Foldable compartment and automatic-unloading trunk capable of preventing material unloading and lateral overturning

A technology of dump trucks and carriages, which is applied in the direction of motor vehicles, loading and unloading vehicles, vehicles used for freight, etc. It can solve the problems of high center of gravity and rollover of the carriages, and achieve the effect of avoiding the rollover of the carriages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

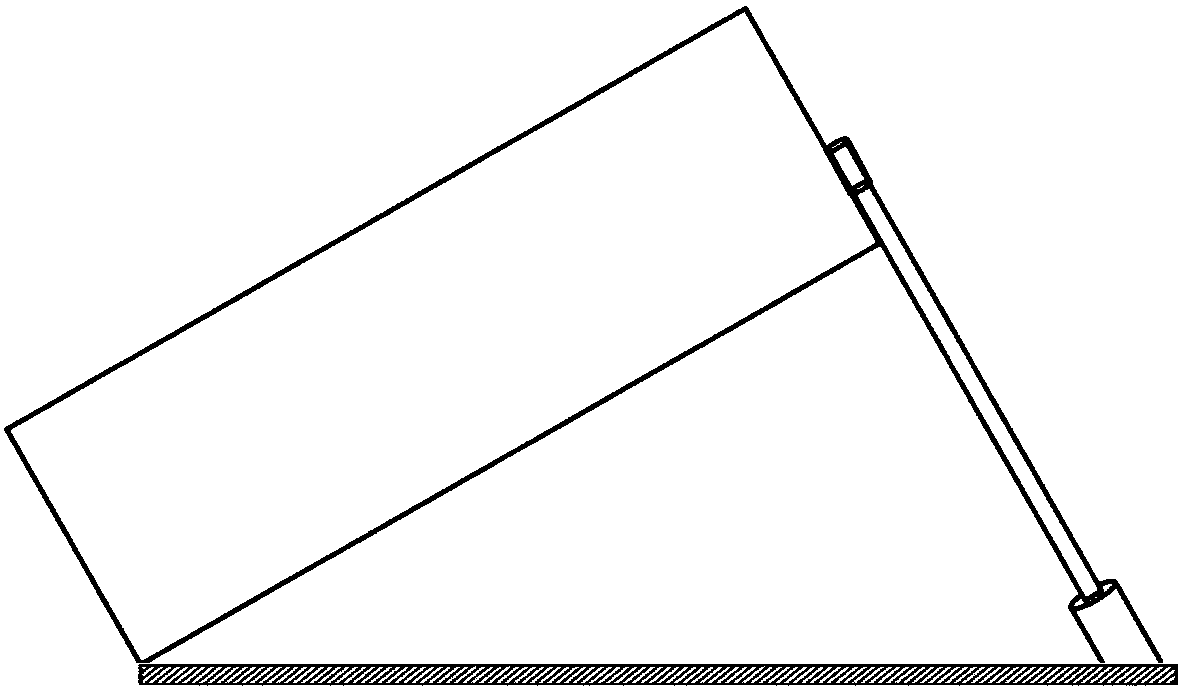

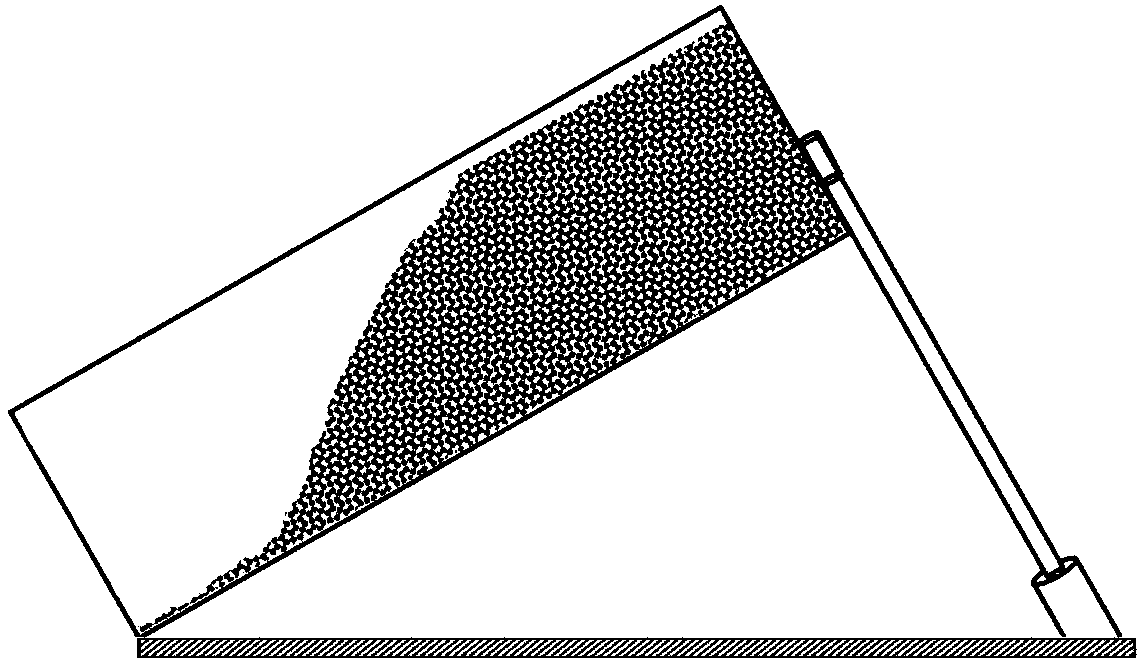

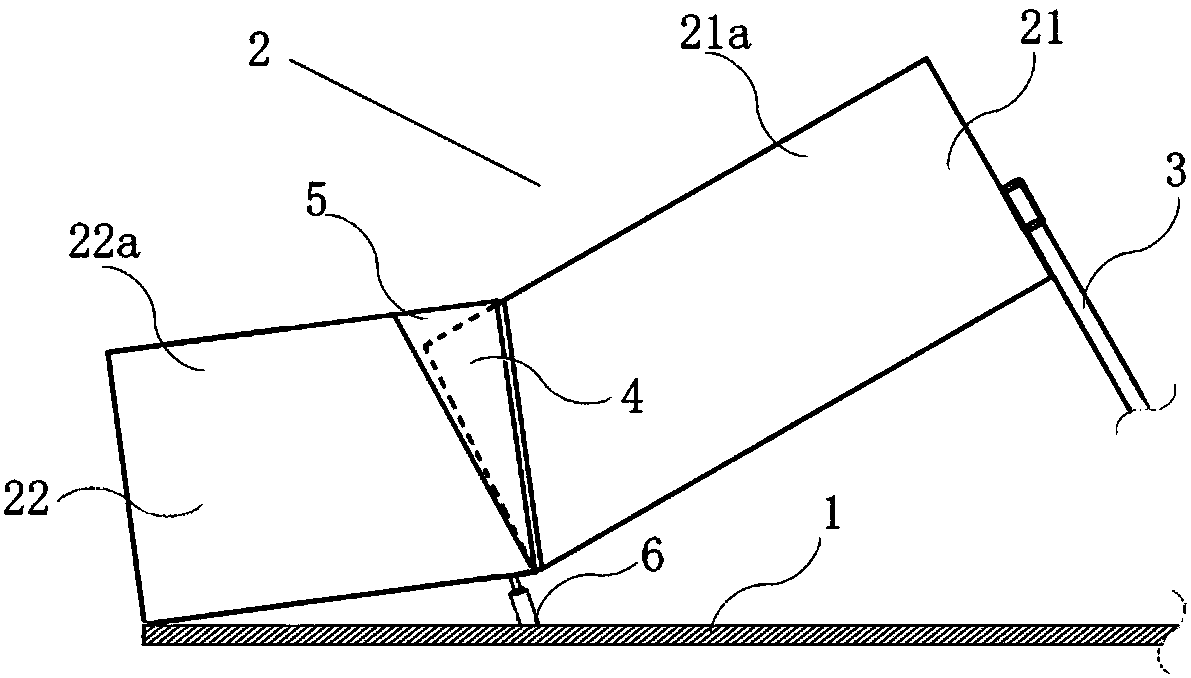

[0026] Such as image 3 As shown, a dump truck with anti-dump rollover includes a frame 1, a compartment 2 and a lifting mechanism 3. The rear portion of the compartment 2 is hinged with the rear portion of the vehicle frame 1, the lifting mechanism 3 is a hydraulic cylinder, and the front end of the compartment 2 is connected to the piston rod of the hydraulic cylinder. This dump truck uses a middle foldable compartment 2, which is made up of side frames and a floor, and the compartment 2 is divided into two parts, a front compartment 21 and a rear compartment 22 in the middle, and the front compartment 21 and the rear compartment 22 are Base plate hinged. The upper corner of the rear end of the front compartment side frame 21a has a triangular tenon 4, and the thickness of the tenon 4 is smaller than the thickness of the front compartment side frame 21a. The upper corner of the front end of the rear compartment side frame 22a has a tenon groove 5 matched with the tenon 4, ...

Embodiment 2

[0031] Such as Figure 6 As shown, on the basis of Embodiment 1, the beam 7 is fixed near the tenon 4 and the tenon groove 5 on the side frame of the carriage to reinforce and protect the folded part of the middle part of the carriage 2 . The beam 71 on the front compartment 21 is framed on the upper edges of the side frames 21a and 21b on both sides and close to the tenon 4, and its upper surface is flush with the upper surfaces of the side frames 21a and 21b. The beam 72 on the rear compartment 22 is added to the upper edge of the side frame 22a and the side frame 22b on both sides and close to the tongue and groove 5, and its upper surface is flush with the upper surface of the side frame 22a and the side frame 22b. In addition, longitudinal beams can also be added on the outside and / or inside of the rear compartment 22 corresponding to the beam 72 , and the longitudinal beam and the cross beam 72 are connected together to reinforce the tongue and groove 5 of the rear compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com