Blade guide rolling device for static frequency detection of large blades

A rolling device and blade technology, which is applied in the field of blade static frequency detection tooling, can solve the problems of oversized and overweight blades with difficulty in frequency measurement installation and easy damage to frequency measurement installation, and achieve the effects of reducing frictional contact area, avoiding blade damage, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

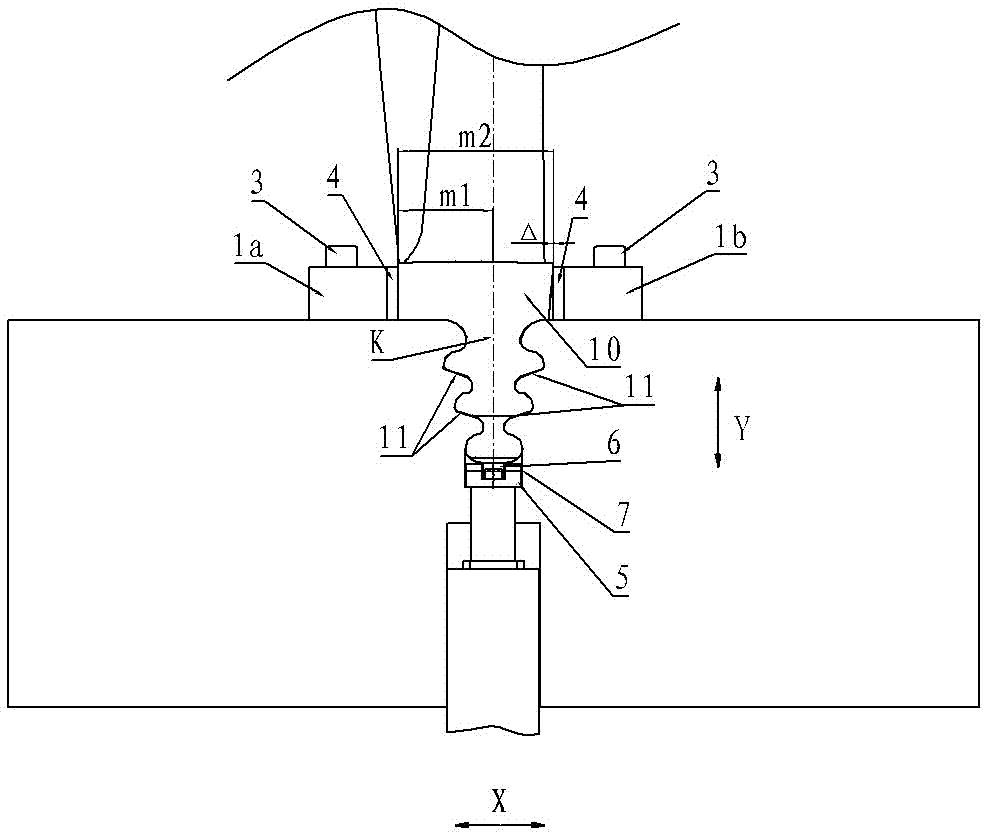

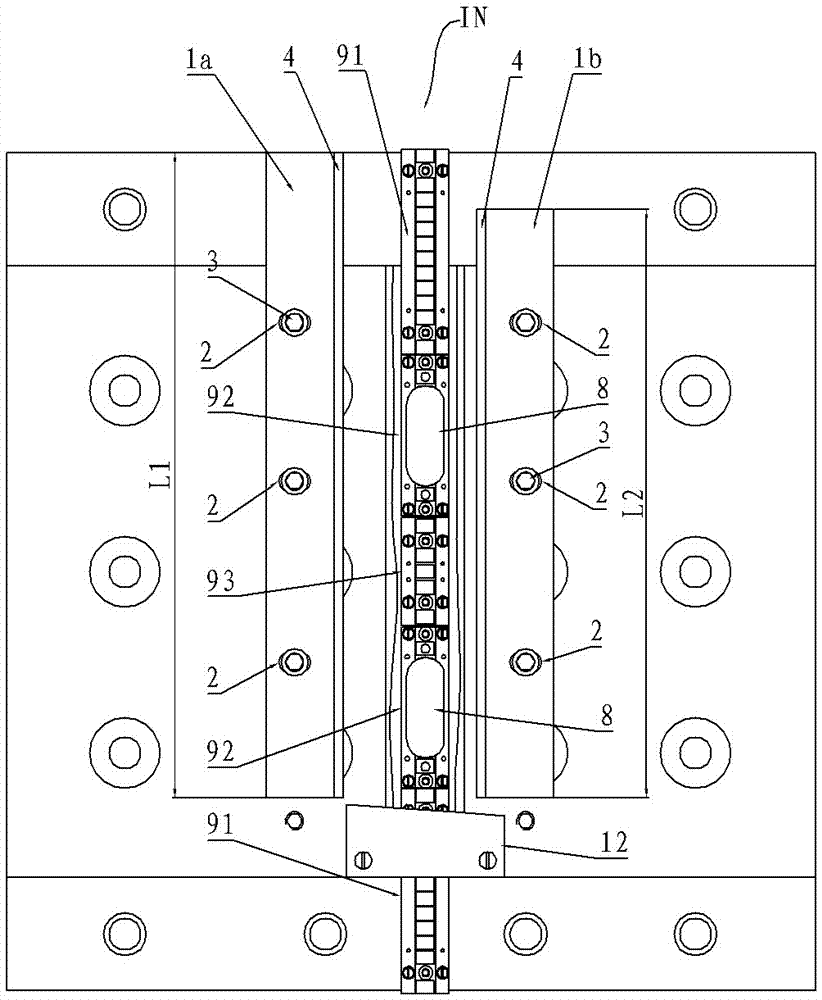

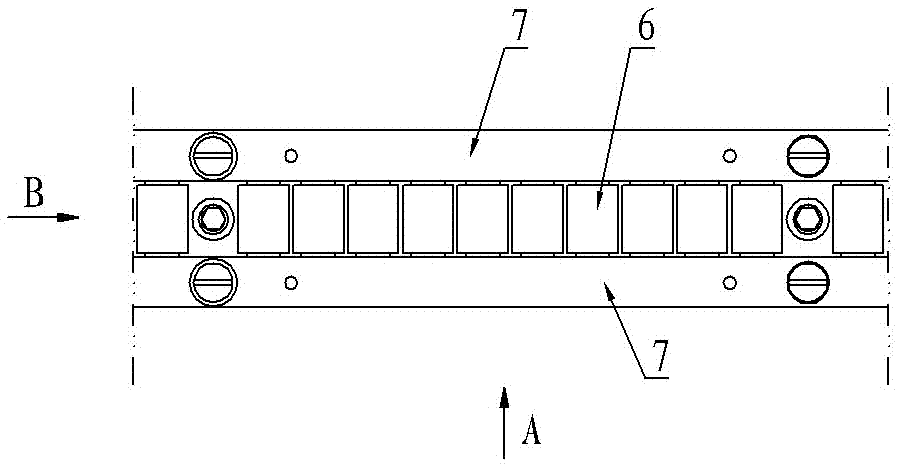

[0020] See figure 1 and figure 2 , the blade guiding and rolling device used for static frequency detection of large blades in the present invention includes a guiding assembly and a rolling assembly, and the guiding assembly includes two guiding blocks, respectively the main guiding block 1a, the secondary guiding block 1b, and the wheel groove of the frequency measuring device The main guide block 1a and the secondary guide block 1b are respectively installed on both sides of the top opening, and the main guide block 1a and the secondary guide block 1b are all extended along the length direction of the wheel groove; the main guide block 1a and the secondary guide block 1b are arranged along the length direction Evenly distributed with transverse waist-shaped holes 2, in this embodiment, the main guide block 1a and the secondary guide block 1b are evenly distributed with three transverse root-shaped holes 2 along the length direction, and the main guide block 1a and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com