Novel motor drive control method of electric forklift

A technology of motor drive control and electric forklift, which is applied in the direction of hoisting device, lifting equipment safety device, etc. It can solve the problems that the stability of forklift truck body needs to be improved, so as to realize the stability of the truck body, avoid the risk of rollover, and improve the stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

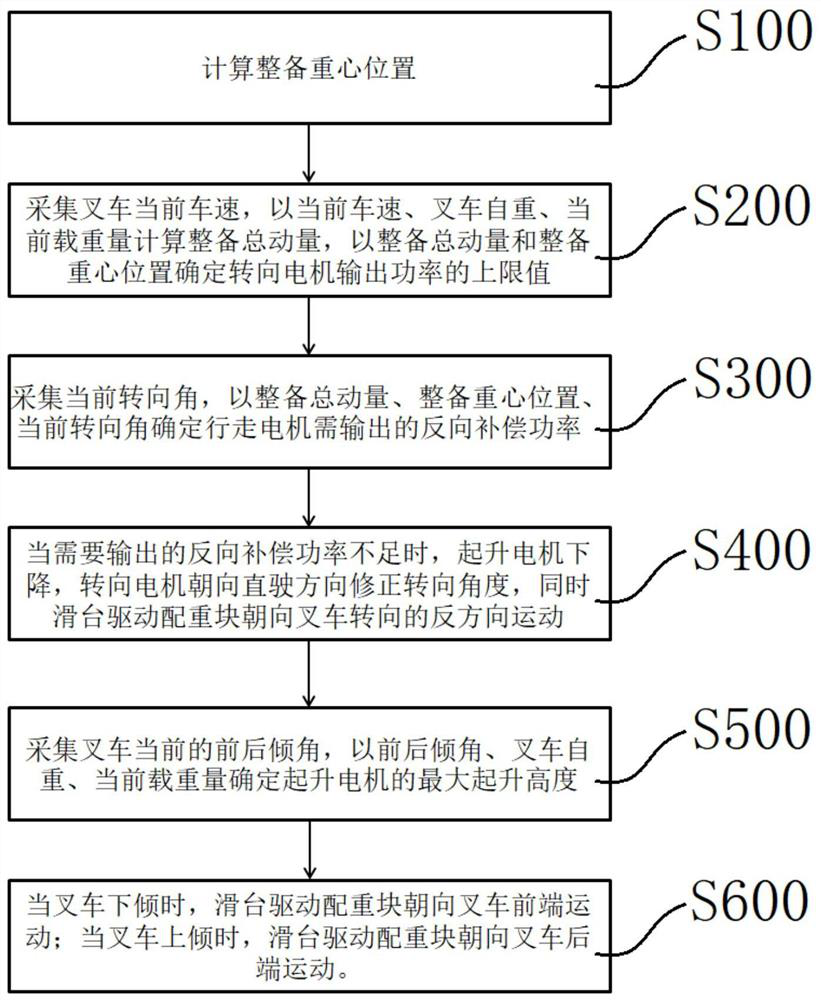

[0024] A novel motor drive control method for an electric forklift. The electric forklift includes a traveling motor, a lifting motor, and a steering motor. A sliding platform with two degrees of freedom is built into the chassis of the electric forklift, and a sliding platform is carried on the sliding platform. counterweight; such as figure 1 As shown, the method includes:

[0025] S100: preset the corresponding relationship between the weight of the load and the height of the center of gravity of the load, collect the current load of the forklift, calculate the current height of the center of gravity of the load, collect the current height of the arm of the forklift, and superimpose the height of the center of gravity of the current load to obtain the current The position of the center of gravity of the load is calculated according to the current load, the position of the center of gravity of the current load, the vehicle's own weight, and the position of the center of grav...

Embodiment 2

[0032] A novel motor drive control method for an electric forklift. The electric forklift includes a traveling motor, a lifting motor, and a steering motor. A sliding platform with two degrees of freedom is built into the chassis of the electric forklift, and a sliding platform is carried on the sliding platform. a counterweight; the method comprising:

[0033] Preset the corresponding relationship between the weight of the load and the height of the center of gravity of the load, collect the current load of the forklift, calculate the current height of the center of gravity of the load, collect the current height of the forklift arm, and superimpose the height of the center of gravity of the current load to obtain the current load The position of the center of gravity is calculated according to the current load, the position of the center of gravity of the current load, the self-weight of the vehicle, and the position of the center of gravity when the vehicle is empty;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com