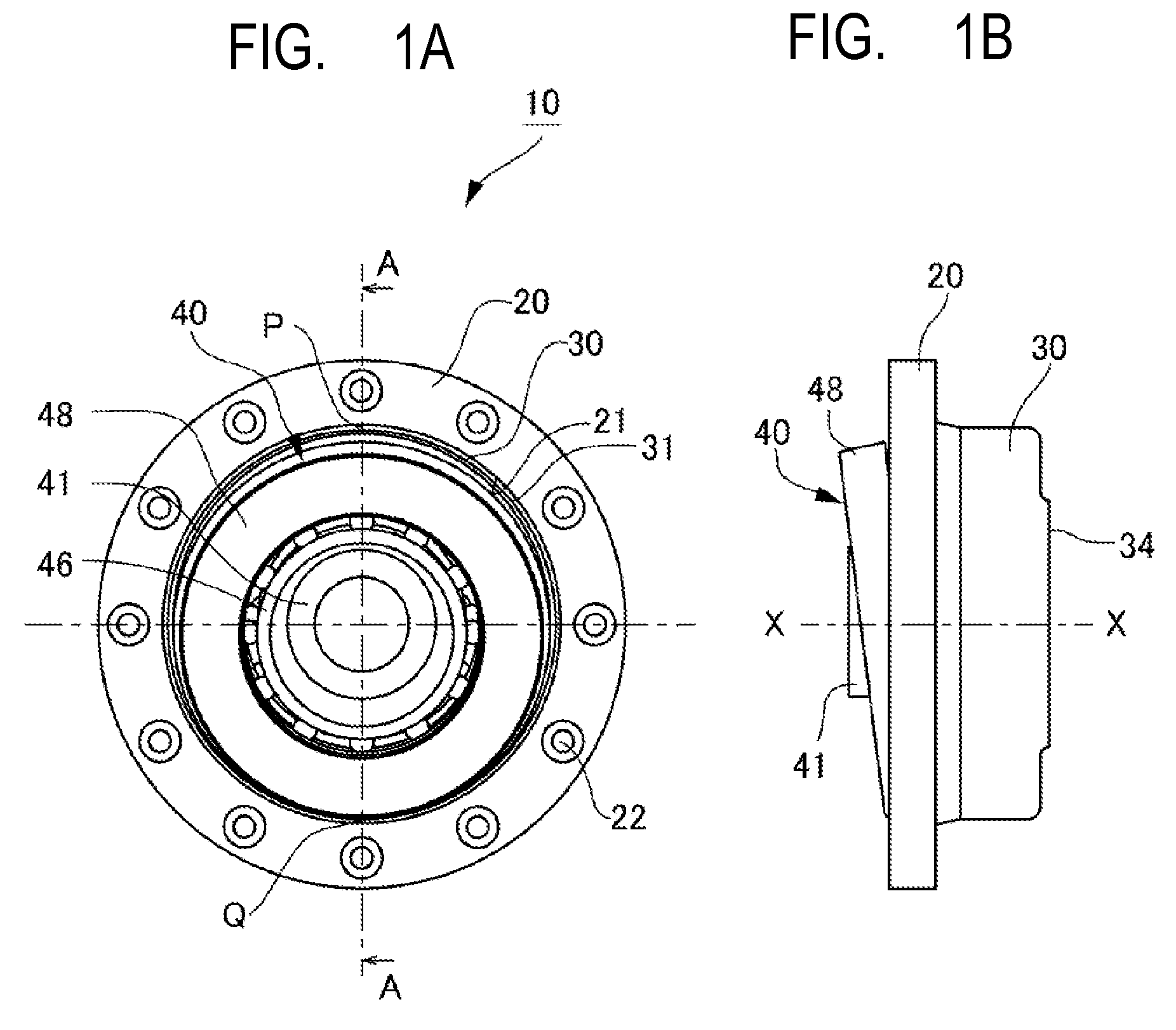

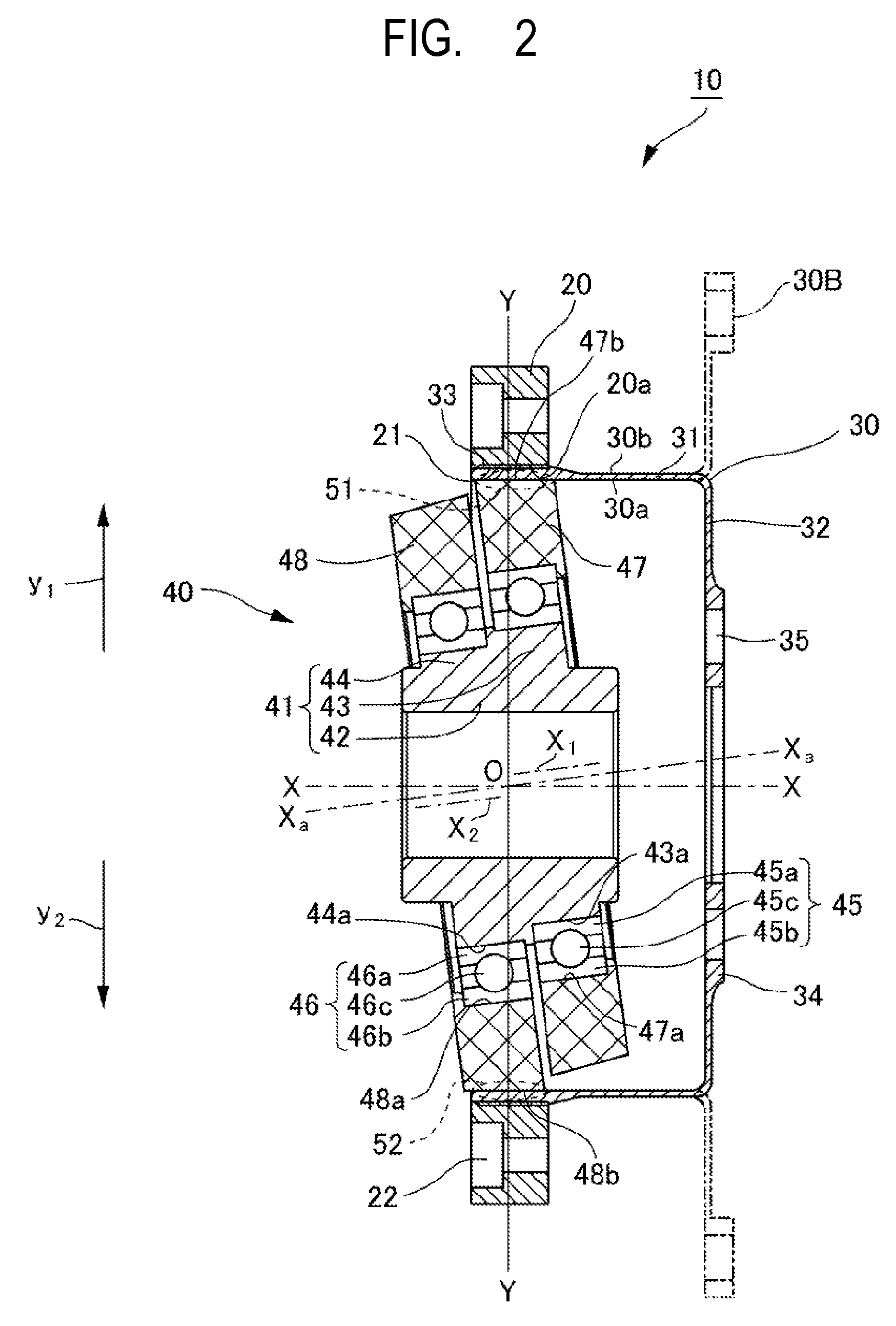

Rotational transfer mechanism

ActiveUS20050087416A1Smoothly transfer torqueStable transmission torqueYielding couplingFriction clutchesRotational axisCam

A rotational transfer mechanism includes a rotary output shaft, a rotary input shaft positioned inside the rotary output shaft; a circumferentially-uneven-width-space forming portion having a cam surface, to form an accommodation space between the rotary input shaft and the torque transfer cylindrical surface; and a torque transfer member installed in the accommodation space. The cam surface shape is determined by defining a straight line through the rotational axis and the torque-transfer-member axis, defining an imaginary circle having the same shape as the torque transfer member on the straight line at a point where the imaginary-circle axis and the torque-transfer-member axis are symmetrical with respect to the rotational axis; determining a cam-surface determining circle which circumscribes the imaginary circle and the torque transfer member; and defining a circular arc which forms a part of the cam-surface determining circle as the cam surface.

Owner:PENTAX RICOH IMAGING CO LTD

Rotational transfer mechanism

ActiveUS7213693B2Stable transmission torqueSmooth transferYielding couplingFriction clutchesEngineeringCam

A rotational transfer mechanism includes a rotary output shaft, a rotary input shaft positioned inside the rotary output shaft; a circumferentially-uneven-width-space forming portion having a cam surface, to form an accommodation space between the rotary input shaft and the torque transfer cylindrical surface; and a torque transfer member installed in the accommodation space. The cam surface shape is determined by defining a straight line through the rotational axis and the torque-transfer-member axis, defining an imaginary circle having the same shape as the torque transfer member on the straight line at a point where the imaginary-circle axis and the torque-transfer-member axis are symmetrical with respect to the rotational axis; determining a cam-surface determining circle which circumscribes the imaginary circle and the torque transfer member; and defining a circular arc which forms a part of the cam-surface determining circle as the cam surface.

Owner:RICOH IMAGING COMPANY

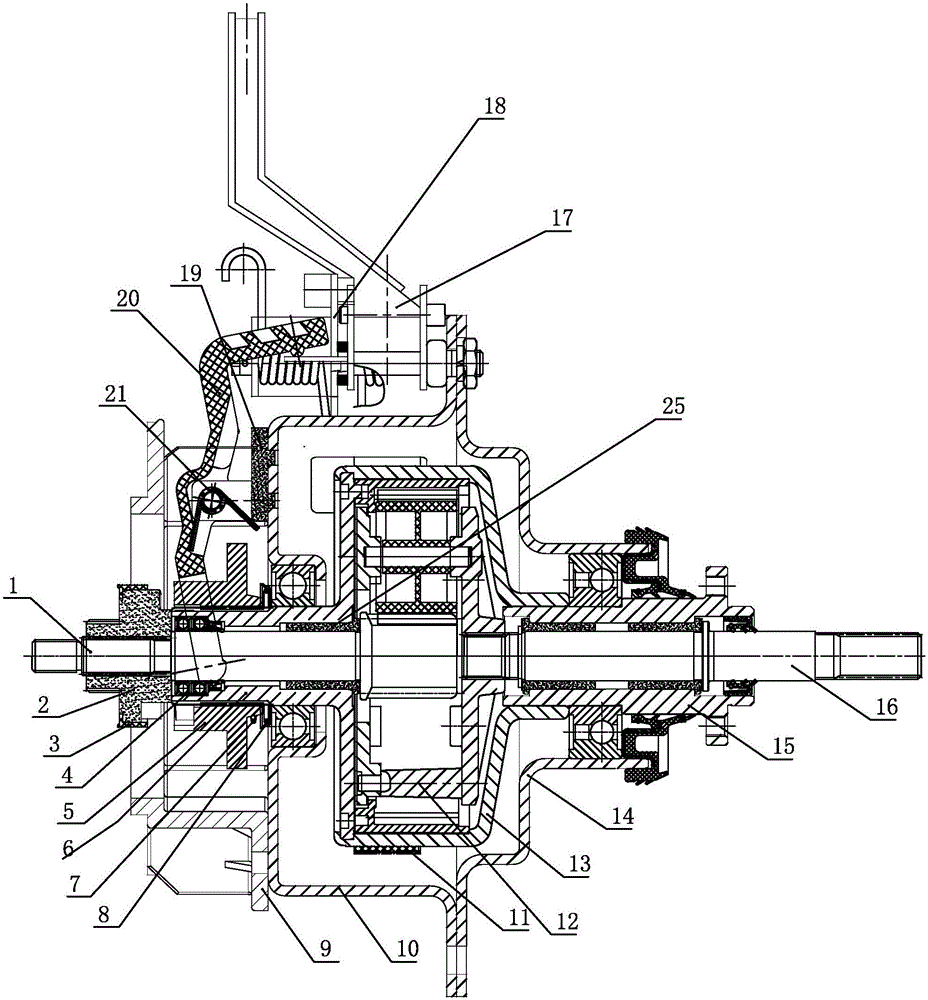

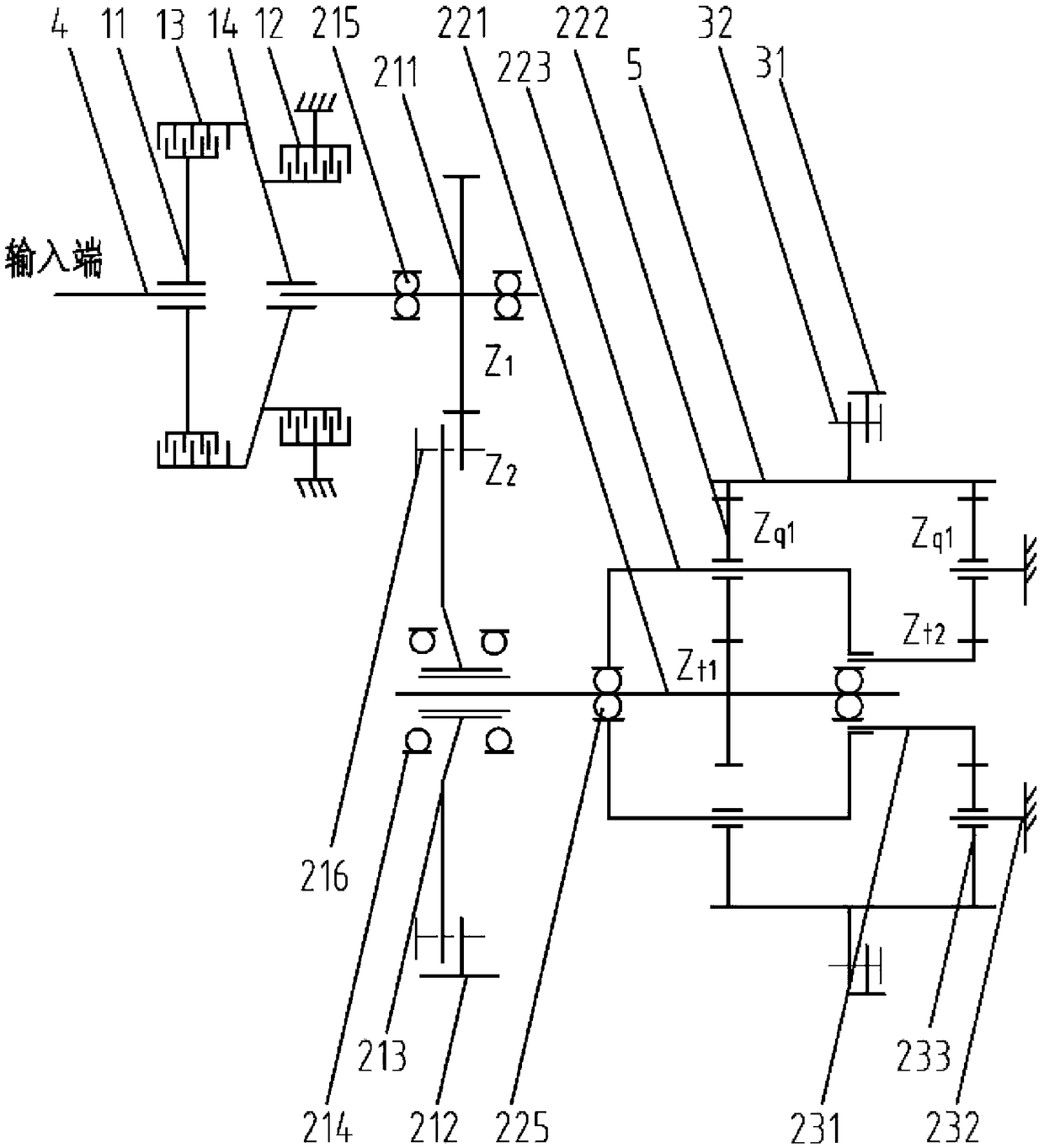

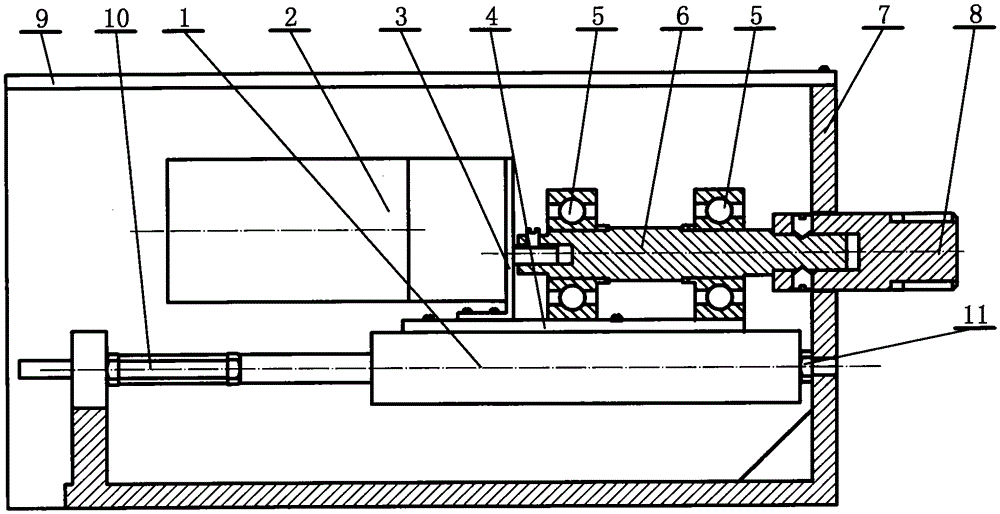

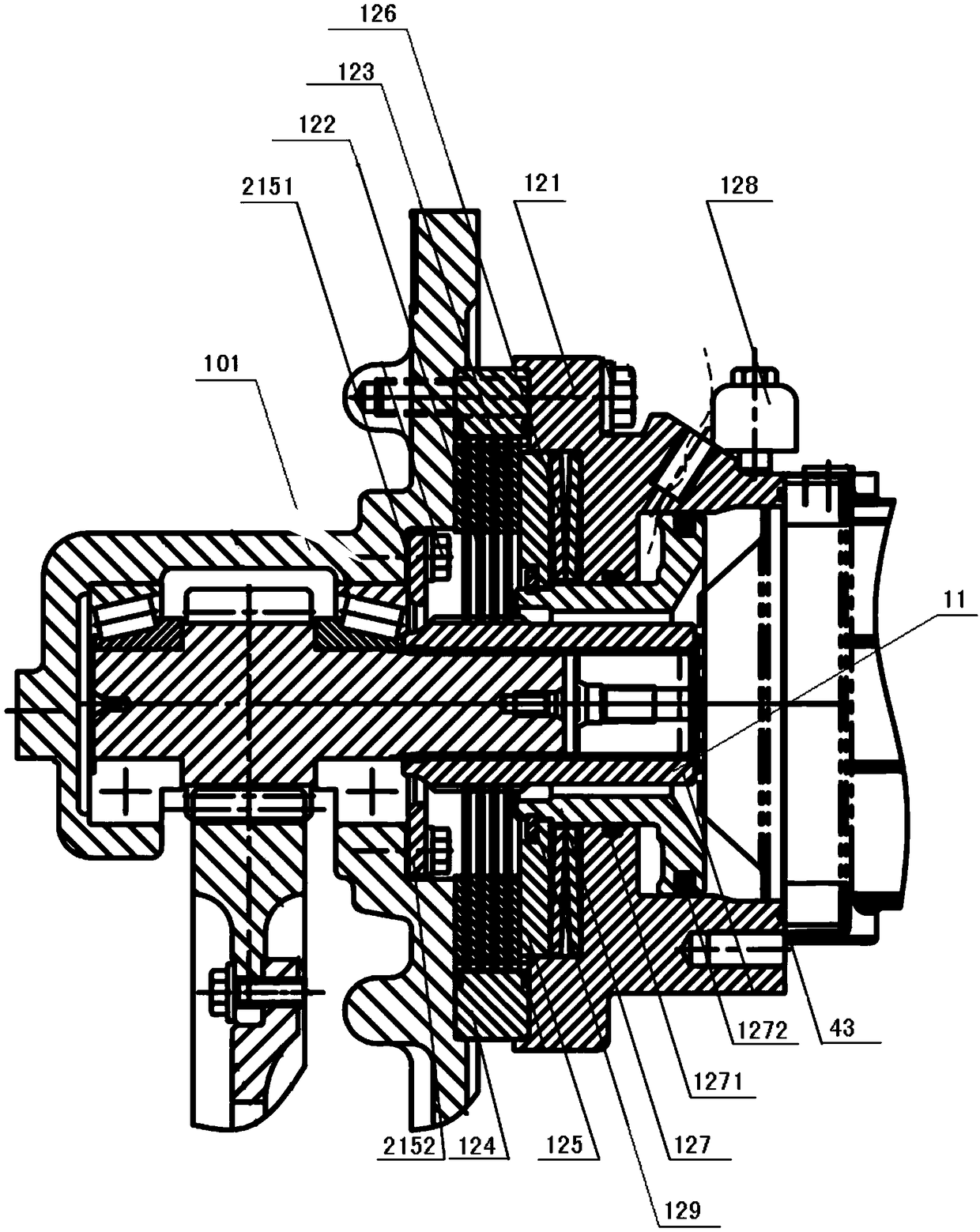

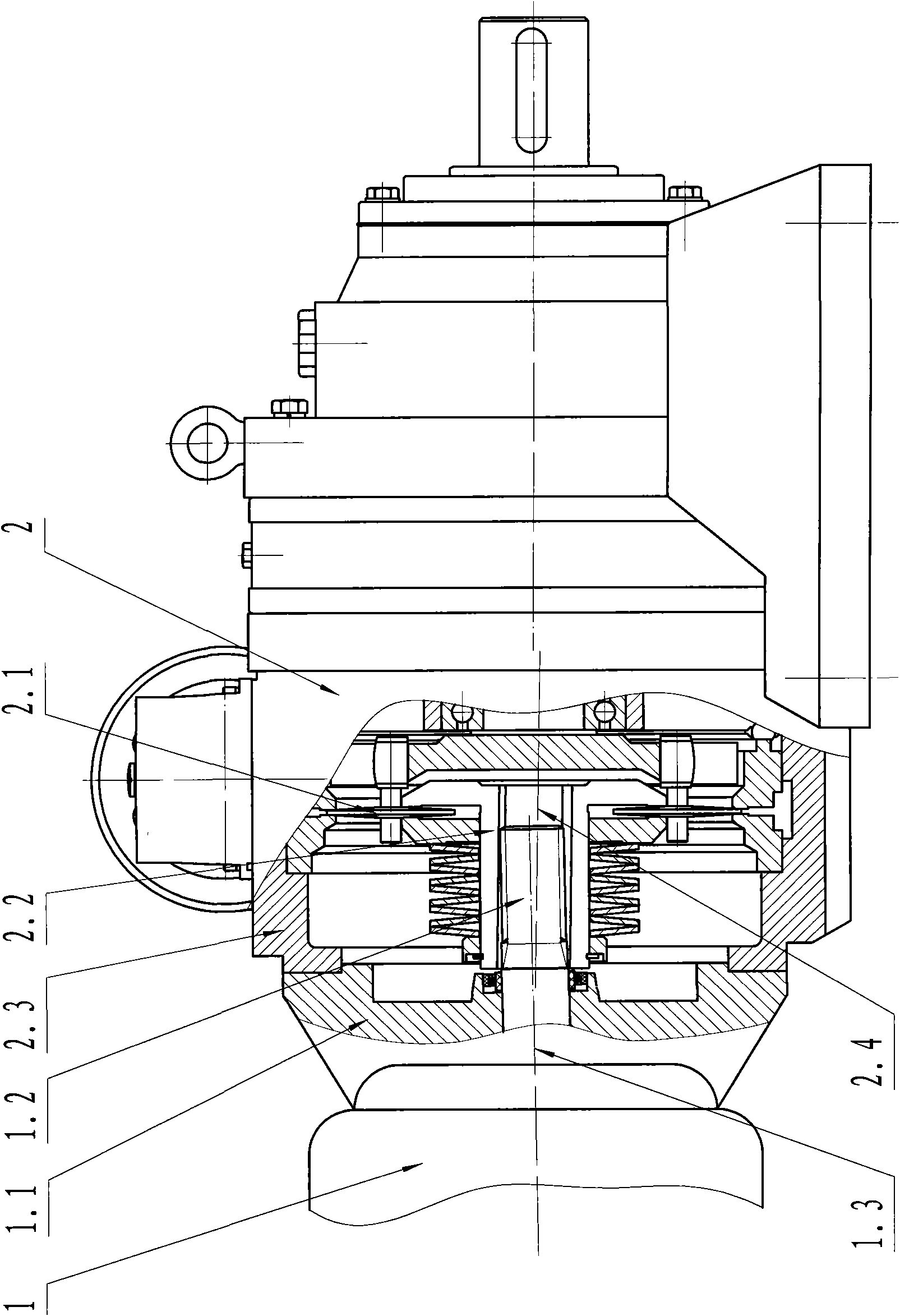

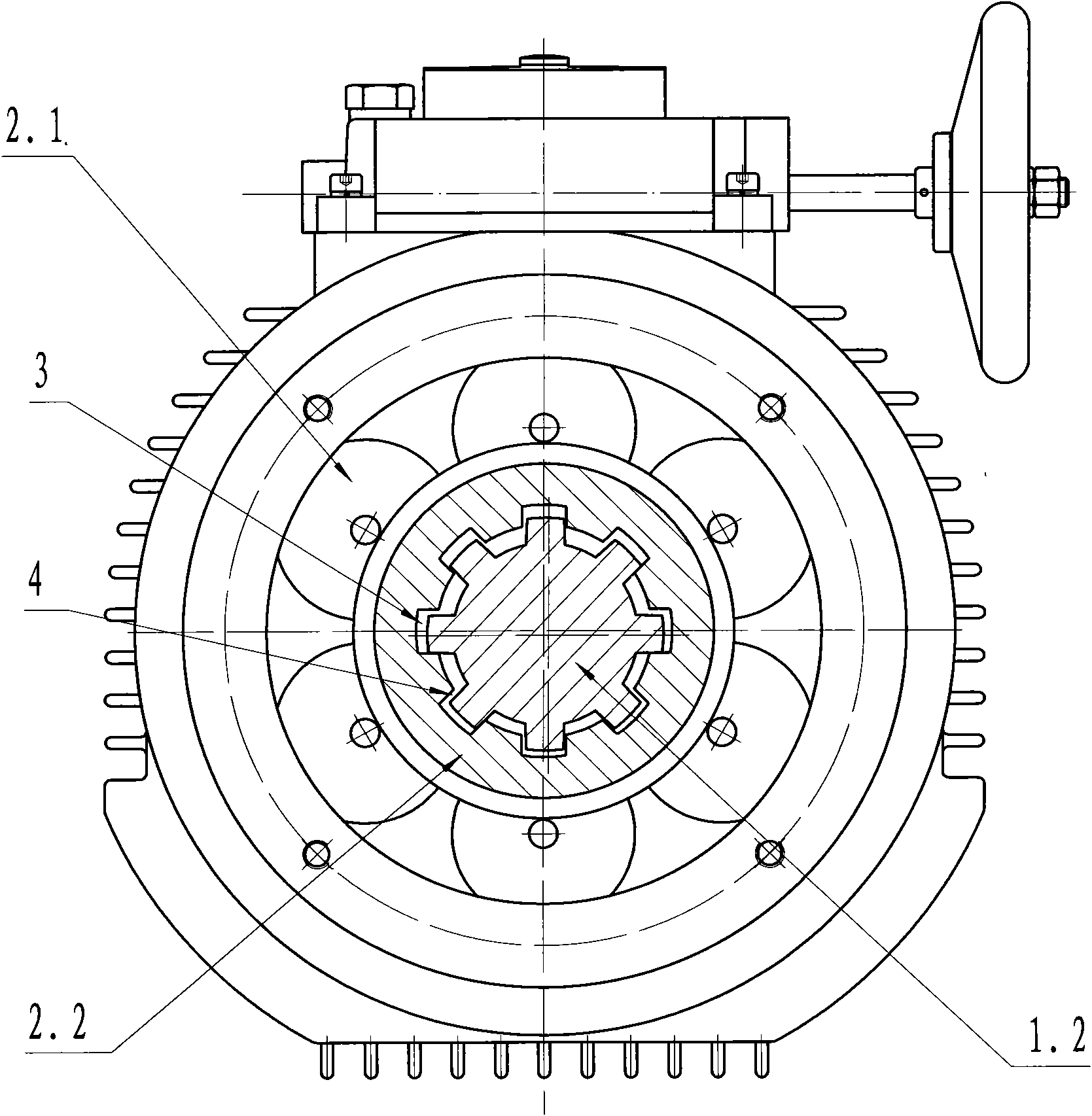

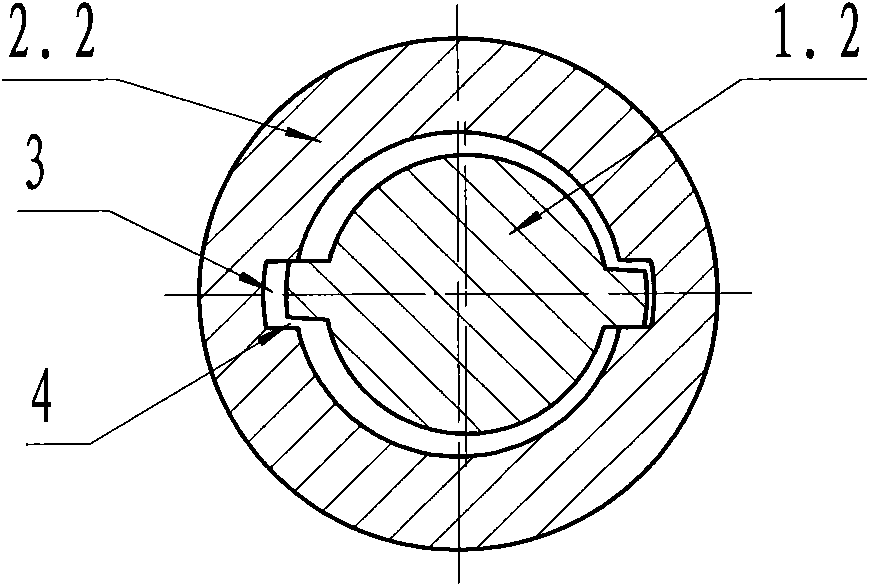

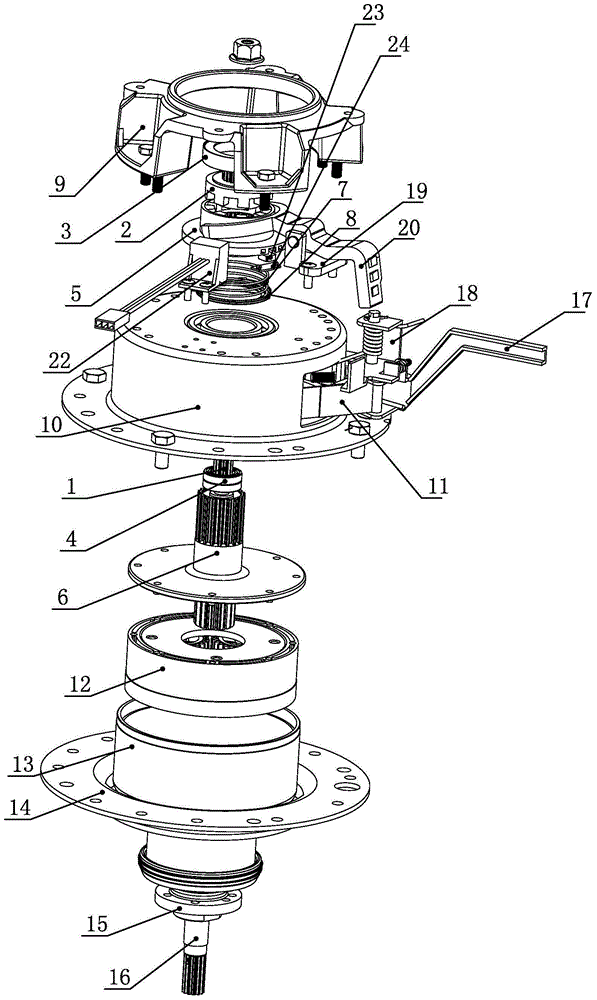

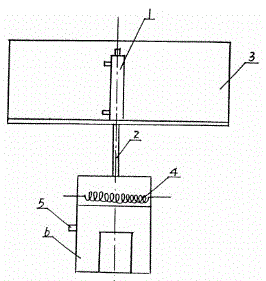

Decelerating clutch of intelligent washing machine

ActiveCN105019192AReliable clutchExtended service lifeOther washing machinesTextiles and paperTorque transmissionControl theory

The invention discloses a decelerating clutch of an intelligent washing machine. The decelerating clutch comprises an upper shell, a lower shell, a connection plate, a torque transmission shaft sleeve and a brake wheel axle. The connection plate is arranged on the brake wheel axle in a sleeving mode. The connection plate is provided with a magnet, a Hall sensor is arranged on the lower end face of the lower shell, the position of the Hall sensor is matched with the position of the magnet, and a gap is reserved between the Hall sensor and the magnet. First splines are arranged on the outer surface of the brake wheel axle, second splines matched with the first splines are arranged on the inner surface of an inner hole of the connection plate, third splines are arranged on the lower end portion of the connection plate, and fourth splines matched with the third splines are arranged on the upper end portion of the torque transmission shaft sleeve. A connection plate spring and a spring gland are arranged at the upper end of the connection plate. The spring gland is located at the upper end of the connection plate spring, and the spring gland abuts against the lower shell. According to the technical scheme, the decelerating clutch of the intelligent washing machine is reasonable in structural design, simple in structure, convenient to assemble, reliable in clutch action, stable in torque transmission and high in safety.

Owner:ZHEJIANG SANXING MECHANICAL & ELECTRONICSAL STOCK

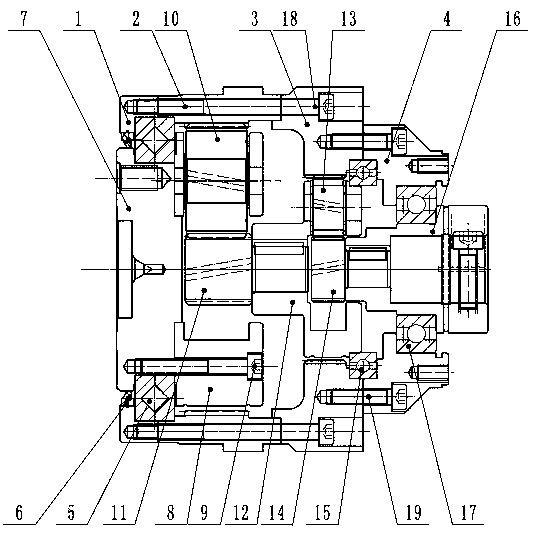

Final transmission structure and bulldozer

ActiveCN106641161AMeet the needs of transmission reduction ratioLarge transmission ratioMechanical machines/dredgersGearingCouplingComputer module

The invention relates to the technical field of bulldozers and particularly relates to a final transmission structure and a bulldozer. The final transmission structure comprises a brake unit and a transmission system, wherein the transmission system comprises a first-grade speed reducing unit, a second-grade speed reducing unit and a third-grade speed reducing unit; the first-grade speed reducing unit comprises two grades of straight tooth speed reducing structures; the second-grade speed reducing unit comprises a first planet row structure; the third-grade speed reducing unit comprises a second planet row structure; and the brake unit is connected with a transmission end of a motor. The invention further relates to the bulldozer. The bulldozer comprises an engine for providing power output, a shaft coupler and a pump connected with the motor; the shaft coupler is connected with the engine and the pump respectively; and the motor is connected with the final transmission structure. The brake unit, the first-grade speed reducing unit, the second-grade speed reducing unit and the third-grade speed reducing unit are used as a large module and the large module is fixedly connected with a main rack of the bulldozer, so that the bulldozer is convenient to dismount and maintain; and a relatively large transmission ratio can be realized and the transmission torque is stable, and the final transmission structure is economical and practical and is safe and reliable.

Owner:SHANTUI CONSTR MASCH CO LTD

Strain wave gear apparatus

A strain wave gear apparatus includes a rigid internal gear, a flexible external gear, and a wave generator. The wave generator includes an input shaft fixing member including eccentric cams, bearings respectively fixed to outer sides of the eccentric cams, and housings respectively fitted to outer peripheral surfaces of the bearings. The eccentric cams are arranged side by side in a direction of an inclined axis inclined with respect to an input rotation axis at an inclination angle (θ) in a manner that respective center axes of the eccentric cams are parallel to the inclined axis and decentered in directions opposite to each other from the inclined axis. The housings are each formed into a tapered shape so that an outer peripheral surface of each of the housings is held in surface contact with an inner peripheral surface of the flexible external gear.

Owner:CANON KK

Safety coupling of vehicular dry-type screw air compressor

InactiveCN102619894ASimple structureStable transmission torqueCouplings with disconnecting safety membersRotary/oscillating piston pump componentsCouplingIn vehicle

The invention relates to a safety coupling of a vehicular dry-type screw air compressor, which is designed for resolving the technical problem that an existing like product is poor in structural stability and safety protection effect. The safety coupling comprises a motor end flange and a compressor end flange, wherein the motor end flange is connected with a motor end, the compressor end flange is connected with a compressor end, and both the motor end flange and the compressor end flange are provided with locking screws. The safety coupling is characterized in that one end of the motor end flange is fixedly connected with a first transitional flange, one end of the compressor end flange is fixedly connected with a second transitional flange, the outside of the first transitional flange is connected with the outside of the second transitional flange via a safety transitional pin in a positioning manner, and the inside of the first transitional flange is movably connected with the inside of the second transitional flange via a center shaft. The safety coupling is simple in structure, stable in driving torque and reliable in safety protection, is suitable, or can be used as an improved structure of a like product.

Owner:骆贻红

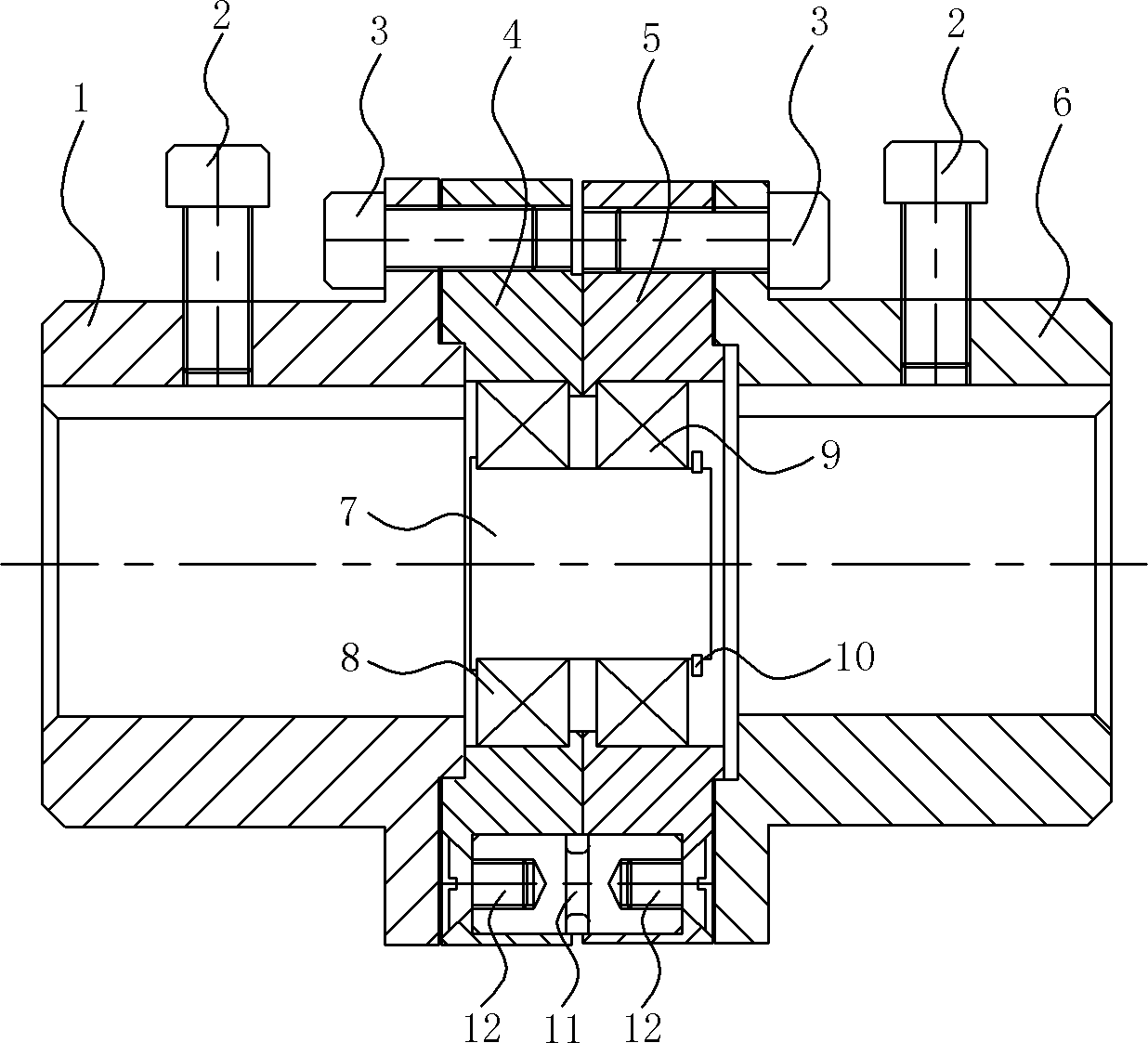

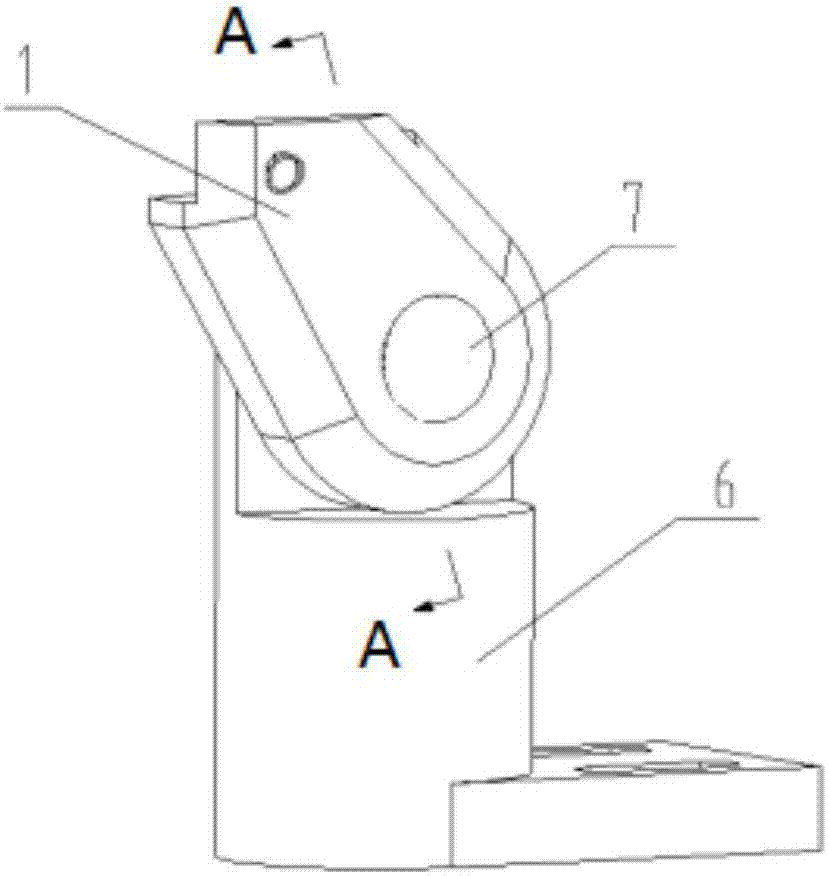

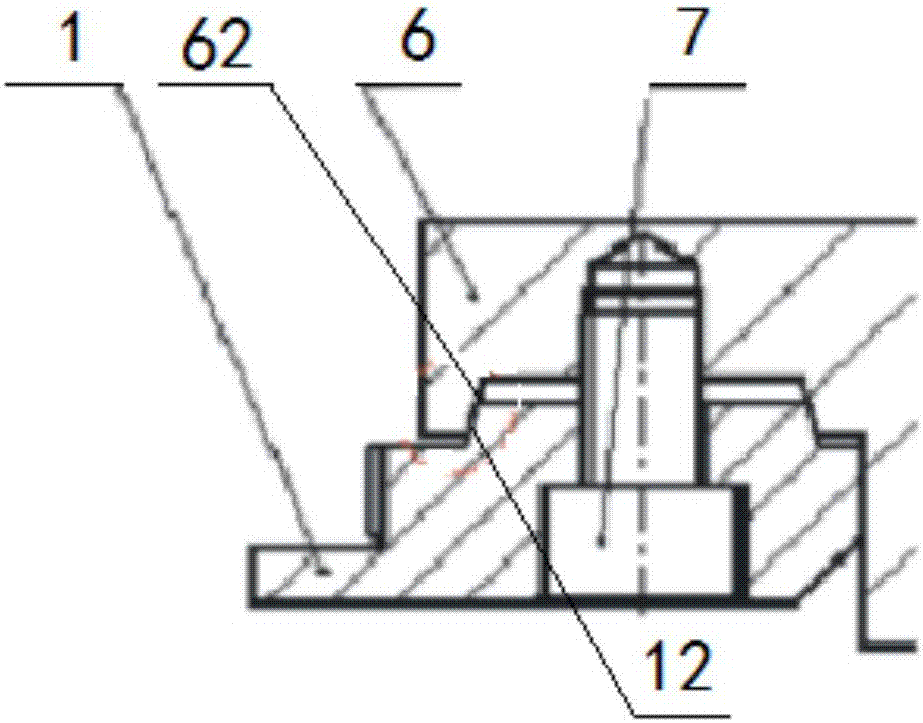

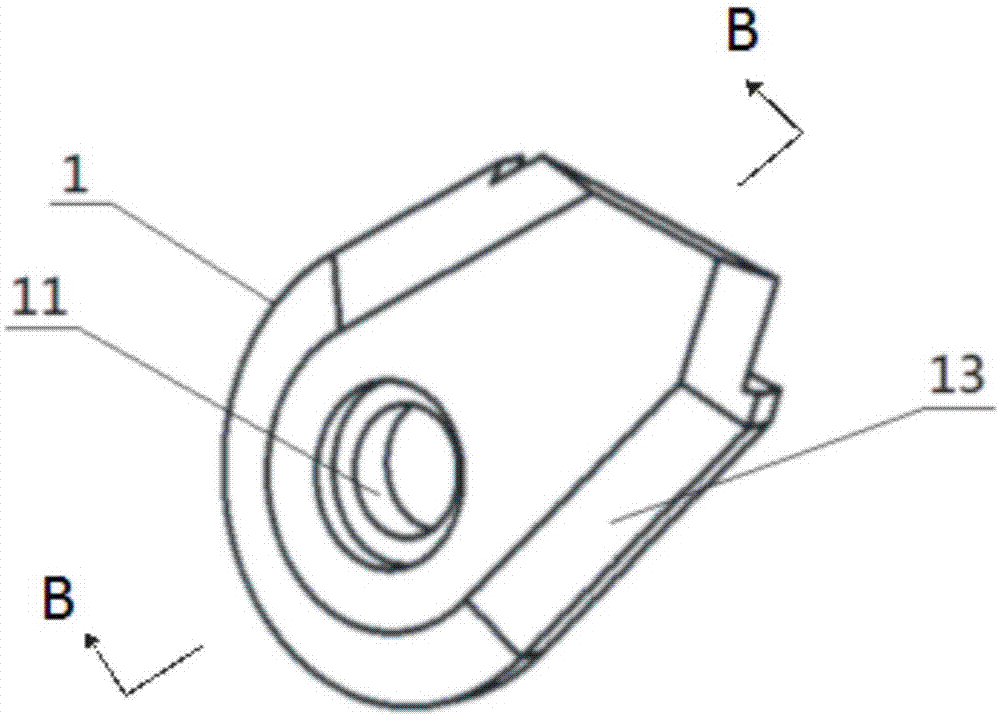

Angle-adjustable rose reamer applied to different pore diameters

InactiveCN107335820AStable transmission torqueRealize stepless adjustment of hole diameterTurning toolsTool holdersReamerPore diameter

The invention relates to an angle-adjustable rose reamer applied to different pore diameters. The rose reamer comprises a reamer base component, a reamer plate which is connected to the reamer base component in a matched mode, a reamer clamp which is connected to the reamer plate in a matched mode and a reamer blade which is connected to the reamer clamp in a matched mode; the reamer base component is a sliding plate type reamer handle, a connection part of the reamer base component is provided with an inner arc cone surface and a screw hole, and the axis line of the screw hole is coincident with that of the inner arc cone surface; a conical convex platform is arranged on the lower portion of the reamer plate, a step hole is formed in the lower portion of the reamer plate, and the axis line of the step hole is coincident with the axis line of the conical convex platform; the reamer plate is matched with the screw hole in the sliding plate type reamer handle through the step hole which runs through a first compression screw, and the conical convex platform on the reamer plate is attached to the inner arc cone surface on the sliding plate type reamer handle. The angle-adjustable rose reamer applied to different pore diameters can integrate multiple reamers into one reamer, is applied to processing of different chamfering angles, solves the problem that each orifice chamfering needs to be provided with a special rose reamer, and can achieve stepless regulation of angle and pore diameter of reamer chamfering.

Owner:CHONGQING HONGJIANG MACHINERY

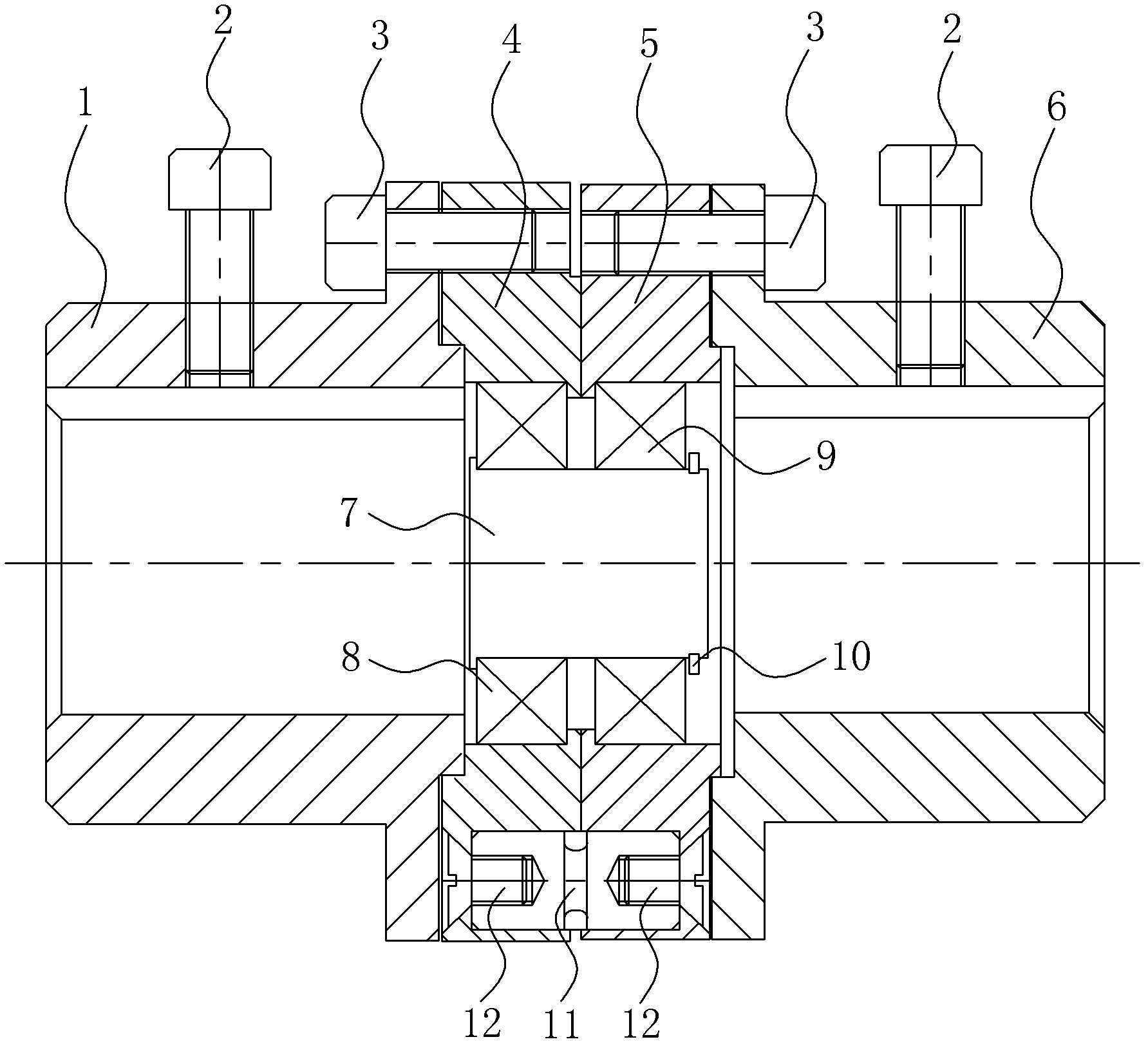

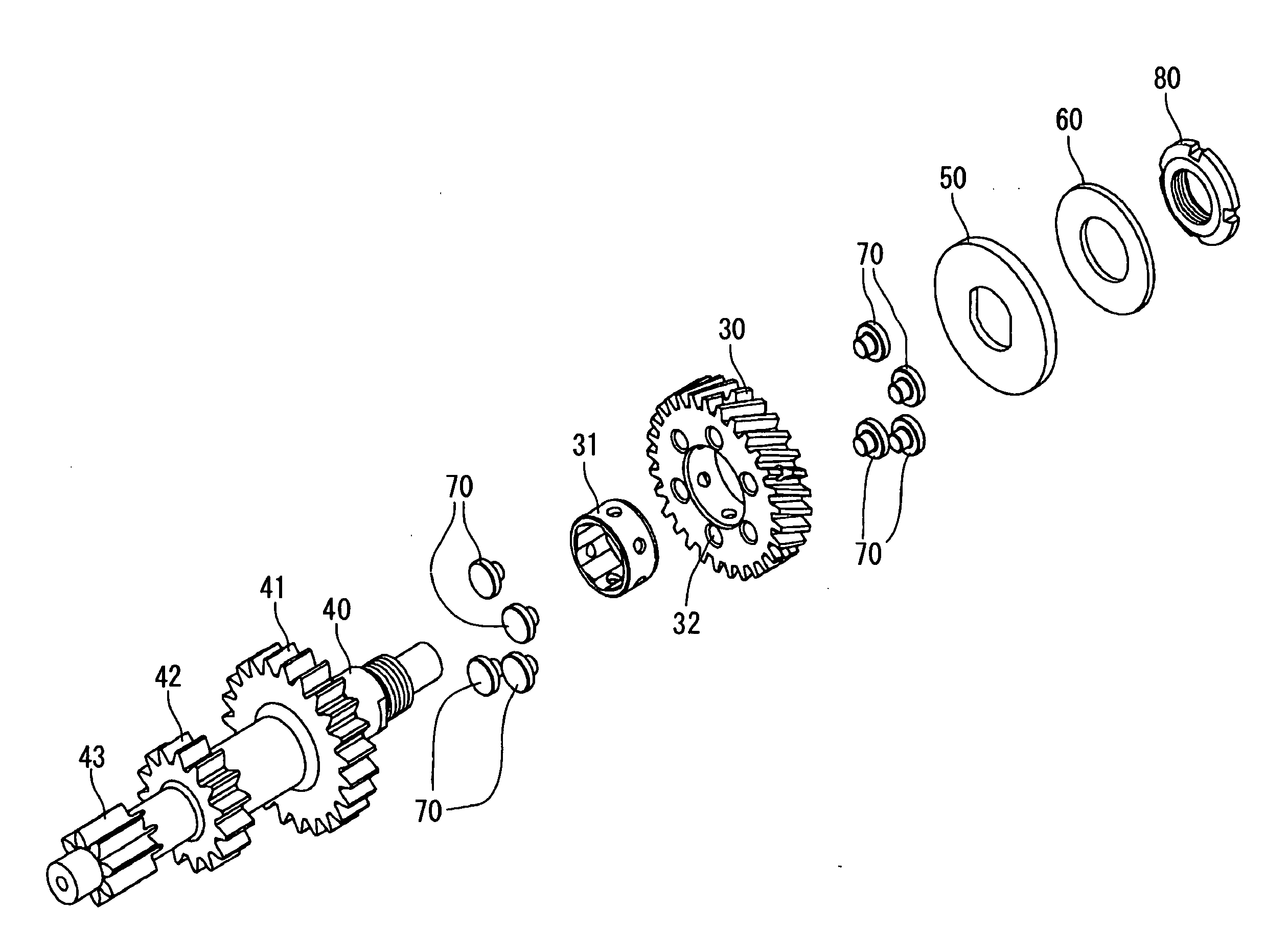

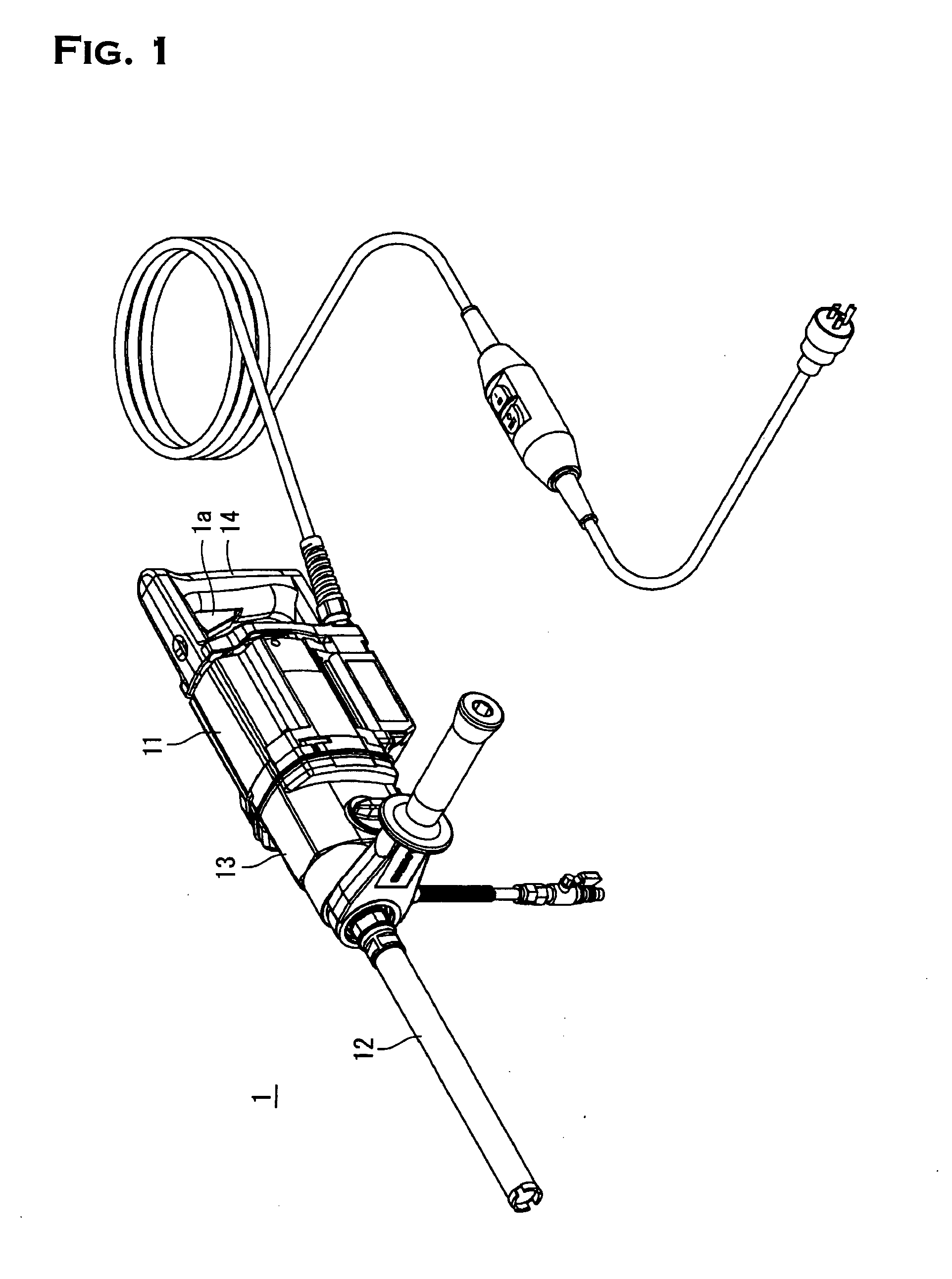

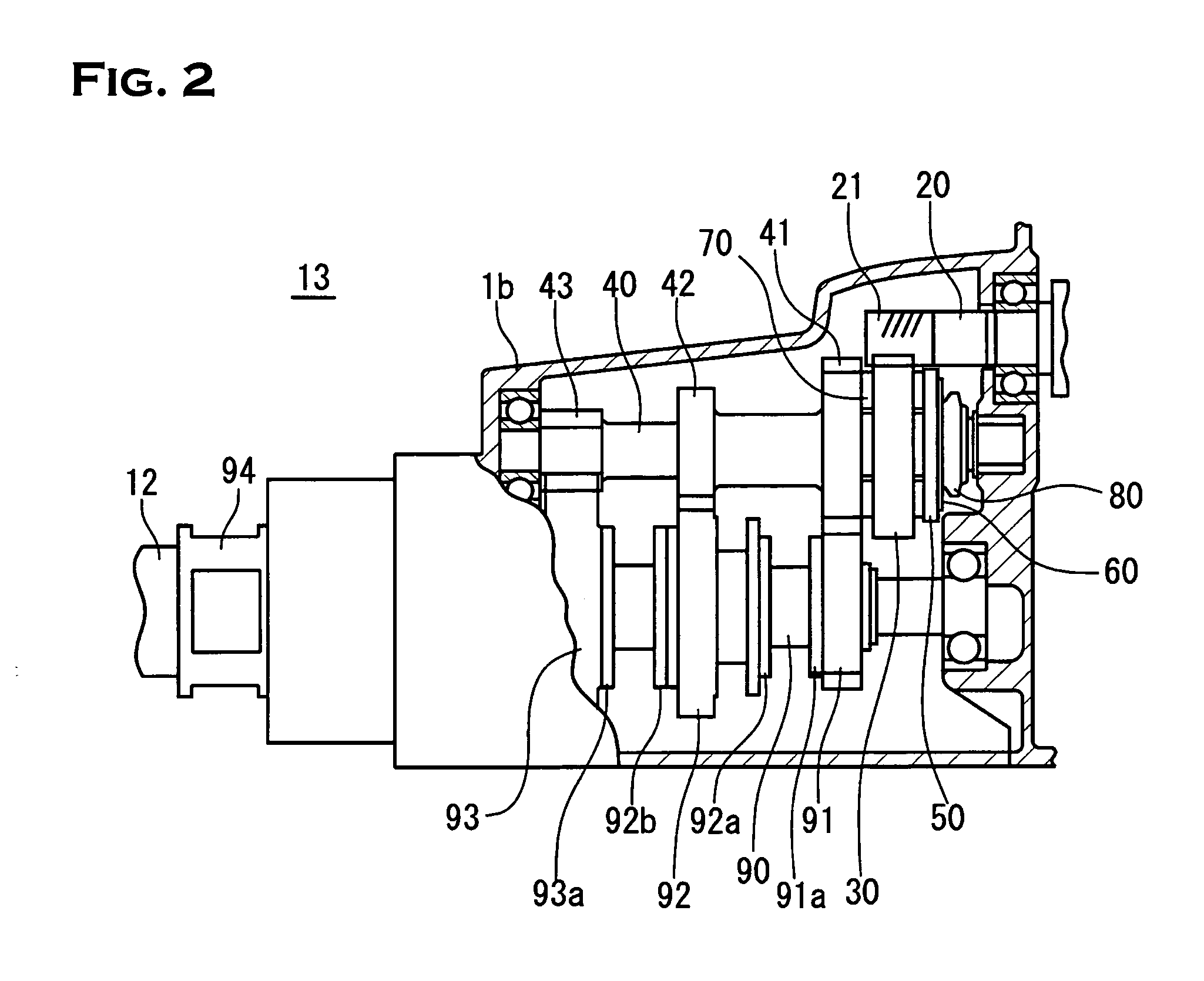

Power transmission device for power tool

The present invention relates to a power transmission device for a power tool, more specifically for a core drill, which device is capable of transmitting predetermined torque in a stable manner and for longer period of time under a condition where a clutch slips. The power transmission device for a core drill comprises of: a gear 30 to which rotation from a power source is input; a disk-shaped rotator 41, 50, which is disposed coaxially with the gear 30 and transmits rotation of the gear 30 to the tip tool side; friction members, which are installed between the gear and rotator and kept pressed against the side face or faces of the gear and / or rotator, and said power transmission device transmitting rotation of the gear to the rotator with the use of friction caused between the gear 30 and / or rotator 41, 50 and the friction members, and as friction members, friction members 70 having two or more friction faces 70a which are spaced apart from each other are used.

Owner:SHIBUYA CO LTD

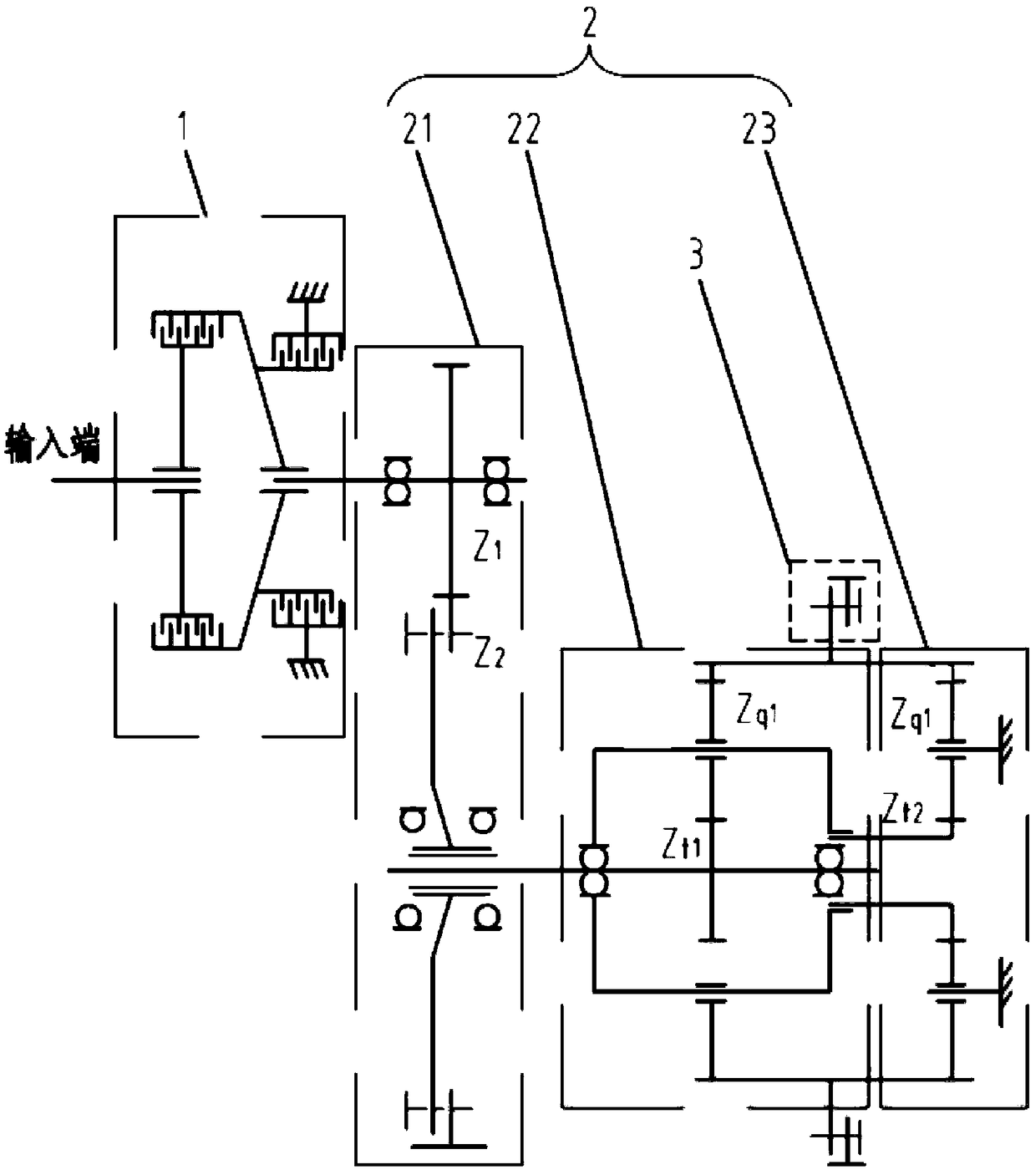

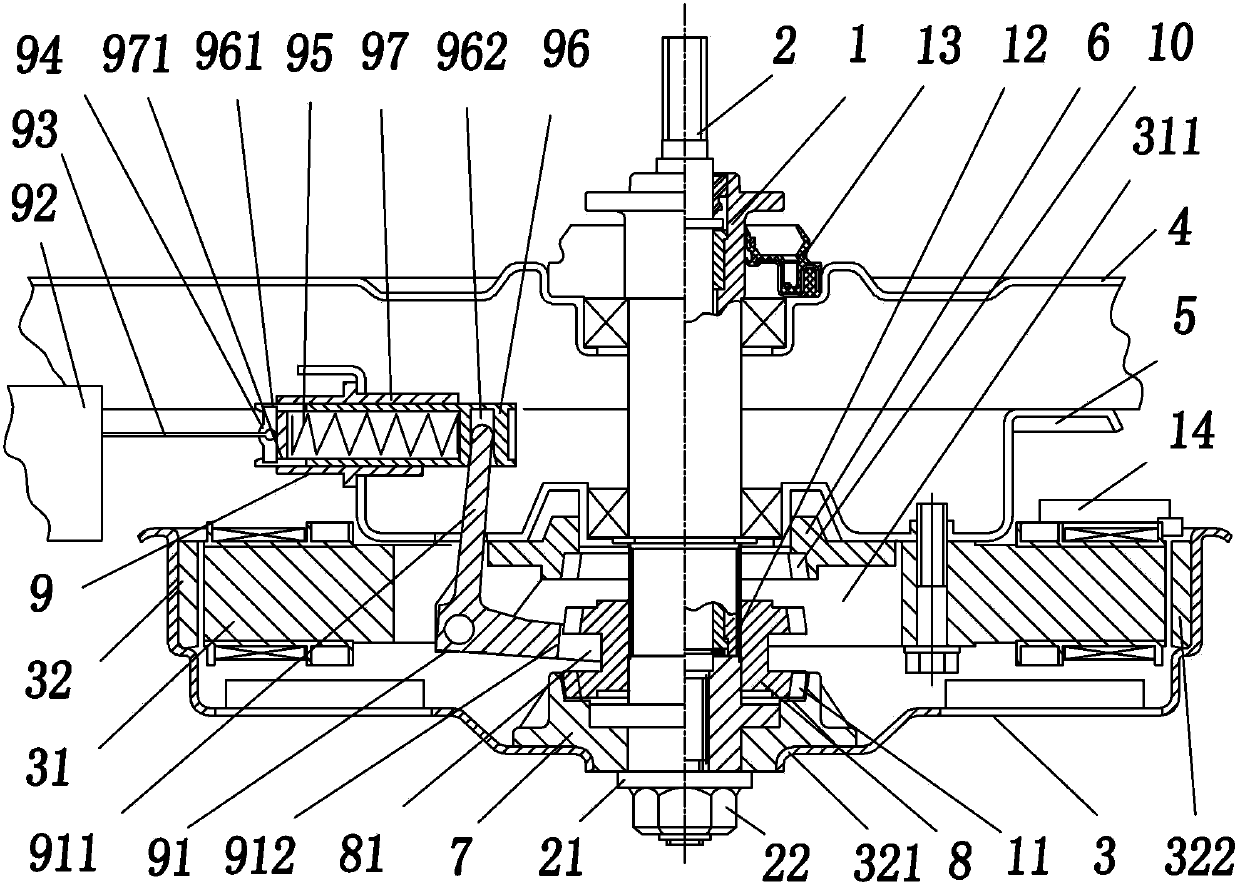

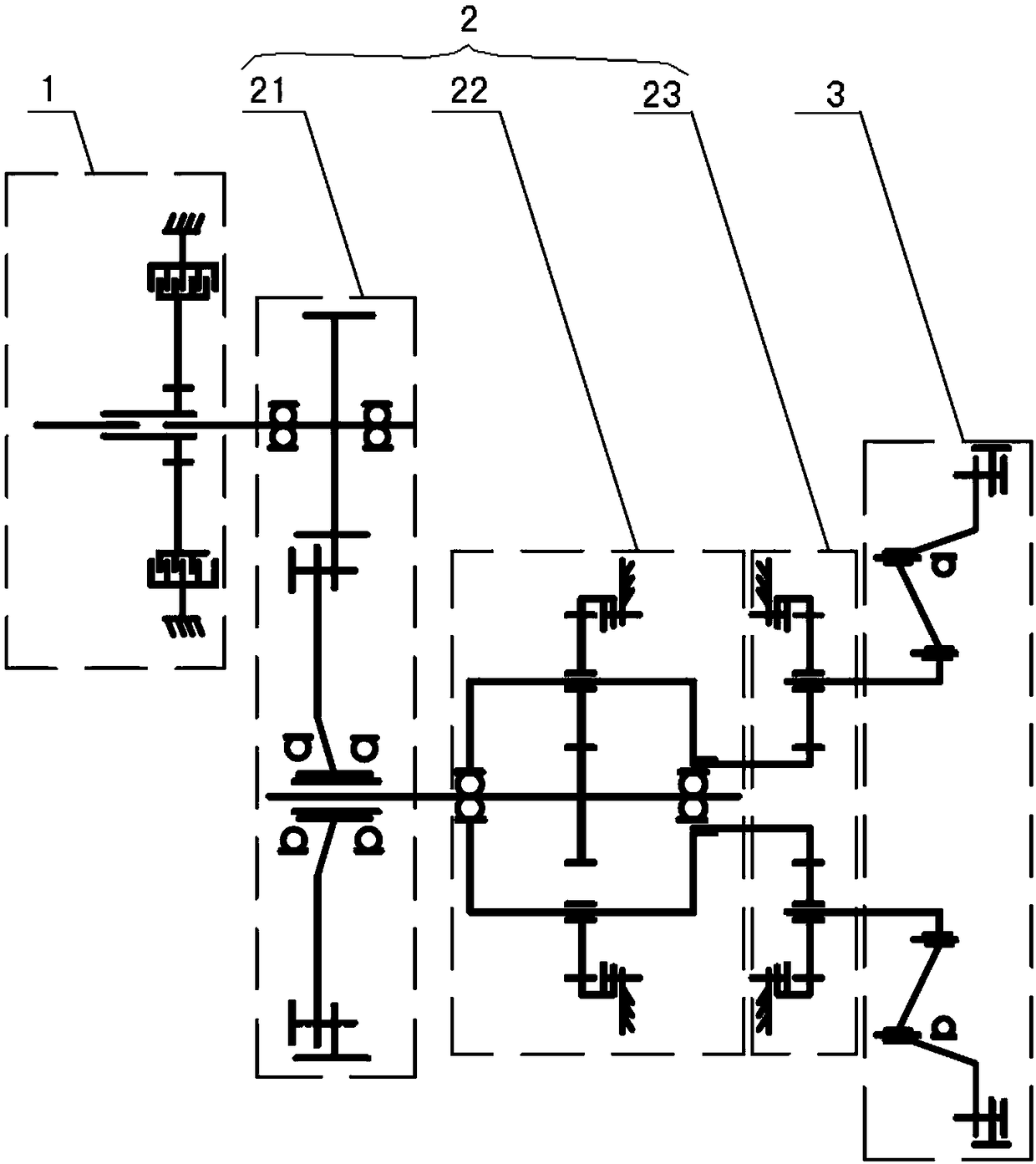

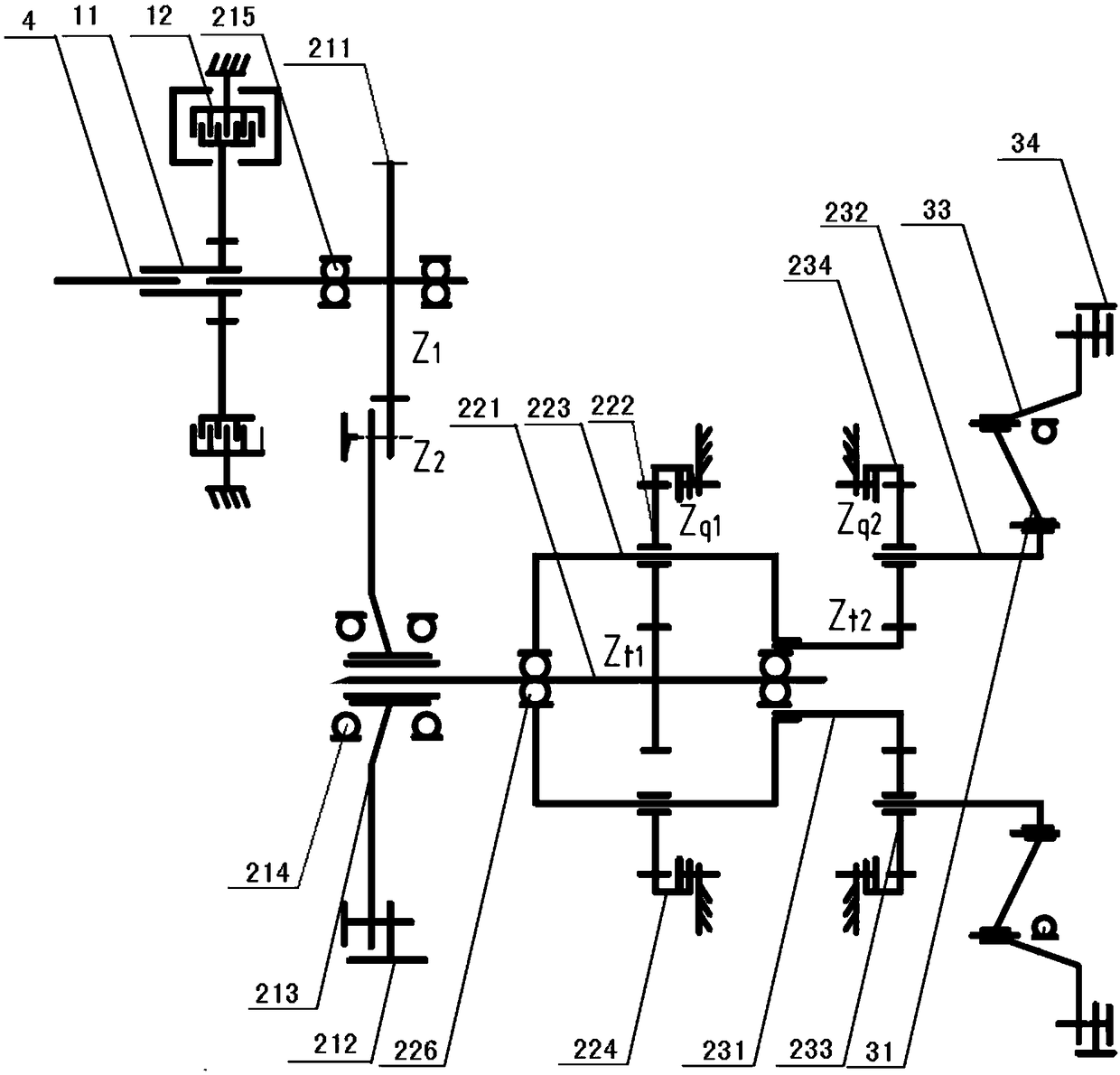

Final transmission structure, bulldozer and turning control method

InactiveCN109139853AMeet the needs of transmission reduction ratioLarge transmission ratioFluid actuated brakesFluid actuated clutchesTorque converter

The invention discloses a final transmission structure, a bulldozer and a turning control method, and relates to the technical field of bulldozers. In the final transmission structure, a steering brake unit comprises a brake, a driving hub, a clutch and a driven hub, wherein the brake is connected with an input shaft through the driving hub, the clutch is connected with a transmission unit througha driven hub, and the brake and the clutch can be selectively unlocked or locked. A first planetary gear ring and a second planetary gear ring form a planetary gear ring of an integrated structure. The bulldozer comprises an engine, a hydraulic torque converter and a gearbox which are connected in sequence. A central transmission structure is connected with the gearbox. A left final transmissionstructure and a right final transmission structure are both connected with the central transmission structure and are both of the final transmission structure. The bulldozer is adopted in the turningcontrol method. The final transmission structure can bear larger torque when rotated leftwards or rightwards, and torque transfer is stable. The turning control method has the large or small radius turning ability, and is high in universality.

Owner:SHANTUI CONSTR MASCH CO LTD

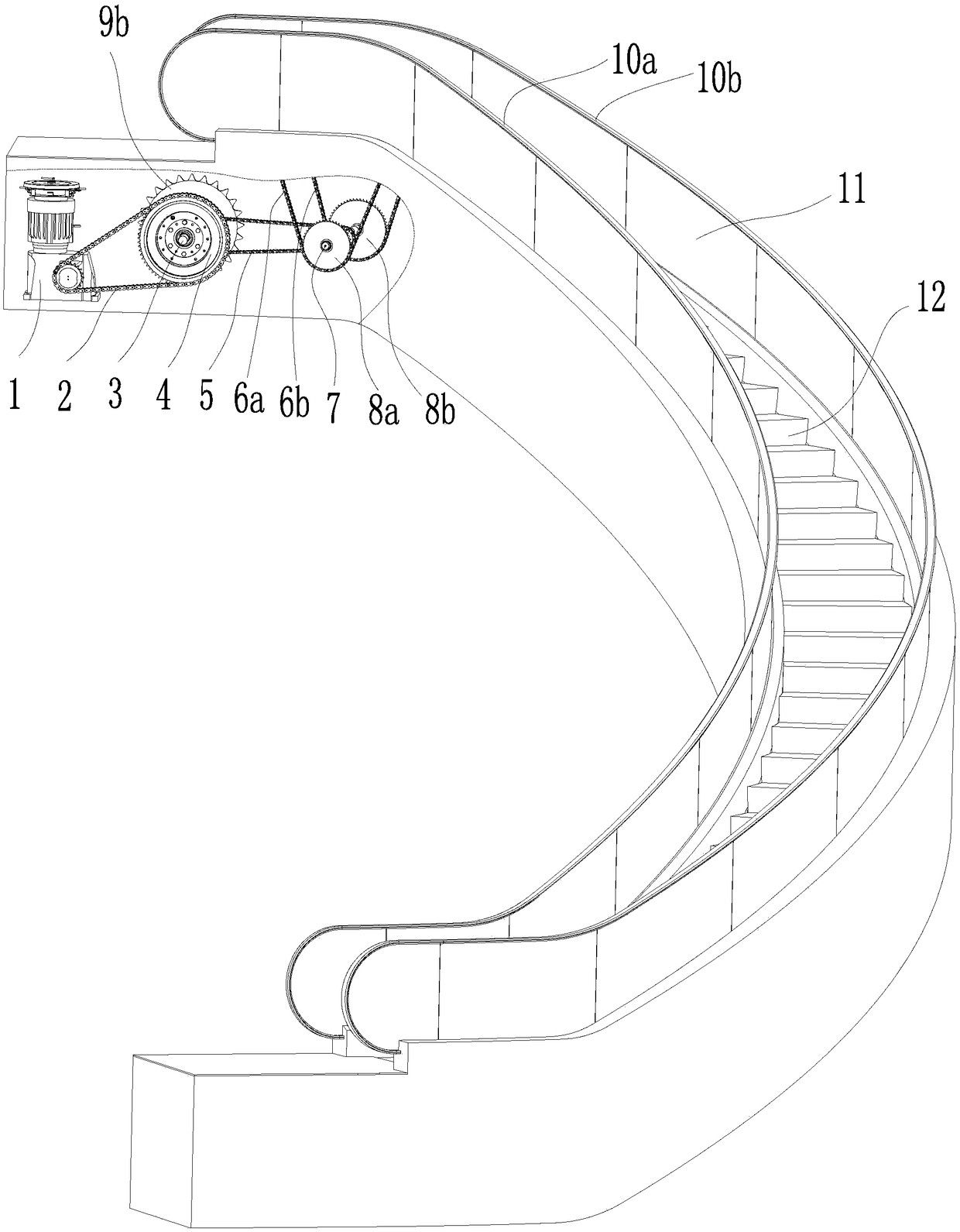

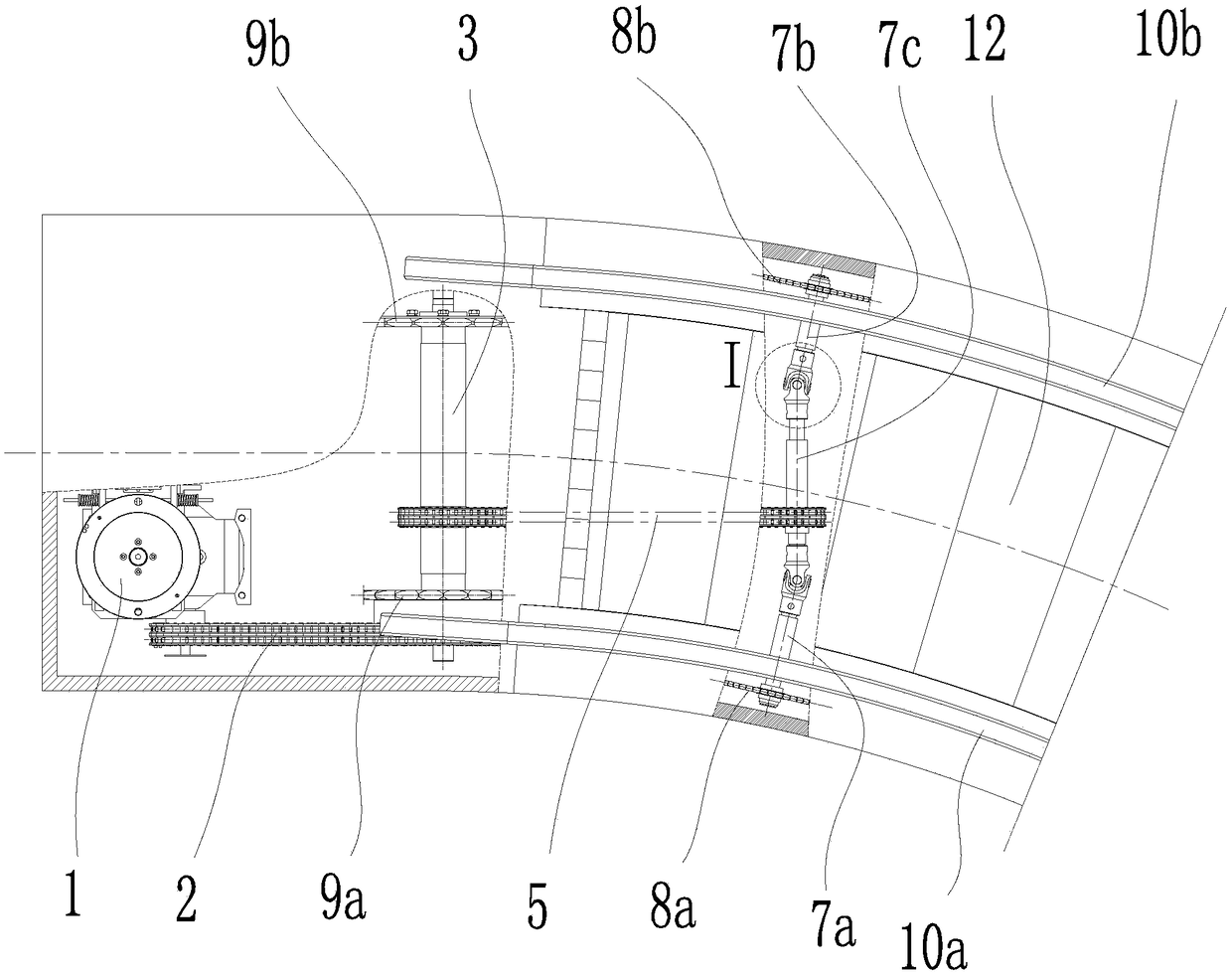

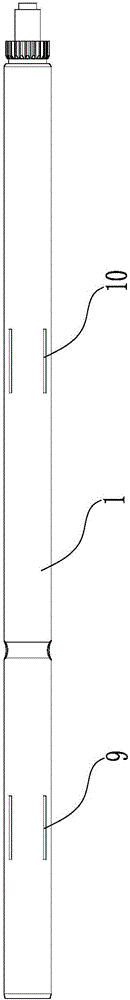

Handrail belt driving device of spiral escalator

PendingCN109466999AAchieve running speedReasonable structural designEscalatorsUniversal structureAngular velocity

The invention discloses a handrail belt driving device of a spiral escalator. The handrail belt driving device comprises a driving main engine, a step driving main shaft, a driving chain connected with the step driving main shaft and the driving main engine, handrail shafts used for driving the handrail belts to move, and a transition chain which drives the handrail shafts and the step driving main shaft to rotate synchronously, wherein the handrail shafts at least comprises an outer side handrail shaft close to the outer side handrail belt, an inner side handrail shaft close to the inner sidehandrail belt, and a connecting shaft which connects the outer side handrail shaft with the inner side handrail shaft, the joint between the outer side handrail shaft and the connecting shaft is of auniversal structure, the joint between the inner side handrail shaft and the connecting shaft is of a universal structure, one side, close to the outer side handrail belt, of the outer side handrailshaft is provided with an outer side handrail belt driving mechanism, and one side, close to the inner side handrail belt, of the inner side handrail shaft is provided with an inner side handrail beltdriving mechanism. The handrail belt driving device can meet the special requirements that the handrail belts can be laterally bent with same angular velocity and different linear speed at two sides.

Owner:SJEC CORP

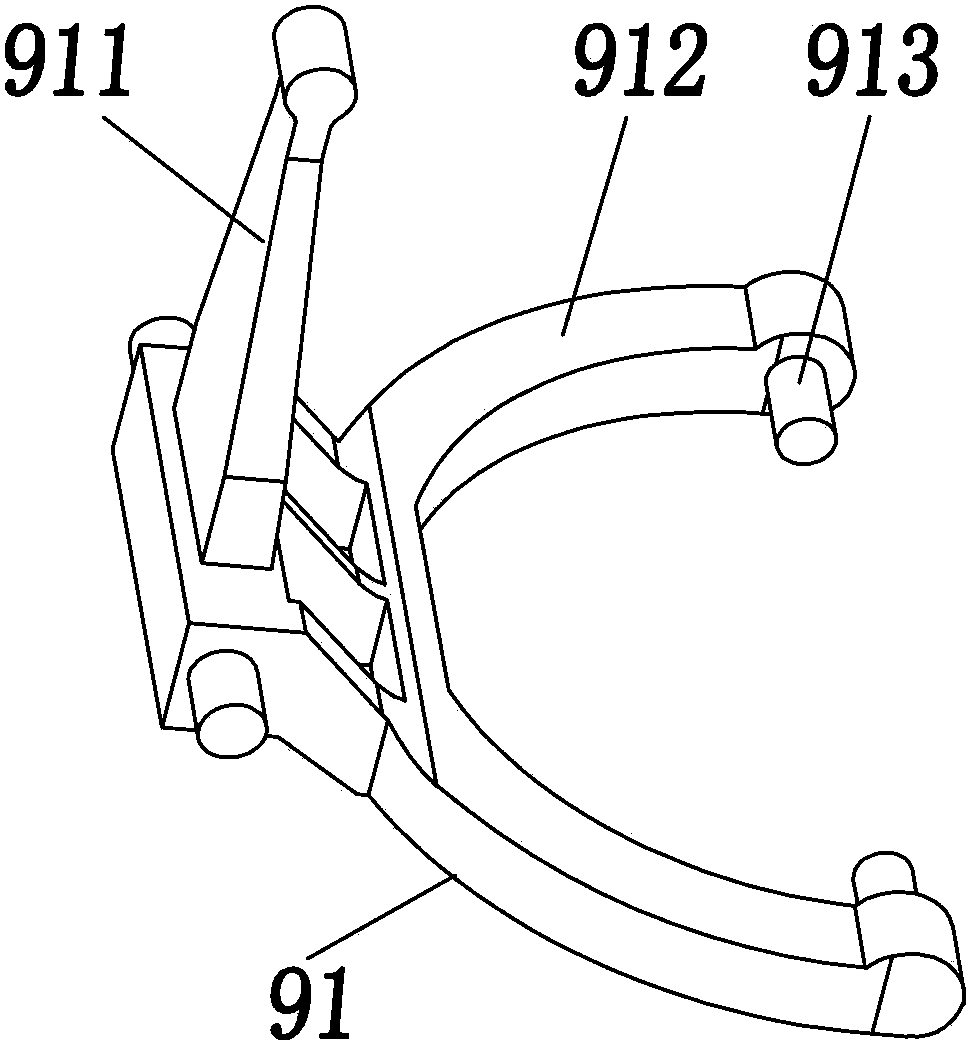

Control shaft assembly of internal gear selecting and shifting device of automobile gearbox

InactiveCN106090209ASimple structureStable transmission torqueGearing controlEngineeringAutomotive transmission

The invention relates to a control shaft assembly, and particularly relates to a control shaft assembly of an internal gear selecting and shifting device of an automobile gearbox, which belongs to the technical field of automobile gearbox equipment. The control shaft assembly comprises a control shaft, wherein a gear shifter assembly and a back three-gear shifting finger respectively sleeves the control shaft, and a first ribbing group and a second ribbing group are respectively arranged in the connecting positions of the control shaft, the gear shifter assembly and the back three-gear shifting finger; the gear shifter assembly comprises a gear shifter, a front four-gear shifting finger and a gear shifter shaft sleeve, and the gear shifter, the front four-gear shifting finger and the gear shifter shaft sleeve are connected into a whole by adopting a welding manner; a first process groove and a second process groove are respectively formed in the front and back ends of a center groove. According to the control shaft assembly, ribbing structures are formed among the control shaft, the gear shifter assembly and the back three-gear shifting finger, so that torque can be stably transferred, the installation is convenient, and the use effect is good; the first process groove and the second process groove are formed, so that the center groove is easy to form, the deformation in a forming process is greatly reduced, and the manufacturing accuracy of parts is increased.

Owner:WUXI ZHONGJIE VIBRATION ISOLATORS

A Safe Nail Roller

Currently, movable parts in a coil nail device of a coil nail machine can not be installed in a protecting cover, and the phenomenon that operators are hurt frequently occurs. According to the safe coil nail device of the coil nail machine, non-universal elements such as a duplex slide cylinder support, a bearing support, a speed reduction motor support, the protecting cover, a coupler and a coil nail shaft are manufactured through universal elements such as a duplex slide cylinder, a direct-current speed reduction motor, a constant-current drive circuit of the direct-current speed reduction motor and a bearing, then the safe coil nail device which is simple in structure, stable in running, small in size, capable of producing high-quality coil nails and free of hurting the operators can be assembled, and the safe coil nail device is used for replacing conventional coil nail devices which are widely used at present.

Owner:翟佑华

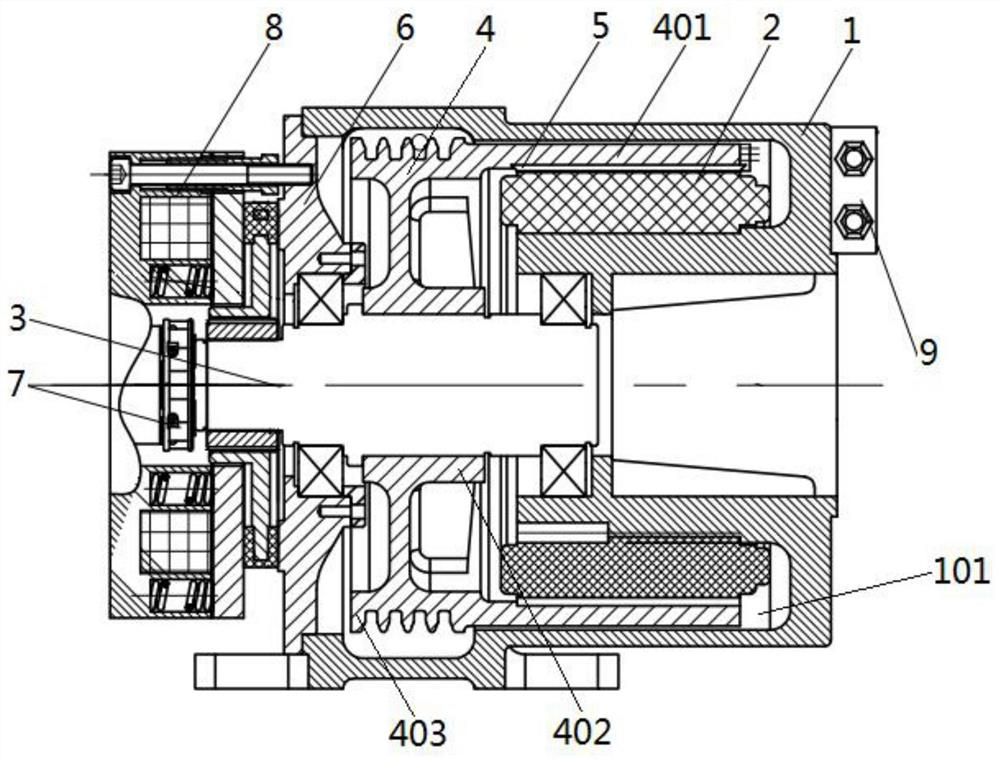

Traction machine with long service life

PendingCN112960517AReduce size thicknessAvoid rollover riskBuilding liftsRotor magnetsTorque transmission

The invention discloses a traction machine with long service life, which comprises a machine base (1), a stator iron core (2), a rotor shaft (3) and a traction wheel (4), the two sides of the rotor shaft (3) are rotationally connected with the machine base (1), the middle of the rotor shaft (3) is connected with the traction wheel (4), a rotor magnet yoke (401) is arranged outside the traction wheel (4), and the rotor magnet yoke (401) and the traction wheel (4) are integrally formed. The traction wheel is arranged in the middle of the rotor shaft, so that the connecting positions of the two ends of the rotor shaft are uniformly stressed, the working stability of the traction wheel is improved, and the required length of the rotor shaft is shortened; and the rotor magnet yoke and the traction wheel are integrally formed, and a connecting piece structure in an original traction machine can be omitted, so that the machining difficulty of equipment is reduced, and the torque transmission stability of the traction machine is improved.

Owner:ZHEJIANG MATO DRIVE EQUIP +1

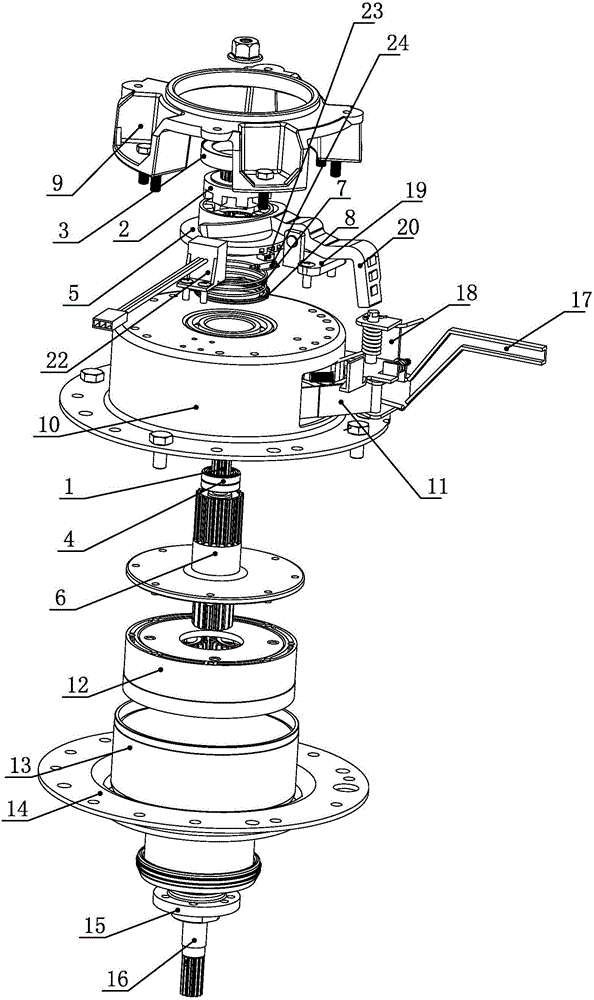

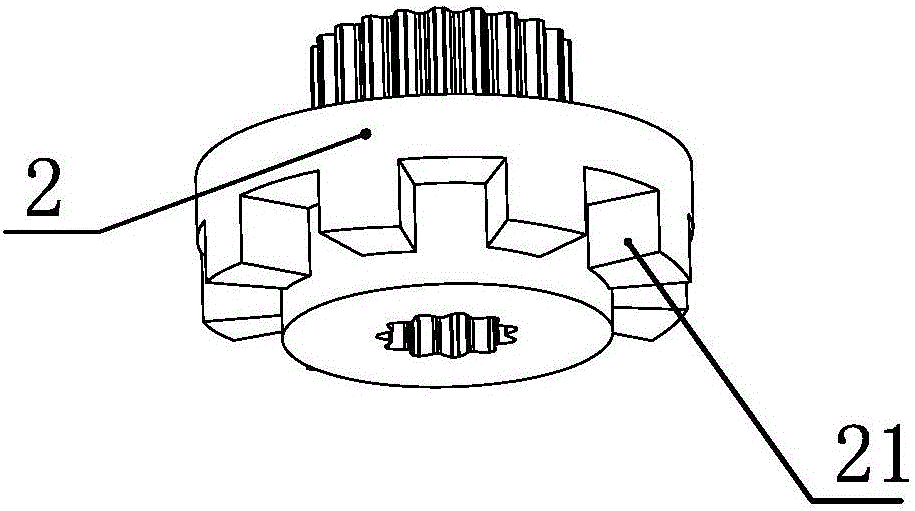

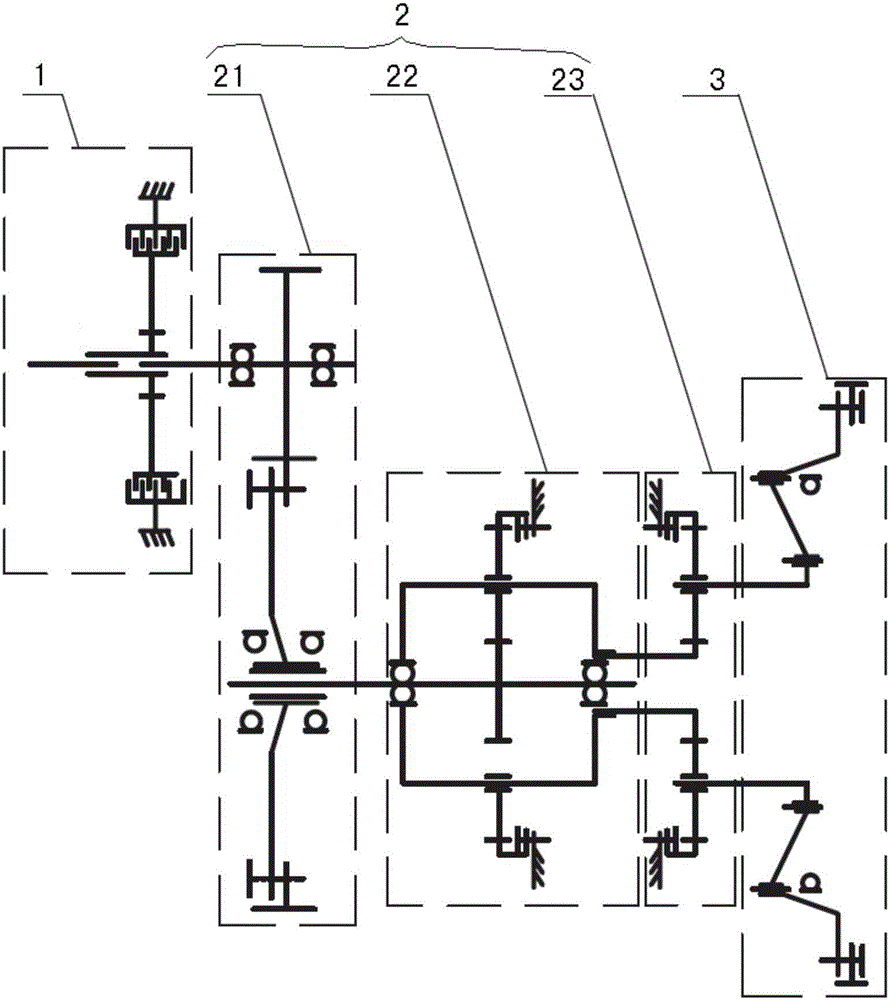

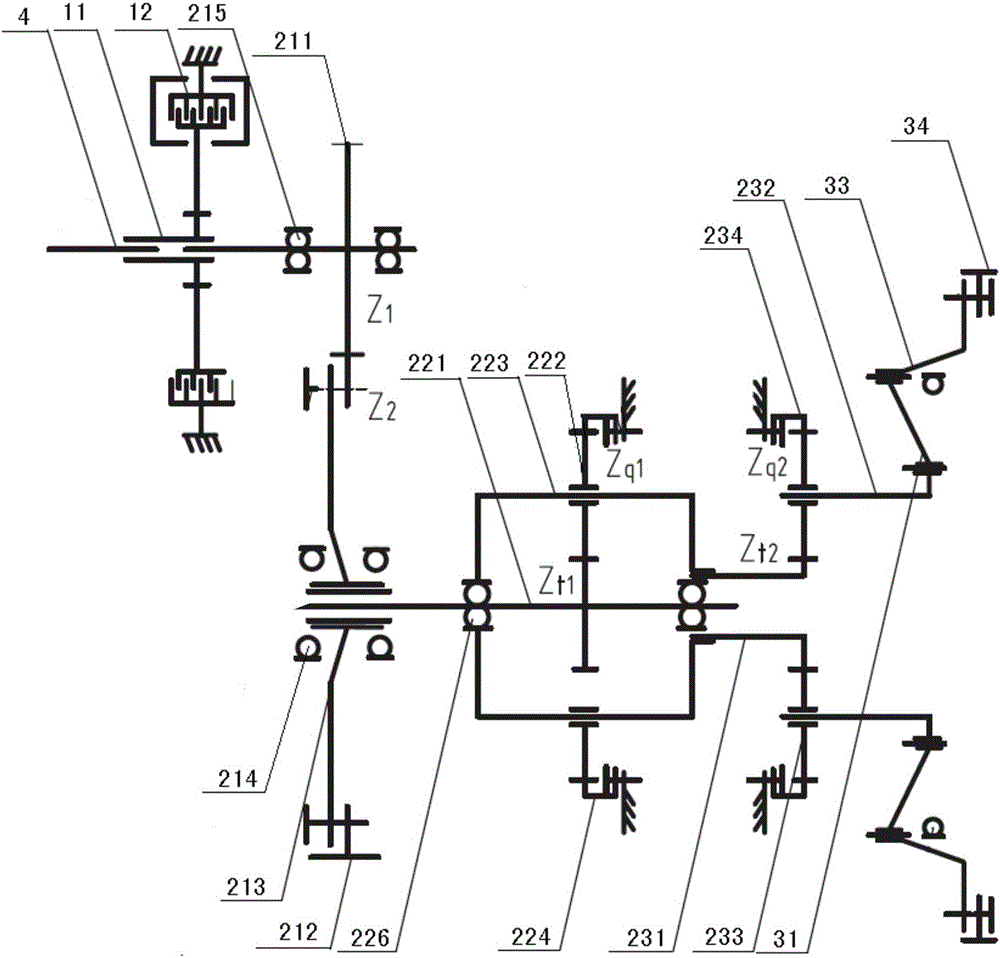

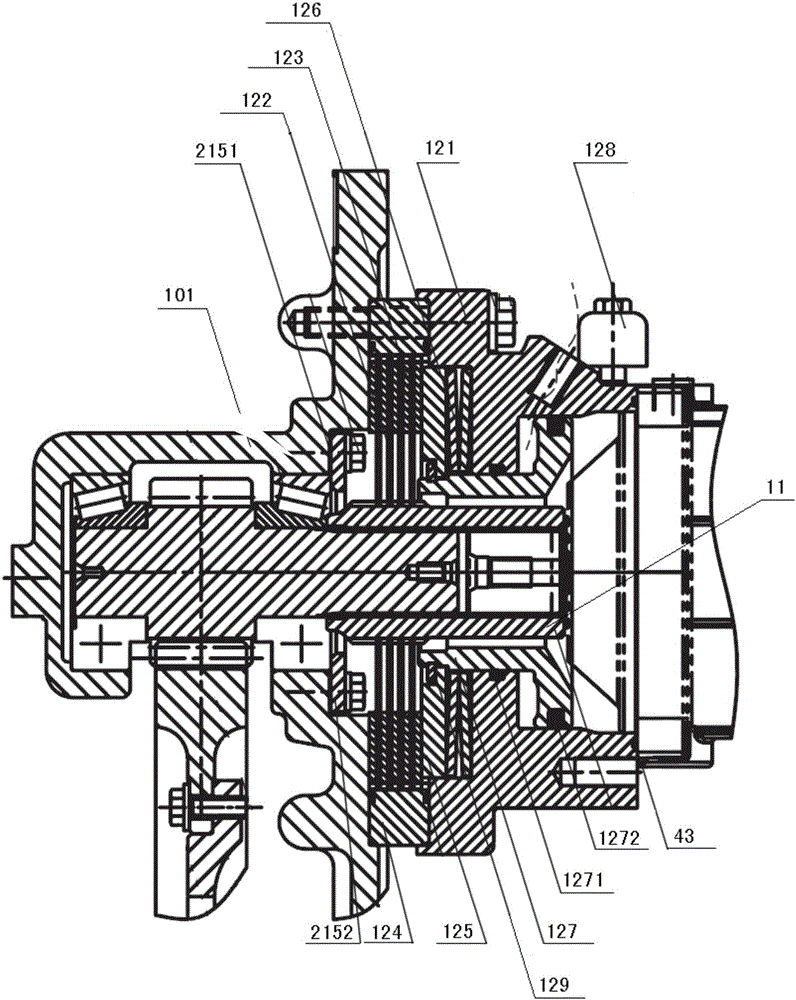

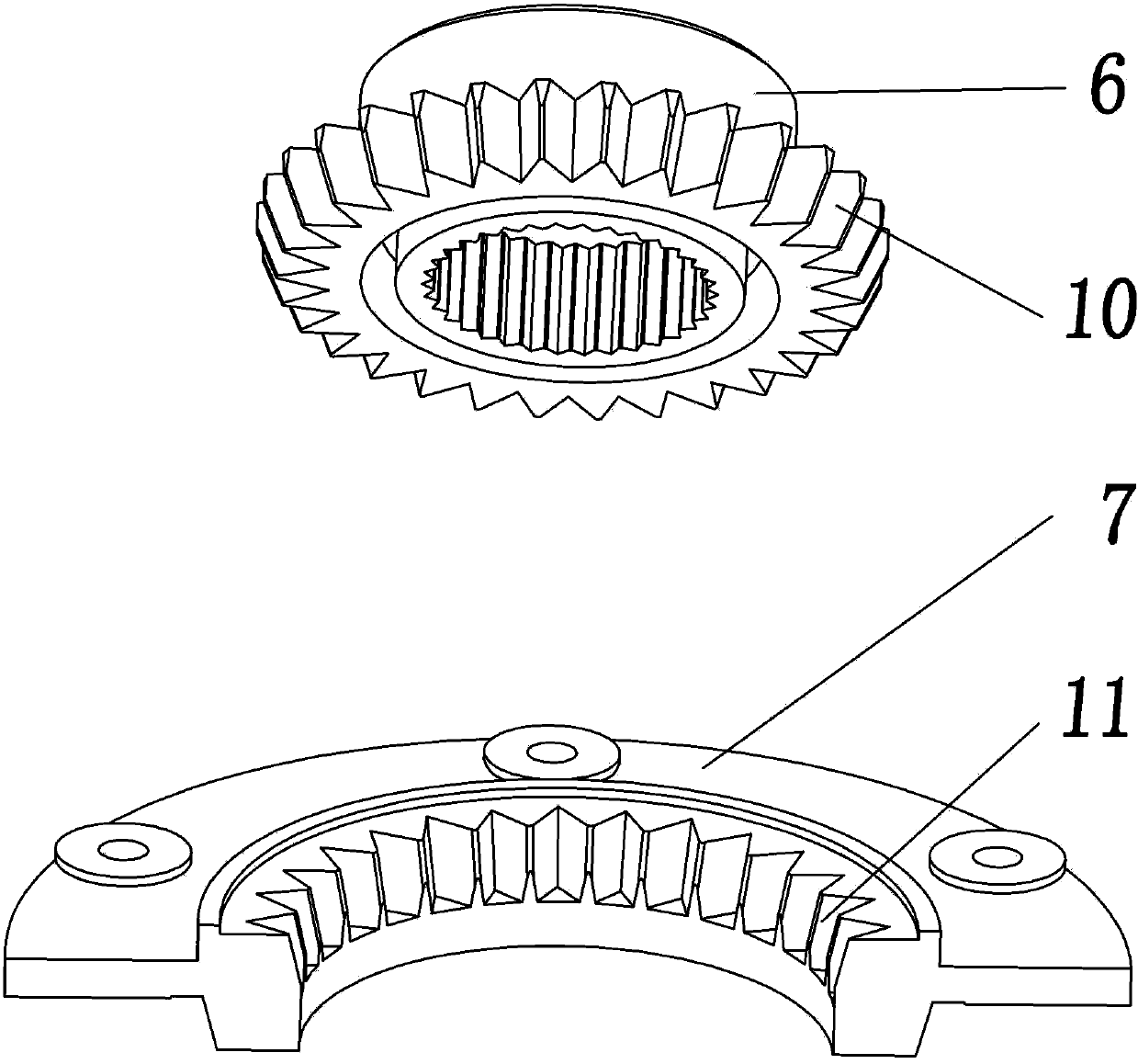

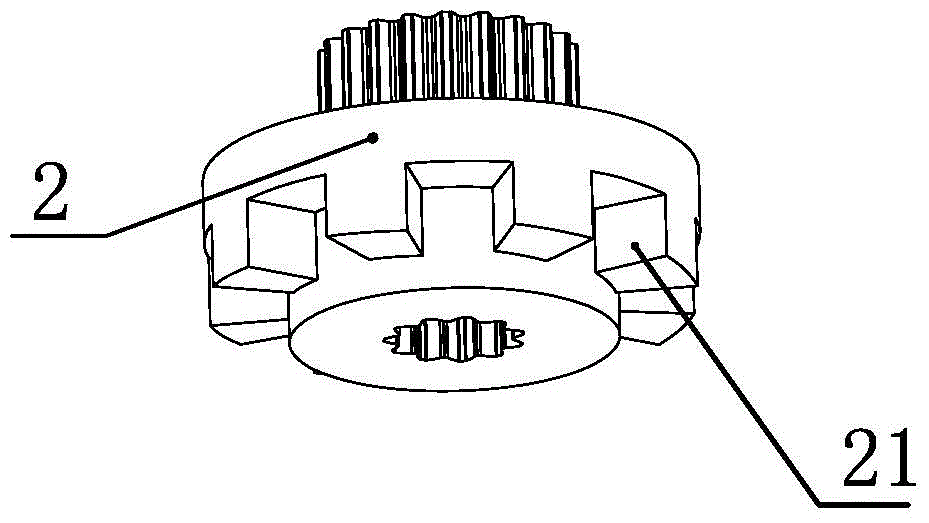

Bipyramid gear clutch driving device of washing machine and control method of bipyramid gear clutch driving device

ActiveCN102704240BCompact structureSimple structureOther washing machinesControl devices for washing apparatusDrive motorEngineering

Owner:ZHEJIANG SANXING MECHANICAL & ELECTRONICSAL STOCK

A final drive structure and bulldozer

ActiveCN106641161BMeet the needs of transmission reduction ratioLarge transmission ratioMechanical machines/dredgersGearingCouplingComputer module

The invention relates to the technical field of bulldozers and particularly relates to a final transmission structure and a bulldozer. The final transmission structure comprises a brake unit and a transmission system, wherein the transmission system comprises a first-grade speed reducing unit, a second-grade speed reducing unit and a third-grade speed reducing unit; the first-grade speed reducing unit comprises two grades of straight tooth speed reducing structures; the second-grade speed reducing unit comprises a first planet row structure; the third-grade speed reducing unit comprises a second planet row structure; and the brake unit is connected with a transmission end of a motor. The invention further relates to the bulldozer. The bulldozer comprises an engine for providing power output, a shaft coupler and a pump connected with the motor; the shaft coupler is connected with the engine and the pump respectively; and the motor is connected with the final transmission structure. The brake unit, the first-grade speed reducing unit, the second-grade speed reducing unit and the third-grade speed reducing unit are used as a large module and the large module is fixedly connected with a main rack of the bulldozer, so that the bulldozer is convenient to dismount and maintain; and a relatively large transmission ratio can be realized and the transmission torque is stable, and the final transmission structure is economical and practical and is safe and reliable.

Owner:SHANTUI CONSTR MASCH CO LTD

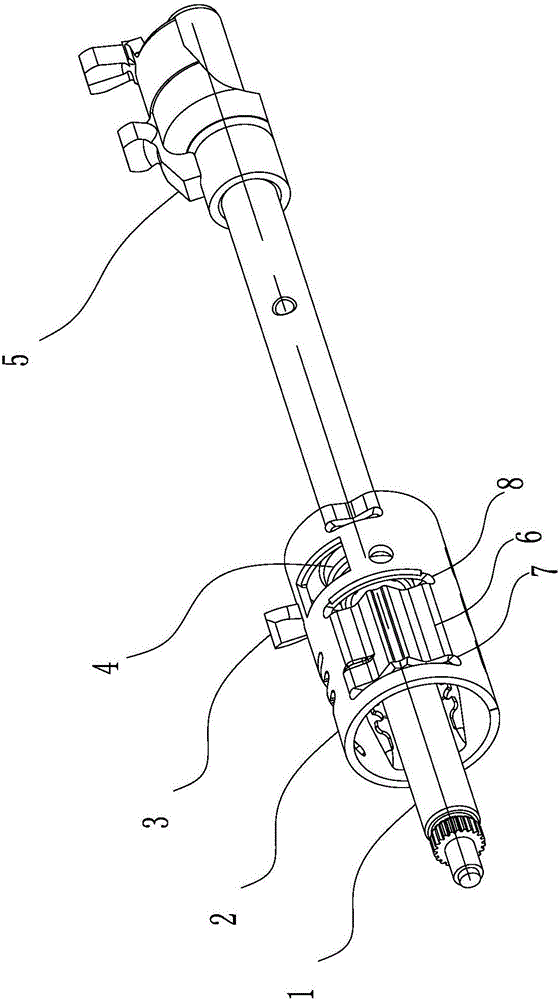

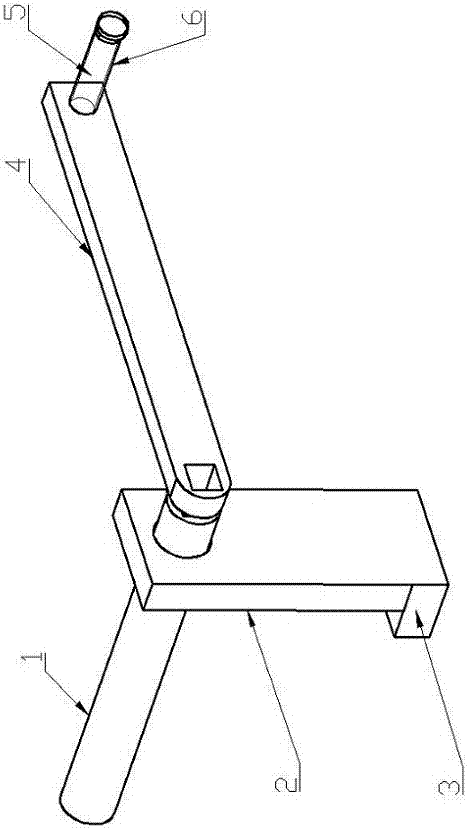

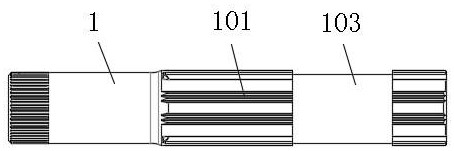

Tool for realizing rapid adjustment for fixture

InactiveCN106994665ALarge torqueStable transmission torqueMetal-working hand toolsCushionEngineering

The invention discloses a tool for realizing rapid adjustment for a fixture. The tool comprises a transfer rod (1), a support (2), a support cushion block (3), a rocker arm (4) and a crank (5), wherein the support cushion block (3) is arranged at the bottom of the support (2), a circular hole is formed in the upper part of the support (2), and the transfer rod (1) penetrates through the circular hole in the support (2); a square hole is machined in one end of the rocker arm (4), an installation hole is machined in the other end of the rocker arm (4), a journal of the transfer rod (1), which stretches out of the support (2), is arranged in the square hole in the end part of the rocker arm (4), and the crank (5) is arranged in the installation hole in the end part of the rocker arm (4); the rocker arm (4) and the support (2) are arranged in parallel; and the transfer rod (1) and the crank (5) are arranged in parallel, and the transfer rod (1) and the support (2) are vertically arranged. The tool disclosed by the invention is capable of realizing rapid adjustment, and labour-saving and time-saving.

Owner:江苏凌云恒晋汽车零部件有限公司

Spline direct-connected planetary conical disc type stepless reducer

InactiveCN101832375AManufacturing and assembly precision requirements are lowEven by forceFriction gearingsLow noiseDrive wheel

The invention relates to a spline direct-connected planetary conical disc type stepless reducer which is characterized in that the driving wheels thereof and the output shaft of a motor are in larger-gap splined connection so that the splines only transmit the torque and can be adapted to the installing and manufacturing error of the driving wheels and the output shaft of the motor. The spline direct-connected planetary conical disc type stepless reducer has the advantages of low installing and manufacturing precision requirement, strong bearing capacity, low noise and long service life.

Owner:孟凡英

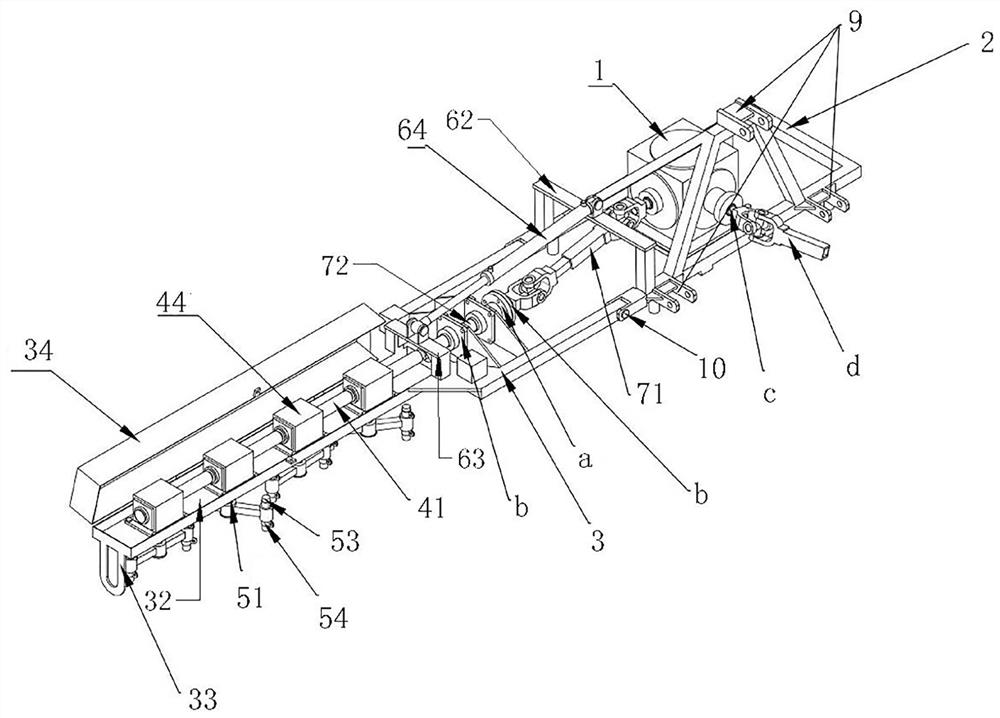

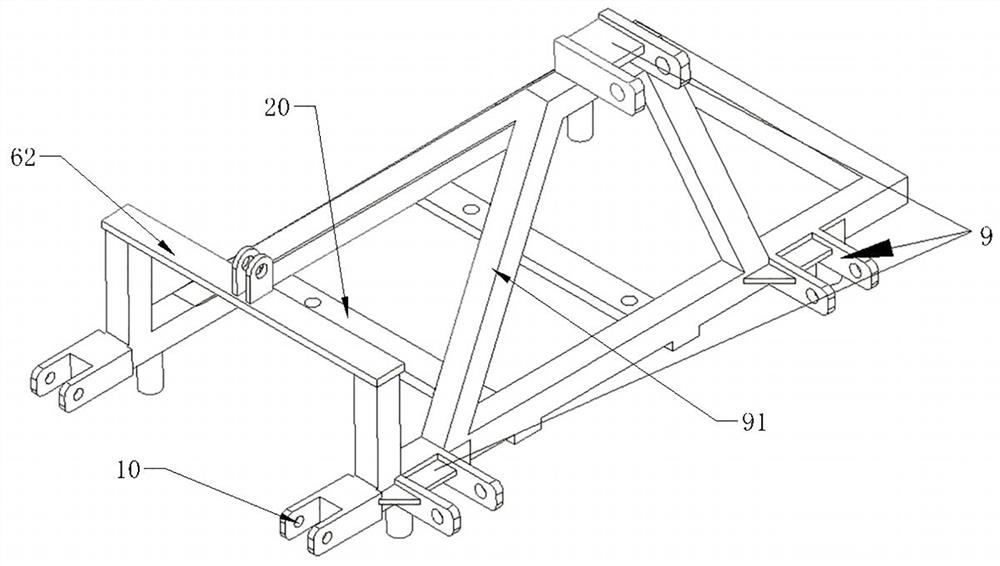

Cattle bed rotary cultivator for cattle farm

PendingCN112970597APrevent infiltrationStable transmission torqueAnimal housingAnimal scienceEngineering

The invention discloses a cattle bed rotary cultivator for a cattle farm. The cattle bed rotary cultivator for a cattle farm comprises a driving mechanism, the driving mechanism is provided with a speed reducer in a matching way, the speed reducer is fixedly arranged on a fixed rack, one end of the fixed rack is fixedly connected with a movable long arm frame, a height adjusting assembly is arranged between the fixed rack and the movable long arm frame, a driven mechanism is fixedly arranged on the movable long arm frame, a synchronous transmission mechanism matched with the height adjusting assembly is arranged between the driven mechanism and the speed reducer, and the driven mechanism is fixedly connected with a matched stirring assembly. The height adjusting assembly is arranged to realize height adjustment of the movable long arm frame, such that design standards of cattle beds in different pastures are met.

Owner:ANJI TIANYOU COMPLETE EQUIP

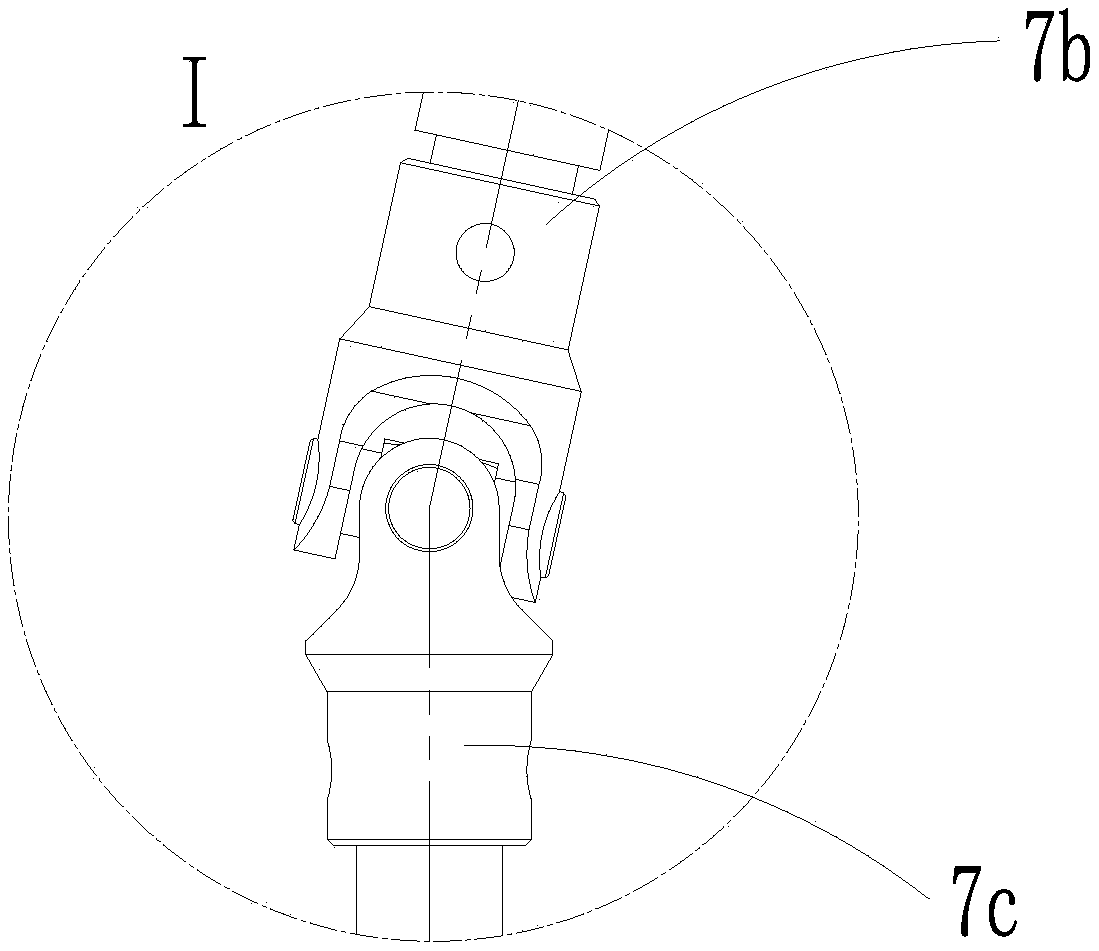

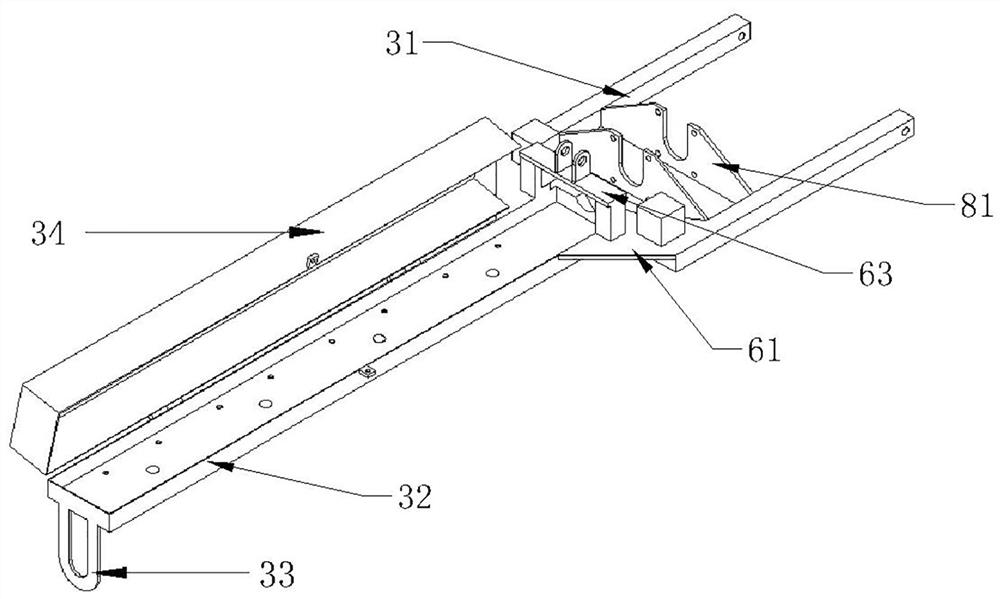

Steering shaft and ball frame structure for transmitting torque

ActiveCN113619677AFully lubricatedReduce wearSteering columnsLubricating systemTorque transmissionStructural engineering

The invention discloses a steering shaft and ball frame structure for transmitting torque; the structure comprises spline shafts arranged in a spline pipe, the outer side wall of each spline shaft is provided with an outer spline and a first arc-shaped roller path, the inner wall of the spline pipe is provided with an inner spline and a second arc-shaped roller path which are matched with the spline pipe, and steel balls are arranged between the first arc-shaped roller path and the second arc-shaped roller path. An annular groove is formed in the position, located at the outer spline, of the outer side wall of each spline shaft, a steel ball retainer is arranged at the position, corresponding to the annular groove, between the spline shafts, the steel ball retainer comprises arc-shaped frame bodies, and the arc-shaped frame bodies are embedded in the positions, located at the first arc-shaped roller paths, of the spline shafts. Containing grooves are formed in the arc-shaped frame bodies. The steering shaft and ball frame structure has the advantages that a complex surface structure can be guaranteed to the maximum extent, assembly can be facilitated, the strength can be guaranteed, steel balls are lubricated more sufficiently, torque transmission is more stable, the service life is long, and the risk that the retainer is disengaged can be effectively prevented.

Owner:YUBEI CSA XINXIANG AUTO TECH CO LTD

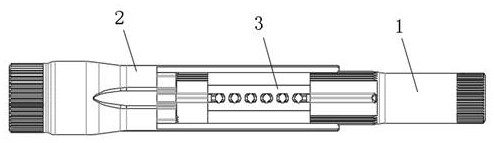

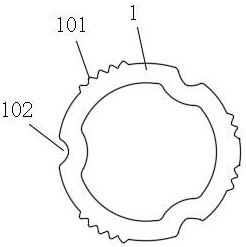

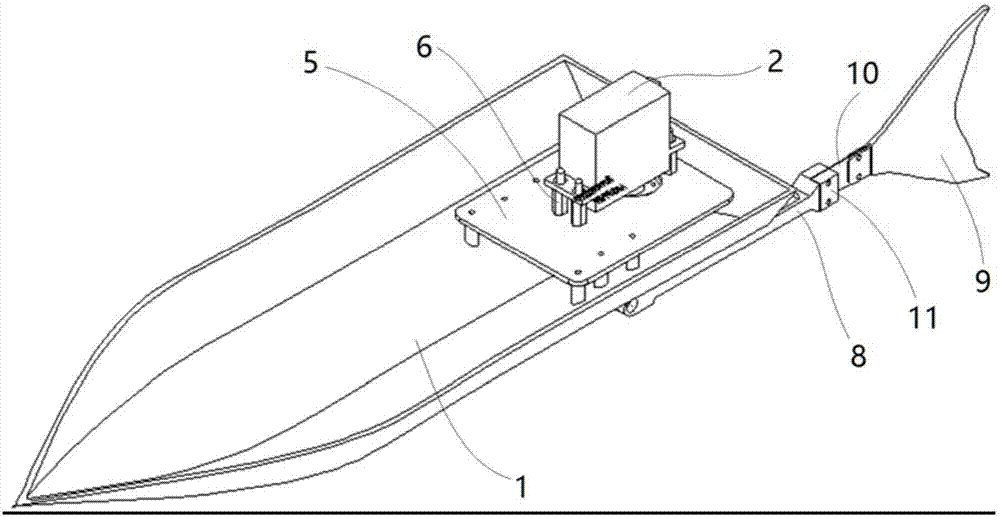

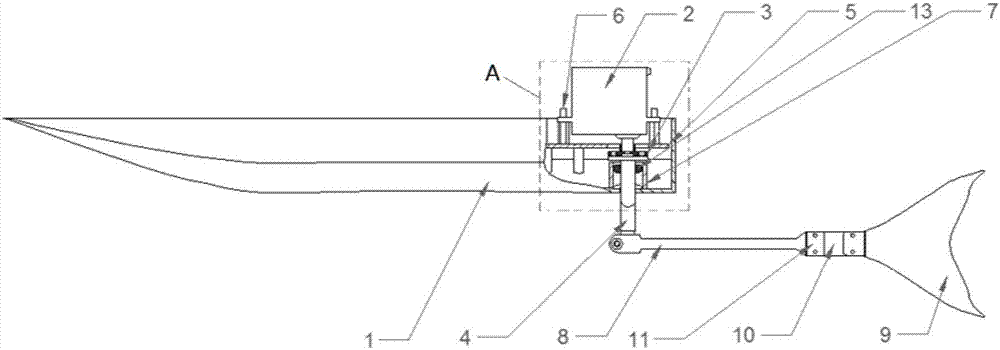

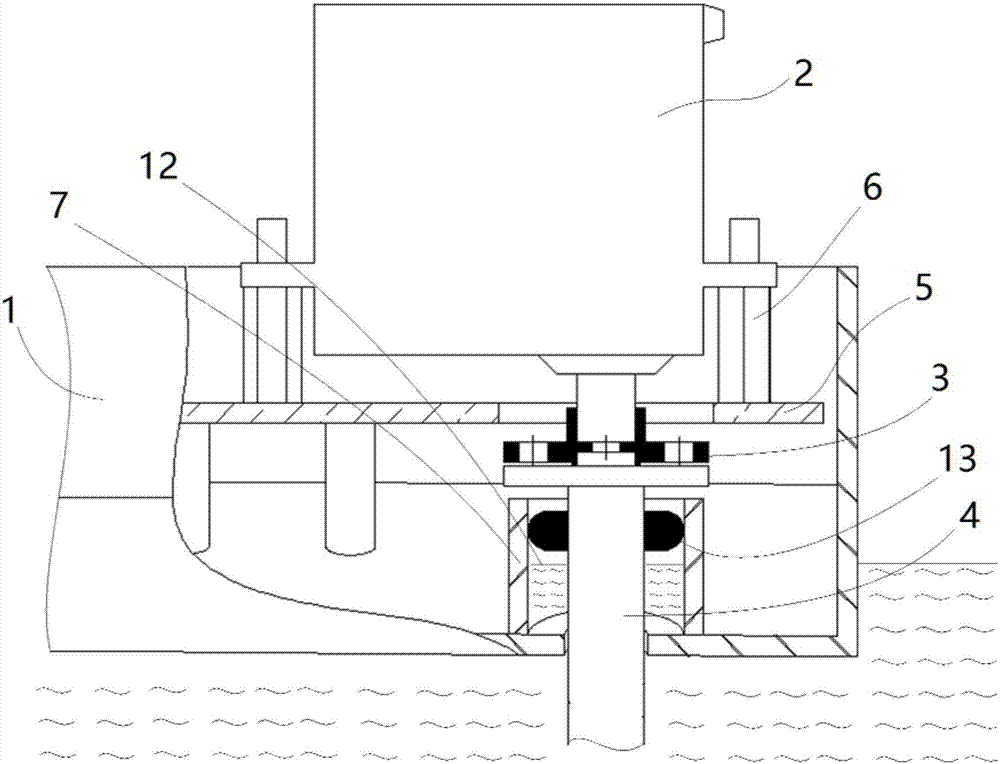

Robotic fish used for tail fin impetus research

InactiveCN108001653AEasy to changeEasy to disassemblePropulsive elements of non-rotary typeTransmission with mechanical gearingUnderwaterPrism

The invention discloses a robotic fish used for tail fin impetus research. A tail board, an elastic sheet and a tail handle are equivalent to a fishtail, a hull floats on the water surface, and the tail board, the elastic sheet and the tail handle extend underwater through a transmission column. The simple self-waterproof robotic fish is provided, the tail board, the elastic sheet and the tail handle are equivalent to the fishtail, the hull floats on the water surface, the tail board, the elastic sheet and the tail handle extend underwater through the transmission column, the front end of thetail handle is connected with a rectangular prism structure at the lower end of the transmission column through a clamping part, the effects that detachment is convenient and the driving torque is stable are achieved, the rear end of the tail handle is connected with the tail board through the elastic sheet, the elastic sheet is arranged to imitate flexible swings of the fishtail, and the swing frequency and the swing range of the tail handle are adjusted through a steering engine. The requirement for tail fin impetus research is met through the structure, the structure is simple, detachment and installation are convenient, cost is low, and a variable can be changed conveniently.

Owner:ZHENGZHOU LONGWEI ELECTRONICS TECH CO LTD

A deceleration clutch of an intelligent washing machine

ActiveCN105019192BReliable clutchExtended service lifeOther washing machinesTextiles and paperTorque transmissionEngineering

The invention discloses a decelerating clutch of an intelligent washing machine. The decelerating clutch comprises an upper shell, a lower shell, a connection plate, a torque transmission shaft sleeve and a brake wheel axle. The connection plate is arranged on the brake wheel axle in a sleeving mode. The connection plate is provided with a magnet, a Hall sensor is arranged on the lower end face of the lower shell, the position of the Hall sensor is matched with the position of the magnet, and a gap is reserved between the Hall sensor and the magnet. First splines are arranged on the outer surface of the brake wheel axle, second splines matched with the first splines are arranged on the inner surface of an inner hole of the connection plate, third splines are arranged on the lower end portion of the connection plate, and fourth splines matched with the third splines are arranged on the upper end portion of the torque transmission shaft sleeve. A connection plate spring and a spring gland are arranged at the upper end of the connection plate. The spring gland is located at the upper end of the connection plate spring, and the spring gland abuts against the lower shell. According to the technical scheme, the decelerating clutch of the intelligent washing machine is reasonable in structural design, simple in structure, convenient to assemble, reliable in clutch action, stable in torque transmission and high in safety.

Owner:ZHEJIANG SANXING MECHANICAL & ELECTRONICSAL STOCK

Planetary reducer for DELTA robot

The invention provides a planetary reducer for a DELTA robot. The planetary reducer fixes a crossed roller bearing on a front shell through an output shaft and a first-stage planetary retainer; a second set screw connects the output shaft and the first-stage planetary retainer integrally to fix the crossed roller bearing in the axial direction; as the crossed roller bearing is small in size and large in axial (front and rear directions) bearing force, only one crossed roller bearing is adopted to enable the planetary reducer to obtain larger axial bearing force and smaller axial length; and the first-stage planetary retainer adopts a four-planet structure to improve the transmission precision and the transmission torque of the reducer so as to obtain a larger reduction ratio. Compared withthe existing planetary reducer, the planetary reducer provided by the invention is larger in bearing force and higher in precision, solves the problems that the existing planetary reducer is small inaxial bearing force, large in size, insufficient in precision, smaller in torque and short in service life and has better application in the industry of the DELTA robots.

Owner:SHAZHOU PROFESSIONAL INST OF TECH

Novel overrunning clutch comprising magnetorheological fluid

PendingCN107830080ACompact structureStable transmission torqueFluid clutchesFreewheel clutchesDrive shaftMagnetorheological fluid

A novel overrunning clutch comprising a magnetorheological fluid comprises a gear shaft, a second gear and an input shaft; a groove is inwards formed in the end surface of a first gear at one end of the gear shaft, one end of the input shaft penetrates through a gland and then extends into the groove, a driven disk is mounted at the end, and the gland covers the groove and is mounted on the end surface of the first gear; the second gear is used as an output piece and is fastened at a shaft shoulder in the middle of the input shaft through a flat key and a spring retaining ring for a shaft; anannular excitation coil is mounted on the inner side surface of the groove sealed by the gland and is filled with the magnetorheological fluid; multiple first sealing rings are arranged between the end surface of the first gear and the gland; multiple second sealing rings are arranged between the gland and the input shaft; multiple electric conduction rings are arranged on a transmission shaft ofthe gear shaft; a lead of the excitation coil is connected with an electric brush; and the electric brush is mounted on a gearbox body and makes contact with the electric conduction rings. The overrunning clutch is simple and compact in structure and can perform real-time meshing or separation according to transmission requirements.

Owner:LUOYANG INST OF SCI & TECH

A Clutch Engagement Adaptive Control Method Based on Statistical Theory

Owner:FAW JIEFANG AUTOMOTIVE CO

Mineral water bucket water filling bucket opening sealing device

InactiveCN106809780ASimple structureEasy to useThreaded caps applicationTorque transmissionEngineering

The invention discloses a sealing device for the mouth of a mineral water barrel, which is characterized in that it comprises a cylinder, a piston rod, a working head bracket, a bearing sleeve, a magnetic field coil, a steam inlet, a driven disk cover, a transmission shaft, and a working head; The transmission rotating shaft is installed in the end of the power input shaft through a bearing socket, the driven disk is socketed and fixed on the transmission rotating shaft, and the rotating head mechanism fixing seat is installed on the outer end surface of the driven disk; the working head It is threadedly connected and fixed with the piston rod of the cylinder, the working head is cup-shaped, the working head bracket is used for fixing the cylinder, the upper chamber is provided with a magnetic field coil, and the magnetic field coil is externally connected with a magnetic field generator, and the lower chamber is provided with There is a steam inlet, which is externally connected with a steam generator. The invention has the advantages of simple structure and convenient use, and realizes cap screwing torque by adjusting the magnitude of the magnetic force, and the transmission torque is relatively stable.

Owner:王柳杨

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com