Angle-adjustable rose reamer applied to different pore diameters

A technology of chamfering knife and angle, which is applied in the field of chamfering knife, can solve problems such as chamfering cannot be guaranteed stably, many rows, poor versatility, etc., and achieve the effect of stepless adjustment of hole diameter and stable transmission of torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

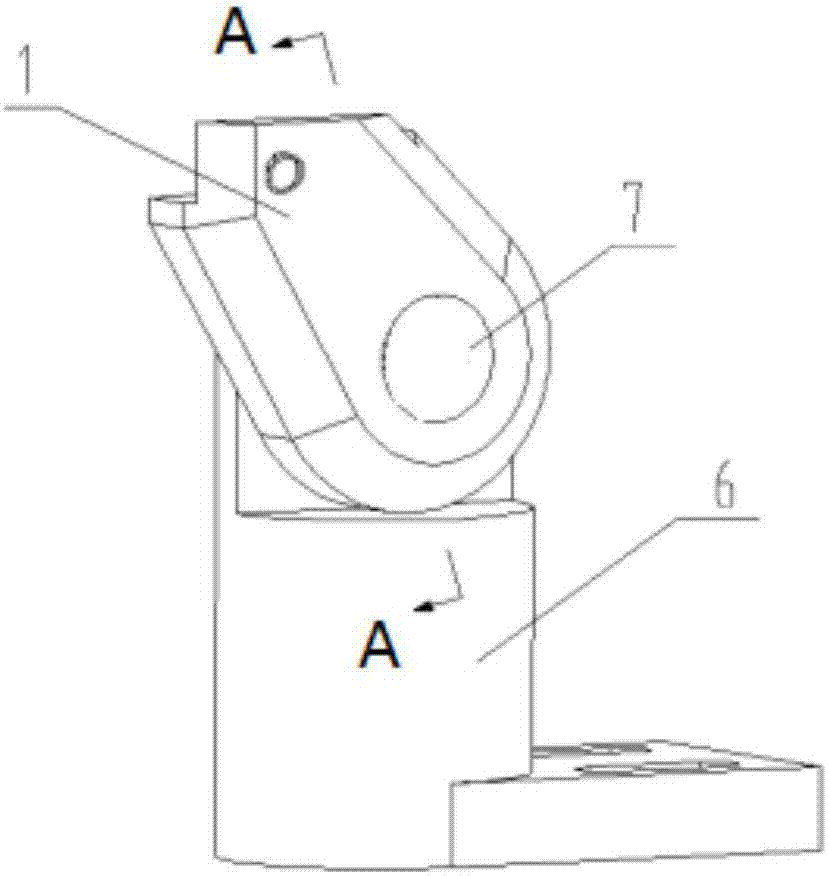

[0029] Embodiment one: see Figure 1 to Figure 6 , the described chamfering knife applicable to different aperture angles, comprising a knife seat member, a knife plate 1 matched and connected to the knife seat member, a knife holder 3 matched and connected to the knife plate, and a knife holder 3 matched and connected to the knife seat The blade 5 on the clip, its outstanding substantive features are:

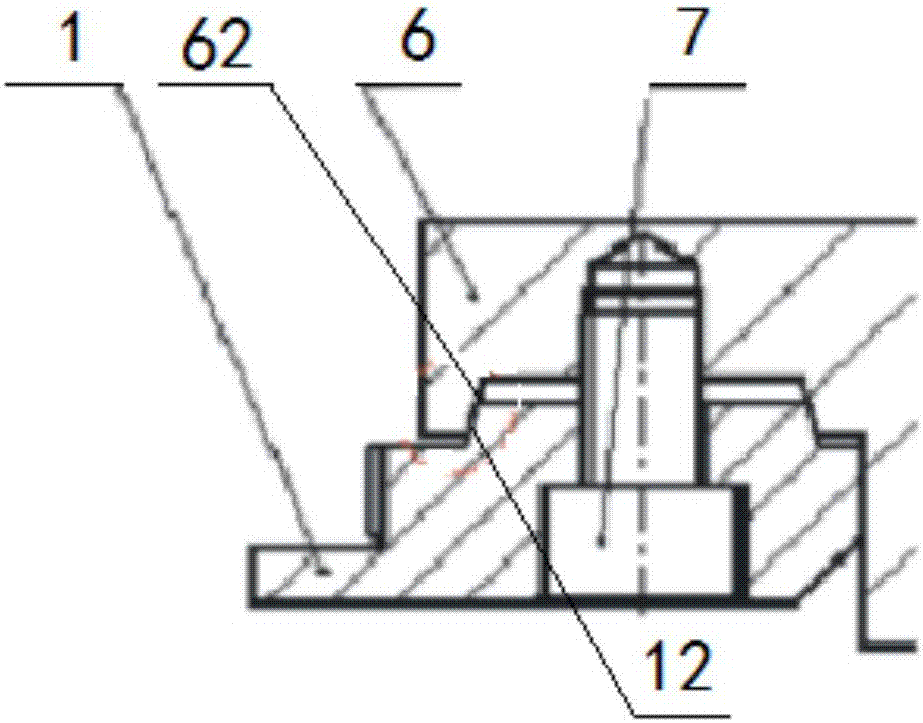

[0030] The knife seat member is a slide plate type knife handle 6, and its connection part is provided with an inner arc cone surface 62 and a screw hole 61, the axis line of the screw hole coincides with the axis line of the inner arc cone surface;

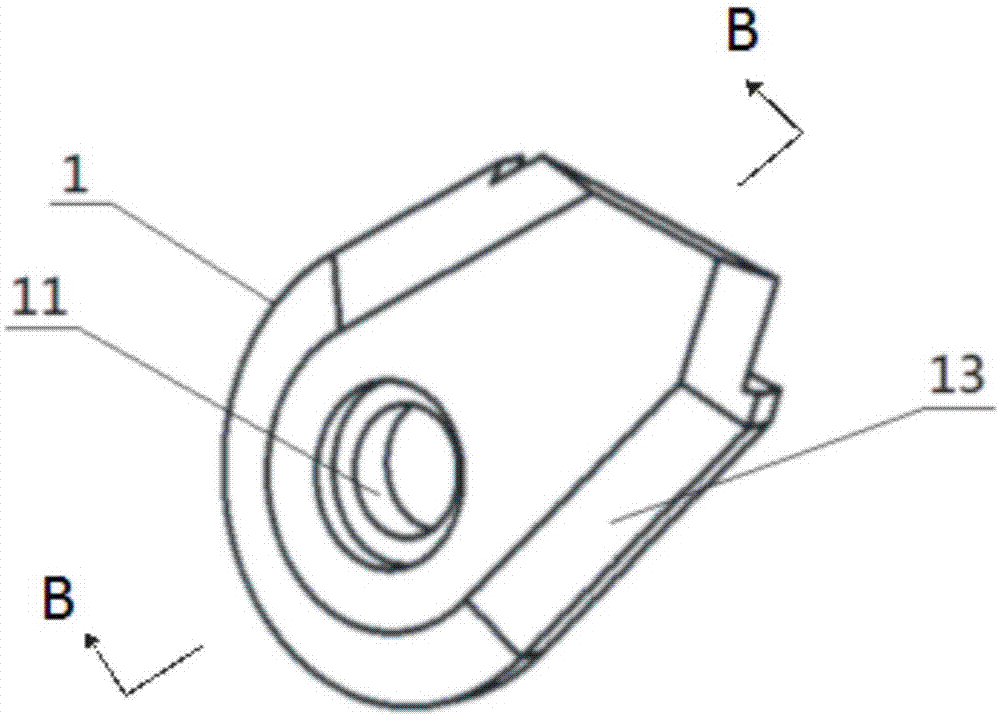

[0031] A conical boss 12 and a stepped hole 11 are provided at the lower part of the knife plate 1, the axis of the stepped hole coincides with the axis of the conical boss;

[0032] The knife plate 1 is connected with the screw hole 61 on the slider handle 6 through the stepped hole 11 through which the first compression screw ...

Embodiment 2

[0037] Embodiment two: see Figure 1 to Figure 7 , the knife seat member is a universal interface knife seat 8; the rest of the structure is the same as that of the first embodiment.

[0038] The universal interface tool holder is mainly used for chamfering small diameter holes, and the slide plate tool holder is mainly used for chamfering large diameter holes with the bridge tool holder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com