Self-learning optimization method and system for half-engagement point of wet double clutch

A wet dual-clutch, half-joint technology, applied in the direction of clutches, mechanical equipment, etc., can solve problems such as poor low-speed torque control performance, and achieve the effect of eliminating adverse effects and good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

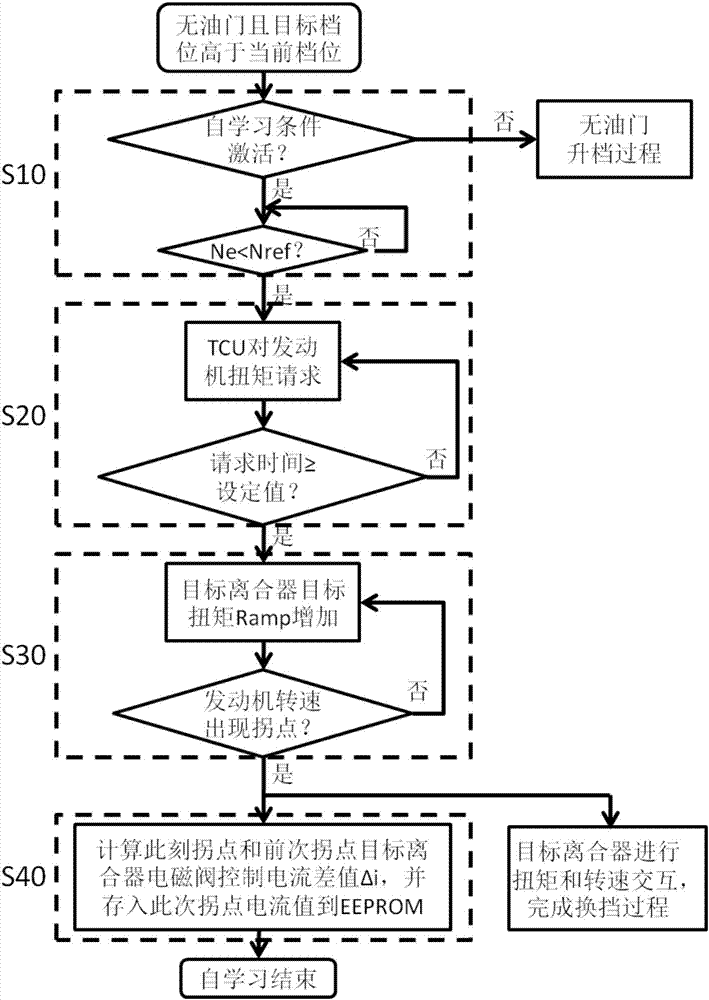

[0025] This embodiment is used for the hybrid electric vehicle of wet dual-clutch, and its method for self-learning optimization of odd-numbered clutch semi-joint points comprises the following steps:

[0026] The driver drives the vehicle with an accelerator of about 30%. When the vehicle speed reaches 35Km / h, the accelerator pedal is completely released. At this time, the vehicle will enter the process of upgrading from 2nd gear to 3rd gear without accelerator.

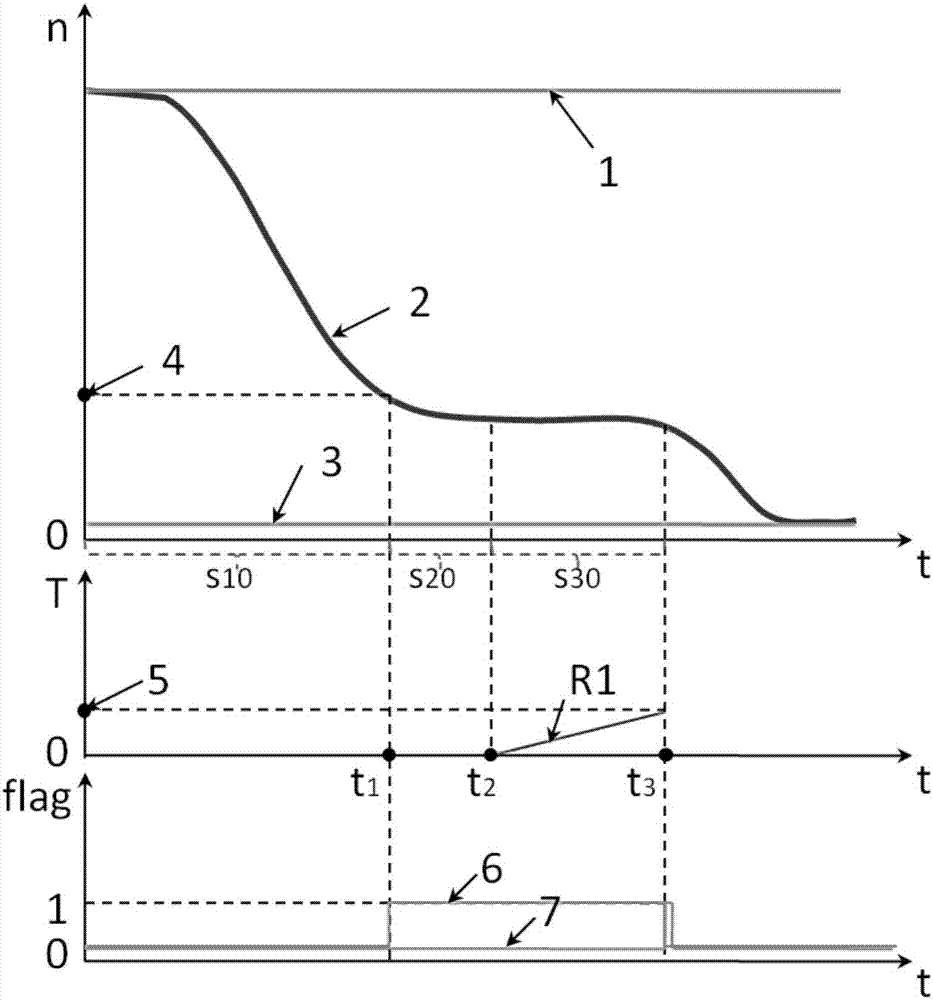

[0027] Stage S10: When the vehicle is in the process of upshifting without throttle, when it detects that the engine speed has dropped to the reference speed of 1888.6rpm / min under the action of the drag torque, the TCU will set the torque request flag and pass the torque request value 3Nm through the controller The LAN bus is sent to the engine controller;

[0028] Stage S20: After the engine receives the torque request flag from the TCU, the engine output torque is about 3Nm at this time. After this torque is bala...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com