Patents

Literature

35results about How to "Avoid rollover risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

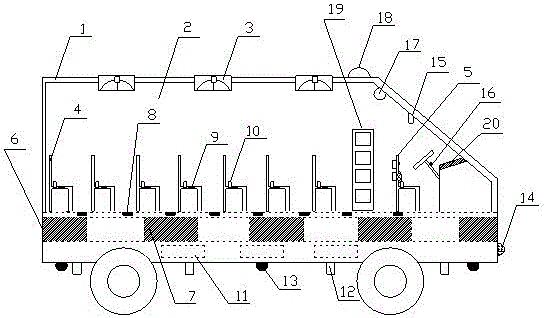

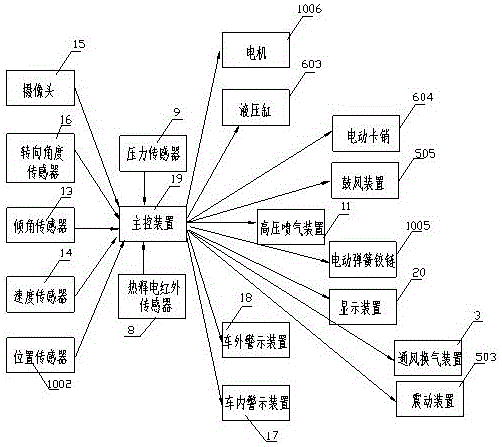

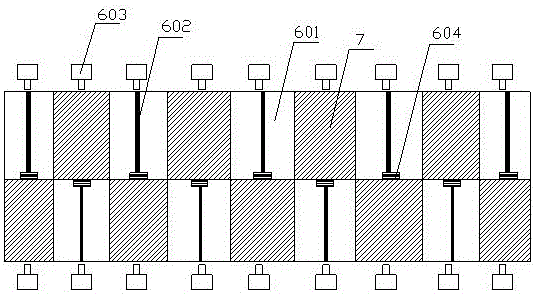

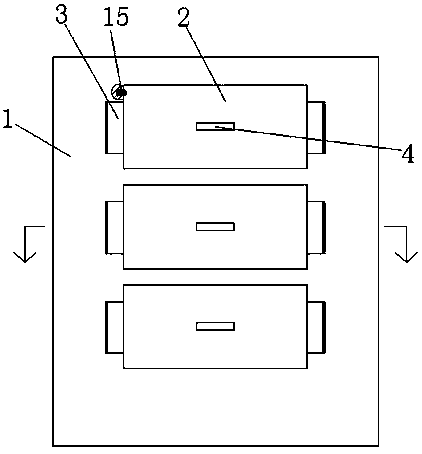

Safety system of school bus

InactiveCN105946771AReduce life riskReduce security risksVehicle body stabilisationPedestrian/occupant safety arrangementDriver/operatorSafe system

The invention discloses a safety system of a school bus. The safety system of the school bus comprises a bus body and a compartment. Passenger seats and a driver seat are arranged in the compartment. The safety system of the school bus is characterized by comprising a passenger locking prevention device, safety belt self-locking devices, a rollover prevention device, a driver state monitoring device and a main control device. By means of the passenger locking prevention device, the situation that a bus is locked when not all passengers leave the bus is effectively avoided, and ventilation, warning and other operations can be conducted automatically once it is found that passengers are trapped in the bus so that the life risk of the passengers trapped in the bus can be reduced; the potential safety hazard caused when a passenger does not tightly lock a safety belt is reduced through the safety belt self-locking devices; the rollover risk of the bus is reduced through the rollover prevention device; and the driver state monitoring device monitors the driving state of a driver and reminds the driver in time, and accordingly the situation that safety accidents are caused due to impaired concentration of the driver is avoided. Thus, the safety performance of the school bus can be greatly improved, the probability of occurrence of safety accidents is lowered, and the practical value is extremely high.

Owner:SOUTHWEST UNIVERSITY

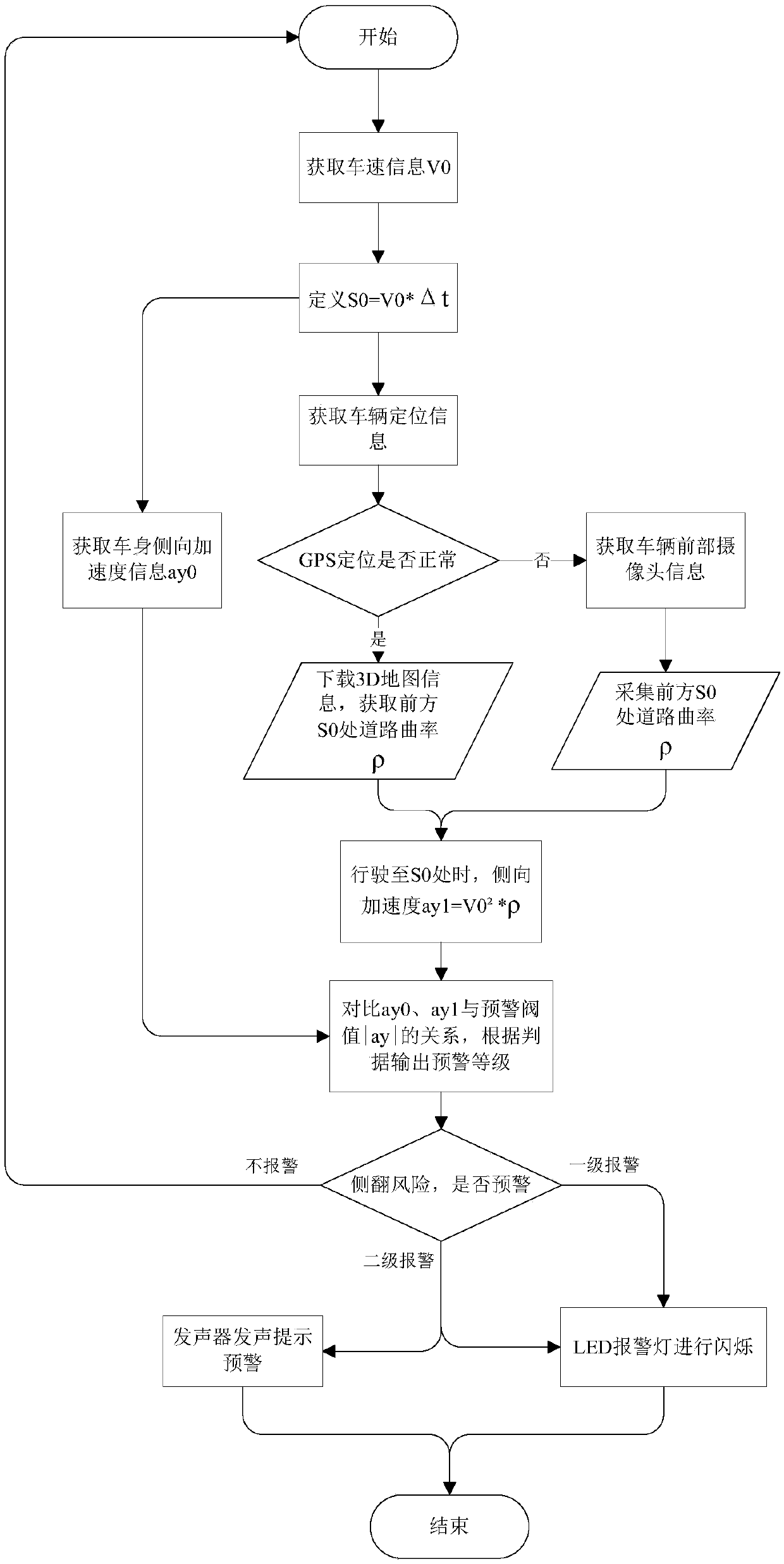

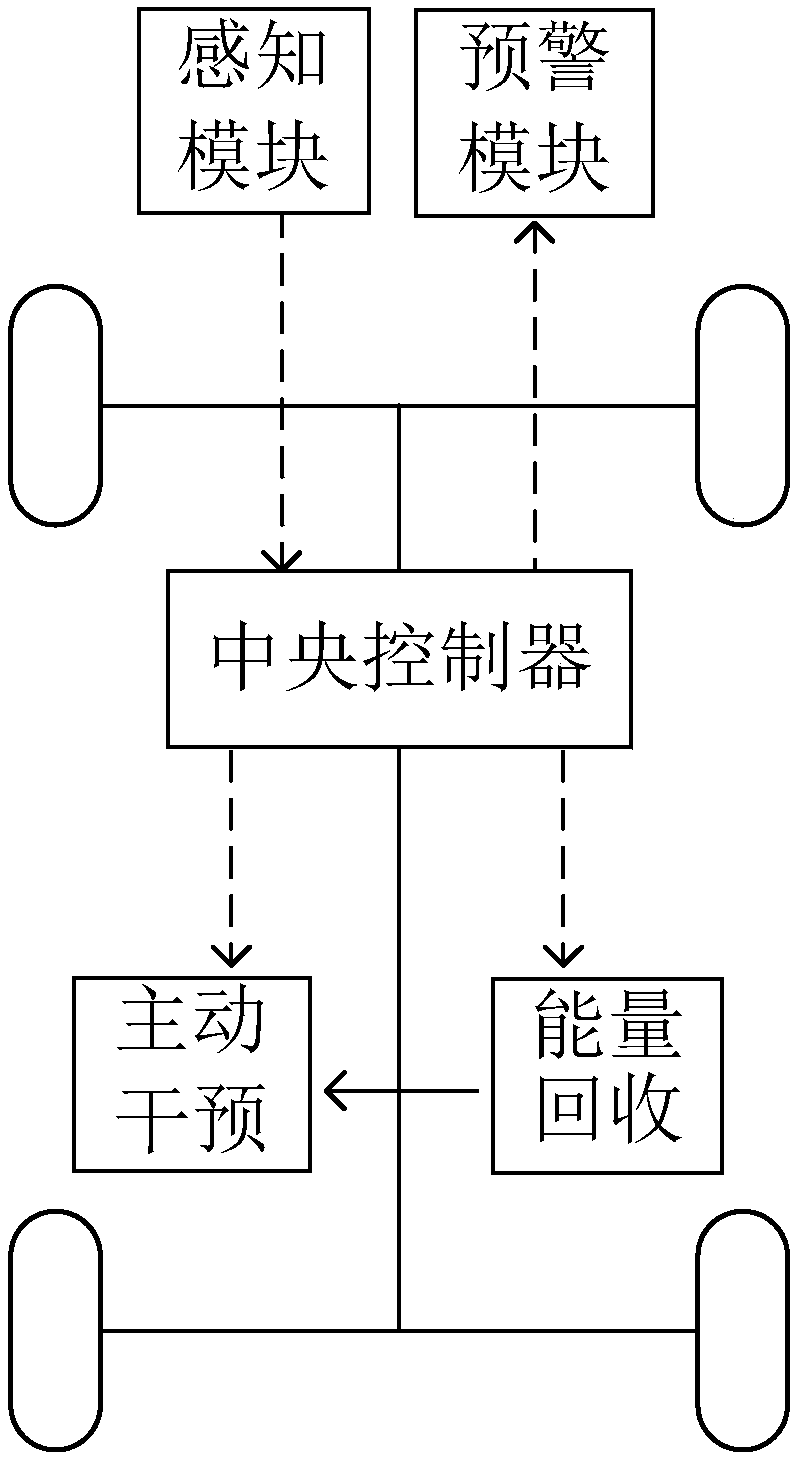

Rollover warning control method and system

The invention relates to a rollover warning control method and system. The method includes the steps: firstly, acquiring road curvature information of a front set distance and current vehicle speed information, calculating the lateral acceleration of a vehicle after corresponding time according to the vehicle speed information and the road curvature information and taking the lateral accelerationas predicted lateral acceleration; secondly, judging the size relationship between set alarm threshold acceleration and the actual lateral acceleration and the predicted lateral acceleration of the current vehicle, and giving an alarm according to judgment results and corresponding data. The rollover warning control method is a prediction method and has perceptiveness, rollover risks caused by a front road are predicted before the vehicle reaches the front road, and the rollover risks caused by the severe degree of a front working condition is estimated in advance. When existence of the rollover risks is estimated, an alarm is given to remind a driver of corresponding operation, so that potential risks are controlled, the potential rollover risks are further avoided, rollover can be maximally avoided, and safety running of the vehicle is ensured.

Owner:ZHENGZHOU YUTONG BUS CO LTD

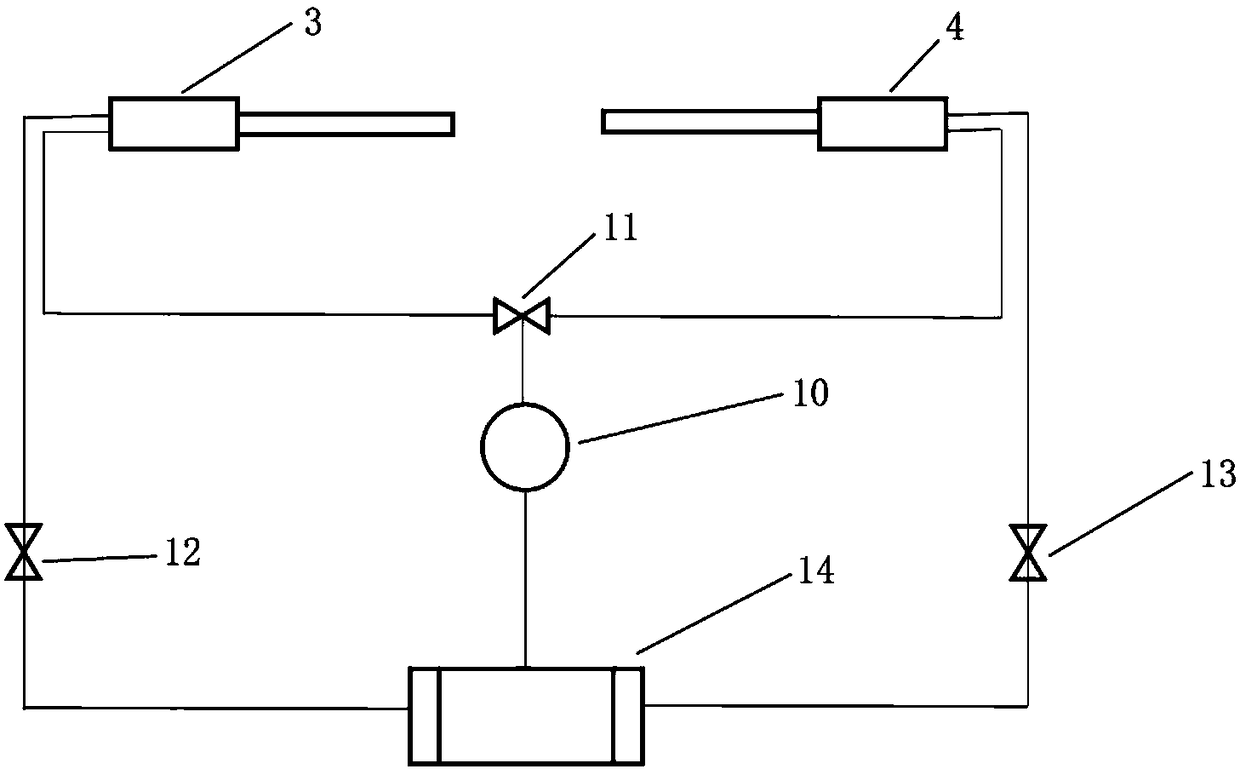

Self-balanced transport vehicle

A self-balanced transport vehicle comprises a compartment, a bottom frame, a first hydraulic cylinder and a second hydraulic cylinder. The self-balanced transport vehicle is characterized by further comprising a hydraulic pump, a three-way solenoid valve, a first solenoid valve, a second solenoid valve, an oil storage tank, a pressure sensor and a controller. A protruding block is arranged in themiddle of the compartment in a downwards-protruding mode in the advancing direction of the transport vehicle. The two ends, perpendicular to the advancing direction of the transport vehicle, of the bottom of the compartment protrude downwards to form sliding blocks correspondingly. Two guiding rails are arranged on the upper portions, corresponding to the sliding blocks, of the two ends of the bottom frame. The sliding blocks extend into the guiding rails and slide left and right in the guiding rails along with left-right moving of the compartment. The bottoms of the first hydraulic cylinder and the second hydraulic cylinder are fixed to the bottom frame. Plungers of the hydraulic cylinders are fixed to the protruding block. According to the self-balanced transport vehicle, the guiding rails and a hydraulic mechanism are additionally arranged at the bottom of the compartment to form a gravity center adjusting system, and the gravity center of the transport vehicle shifts to a certain extent by laterally pushing the compartment when the transport vehicle turns so as to counteract centrifugal moment, so that the rollover risk when the transport vehicle turns is overcome.

Owner:XUZHOU NORMAL UNIVERSITY

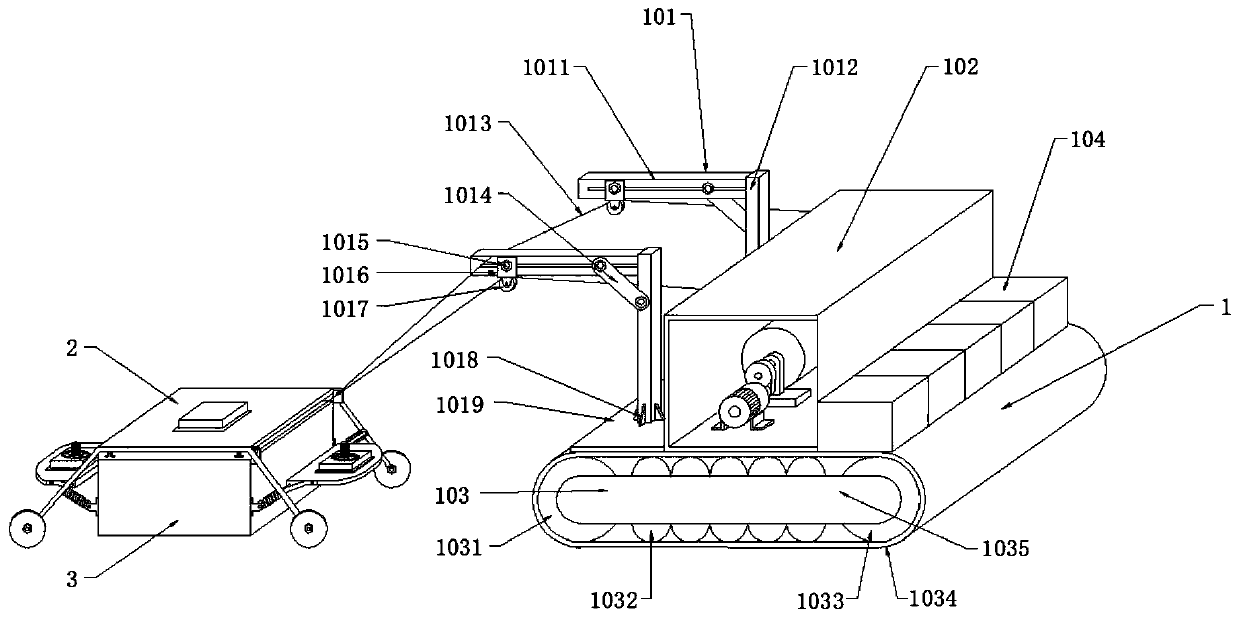

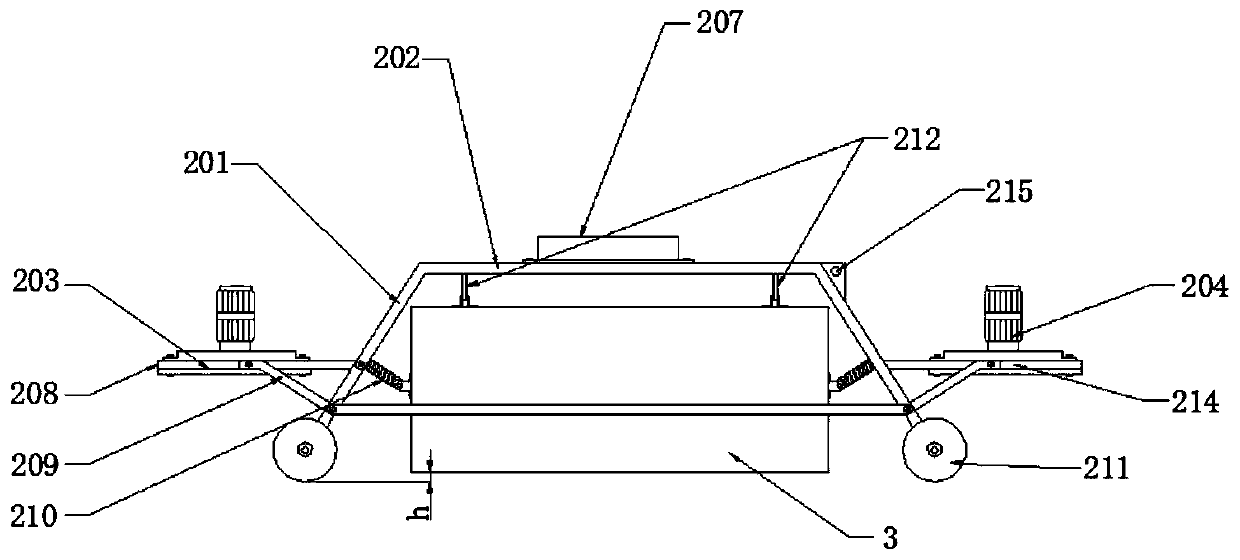

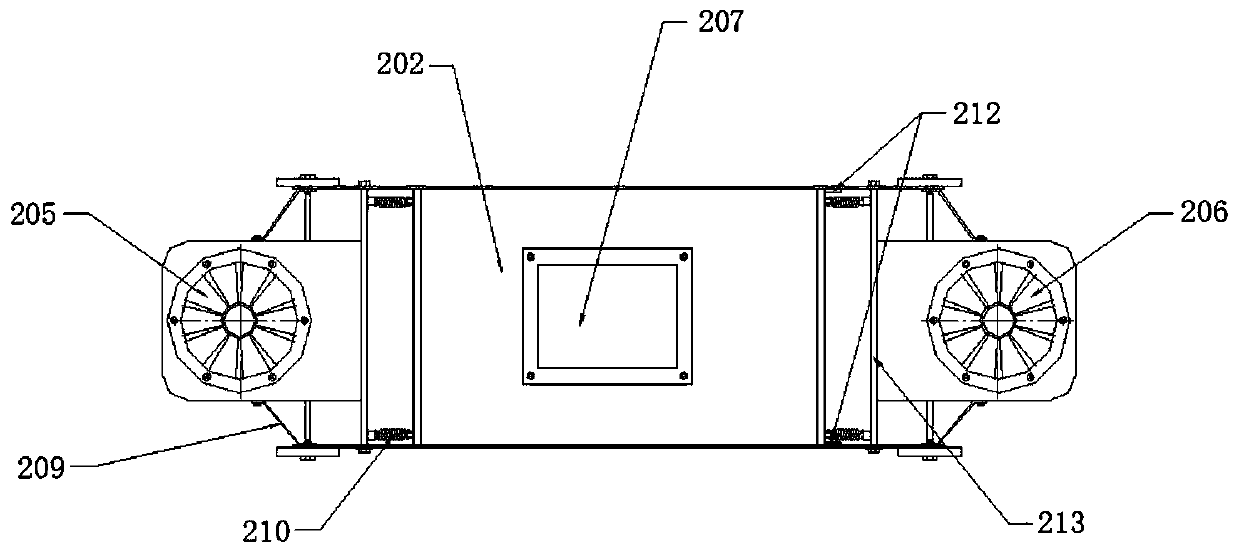

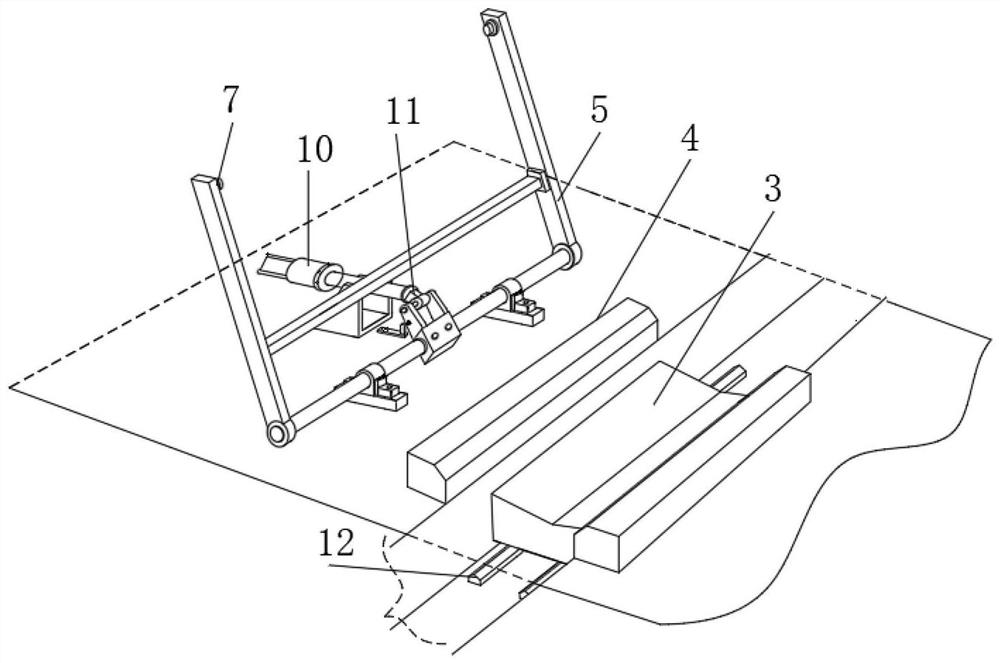

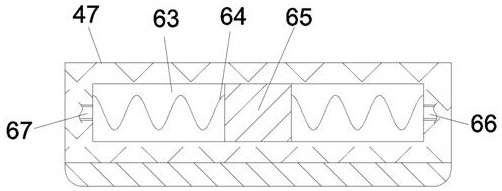

Auxiliary device of ground penetrating radar

PendingCN110082755AImprove fitAvoid walking difficultiesDetection using electromagnetic wavesRadio wave reradiation/reflectionEngineeringSteep slope

The invention discloses an auxiliary device of a ground penetrating radar. The device comprises a walking device, a detection trolley and a ground penetrating radar device, wherein the walking deviceand the detection trolley are connected through a cable, the ground penetrating radar device is installed on the detection trolley, the detection trolley is dragged through the cable, the ground penetrating radar device is slowly moved from the dam to the position below the dam for detection operation, and the problem that slope walking is inconvenient during manual operation is solved; meanwhile,spiral fans are designed at the front end and the rear end of the detection trolley, the detection trolley can be better attached to a steep slope and a dam through additional thrust generated by thespiral fans and is not prone to rollover, when the detection trolley conducts detection on a straight wall through the additional thrust of the spiral fans, the detection trolley can be kept attachedto the wall face all the time, and a detection task can be better completed.

Owner:武汉驰驭科技有限公司

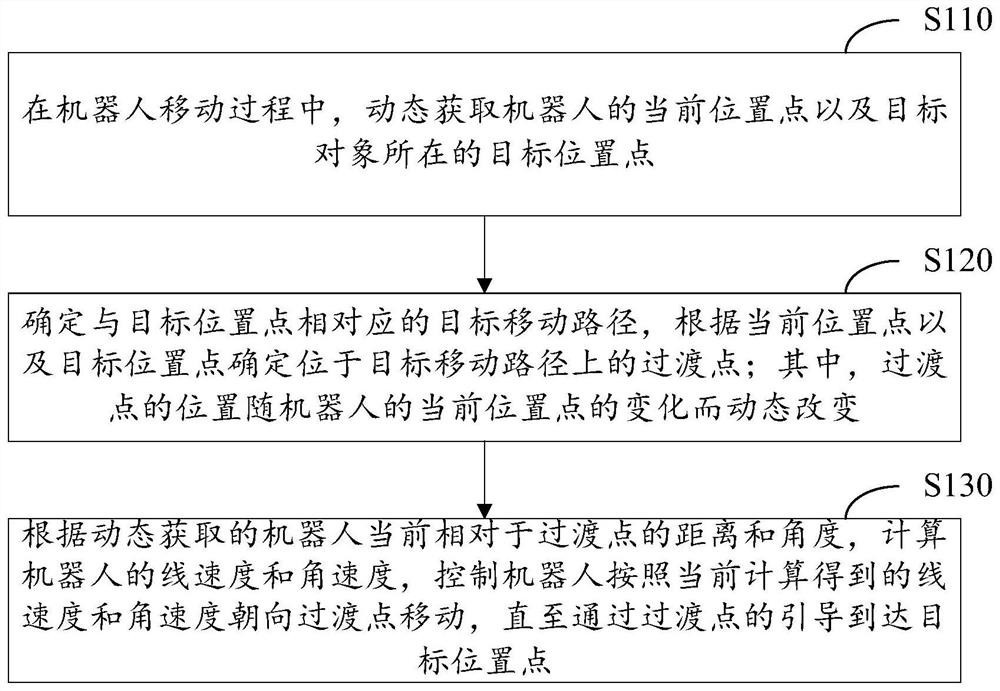

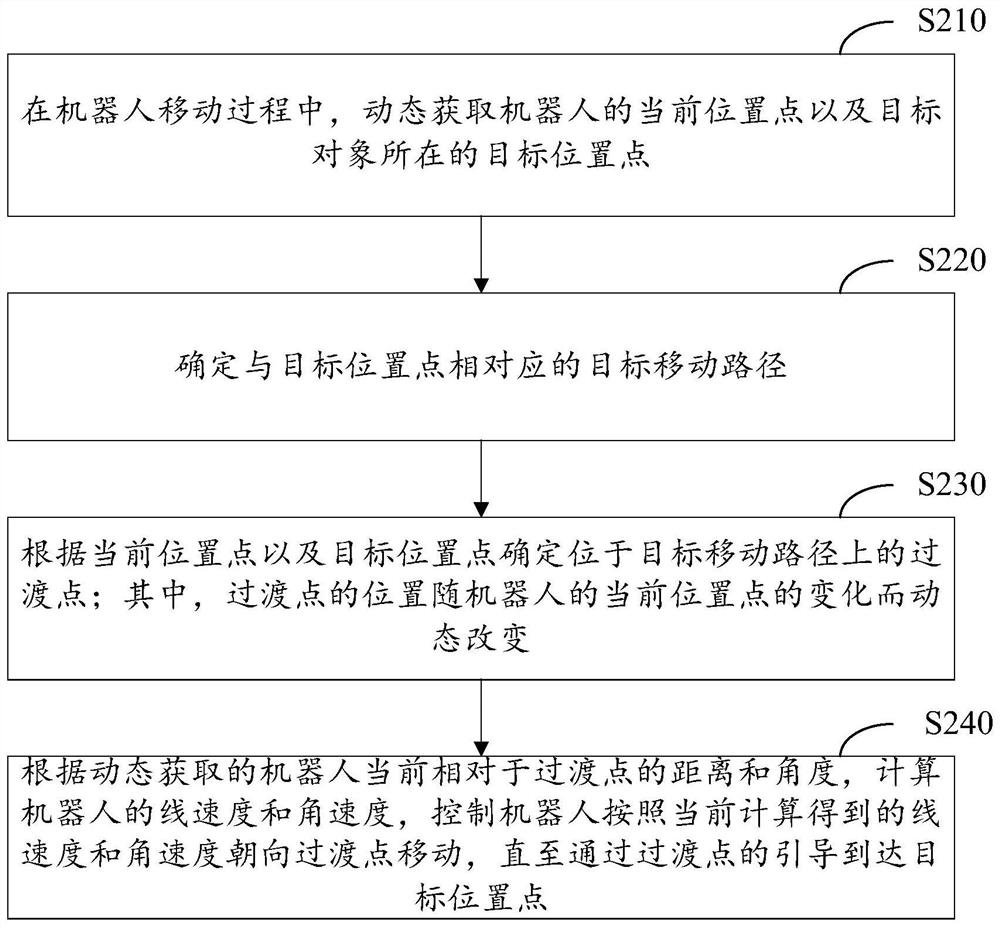

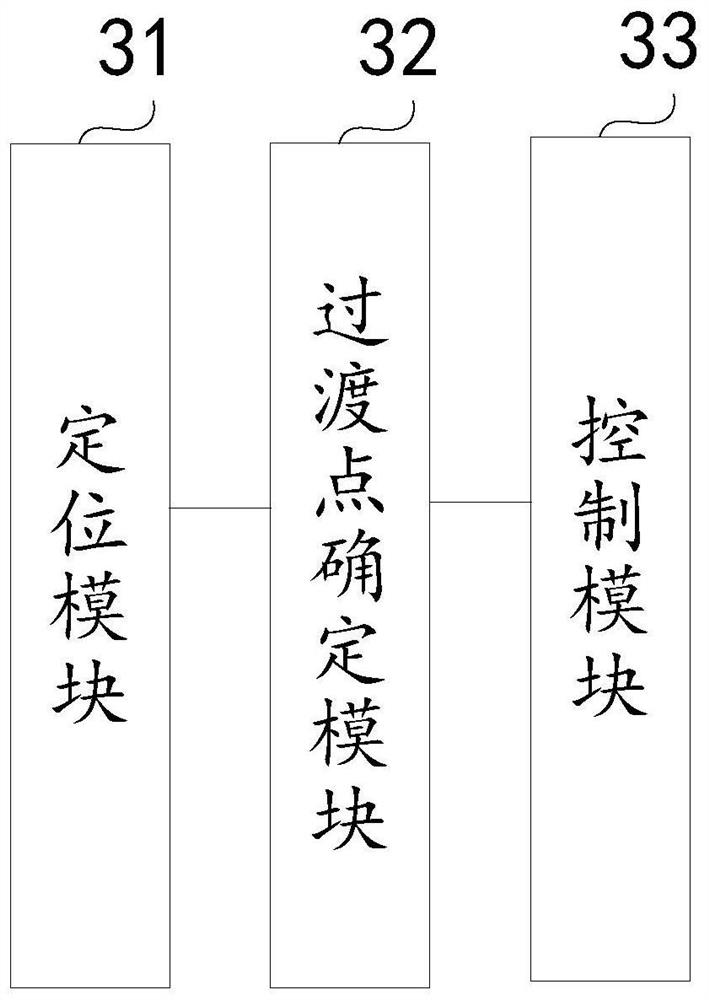

Movement control method and device of robot and robot

PendingCN112068570APrevent large rotationAvoid rollover riskPosition/course control in two dimensionsVehiclesSimulationMovement control

The invention discloses a movement control method and device of a robot and the robot. The method comprises the steps of dynamically acquiring a current position point of a robot and a target positionpoint where a target object is located; determining a target moving path corresponding to the target position point, and determining a transition point located on the target moving path according tothe current position point and the target position point; calculating the linear speed and the angular speed of the robot according to the dynamically obtained distance and angle of the robot relativeto the transition point at present, and controlling the robot to move towards the transition point according to the linear speed and the angular speed obtained through calculation at present until the robot reaches the target position point through the guidance of the transition point. By means of the mode, the transition point can be dynamically adjusted in real time according to the current position of the robot in the moving process, the linear speed and the angular speed of the robot are dynamically adjusted accordingly, and therefore the problem of robot route deviation caused by controlerrors can be effectively prevented.

Owner:RAJAX NETWORK &TECHNOLOGY (SHANGHAI) CO LTD

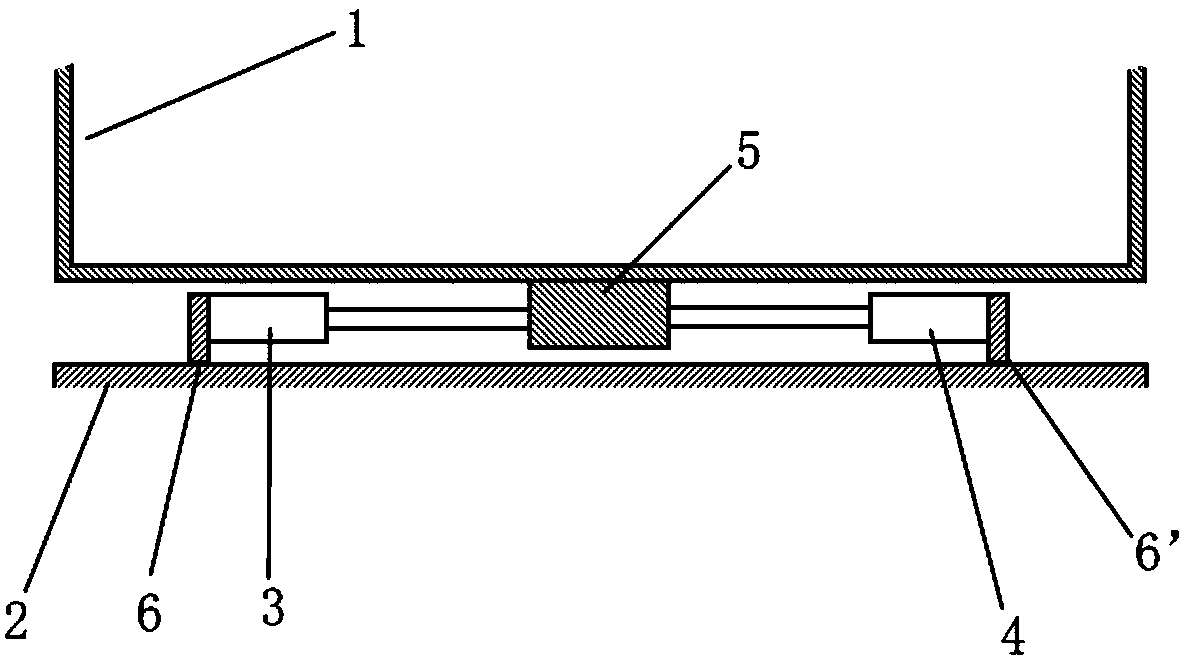

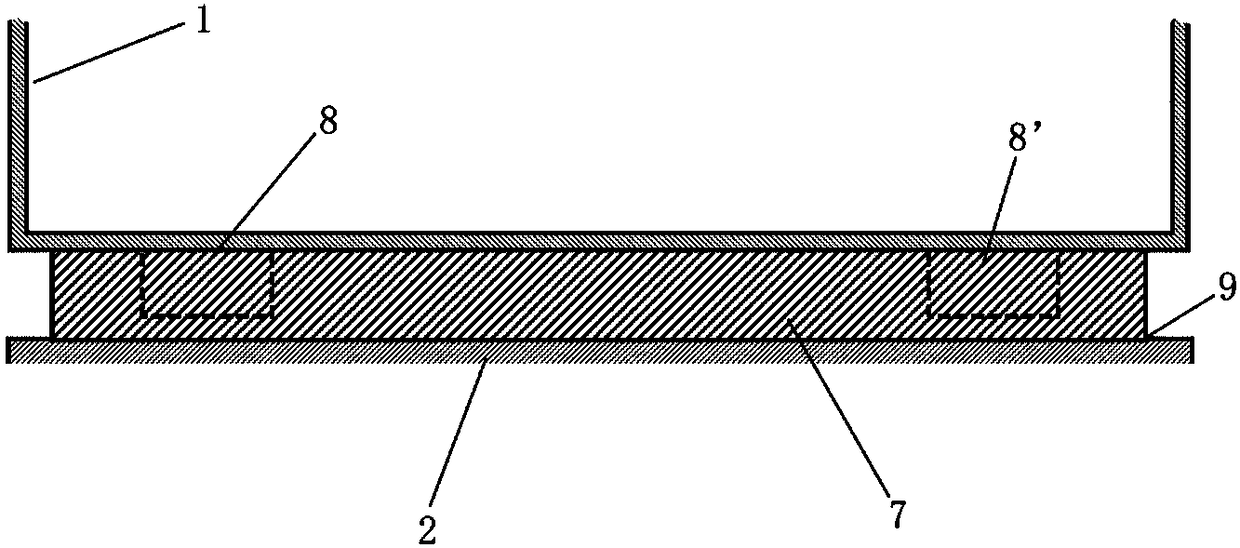

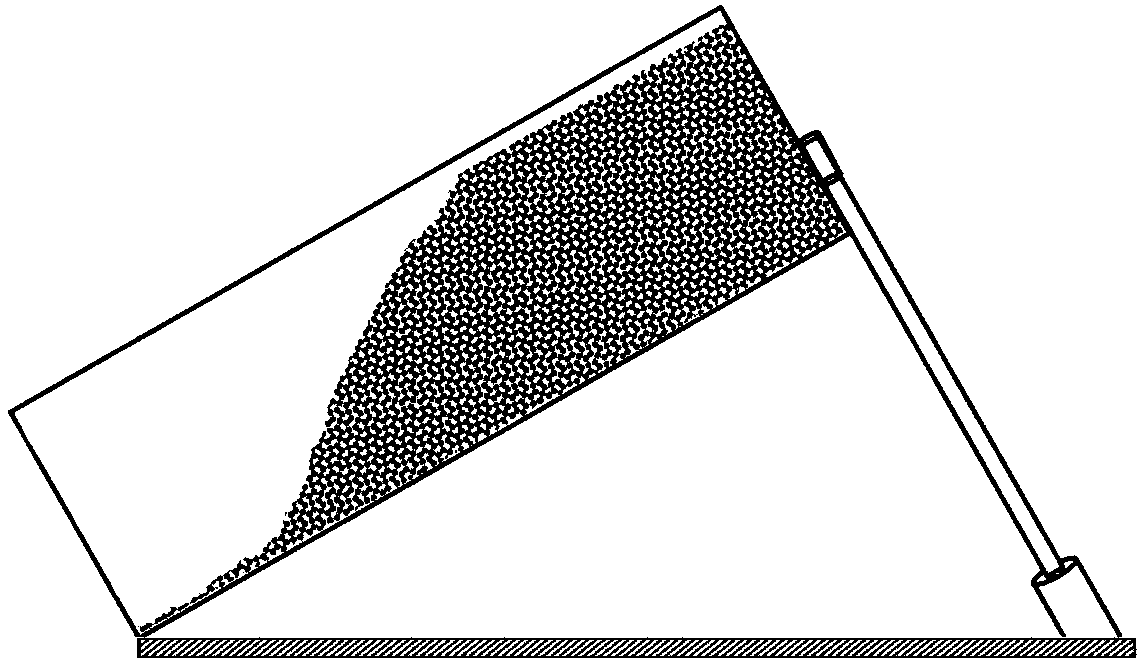

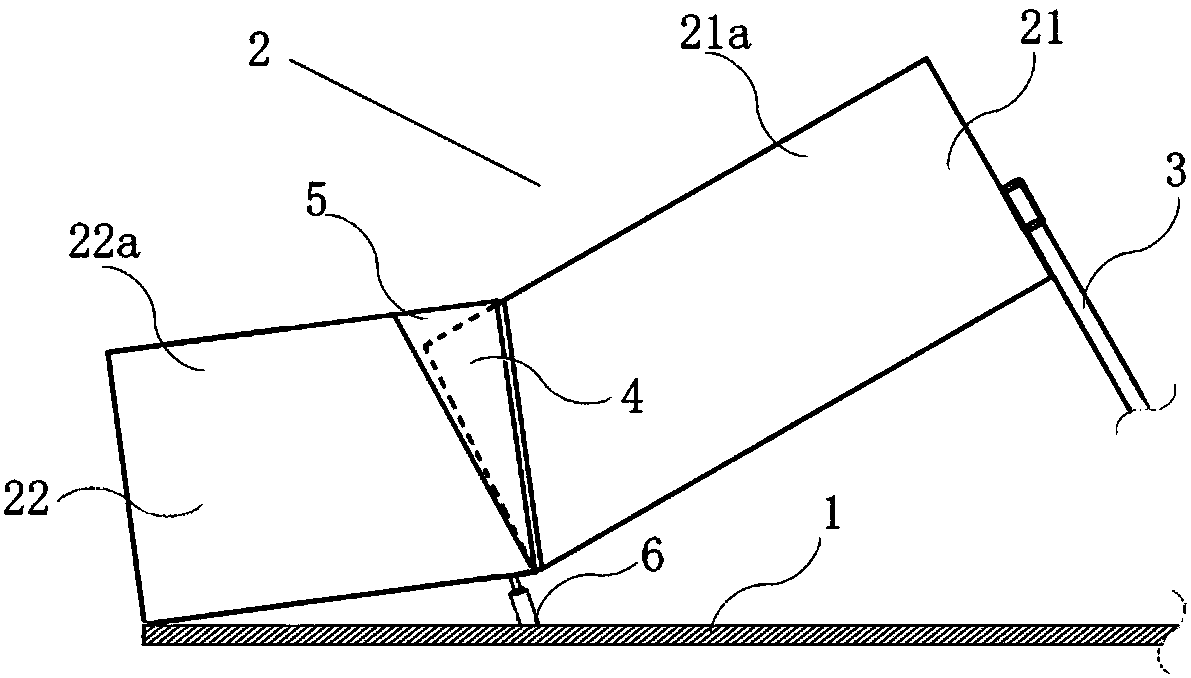

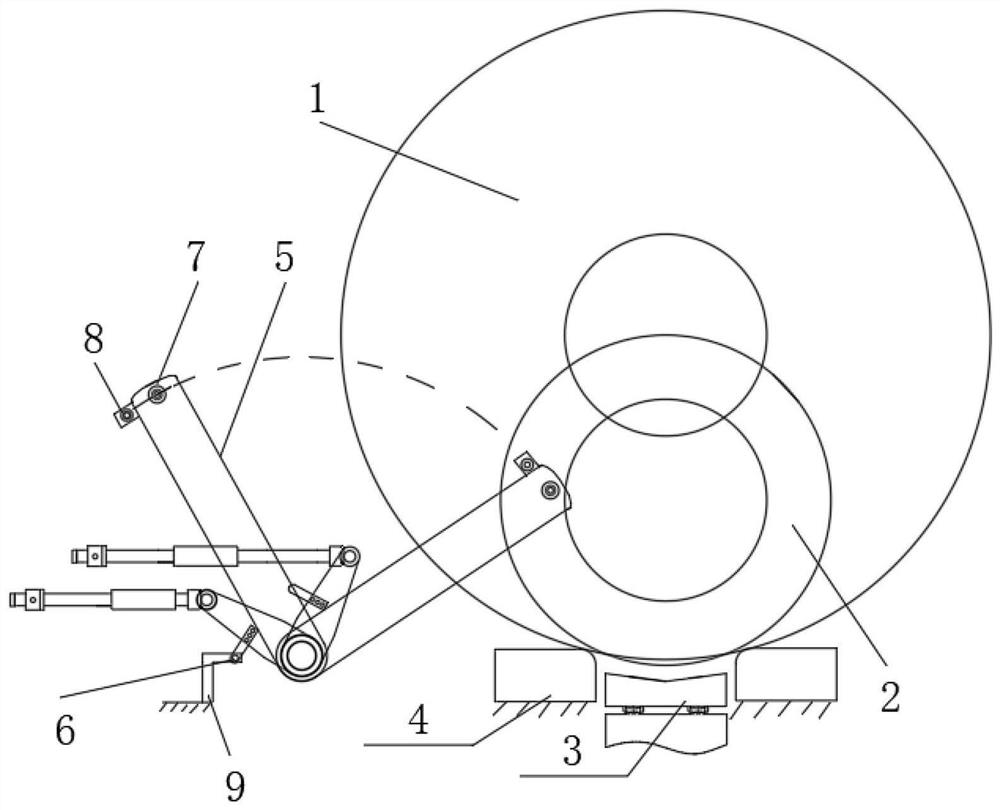

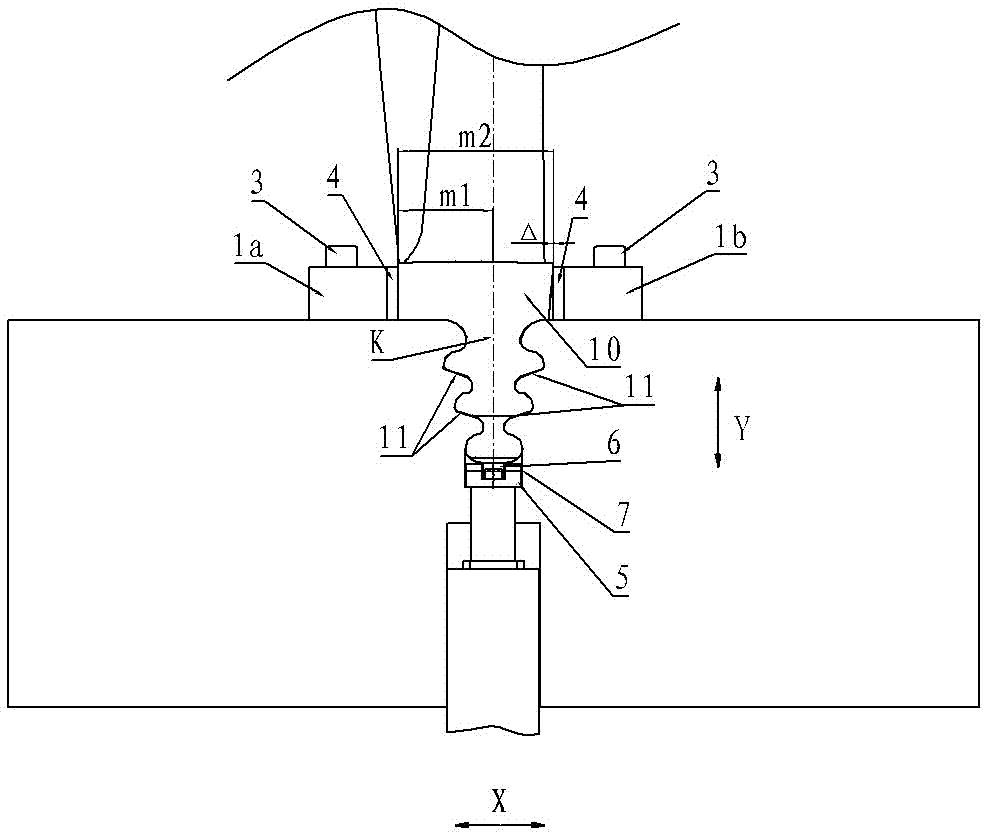

Foldable compartment and automatic-unloading trunk capable of preventing material unloading and lateral overturning

InactiveCN108515895AAvoid car rolloverAvoid rollover riskVehicle with tipping movementTransportation itemsVehicle frameBiomedical engineering

The invention relates to a foldable compartment. The foldable compartment comprises side frames and baseplates. The compartment is divided into two parts including a front part and a rear part. The baseplates of the front and rear parts are hinged, and the junction of the side frames of the front and rear parts is of a movable meshing structure. An automatic-unloading trunk capable of preventing material unloading and lateral overturning using the foldable compartment comprises a trunk frame, the compartment and a lifting mechanism. One end of the compartment is hinged to one end of the trunkframe, one end of the lifting mechanism is connected to the other end of the trunk frame, and the other end of the compartment is connected to the other end of the lifting structure. The centrally foldable compartment is used for replacing conventional compartments. When materials are unloaded, the front part of the compartment rises first, and then the rear part of the compartment rises. Since aninclination angle of the front part of the compartment reaches a critical inclination angle of material falling earlier than the rear part of the compartment, materials at the front part of the compartment slides down first, and materials at the rear part of the compartment are pushed to slide down together. In this way, the problem is avoided that the compartment is laterally overturned due to the fact that the gravity center of the compartment is higher since the materials at the rear part of the compartment slide down earlier than the materials at the front part of the compartment.

Owner:XUZHOU NORMAL UNIVERSITY

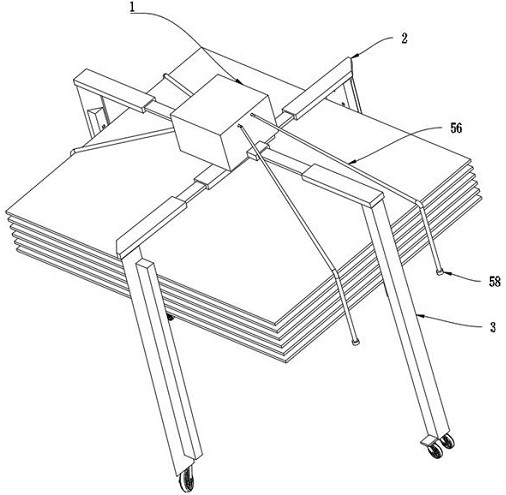

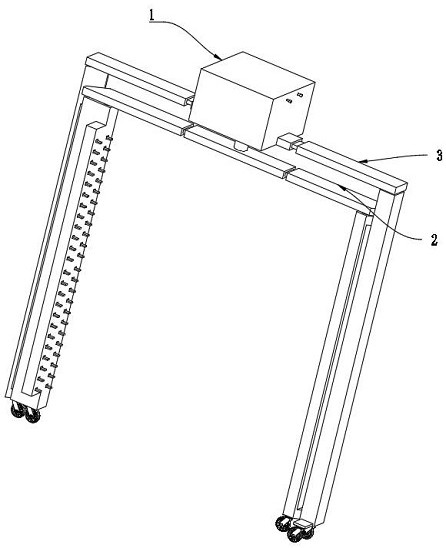

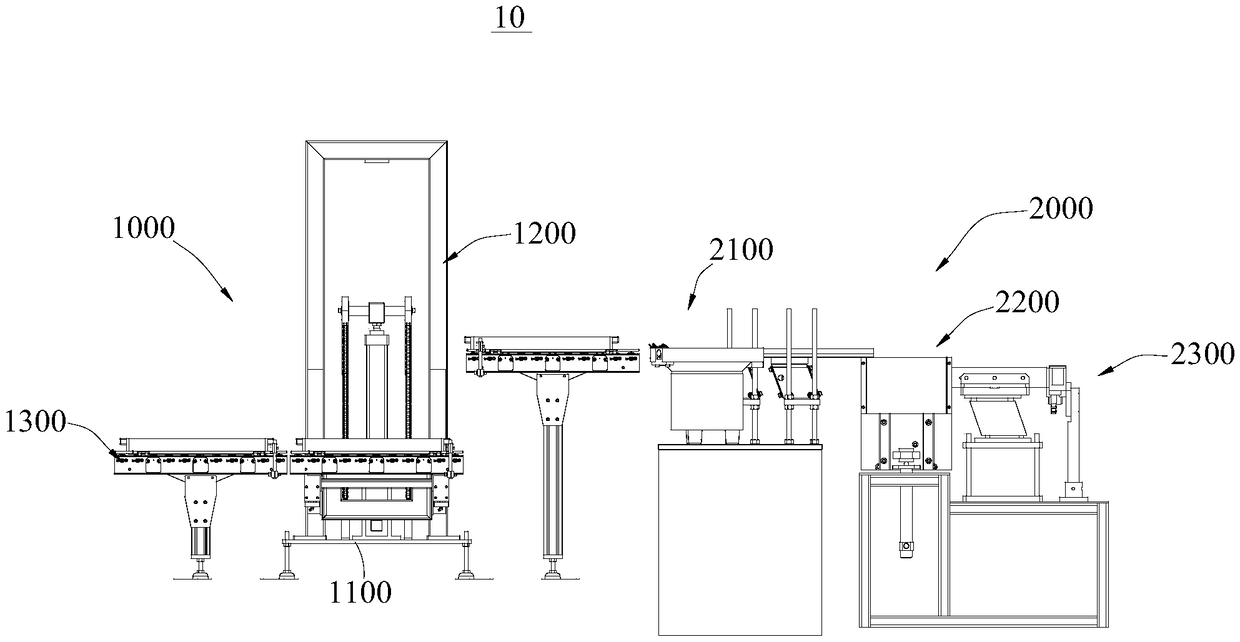

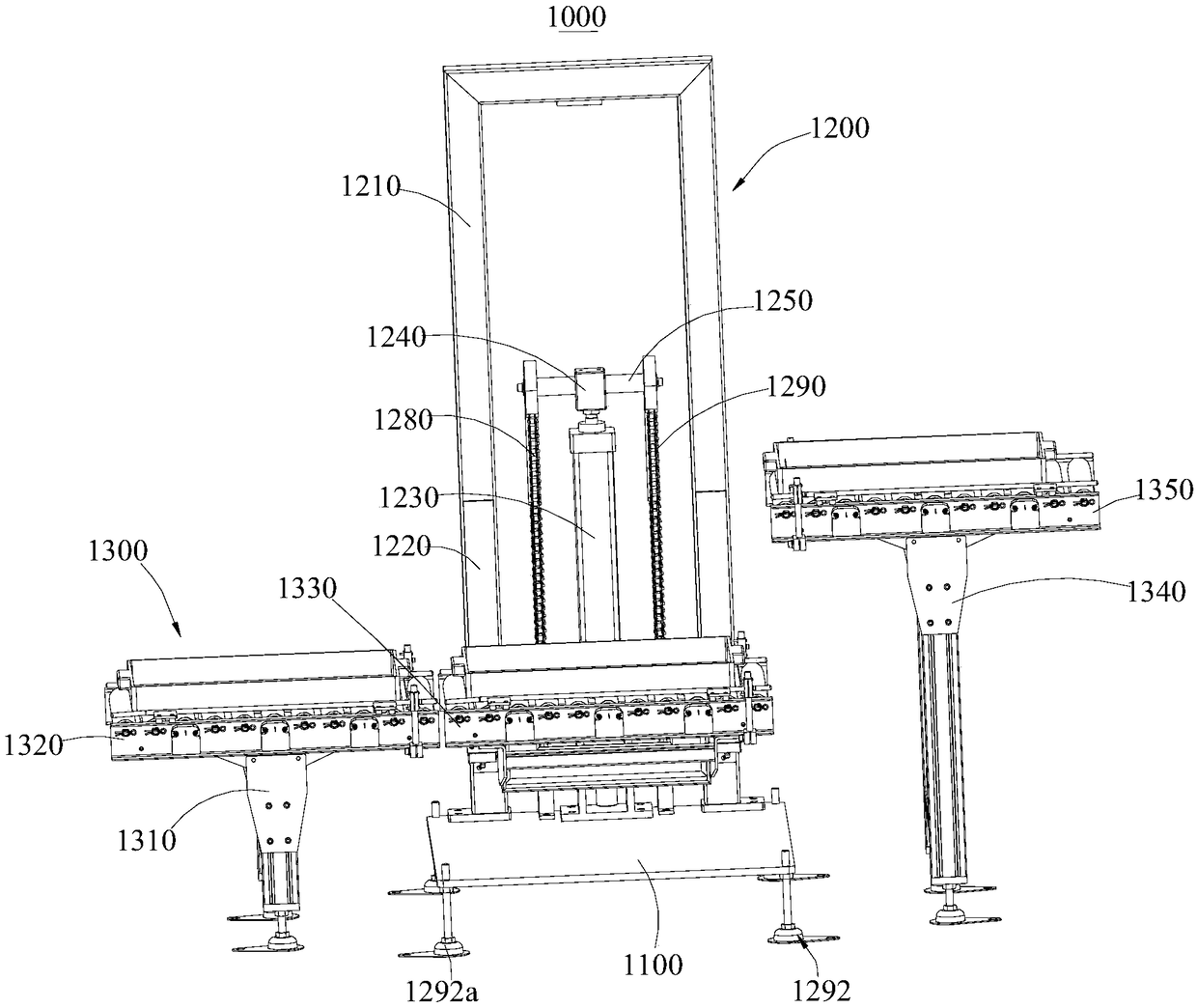

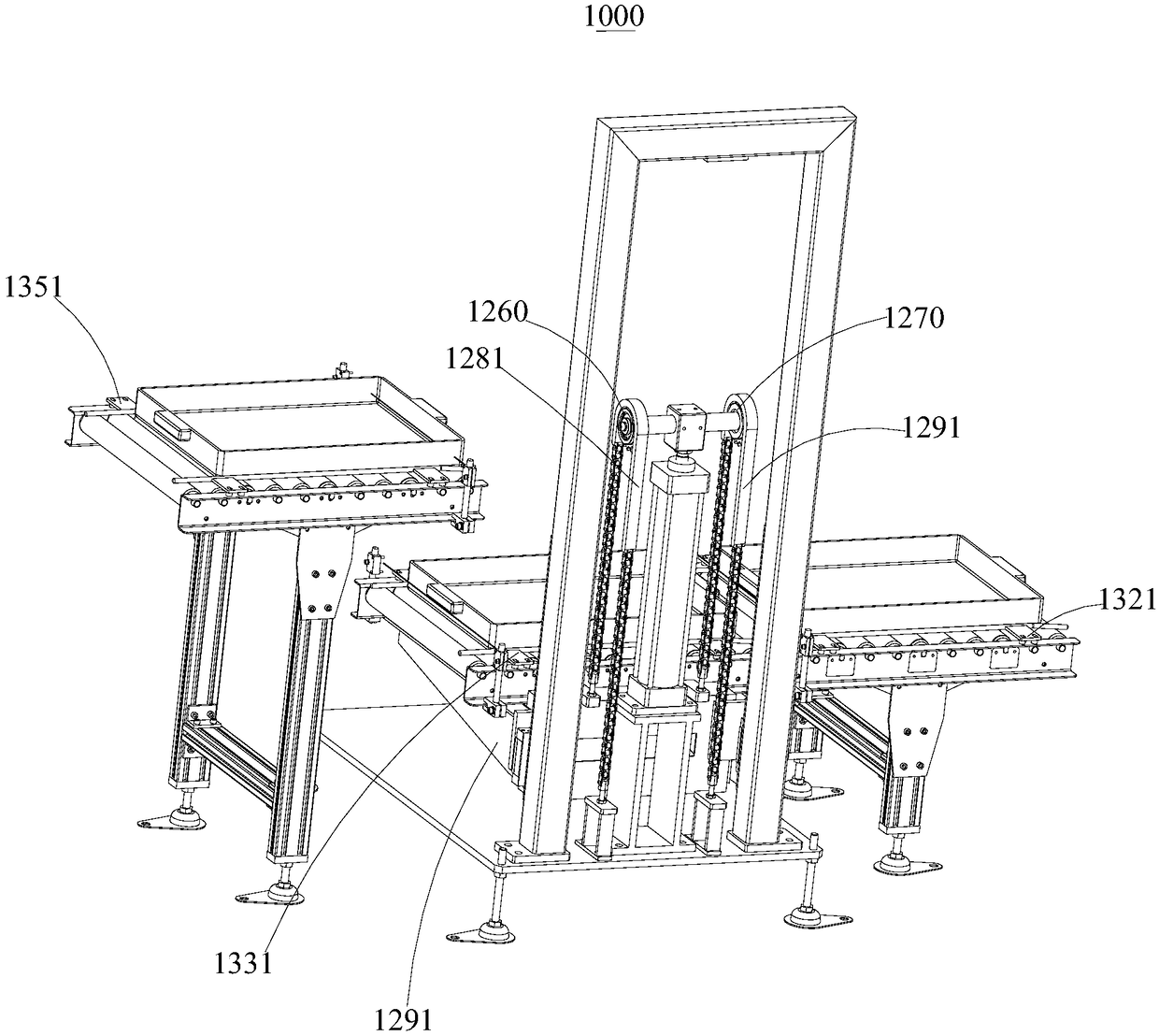

Retractable glass lifting, placing and transporting device

ActiveCN114803517AAvoid the risk of rolloverLarge capacityCharge manipulationConveyor partsArchitectural glassEngineering

The invention discloses a retractable glass lifting, placing and transporting device. The retractable glass lifting, placing and transporting device comprises a rotary pneumatic control type driving assembly, an inner rod rotary type supporting assembly and an outer rod fixed type supporting assembly. The invention belongs to the field of building glass carrying, and particularly relates to a retractable glass lifting, placing and transporting device. A traditional vertical placement method is changed into a horizontal placement method by controlling the air bags to suck the building glass, so that the gravity center of the building glass is balanced, the risk of rollover of the building glass during carrying can be effectively prevented, the capacity of the building glass carried by the device is greatly increased, and the labor cost is reduced; meanwhile, on the basis of the method for changing harm into benefit, the directions of the two sets of fixed pulleys and the direction of the movable twisting pulley mechanism are different in different use stages, and harmful factors prone to rollover are converted into beneficial factors for stable advancing. And the possibility that the building glass is scratched in the bottom-to-top carrying process is reduced to the minimum.

Owner:江苏中泓光电科技有限公司

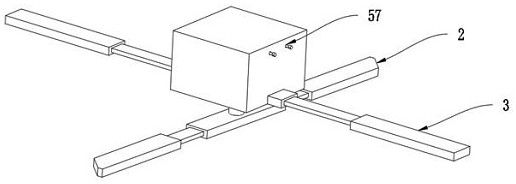

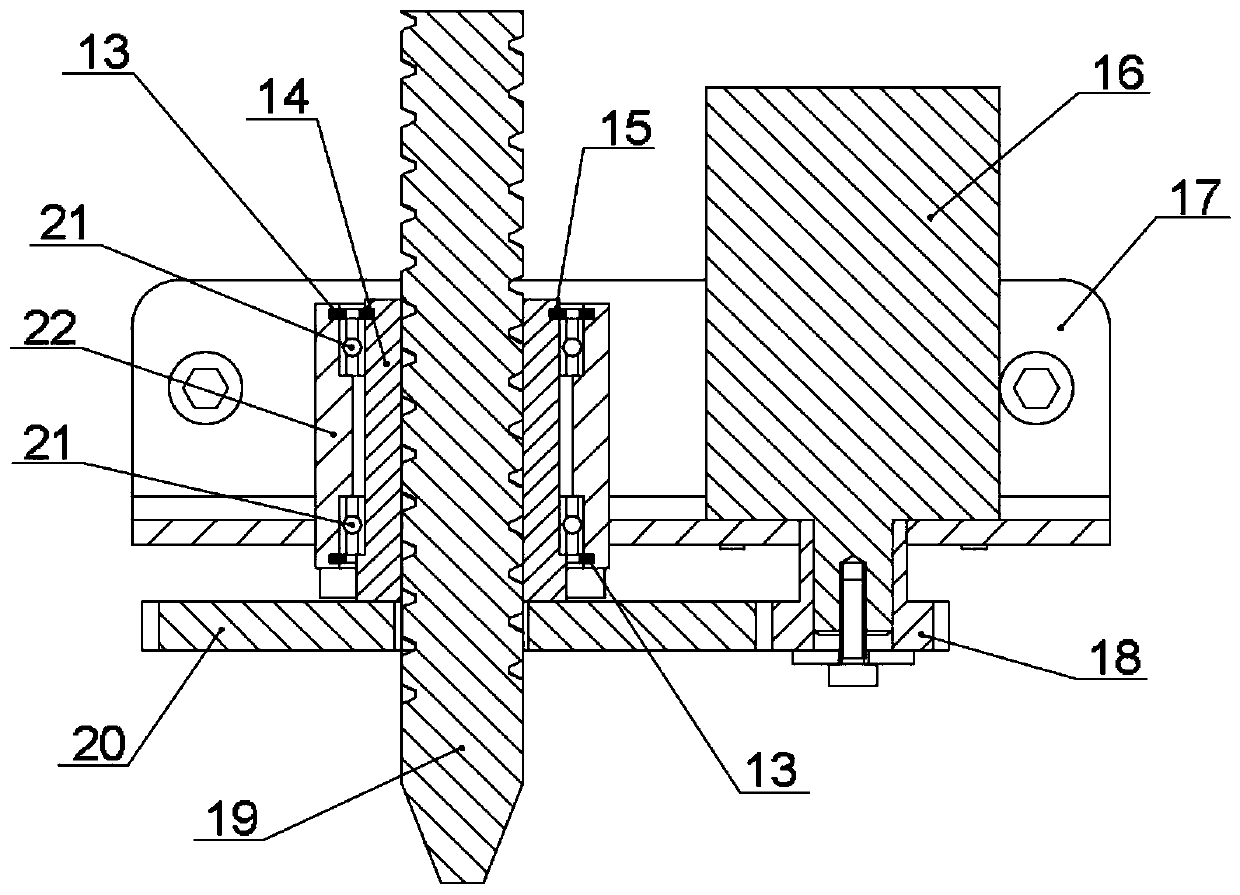

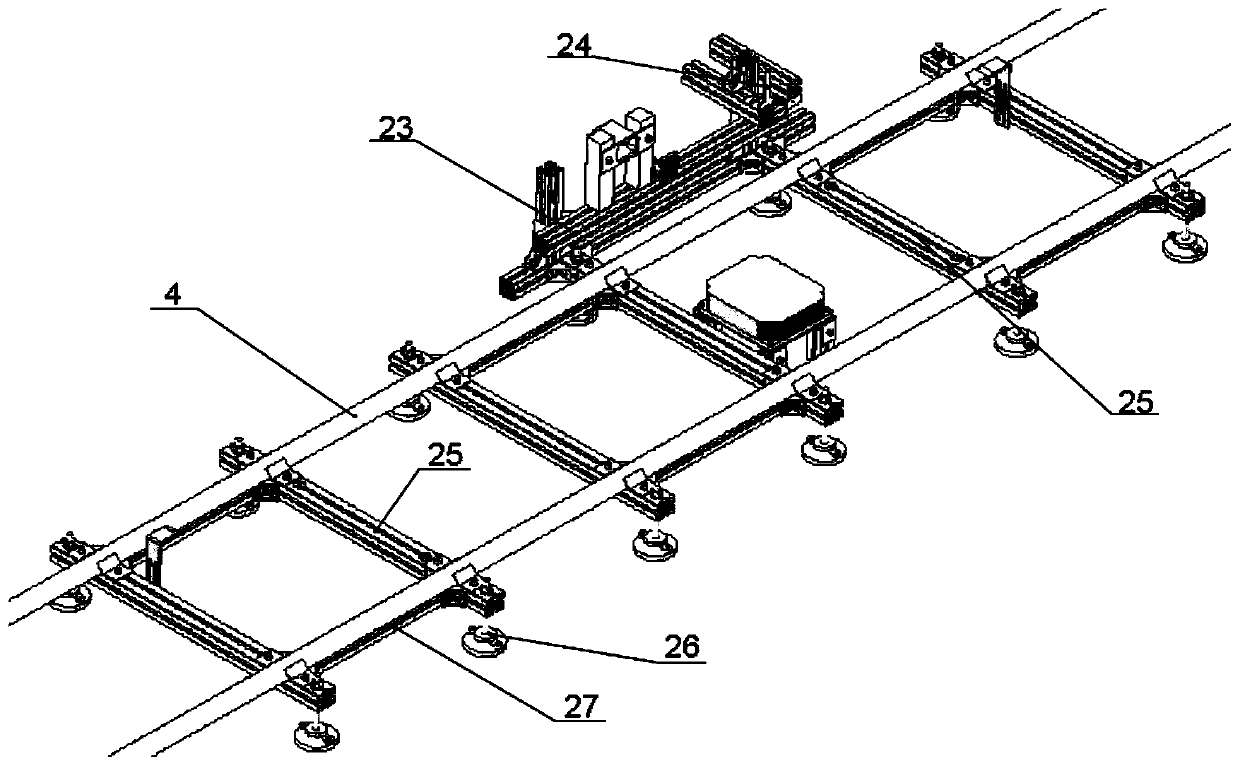

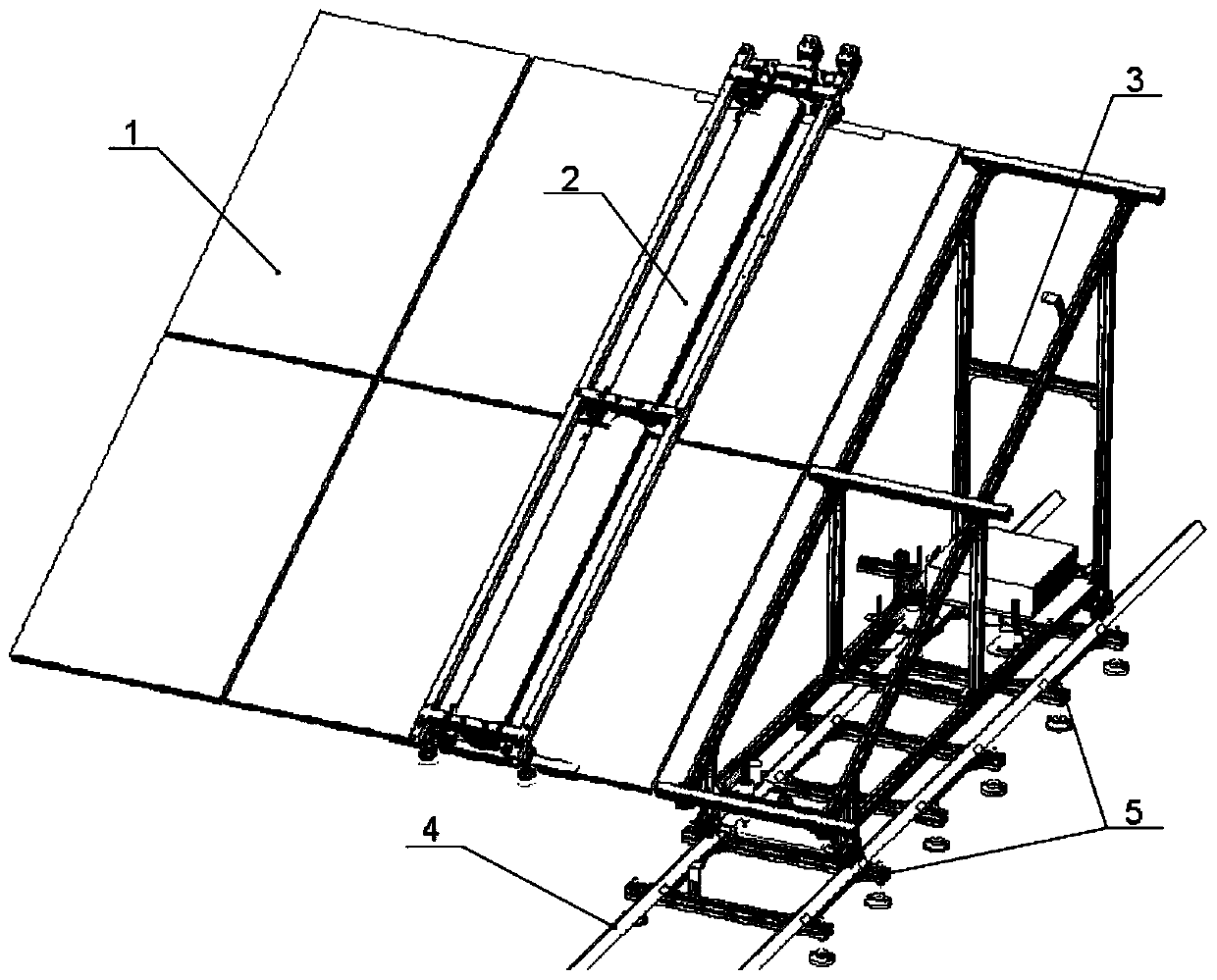

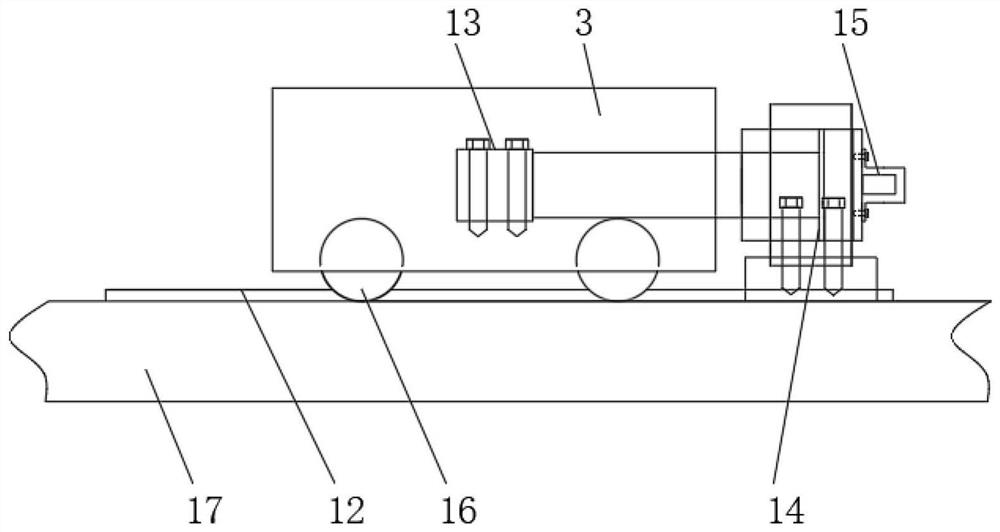

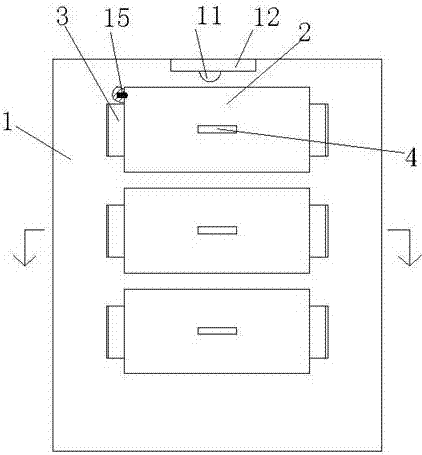

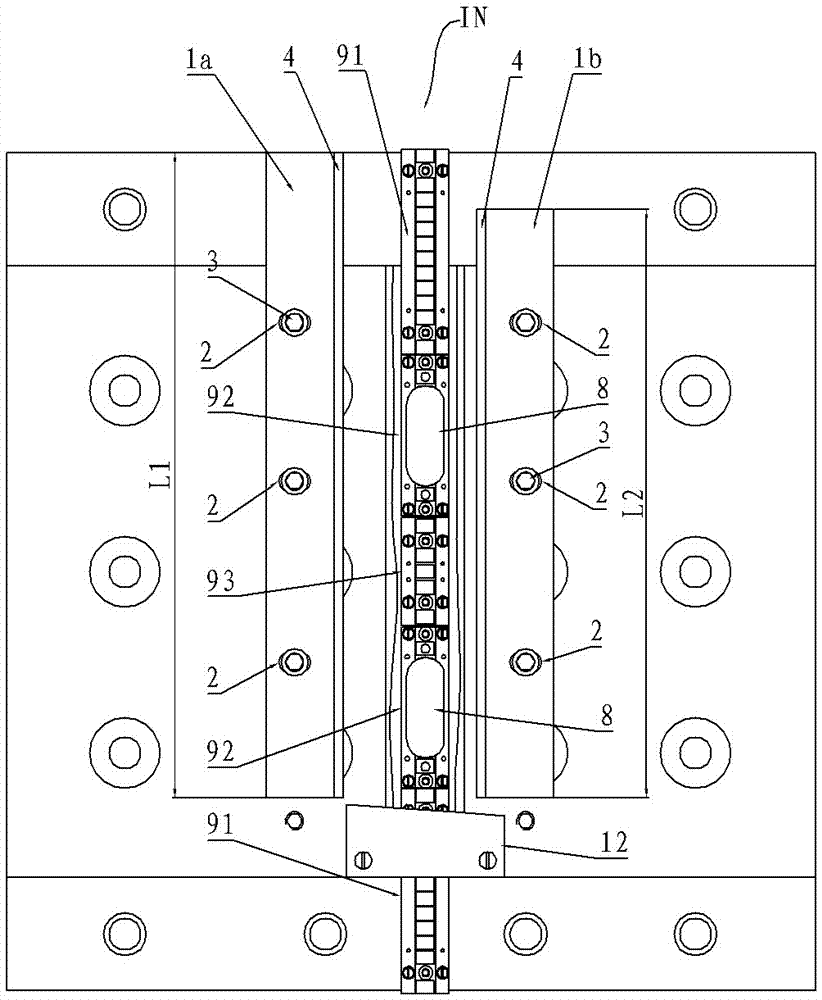

Downward locking device used for transport trolley for photovoltaic module cleaning robot

PendingCN110625643ARealize the longitudinal locking functionSolve slippagePhotovoltaicsPhotovoltaic energy generationEngineeringMechanical engineering

The invention discloses a downward locking device used for a transport trolley for a photovoltaic module cleaning robot. Transport rails are arranged on one sides of all rows of photovoltaic modules and are parallel to the edges of the photovoltaic modules. The transport trolley carrying a cleaning trolley travels on the transport rails. A plurality of locking rail frames are arranged on the innersides of the transport rails. Four vehicle-mounted locking devices are mounted on the transport trolley. The downward locking device comprises the vehicle-mounted locking devices and the locking railframes. The downward locking device is reasonable in structure; the longitudinal locking function of the transport trolley is realized through the first locking device, the second locking device, thethird locking device and the fourth locking device which are internally provided with longitudinal lead screws; and the problem that the transport trolley slides in the operating process due to the gravity and other accidents is solved, and the safety of the robot in the operating process is improved.

Owner:NANTONG UNIVERSITY

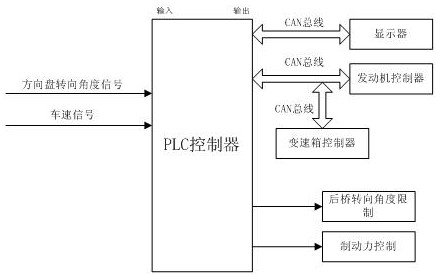

Heavy forklift sharp turn safety control system and method

InactiveCN112079299AImprove securityImproves safety on sharp turnsSafety devices for lifting equipmentsDriver input parametersSteering wheelSteering angle

The invention discloses a heavy forklift sharp turn safety control system and method. According to the method, when it is judged that the speed of a vehicle is greater than or equal to a preset value,it is indicated that the whole vehicle runs at a high speed; if the steering angle change rate of a steering wheel is greater than or equal to a preset value, it is indicated that the vehicle is in asharp turn state currently; the steering angle of a rear axle is limited at a preset angle limit value; the speed of the vehicle is limited at the preset value; and braking force is gradually increased to realize slow braking.

Owner:徐州徐工港口机械有限公司

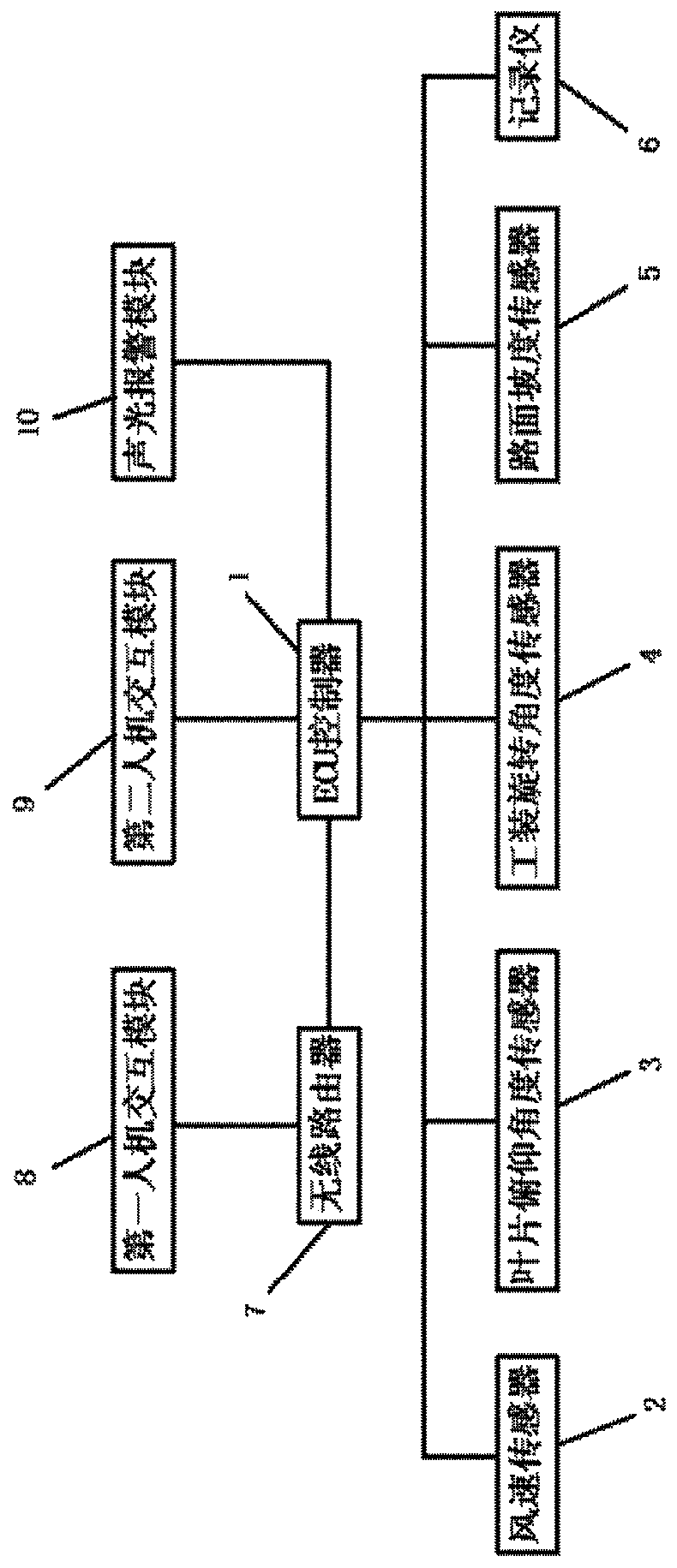

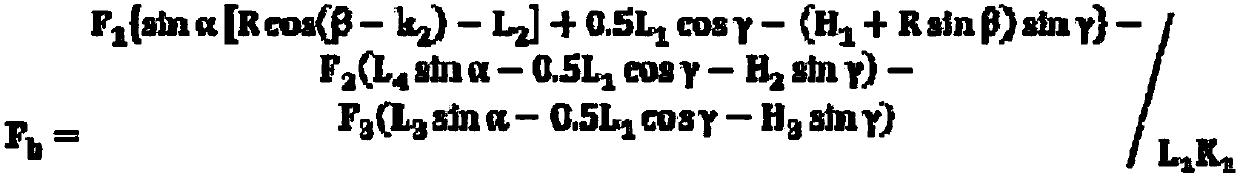

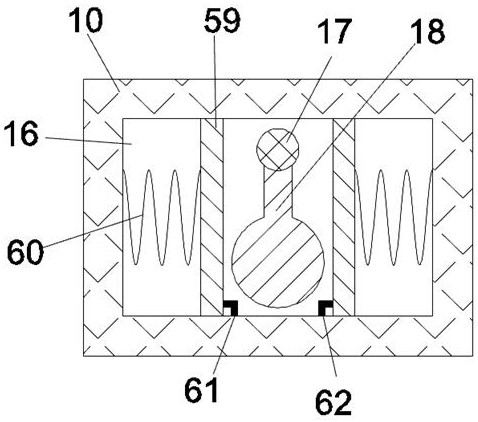

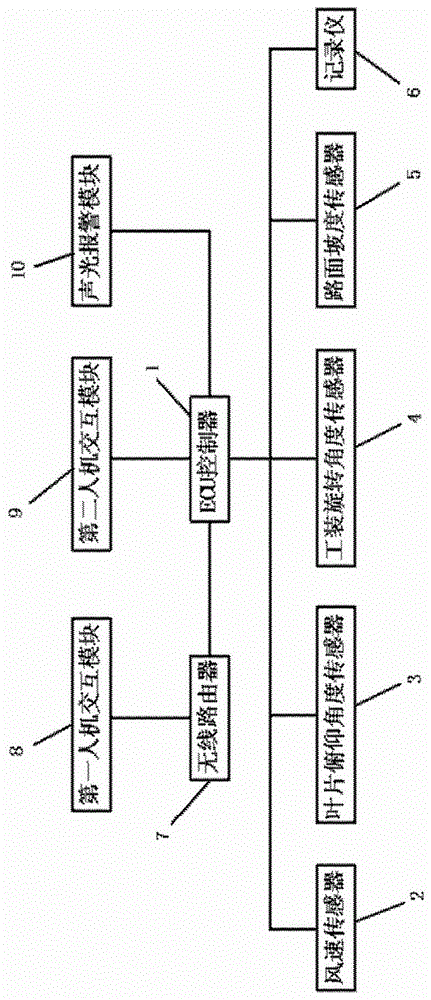

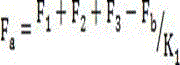

Wind power blade transport balance monitoring device and monitoring method thereof

ActiveCN105739409BAvoid rollover riskLessons LearnedProgramme controlComputer controlElectricityWireless router

The present invention discloses a wind power blade transport balance monitoring device. The wind power blade transport balance monitoring device comprises an ECU controller which is in communication connection with a wind speed sensor, a blade pitching angle sensor, a tooling rotation angle sensor, a road gradient sensor and a recorder separately, is in communication connection with a remote first man-machine interaction module via a wireless router, and is also in communication connection with a second man-machine interaction module and an audible and visual alarm module separately. The present invention also discloses a monitoring method using the above wind power blade transport balance monitoring device. According to the present invention, the insufficiency of the prior art can be improved, the transport state can be monitored automatically, and the danger early warning can be realized.

Owner:HEBEI HUAYUN SHUNTONG SPECIAL VEHICLE CO LTD

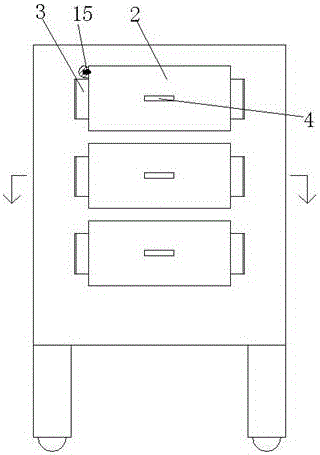

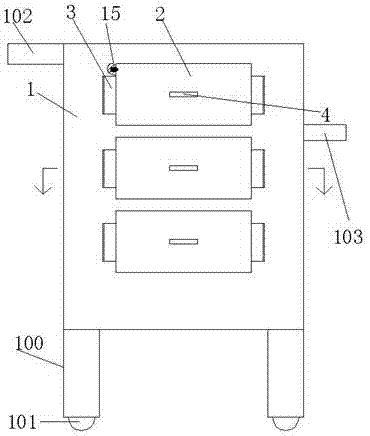

Drawer type power installation cabinet device capable of quick heat dissipation

ActiveCN106992456AAvoid the risk of rolloverEasy to useSwitchgear with withdrawable carriageSubstation/switching arrangement cooling/ventilationEngineeringMechanical engineering

Owner:PANJIN GUANGLIDA ELECTRIC

Device and method for completing steel coil width centering on walking beam

PendingCN112808783AAchieve a streamlined effectEliminate field workGuiding/positioning/aligning arrangementsMeasuring devicesRotational axisGravity center

The invention discloses a device for completing steel coil width centering on walking beam. The device comprises a large steel coil, a small steel coil, a width centering trolley, a fixed saddle, a cantilever support, a position sensor, an ultrasonic sensor and a temperature sensor, wherein the small steel coil is arranged at the bottom of the inner side of the large steel coil, the width centering trolley is arranged at the bottom of the large steel coil and the bottom of the small steel coil, the walking beam is fixedly arranged at the bottom of a sliding rail, the cantilever support is arranged at the front end of the fixed saddle, an ultrasonic sensor is arranged at the inner side end of the top of the cantilever support, the temperature sensor is arranged at the front end of the top of the cantilever support, a rotating shaft is arranged in the middle of the bottom of the cantilever support, an oil cylinder is connected to the front end of the rotating shaft, and the position sensor is arranged at the front end of the cantilever support. Width centering of the steel coil at an inlet is achieved according to a gravity center position of the steel coil, coil upending accidents are avoided, the automatic production efficiency is improved, the effect of personnel simplification is achieved, full-automatic operation is achieved, safety and reliability are achieved, measurement is accurate, and maintenance is easy.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD

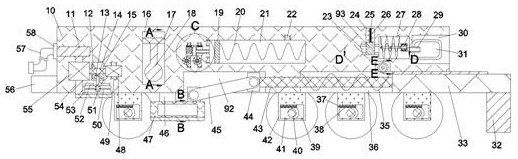

A truck compartment for rear-end collision protection

ActiveCN112572133BRealize automatic balanceRealize braking decelerationPortable emergency signal deviceBraking element arrangementsAutomobile AccidentEngineering

The invention discloses a truck compartment for rear-end collision protection, comprising a compartment, a front connecting piece connected to the front is fixed on the left end surface of the compartment, and an air bag cavity opening to the right is arranged on the right end surface of the compartment And the large rack chute with the opening downwards located on the lower side of the airbag chamber, the left inner wall of the large rack chute is provided with a hinged block chute with the opening downward; the present invention realizes the automatic The balance and the braking deceleration of the vehicle avoid the risk of the center of gravity of the vehicle being shifted due to the road conditions or the vehicle turning too sharply during the transportation of the truck, thereby causing the risk of rollover. While completing the braking deceleration, the center of gravity of the carriage can be effectively lowered, so that the truck can remain stable. At the same time, by forming a buffer protection, the rear vehicle can be effectively protected, and the warning signs on both sides are deployed to warn the vehicles coming from the rear that there will be a traffic accident here, and be careful to avoid it. .

Owner:安徽轻运达科技有限公司

Wind power blade transport balance monitoring device and monitoring method thereof

ActiveCN105739409AAvoid rollover riskLessons LearnedProgramme controlComputer controlElectricityWireless router

The present invention discloses a wind power blade transport balance monitoring device. The wind power blade transport balance monitoring device comprises an ECU controller which is in communication connection with a wind speed sensor, a blade pitching angle sensor, a tooling rotation angle sensor, a road gradient sensor and a recorder separately, is in communication connection with a remote first man-machine interaction module via a wireless router, and is also in communication connection with a second man-machine interaction module and an audible and visual alarm module separately. The present invention also discloses a monitoring method using the above wind power blade transport balance monitoring device. According to the present invention, the insufficiency of the prior art can be improved, the transport state can be monitored automatically, and the danger early warning can be realized.

Owner:HEBEI HUAYUN SHUNTONG SPECIAL VEHICLE CO LTD

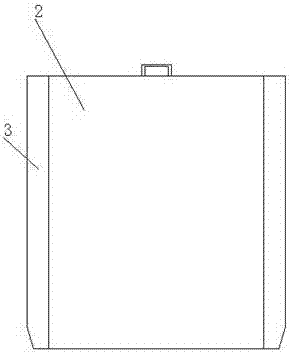

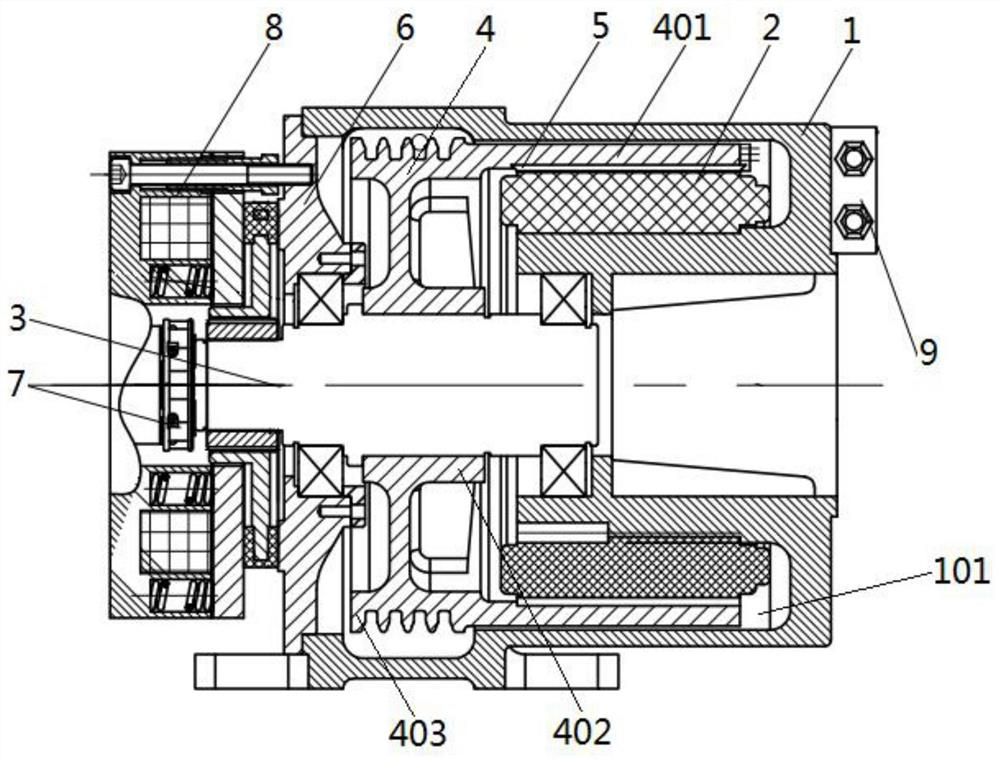

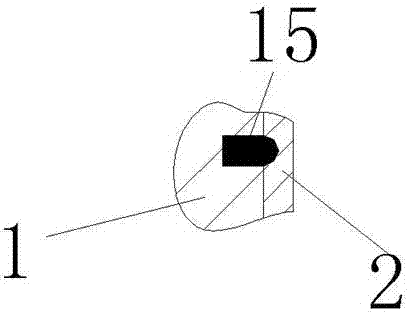

Traction machine with long service life

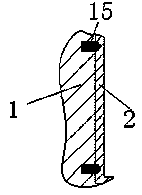

PendingCN112960517AReduce size thicknessAvoid rollover riskBuilding liftsRotor magnetsTorque transmission

The invention discloses a traction machine with long service life, which comprises a machine base (1), a stator iron core (2), a rotor shaft (3) and a traction wheel (4), the two sides of the rotor shaft (3) are rotationally connected with the machine base (1), the middle of the rotor shaft (3) is connected with the traction wheel (4), a rotor magnet yoke (401) is arranged outside the traction wheel (4), and the rotor magnet yoke (401) and the traction wheel (4) are integrally formed. The traction wheel is arranged in the middle of the rotor shaft, so that the connecting positions of the two ends of the rotor shaft are uniformly stressed, the working stability of the traction wheel is improved, and the required length of the rotor shaft is shortened; and the rotor magnet yoke and the traction wheel are integrally formed, and a connecting piece structure in an original traction machine can be omitted, so that the machining difficulty of equipment is reduced, and the torque transmission stability of the traction machine is improved.

Owner:ZHEJIANG MATO DRIVE EQUIP +1

storage rack for items

ActiveCN106724133BLess forward leanAvoid rollover riskChestsDressing tablesGear wheelStructural engineering

Owner:温州联科知识产权服务有限公司

Blade guide rolling device for static frequency detection of large blades

ActiveCN105414922BAvoid damageRestricted freedom of movementMachine part testingMetal working apparatusEngineeringFrequency detection

The invention provides a blade guiding rolling device for static frequency detection of large blades. The blade guiding rolling device is capable of solving the problems of difficult frequency detection mounting of existing huge and superheavy blades and easy damage of roots of blades during frequency detection mounting. The blade guiding rolling device comprises a guiding assembly and a rolling assembly; the guiding assembly comprises two guide blocks; the two guide blocks are mounted on two side surfaces of a top opening of a wheel slot of a frequency detector, respectively, and arranged to extend in a length direction of the wheel slot; the rolling assembly extending in the length direction of the wheel slot is mounted on a bottom surface of the wheel slot of the frequency detector.

Owner:WUXI TURBINE BLADE

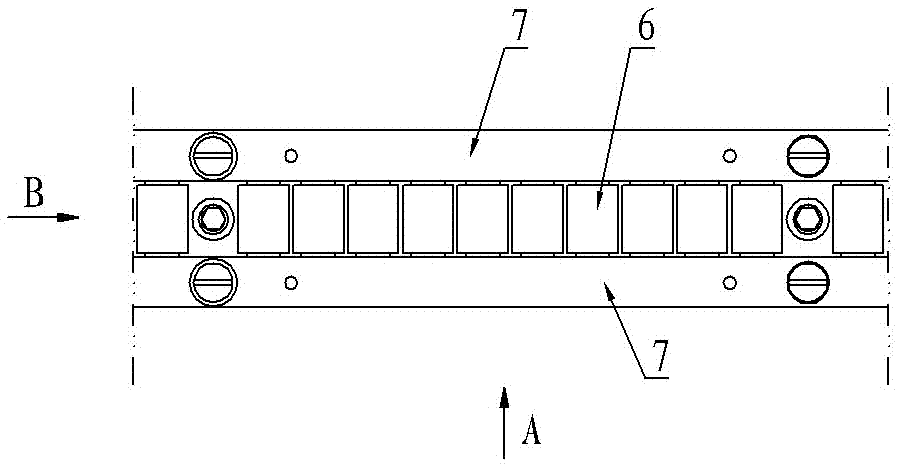

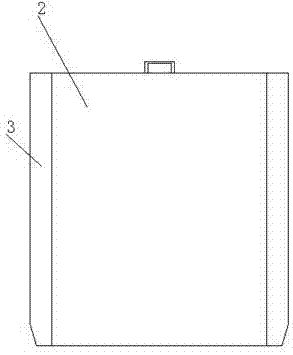

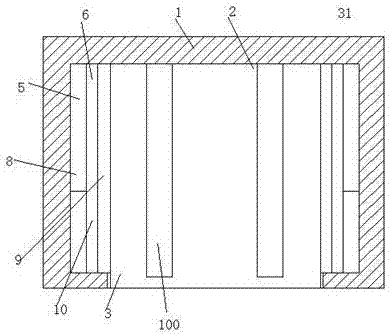

Toolbox for electromechanical maintenance

Disclosed is a toolbox for electromechanical maintenance. The toolbox for the electromechanical maintenance comprises a toolbox body (1), a plurality of telescopic main grooves formed in the toolbox body and separated up and down, and a plurality of placing boxes (2) installed in the telescopic main grooves and used for placing maintenance tools, the two sides of each telescopic main groove are symmetrically provided with telescopic vice grooves, the outer side of each telescopic vice groove is provided with an inner slide way, each inner slide way comprises an outer slide way (5) at the outer side, a middle slide way (6) at the middle position and an inner slide way (7) at the inner side, an inert rotary tooth (9) is installed at the middle position of each inner slide way, an adjusting block (8) is installed at the middle position of the outer slide way (5) in a sliding mode, a push rod (10) is installed at the front end of the middle slide way (6) in a sliding mode, the inner side end surface of the push rod is provided with a function tooth meshed with the inert rotary tooth, the rear end of the outer side end surface of the push rod (10) is fixedly connected with the adjusting block (8), and bearing arms matched with the telescopic vice grooves are symmetrically arranged on the left and right side surfaces of each placing box (2).

Owner:嵊州市诺米克进出口有限公司

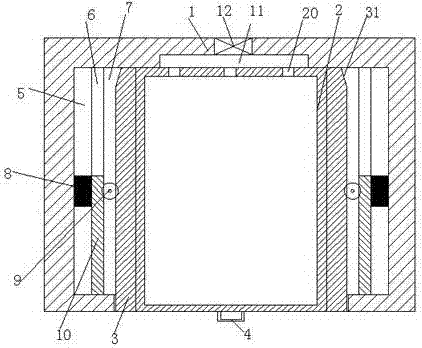

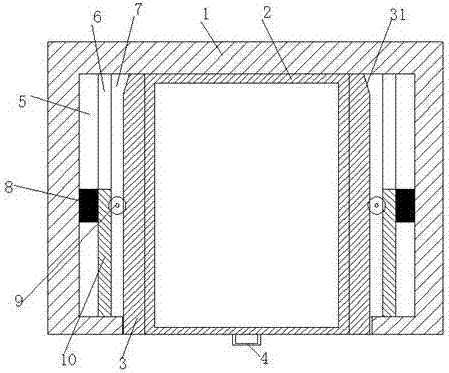

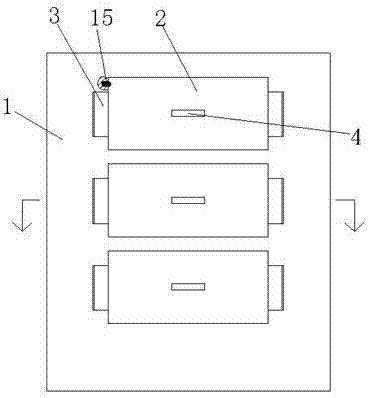

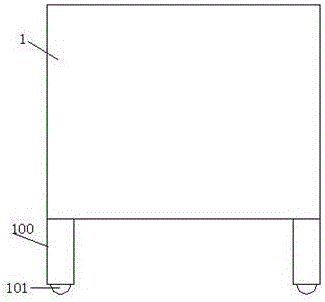

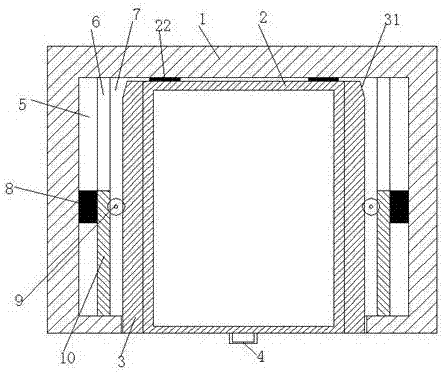

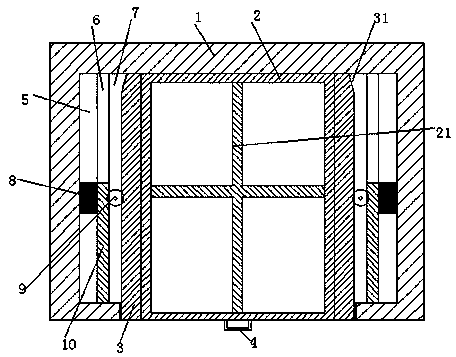

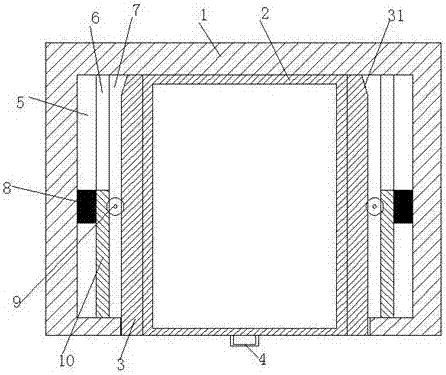

Medical treatment cart device

InactiveCN106491299ALess forward leanAvoid rollover riskNursing accommodationAmbulance servicePush and pullEngineering

A medical treatment cart device comprises a cart body (1), a support (100) fixedly arranged at the bottom end of the cart body (1) and rollers (101) installed at the bottom of the support. A plurality of cavities extending in a front-rear mode are arranged in the cart body (1), push-and-pull boxes (2) for placing medical devices and medicines are installed in the cavities in a front-rear movable mode, tracks are symmetrically arranged on the two sides of each cavity, and the outer sides of the tracks are provided with moving grooves. The moving grooves each comprise an outer moving groove (5) on the outer side, a middle moving groove (6) in the middle part and an inner moving groove (7) on the inner side. Rotating teeth (9) are installed in the middle part of the inner moving groove (7), a balance block (8) is slidably installed in the middle part of the outer moving groove (5), and a pushing strip (10) is slidably installed at the front end of the middle moving groove (6).

Owner:SHENGZHOU BAIEN TRADE

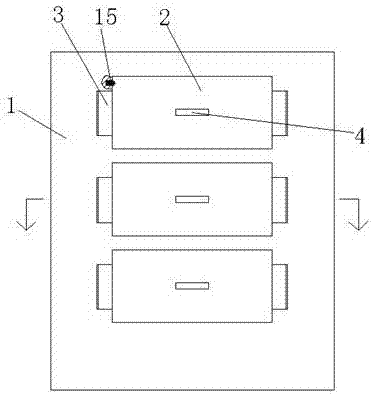

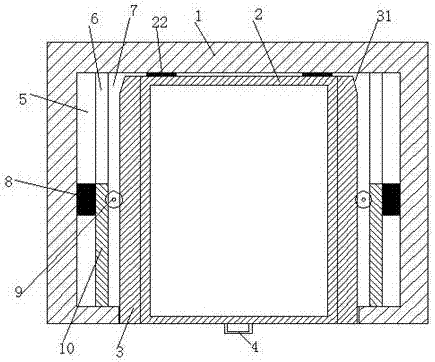

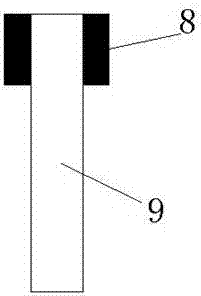

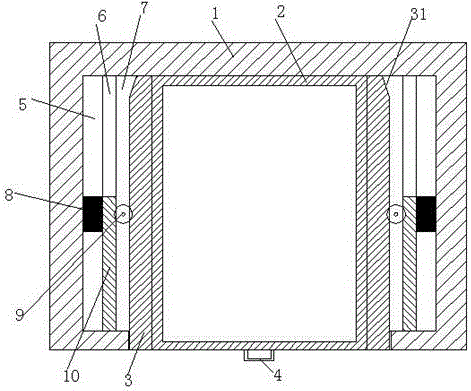

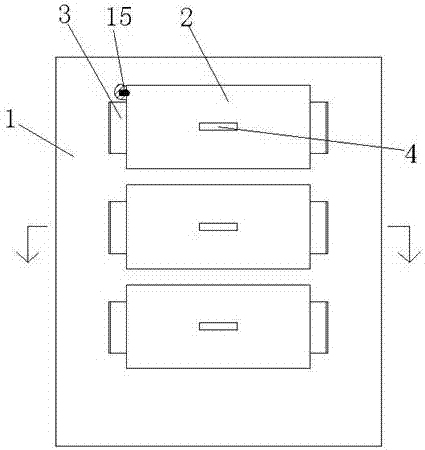

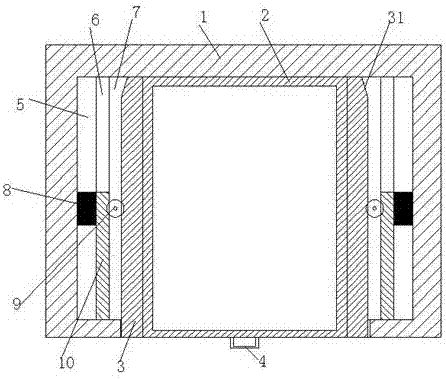

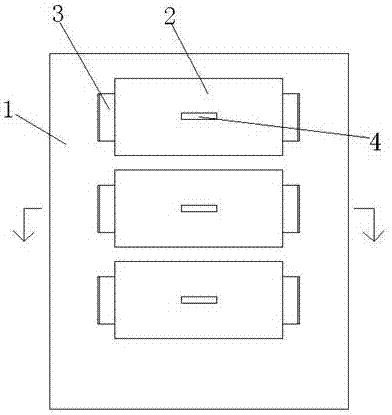

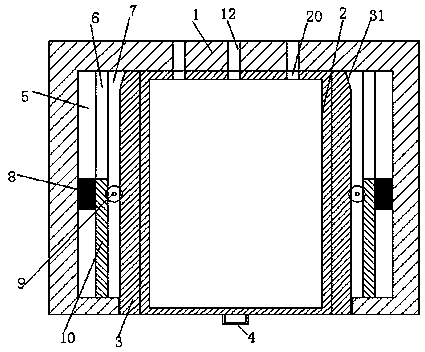

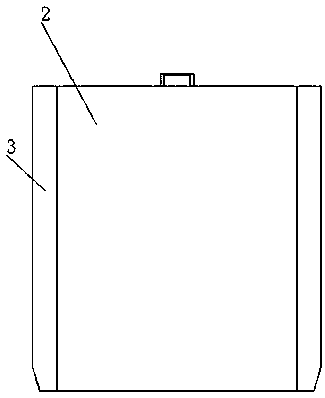

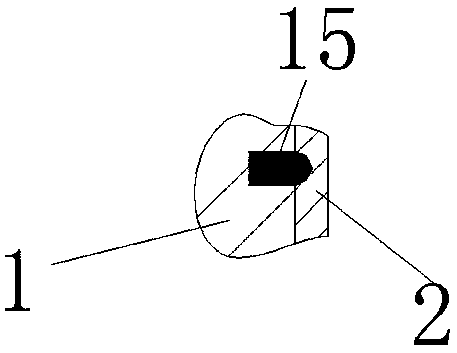

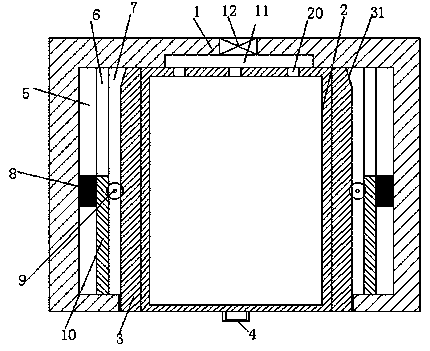

A drawer type power installation cabinet device

InactiveCN106451186BLess forward leanAvoid rollover riskSwitchgear with withdrawable carriageEngineeringElectric power

The invention discloses a drawer-type electric power installation cabinet device which comprises a cabinet body (1), a plurality of installation grooves and a plurality of installation drawer boxes (2), wherein the installation grooves are formed in the cabinet body and vertically separated, the installation drawer boxes for installing components are installed in the installation grooves. Sliding grooves are symmetrically formed in two sides of each installation groove, gliding grooves are formed in outer sides of the sliding grooves and comprise first outer guide grooves (5), second middle guide grooves (6) and inner empty grooves (7), gears (9) are mounted in the middles of the empty grooves, balancing weights (8) are slidably mounted in the middles of the first guide grooves (5), sliders (10) are slidably mounted at the front ends of the second guide grooves (6), driven gears meshed with the gears are arranged on the end surfaces of the inner sides of the sliders, the rear ends of the end surfaces of the outer sides of the sliders (10) are fixedly connected with the balancing weights (8), and sliding arms matched with the sliding grooves are symmetrically arranged on the left end surface and the right end surface of each drawer box (2).

Owner:盐城中咏投资发展有限公司

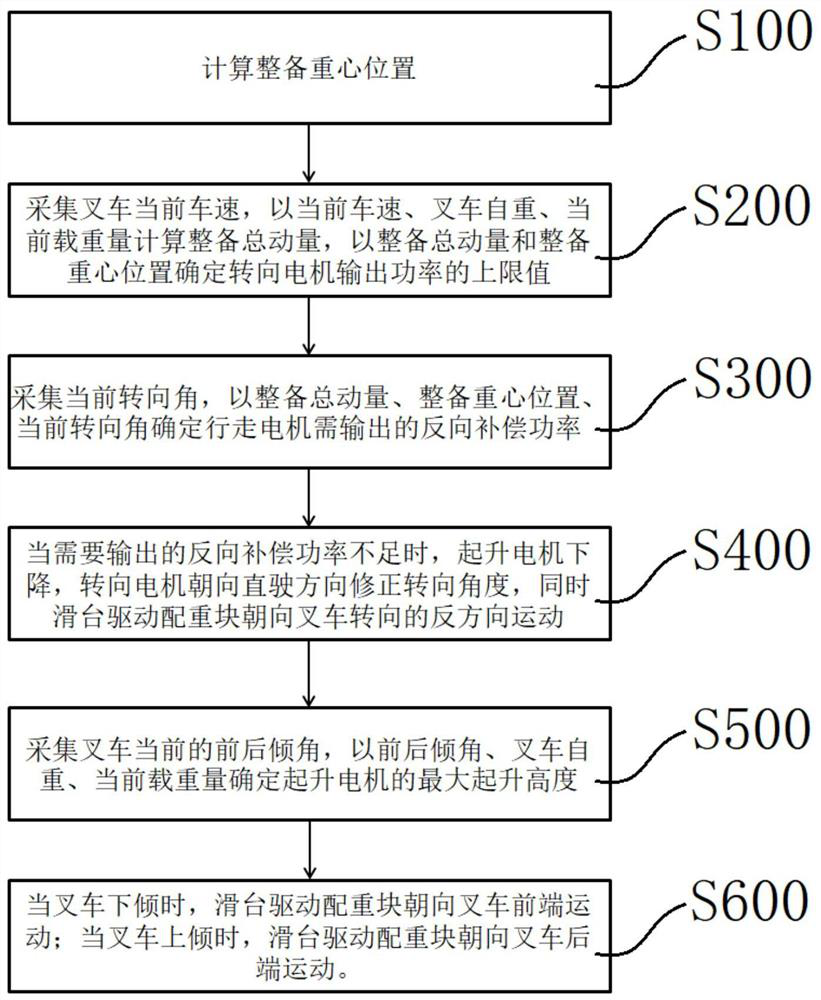

Novel motor drive control method of electric forklift

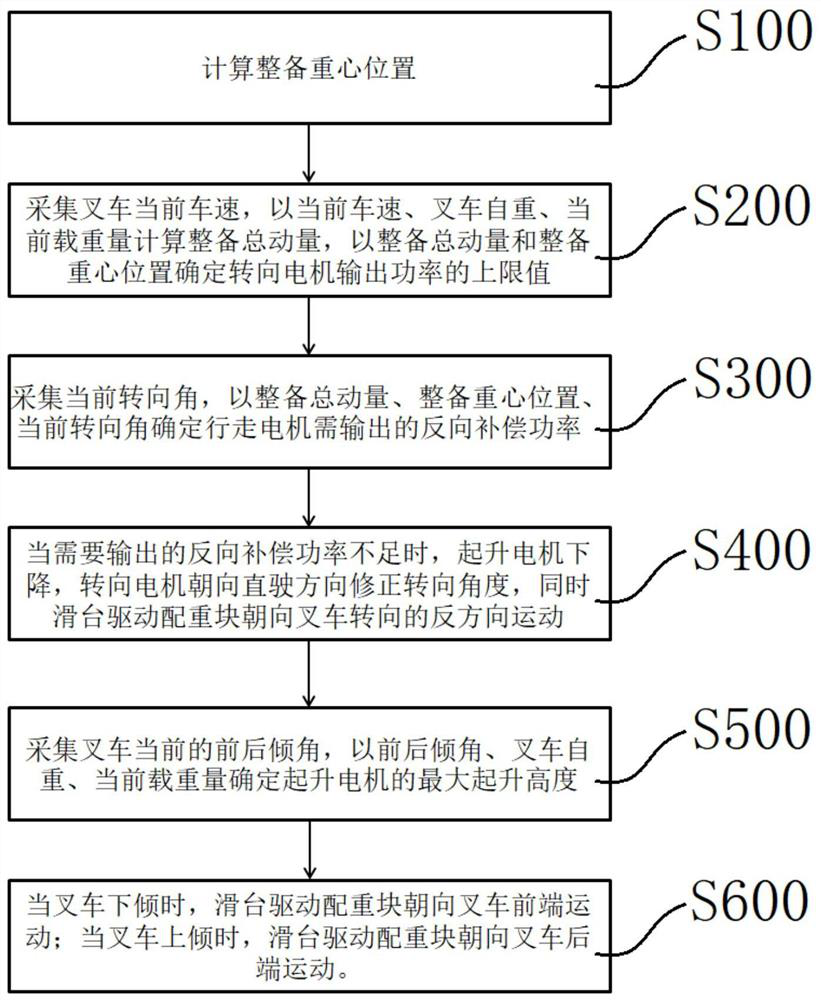

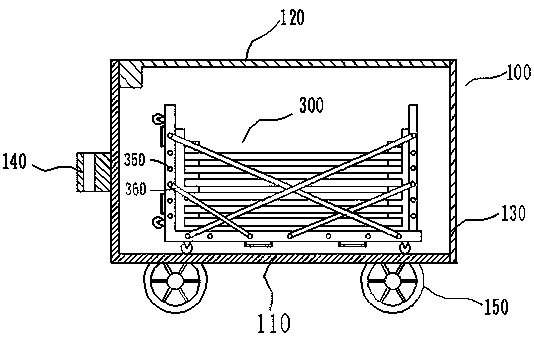

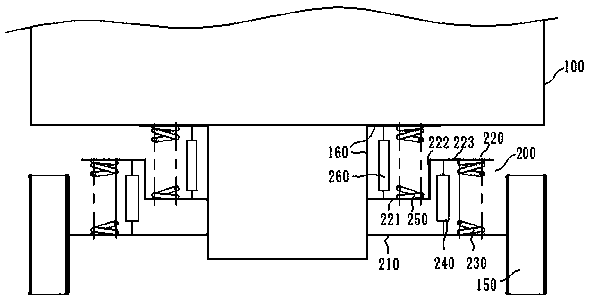

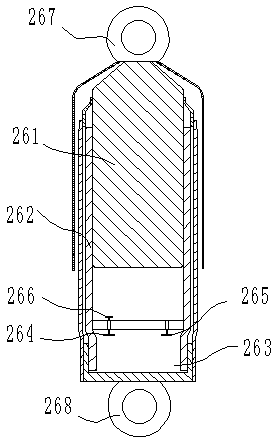

ActiveCN112279153APlay a stabilizing roleAchieve stabilitySafety devices for lifting equipmentsRolloverSteering angle

The invention provides a novel motor drive control method of an electric forklift. According to the technical scheme, a protective control strategy is designed for steering motion of the forklift in ahigh-speed state. Specifically, the method comprises the following steps that firstly, the approximate corresponding relationship between the weight of goods and the height of the center of gravity of the goods is manually input by combining the proportion of the goods, and then a servicing center-of-gravity position is calculated on the basis of he relationship; then the output power of a steering motor is limited according to the servicing center-of-gravity position and the servicing total momentum; on the basis, when the current steering angle is too large, a walking motor is used for assisting in braking; when the auxiliary braking power is insufficient, the steering motor is forced to correct the steering direction, a lifting motor lowers the whole gravity center, and meanwhile a built-in balancing weight is made to move reversely to play a stabilizing role. Based on the principle, when the forklift steers at a high speed, a forklift body can be stabilized, and the rollover riskis avoided. In addition, when the forklift is driven into a slope, the position of the gravity center can be corrected through the balancing weight, and the stability of the forklift on the slope is improved.

Owner:ZIBO GREEN ELECTRONICS TECH

Building glass transporting device and application method thereof

ActiveCN110980299AImprove shock absorptionImprove securitySledge wheelsCharge manipulationVehicle frameShock resistance

The invention relates to a building glass transporting device and an application method thereof. The building glass transporting device comprises a car frame, wherein a compartment is arranged on thecar frame; an extensible top cover is arranged on the top part of the compartment; car wheels are further arranged on the bottom part of the compartment and are connected with the car frame through suspension systems; each suspension system comprises a main suspension arm and an auxiliary suspension arm; one ends of the main suspension arms are connected with the car wheels; the other ends of themain suspension arms are hinged with the car frame; one ends of the auxiliary suspension arms are hinged with the car frame; the auxiliary suspension arms are connected with the main suspension arms through main damping springs and dampers; and the auxiliary suspension arms are connected with the car frame through auxiliary damping springs and support pieces. A carrying device is arranged in the compartment and comprises a placement plate A and a placement plate B arranged perpendicularly; a plurality of support frames are slidably arranged on the placement plate A; and a sliding support assembly is arranged on the placement plate B. The device can adjust the shock resistance according to different road conditions and is matched with the shock-resistant carrying device, so that the damagerate of glass is reduced.

Owner:山东炎黄工业设计有限公司

Toolbox structure for electromechanical maintenance

Disclosed is a toolbox structure for electromechanical maintenance. The toolbox structure for the eletromechanical maintenance comprises a toolbox body (1), a plurality of telescopic main grooves formed in the toolbox body and separated up and down, and a plurality of placing boxes (2) installed in the telescopic main grooves and used for placing maintenance tools, the two sides of each telescopic main groove are symmetrically provided with telescopic vice grooves, the outer side of each telescopic vice groove is provided with an inner slide way, each inner slide way comprises an outer slide way (5) at the outer side, a middle slide way (6) at the middle position and an inner slide way (7) at the inner side, an inert rotary tooth (9) is installed at the middle position of each inner slide way, an adjusting block (8) is installed at the middle position of the outer slide way (5) in a sliding mode, a push rod (10) is installed at the front end of the middle slide way (6) in a sliding mode, the inner side end surface of the push rod is provided with a function tooth meshed with the inert rotary tooth, the rear end of the outer side end surface of the push rod (10) is fixedly connected with the adjusting block (8), and bearing arms matched with the telescopic vice grooves are symmetrically arranged on the left and right side surfaces of each placing box (2).

Owner:嵊州市诺米克进出口有限公司

A drawer type power switch cabinet device

ActiveCN106992455BLess forward leanAvoid rollover riskSwitchgear with withdrawable carriageEngineeringMechanical engineering

Owner:山东永锦电气股份有限公司

A storage rack device for items

Owner:如皋市强固机械配件厂

High-strength aluminum alloy hub structure

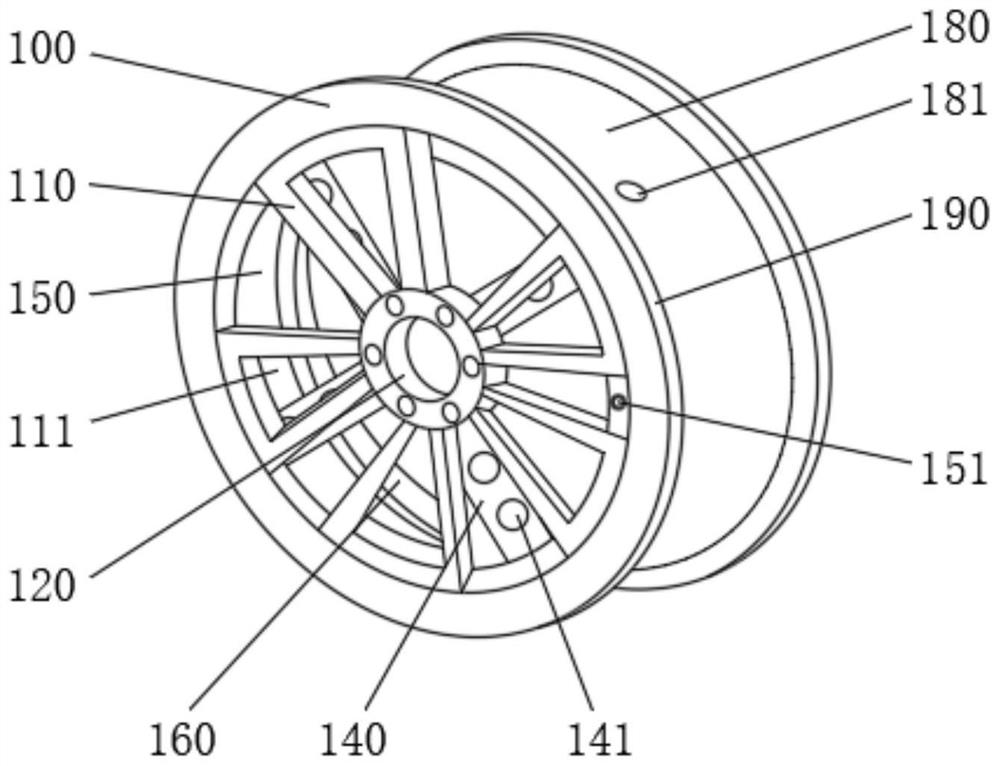

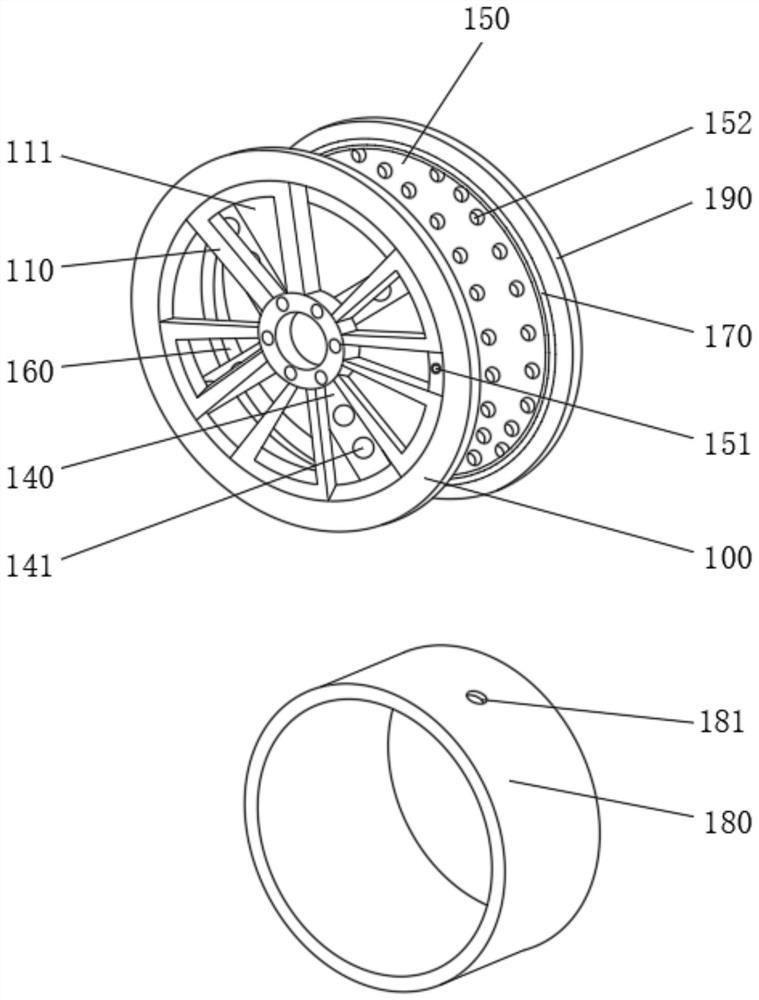

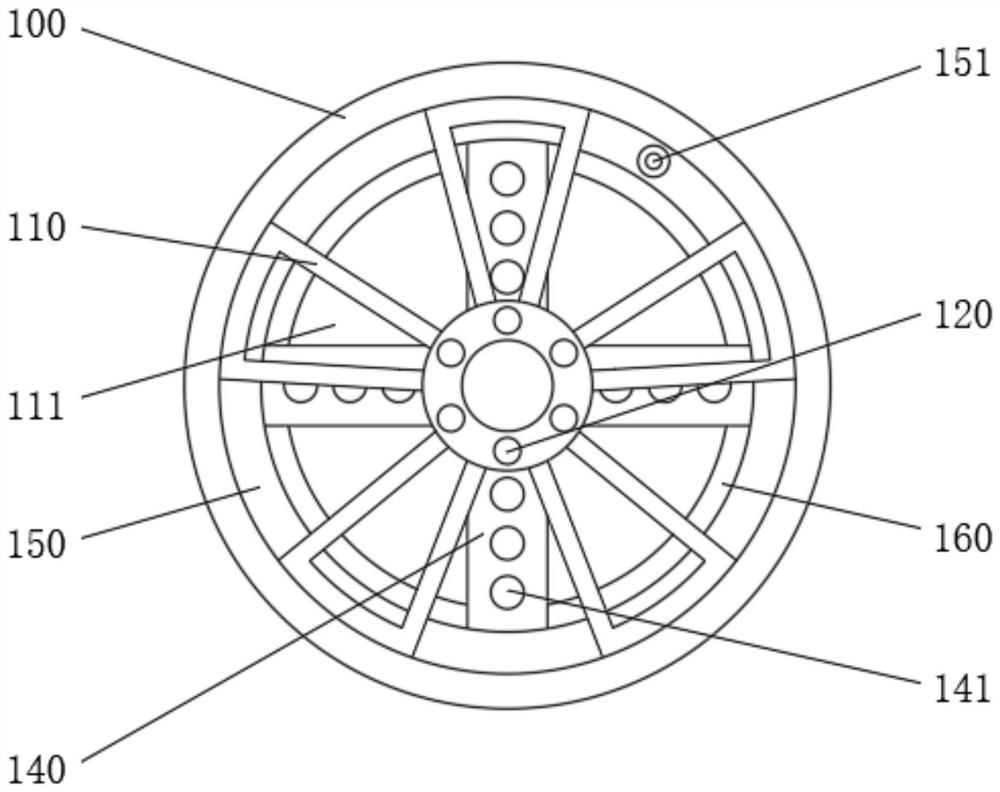

PendingCN113246650AGuaranteed aestheticsIncrease stiffnessDisc wheelsHigh resiliency wheelsRolloverSilumin

The invention discloses a high-strength aluminum alloy hub structure in the technical field of automobile hubs, the high-strength aluminum alloy hub structure comprises a hub body, a mounting seat is arranged at the center of the front side wall of the hub body, and a plurality of spokes are arranged between the outer side wall of the mounting seat and the inner side wall of the hub body; and a matching seat is arranged on the outer side wall of the mounting seat and is located behind a spoke; according to the high-strength aluminum alloy hub structure, the structural design is reasonable, the strength of acting force borne in the spokes is greatly reduced, the effect of stabilizing a vehicle body is achieved, the controllability of a driver for vehicle driving is ensured, the risk of vehicle rollover is fundamentally avoided, personal safety of a driver is guaranteed, damage to the hub body is avoided, the service life of a product is effectively prolonged, meanwhile, the overall weight of the hub body is effectively reduced, the unsprung mass of a vehicle is reduced, and then the rotational inertia of a tire in the driving process of the vehicle is reduced.

Owner:安徽拓普勒汽车科技有限公司

Medical trolley device

InactiveCN107095754ALess forward leanAvoid rollover riskNursing accommodationAmbulance servicePush and pullEngineering

A medical trolley device comprises a trolley body (1), a support (100) firmly disposed on the bottom end of the trolley body (1), and rollers (101) installed on the bottom of the support, wherein multiple cavities which extend back and forth are disposed in the trolley body (1); a push and pull box (2) which is used to place medical appliances and medicines is installed in each cavity in a back and forth movable manner; tracks are disposed symmetrically on two sides of each cavity; movable grooves are formed outside the tracks; the movable grooves comprise an outer movable groove (5) in the outer side, a middle movable groove (6) in the middle part and an inner movable groove (7) in the inner side; rotation teeth (9) are installed at the middle part of the inner movable groove; a balance block (8) is installed at the middle part of the outer movable groove (5) in a sliding manner; and a push bar (10) is installed on the front end of the middle movable groove (6) in a sliding manner.

Owner:SHENGZHOU BAIEN TRADE

A new motor drive control method for electric forklift

ActiveCN112279153BPlay a stabilizing roleAchieve stabilitySafety devices for lifting equipmentsRolloverSteering angle

Owner:ZIBO GREEN ELECTRONICS TECH

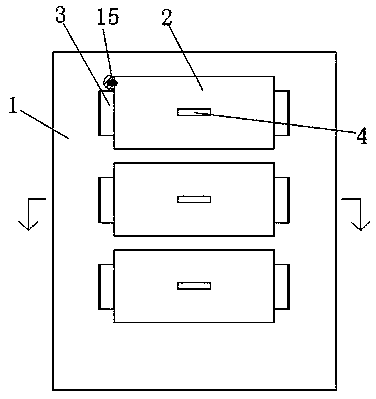

Screw lifting device and automatic separation equipment thereof

PendingCN108906643AAvoid rollover riskReduce work intensityLifting framesSortingMechanical engineeringEngineering

Owner:惠州市昇沪汽车紧固件科技有限公司

A drawer-type power installation cabinet device capable of rapid heat dissipation

ActiveCN106992456BLess forward leanAvoid rollover riskSwitchgear with withdrawable carriageSubstation/switching arrangement cooling/ventilationEngineeringMechanical engineering

Owner:PANJIN GUANGLIDA ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com