Big-gradient crossheading step-forward self-moving equipment train

A technology of self-moving equipment trains and large gradients, which is applied to mine cars, transport passenger cars, railway car body parts, etc., can solve problems such as accidents, self-slipping of trains, sports cars, etc. , to ensure the effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

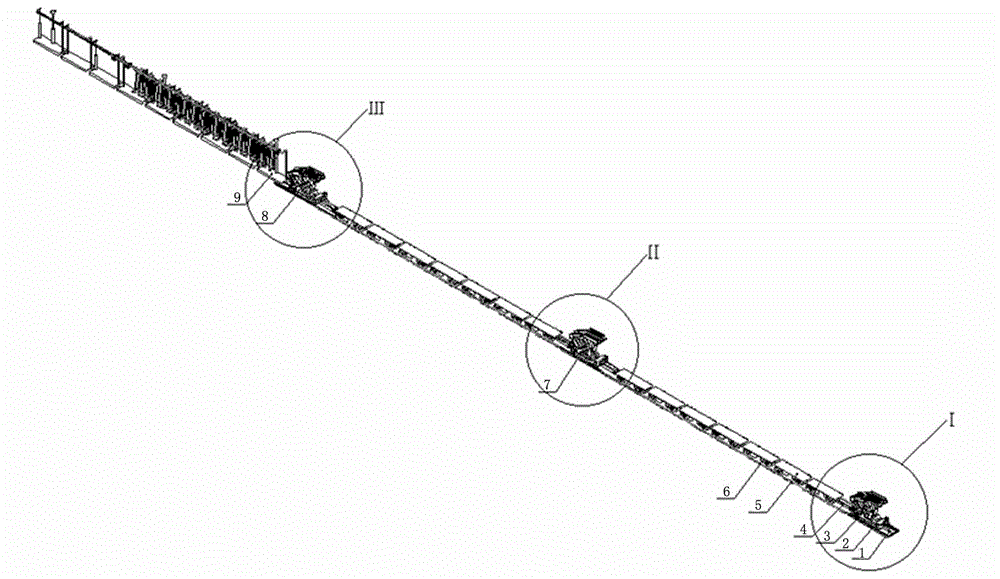

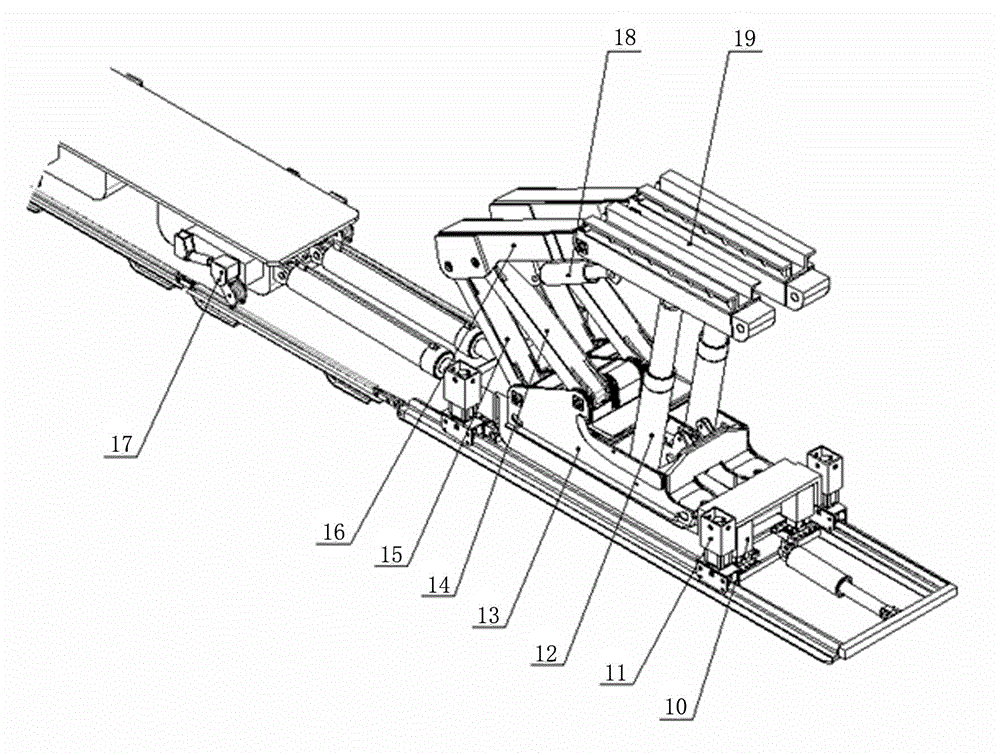

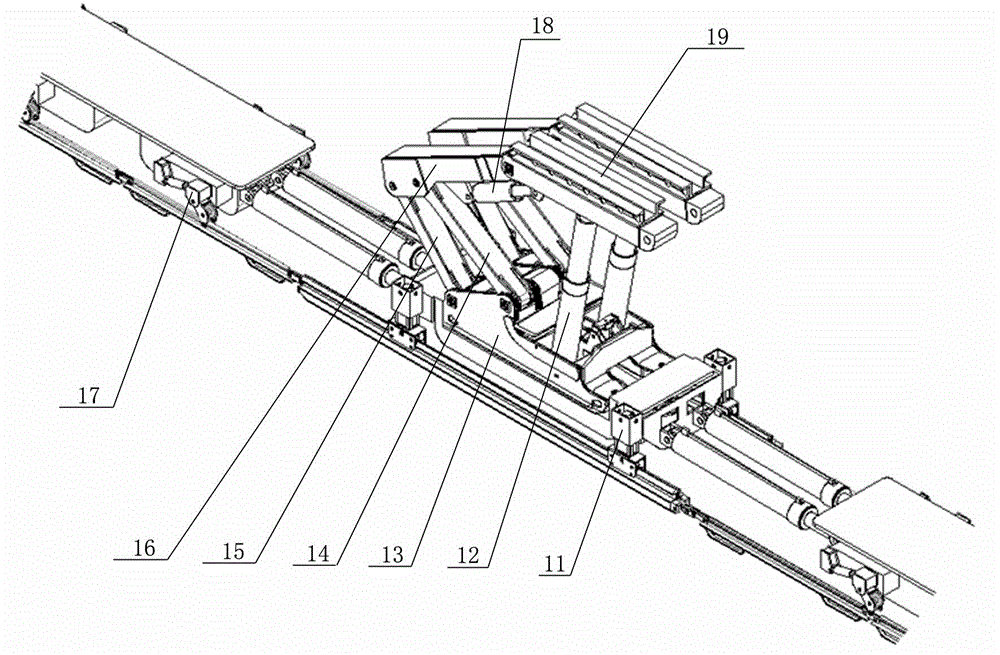

[0030] like figure 1 As shown, a large-slope self-moving equipment train with steps along the trough includes an anchoring pulling device, a flatbed car 5, a push jack, an anchoring pulling device guide rail 3, a flatbed truck guide rail 6 and a pipe cable telescopic bearing system 9, and the anchoring pulling device The device is erected on the guide rail 3 of the anchoring and pulling device, and the flatbed car 5 is erected on the flatbed cart guide rail 6 through the flatbed cart lifting device 17, and two adjacent flatbed carts 5 are connected by universal cross joints to adapt to the working conditions of the large-slope roadway. Described anchor pulling device comprises front anchor pulling device 2, middle anchor pulling device 7 and rear anchor pulling device 8, and the front end of front anchor pulling device 2 is provided with forward moving jack 1, and forward moving jack 1 is connected with anchor pulling device 8. The moving device guide rail 3 is connected, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com