Mineral water bucket water filling bucket opening sealing device

A sealing device and mineral water technology, applied in the direction of threaded bottle caps, etc., can solve the problems of unstable packaging quality, long packaging time, and low productivity, and achieve the effects of simple structure, stable transmission torque, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

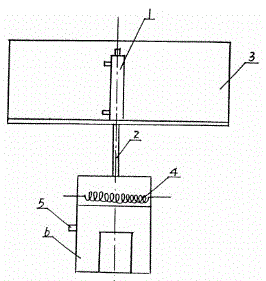

[0010] like figure 1 As shown, the technical scheme of the present invention is: a barrel mouth sealing device for mineral water barrels, which is characterized in that it includes a cylinder, a piston rod, a working head bracket, a bearing socket, a magnetic field coil, a steam inlet, a driven disk socket, a transmission a rotating shaft and a working head; the transmission rotating shaft is sleeved and installed in the end of the power input shaft through a bearing, the driven disk is sleeved and fixed on the transmission rotating shaft, and the rotating head mechanism fixing seat is installed outside the driven disk end face.

[0011] To further illustrate, the working head is threadedly connected and fixed with the piston rod of the cylinder, the working head is in the shape of a cup, and the working head bracket is used for fixing the cylinder.

[0012] To further illustrate, the upper cavity is provided with a magnetic field coil, the magnetic field coil is externally c...

Embodiment 2

[0014] like figure 1 As shown, the technical scheme of the present invention is: a barrel mouth sealing device for mineral water barrels, which is characterized in that it includes a cylinder, a piston rod, a working head bracket, a bearing socket, a magnetic field coil, a steam inlet, a driven disk socket, a transmission a rotating shaft and a working head; the transmission rotating shaft is sleeved and installed in the end of the power input shaft through a bearing, the driven disk is sleeved and fixed on the transmission rotating shaft, and the rotating head mechanism fixing seat is installed outside the driven disk end face.

[0015] To further illustrate, the working head is threadedly connected and fixed with the piston rod of the cylinder, the working head is in the shape of a cup, and the working head bracket is used for fixing the cylinder.

[0016] To further illustrate, the upper cavity is provided with a magnetic field coil, the magnetic field coil is externally c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com