Patents

Literature

35results about How to "Reduce frictional contact area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

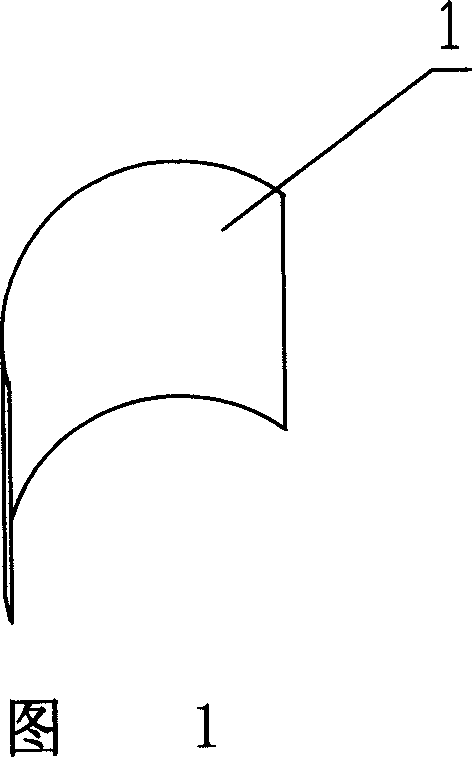

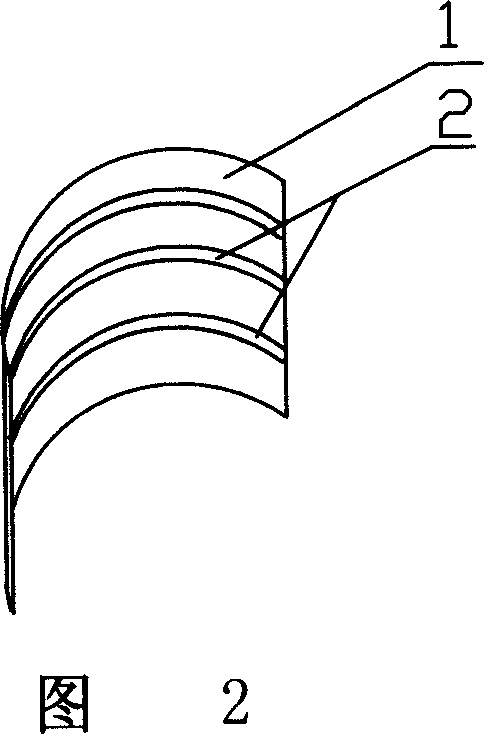

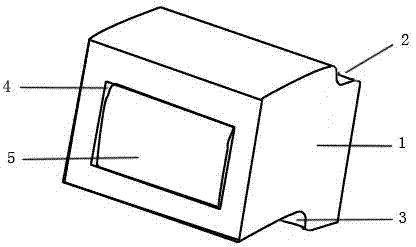

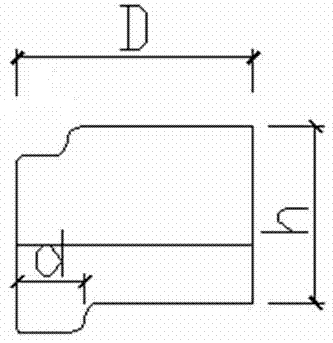

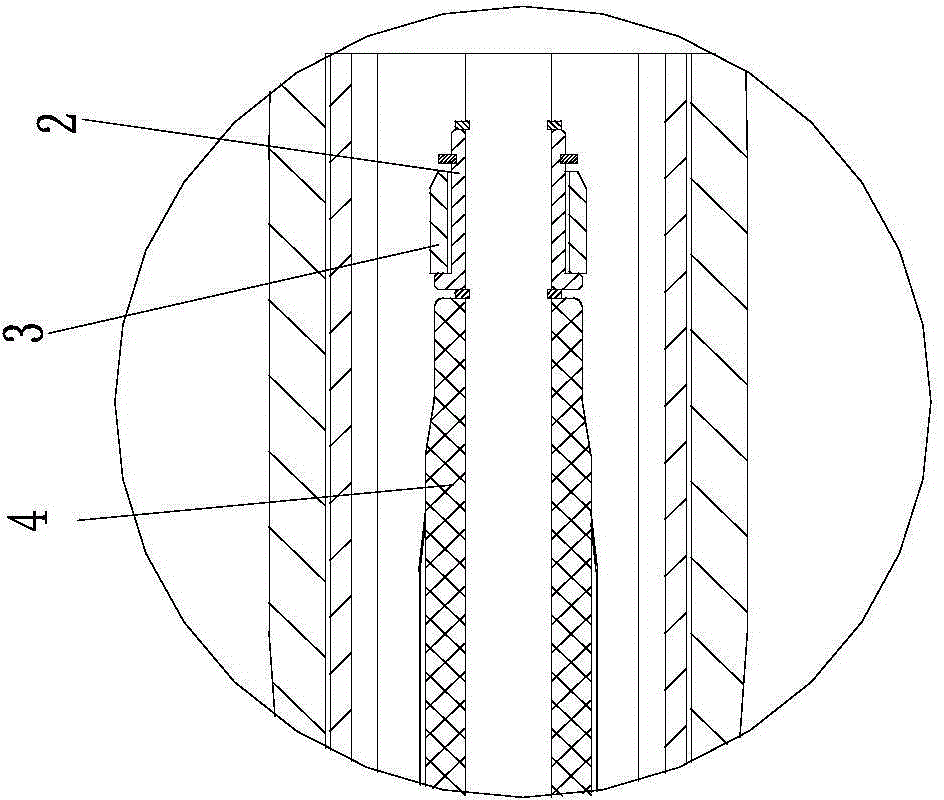

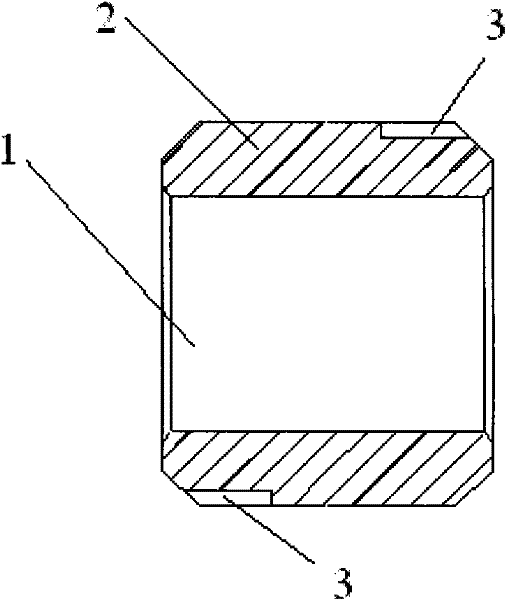

Crankshaft bush and connecting rod bush of internal combustion engine

InactiveCN1920314AIncrease powerReduce frictional contact areaConnecting rod bearingsCrankshaft bearingsExternal combustion engineEngineering

The invention relates to a crank bush and connecting rod bush of internal combustion engine, wherein the invention is characterized in that: the inner surfaces of crank bush and connecting rod bush that contacted with the crank have lubricant grooves, to reduce the friction contact area, and the groove contains oil to realize better lubricant effect, reduce the friction factor, improve the power of engine and reduce the energy consumption.

Owner:田泽华

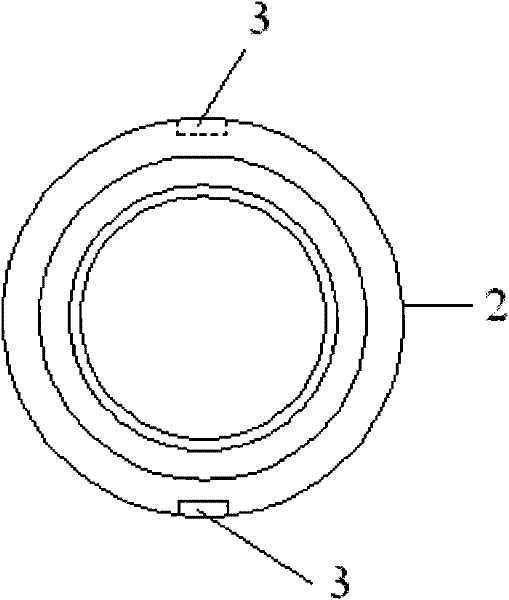

Powder metallurgy oil-free lubricating bearing and method for preparing same

ActiveCN101576122AImprove rotation efficiencyReduce running noiseBearing componentsOil freeMaterials science

The invention discloses a powder metallurgy oil-free lubricating bearing and a method for preparing the same. The powder metallurgy oil-free lubricating bearing comprises a shaft body provided with an axial central hole, and the outer surface of the shaft body is provided with an oil storage tank. The preparation method comprises the following steps: (1) evenly mixing Cu-Sn powder and C powder for forming, wherein the weight portion of all components is that: C is 0.5 to 3.0 portion, Cu is 85 to 93 portions and Sn is 5 to 13 portions; (2) controlling the temperature to between 650 and 730 DEG C, and performing sintering; (3) orderly performing finishing and cleaning; (4) performing vacuum oil immersion; and (5) performing deoiling treatment. The product has high precision and good dimension stability. Because the internal diameter tolerance of the product is controlled at 8u, and the axiality of the product is less than 0.05mm, and the matching gap between the product and the shaft is small, so that the friction contact area is small, the rotating efficiency of a fan is improved, the operating noise of the fan is reduced, and the service life of the fan is prolonged.

Owner:扬州保来得科技实业有限公司

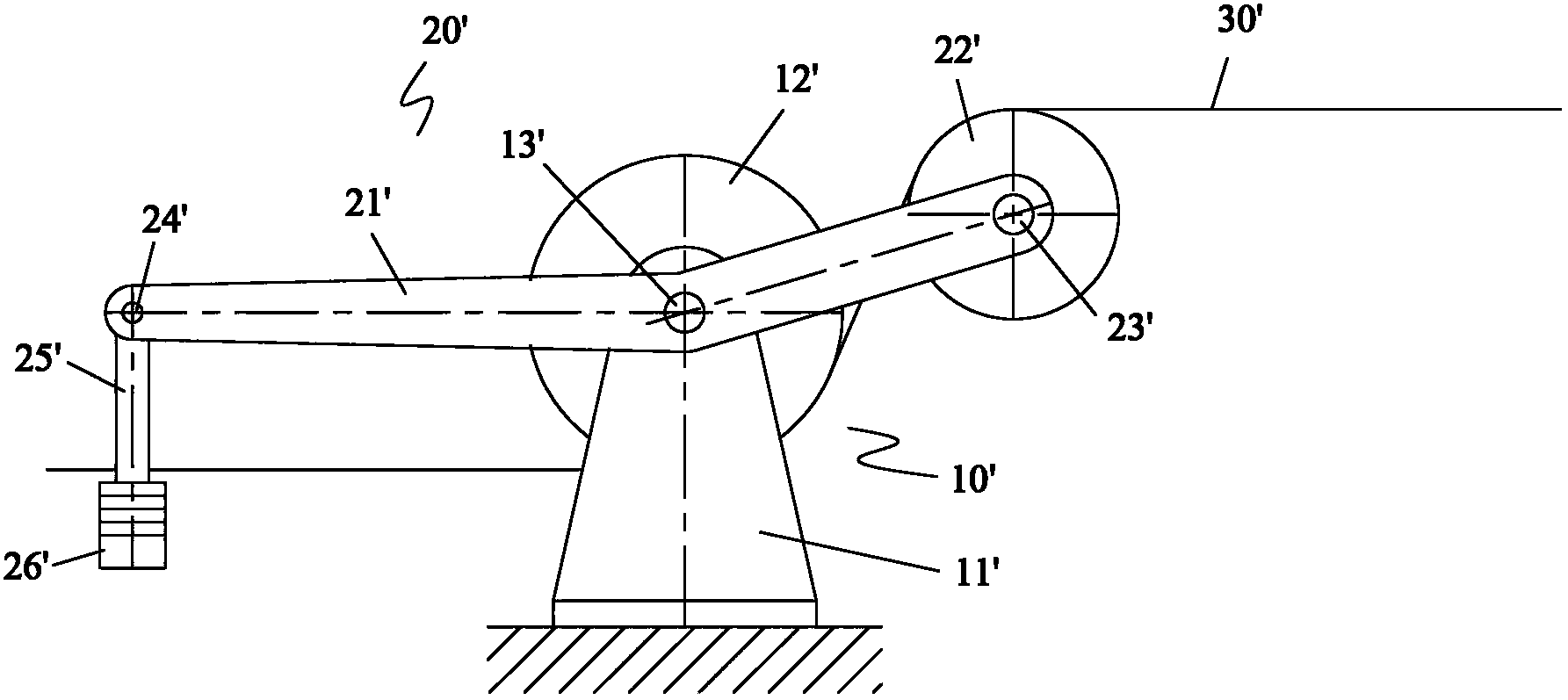

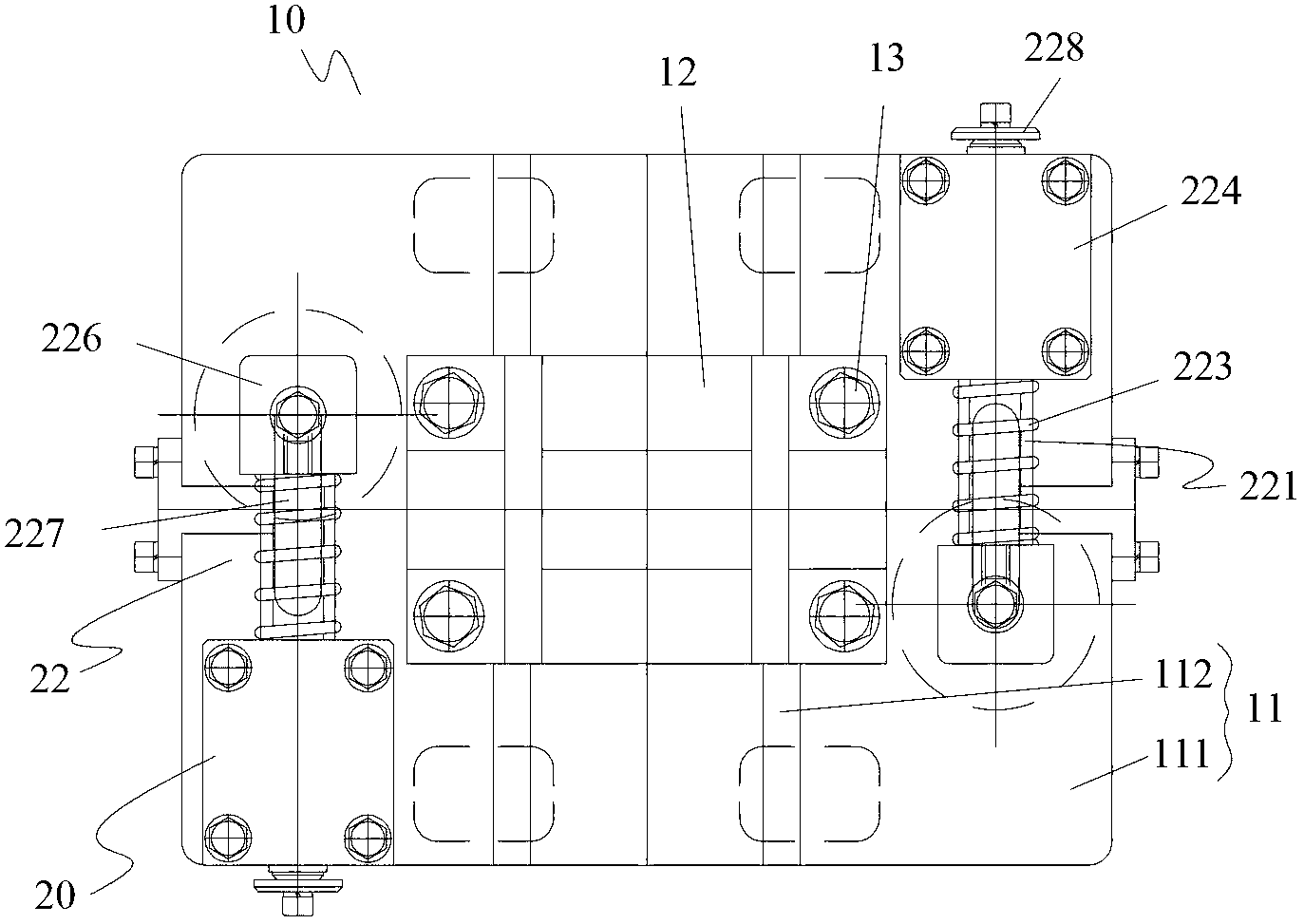

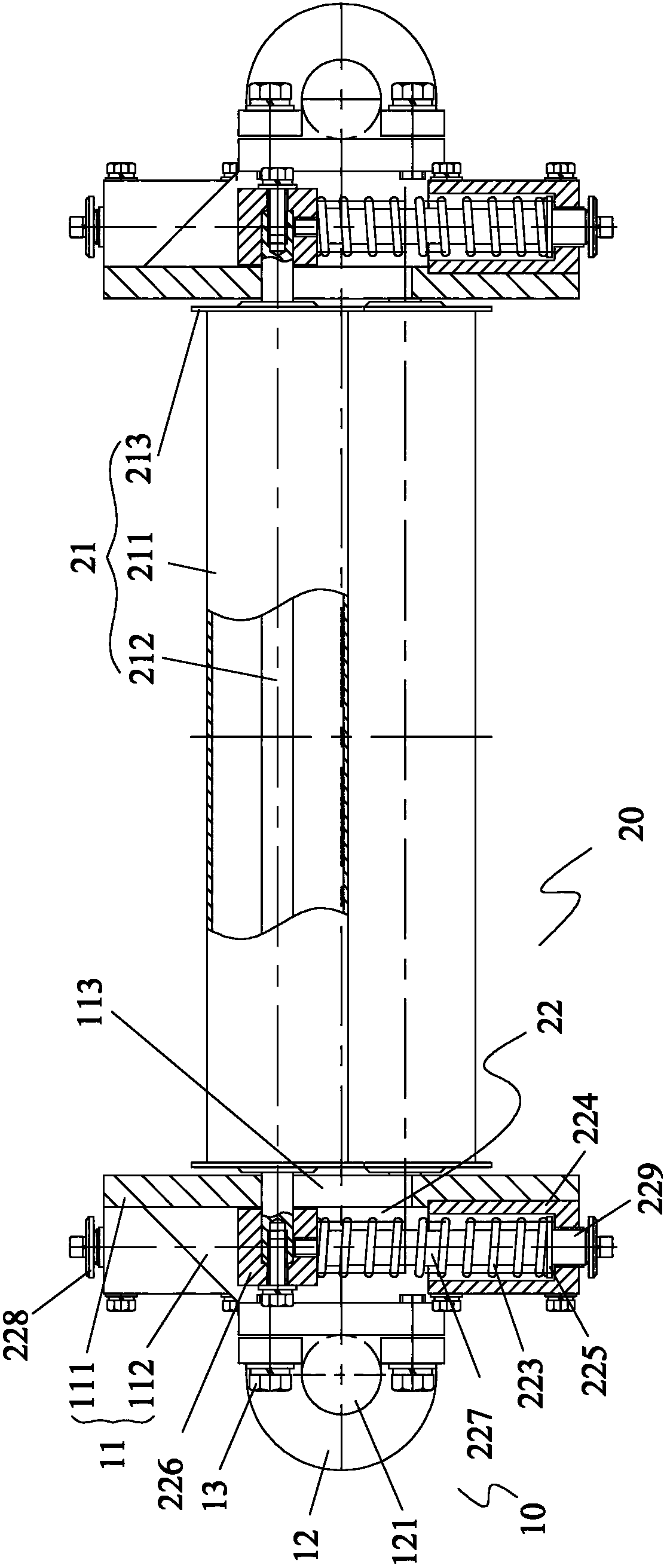

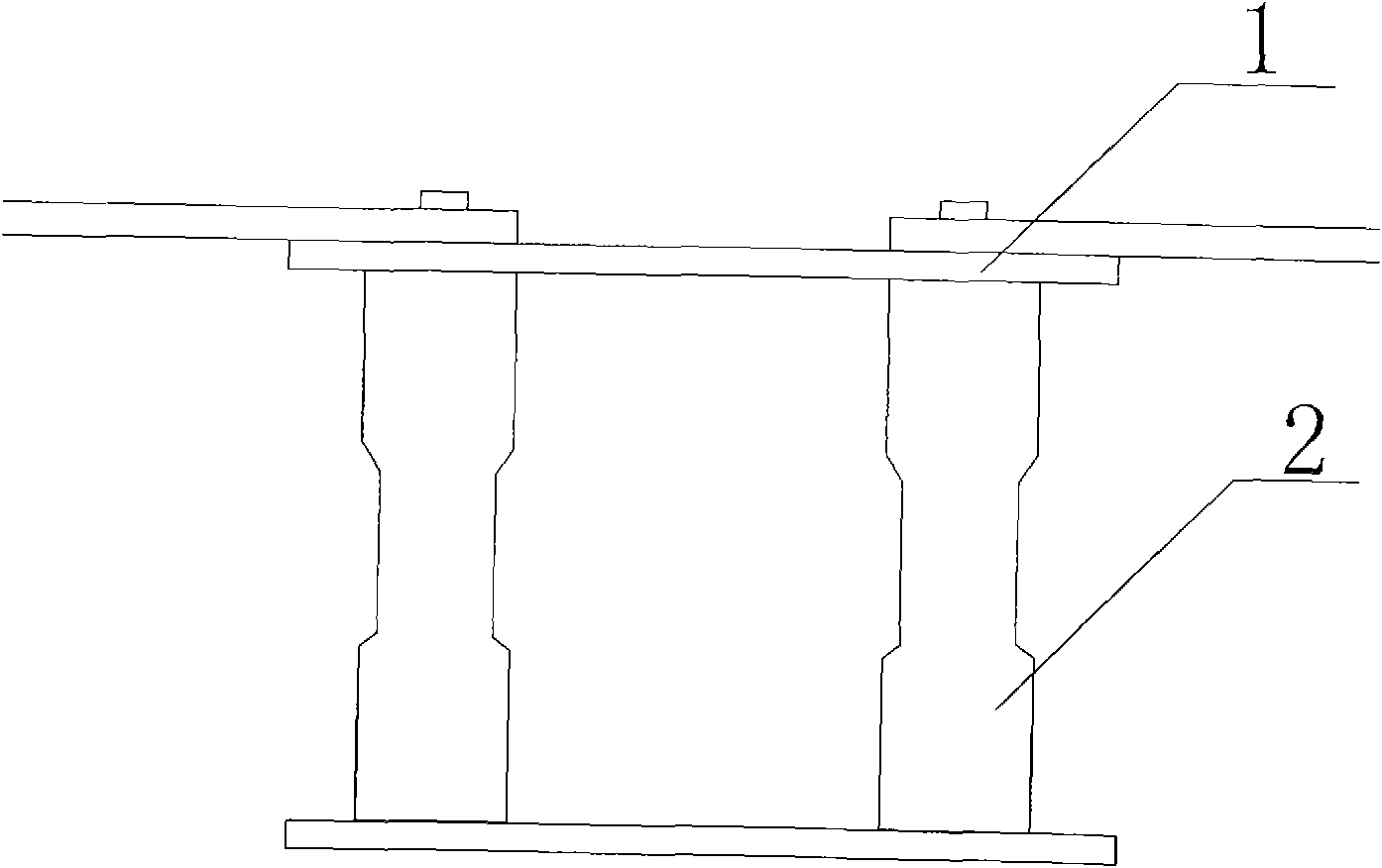

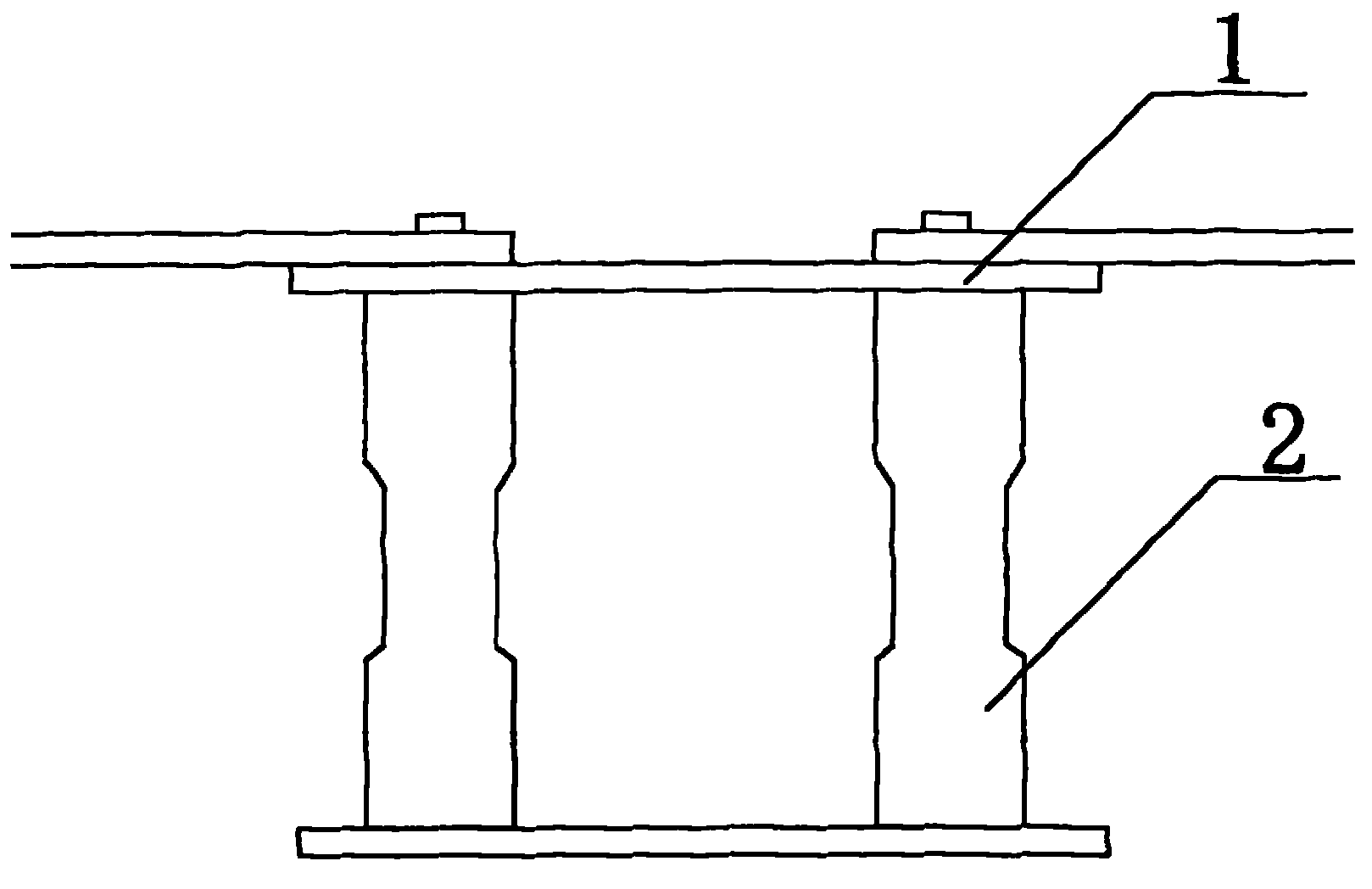

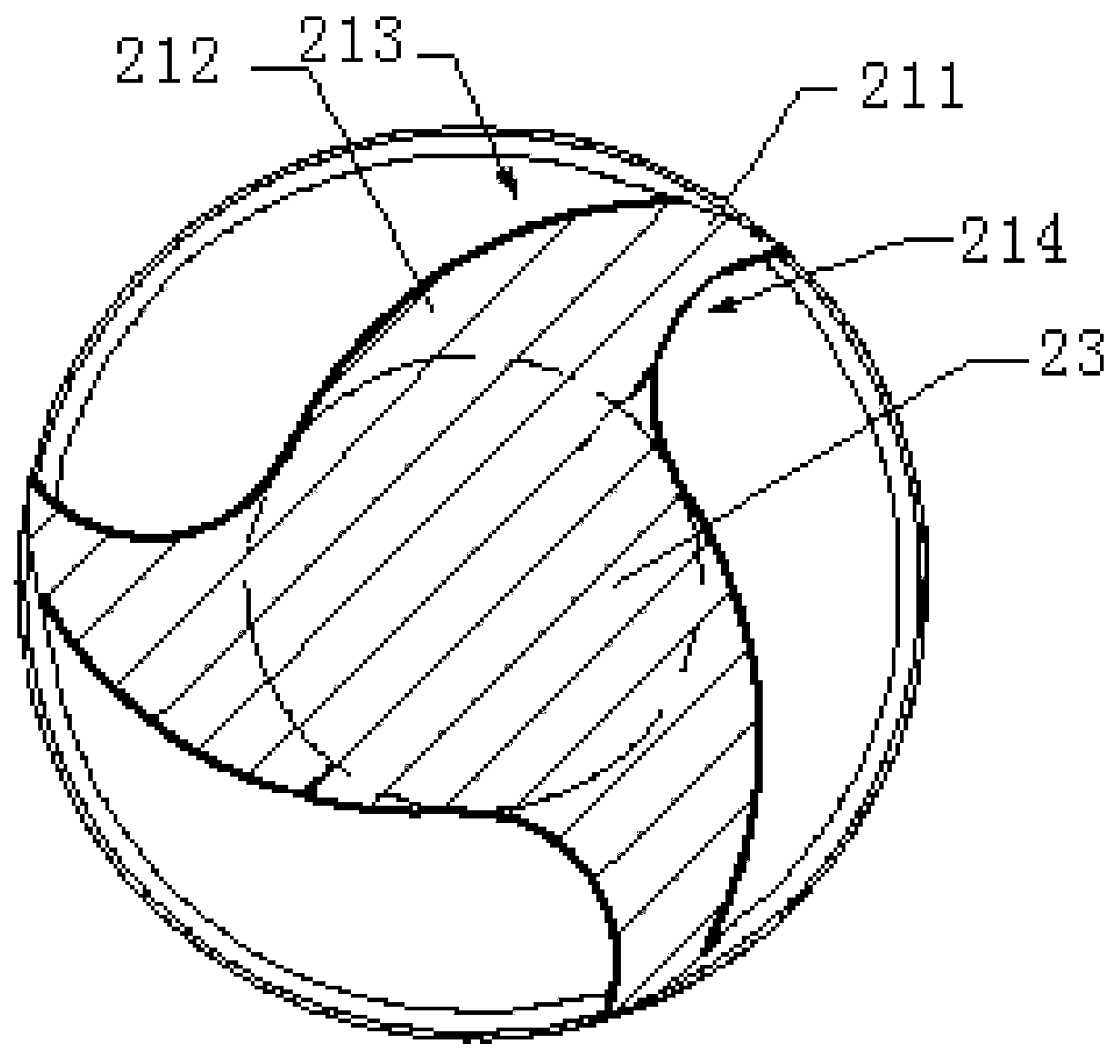

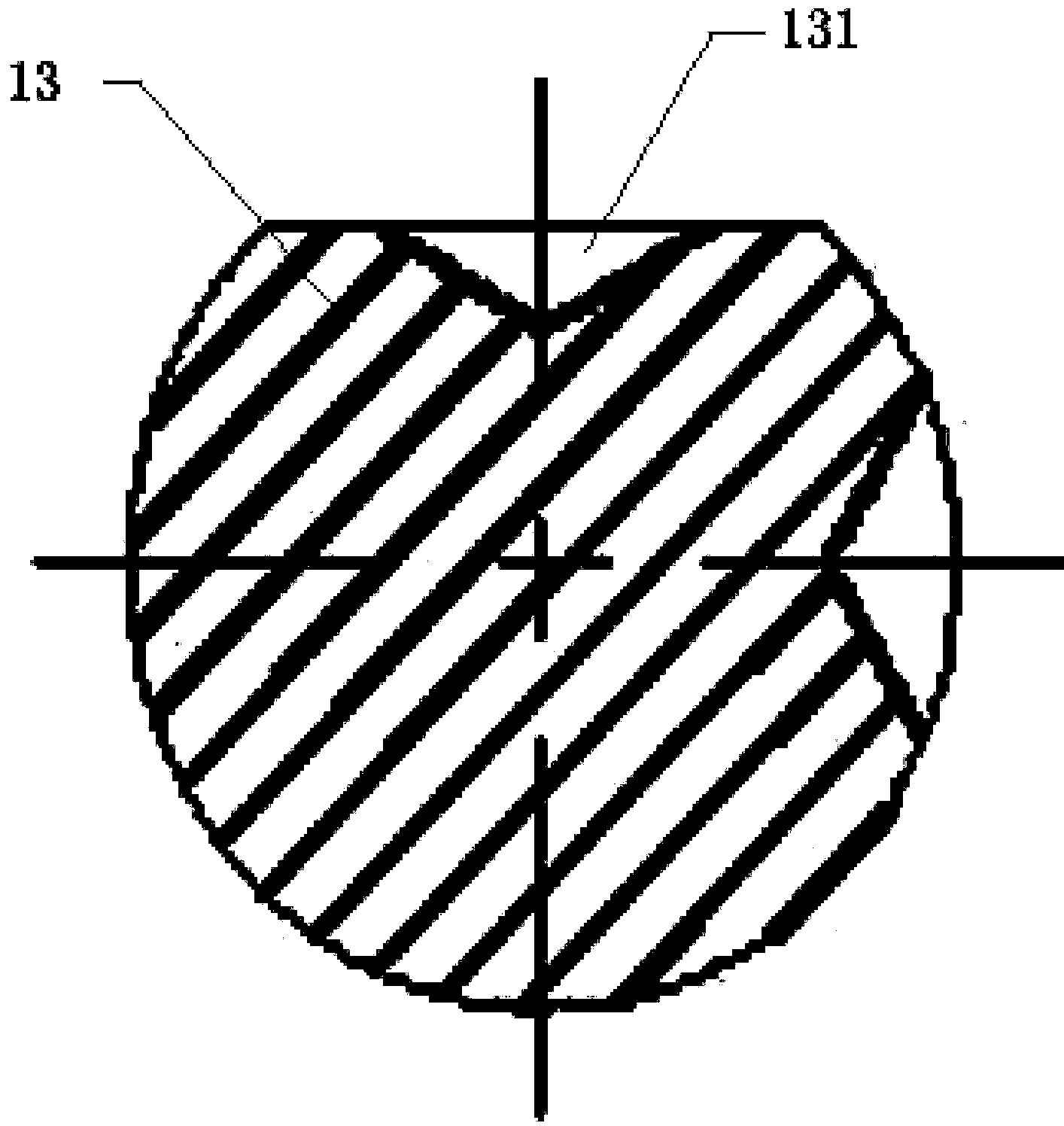

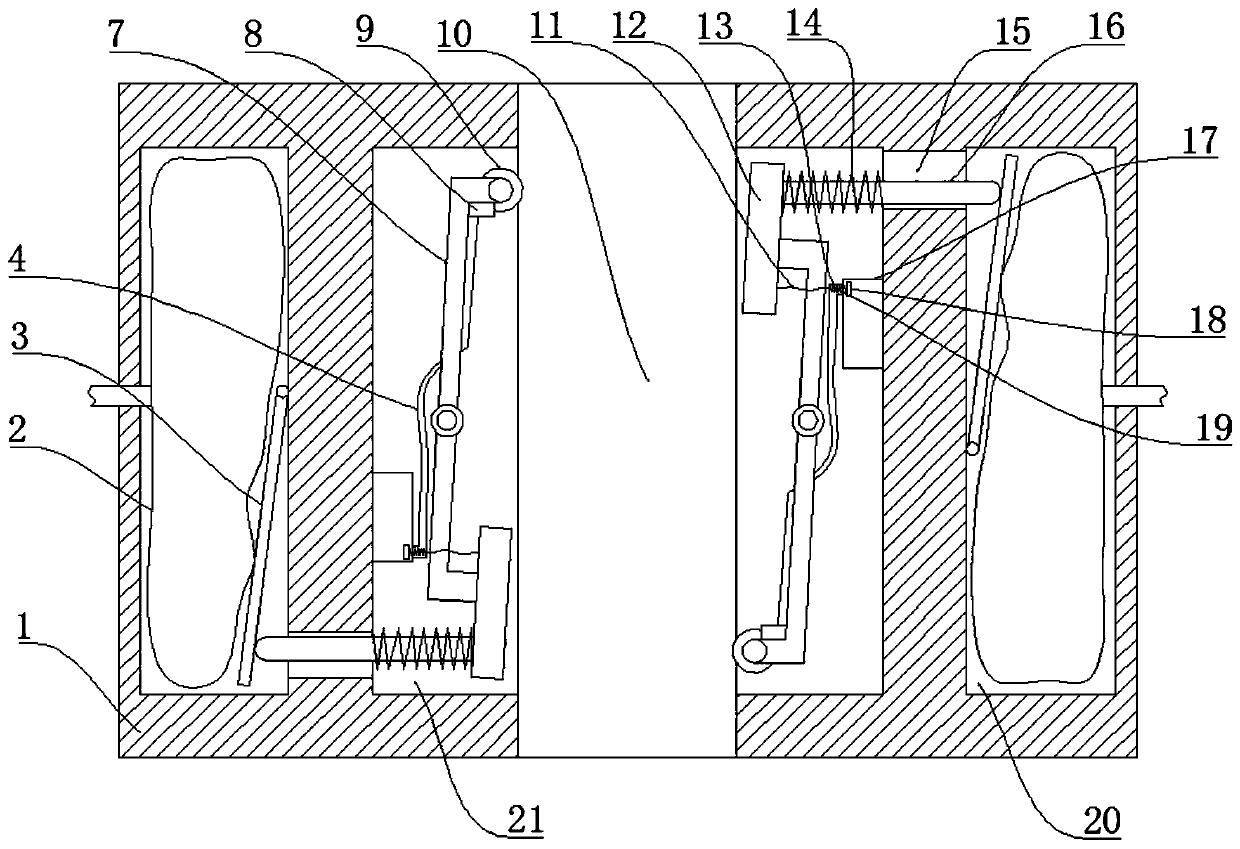

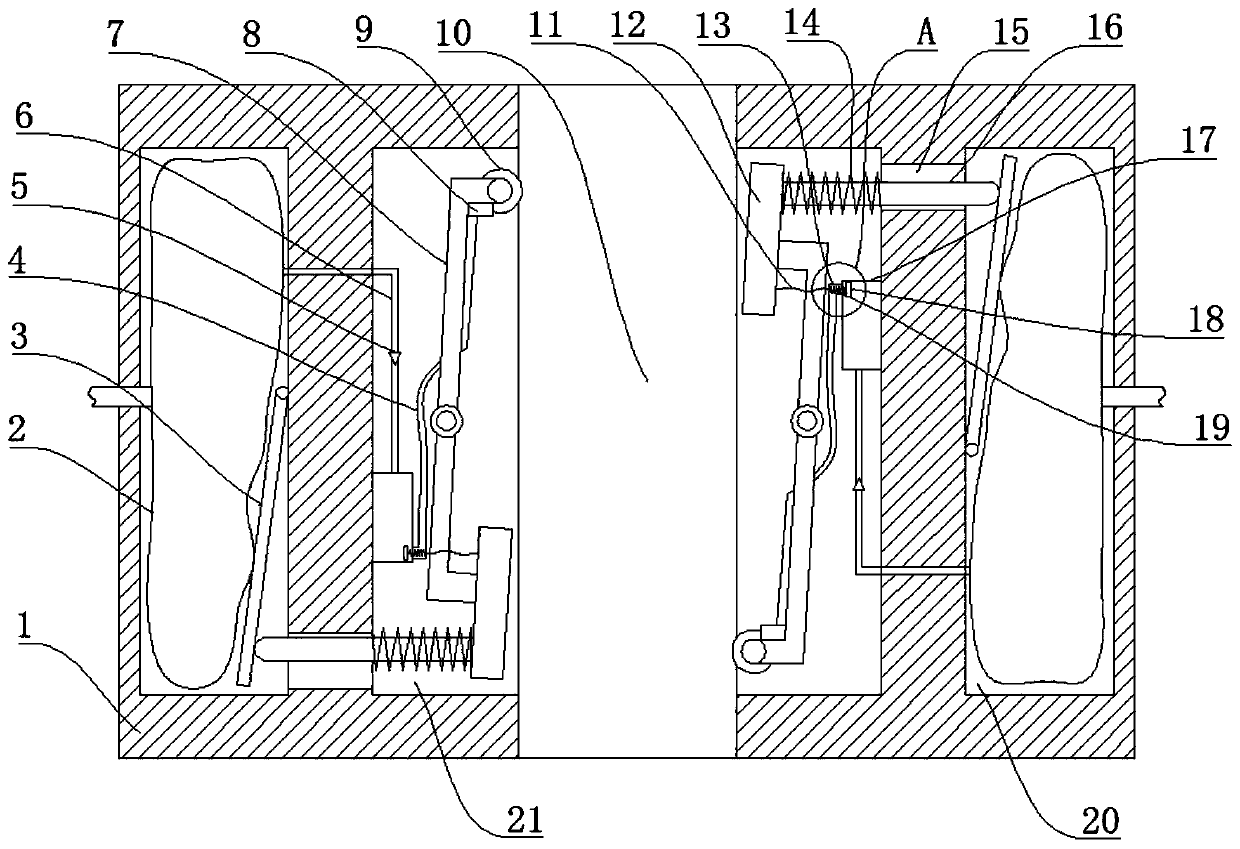

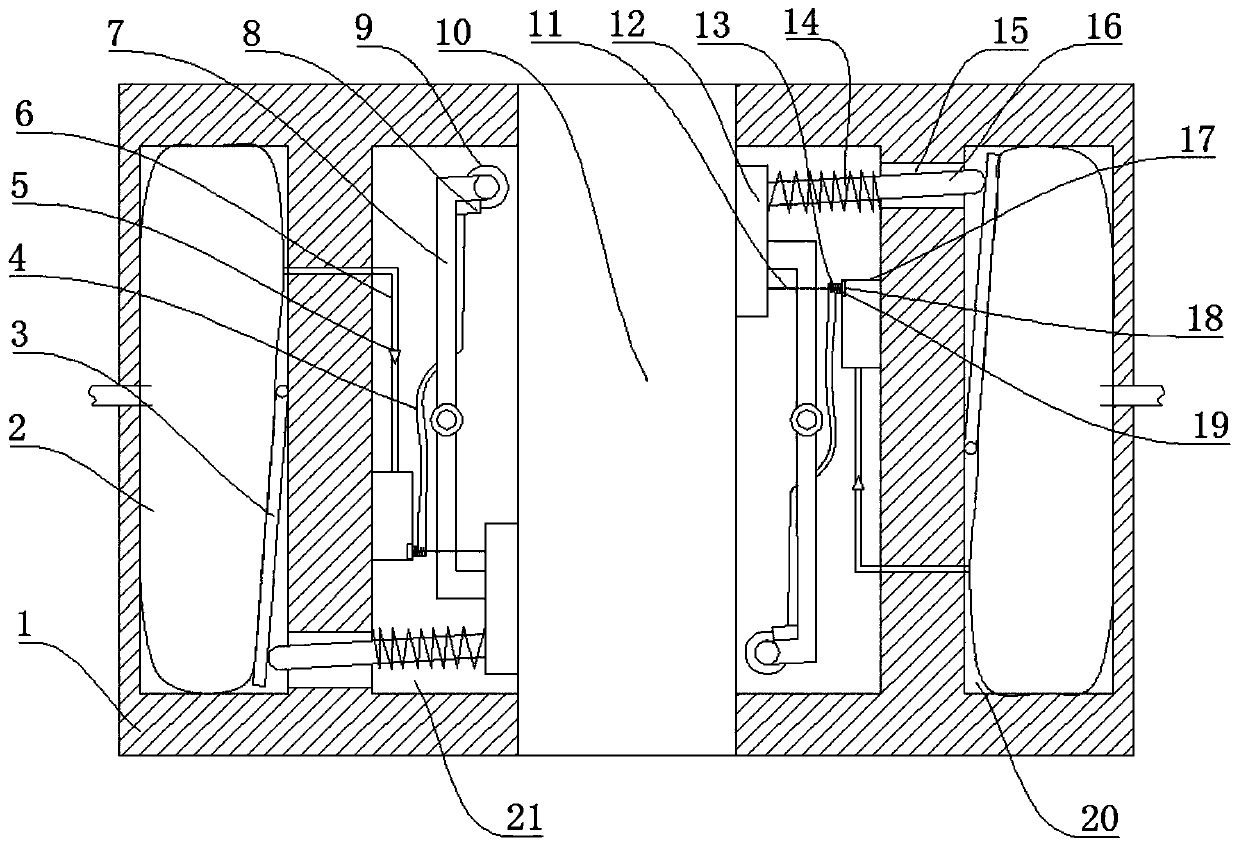

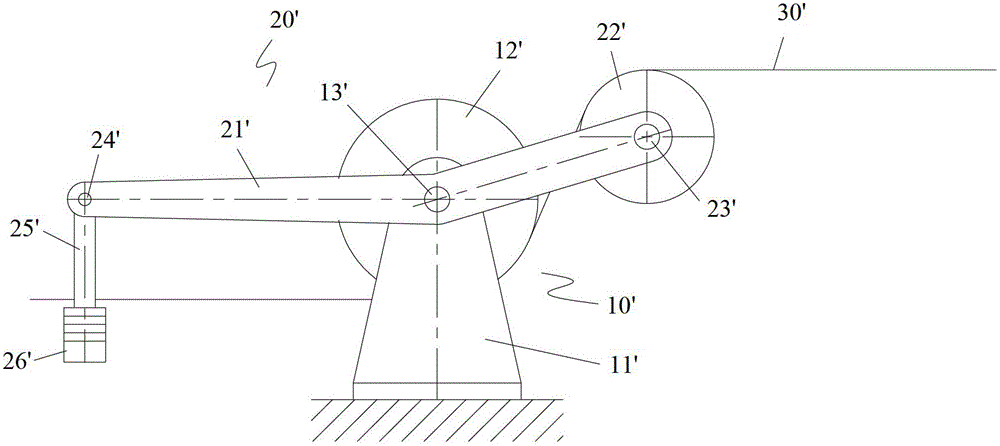

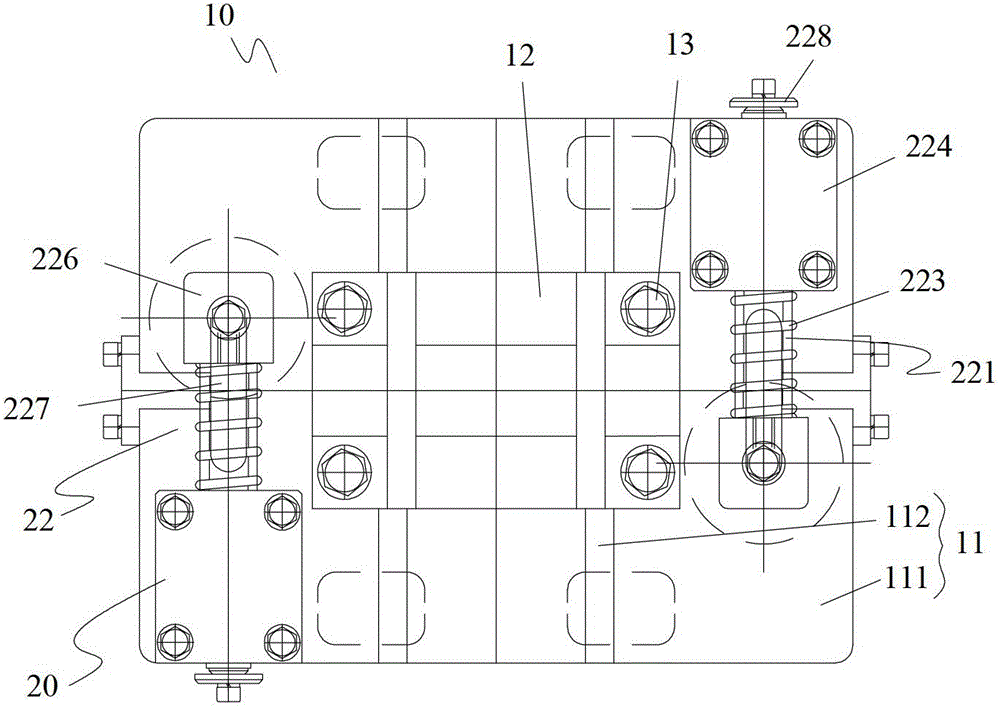

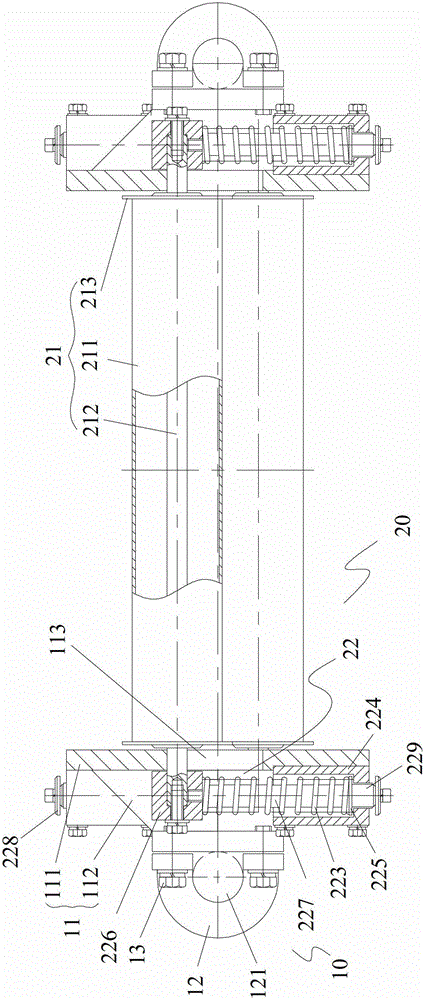

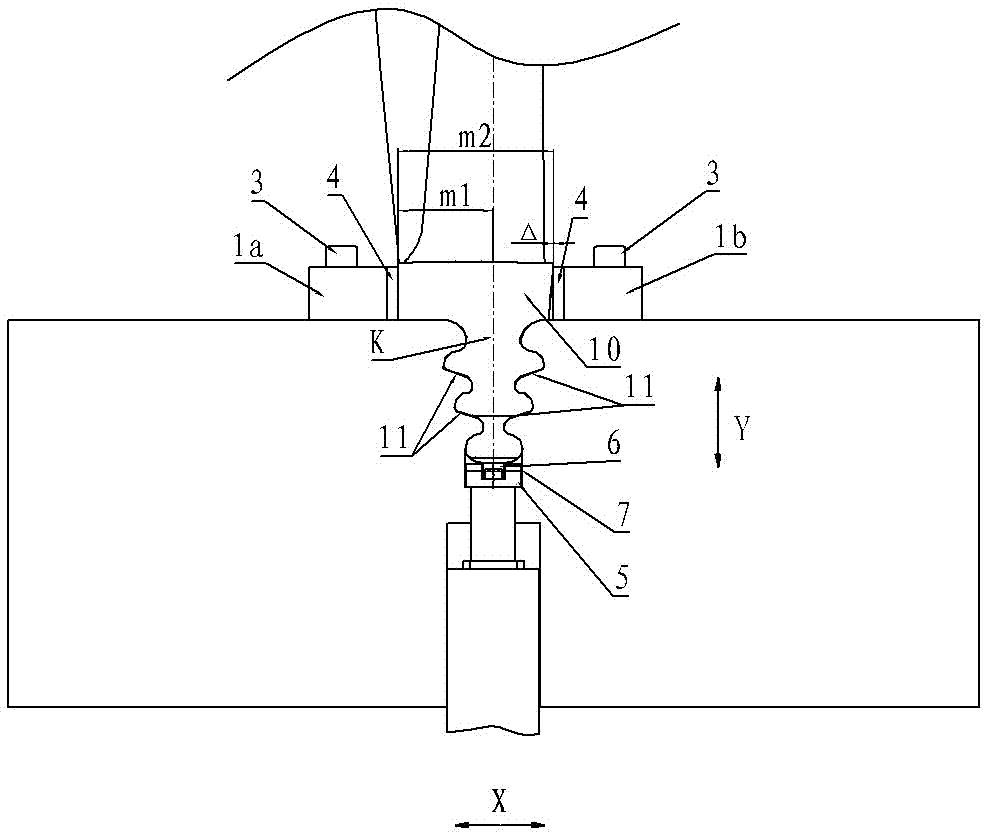

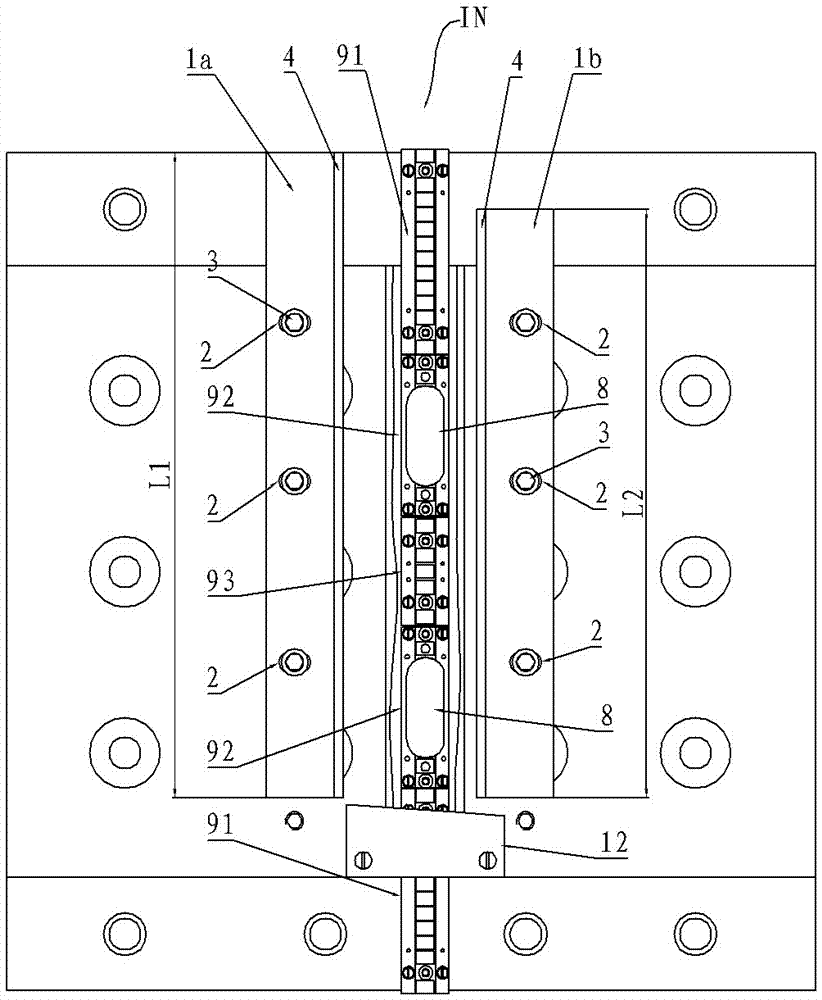

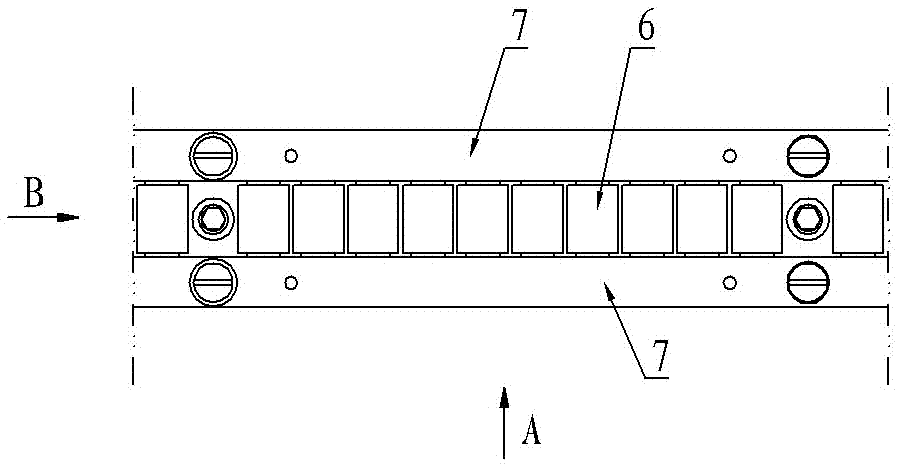

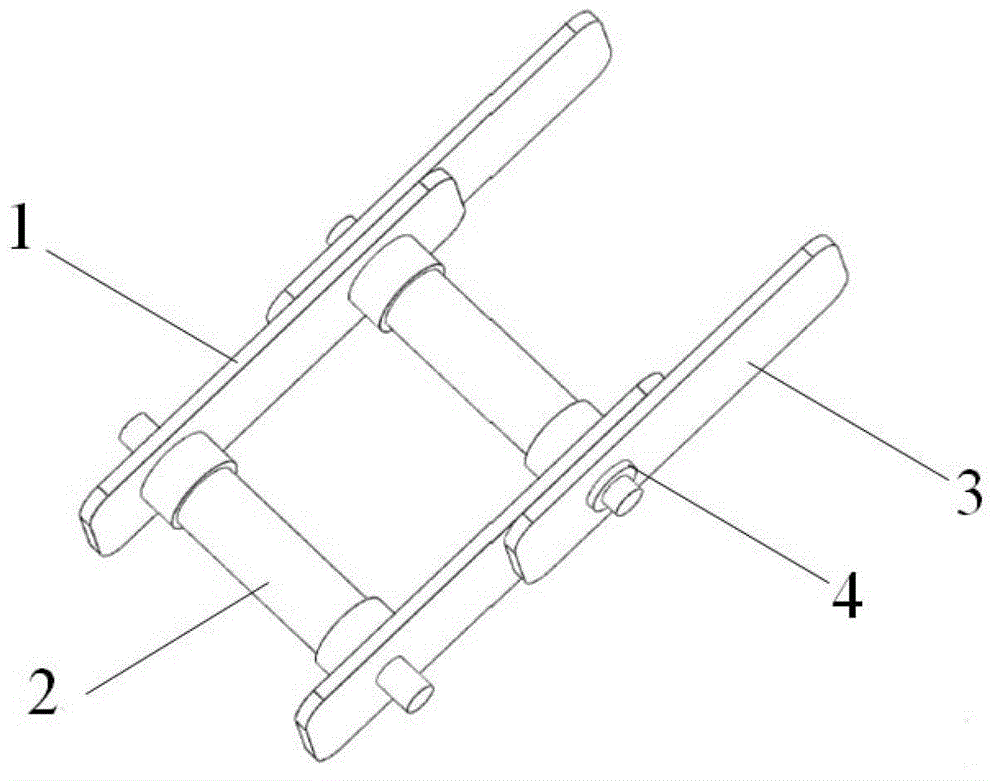

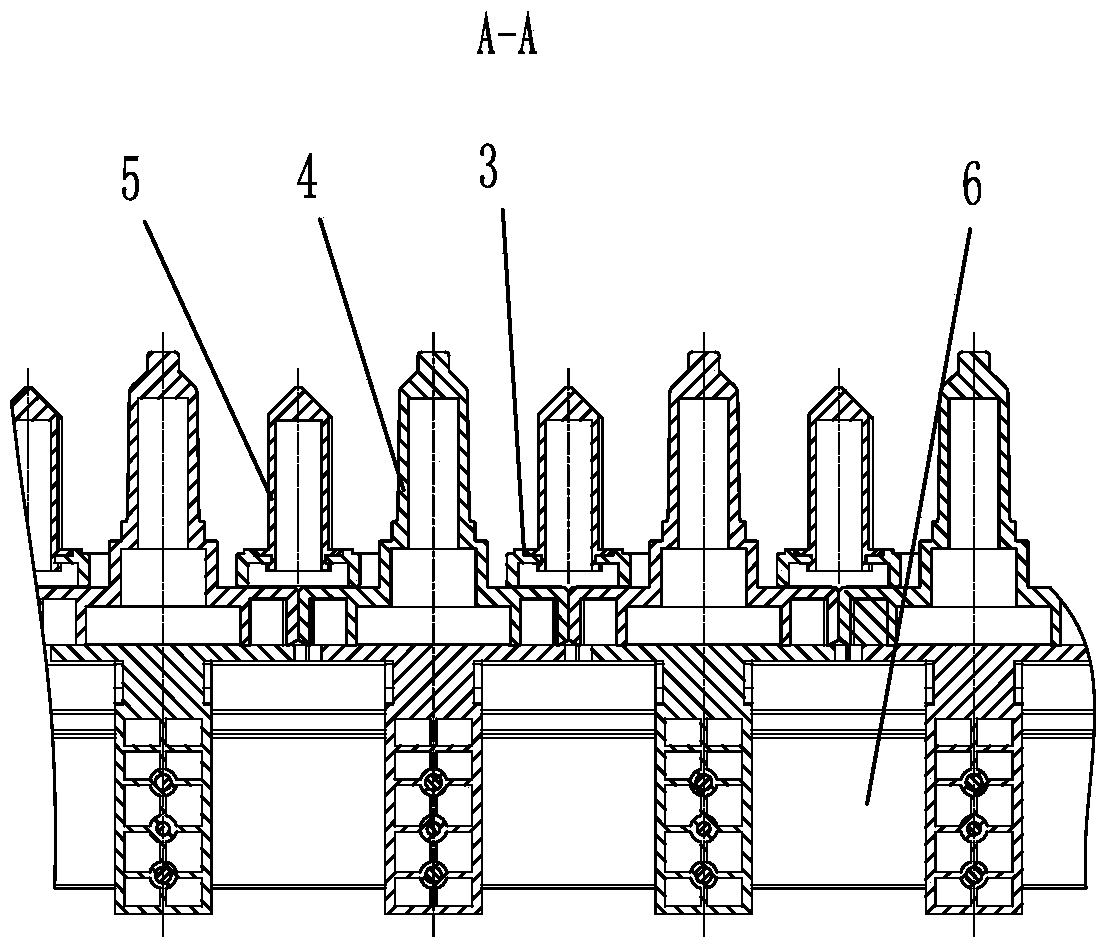

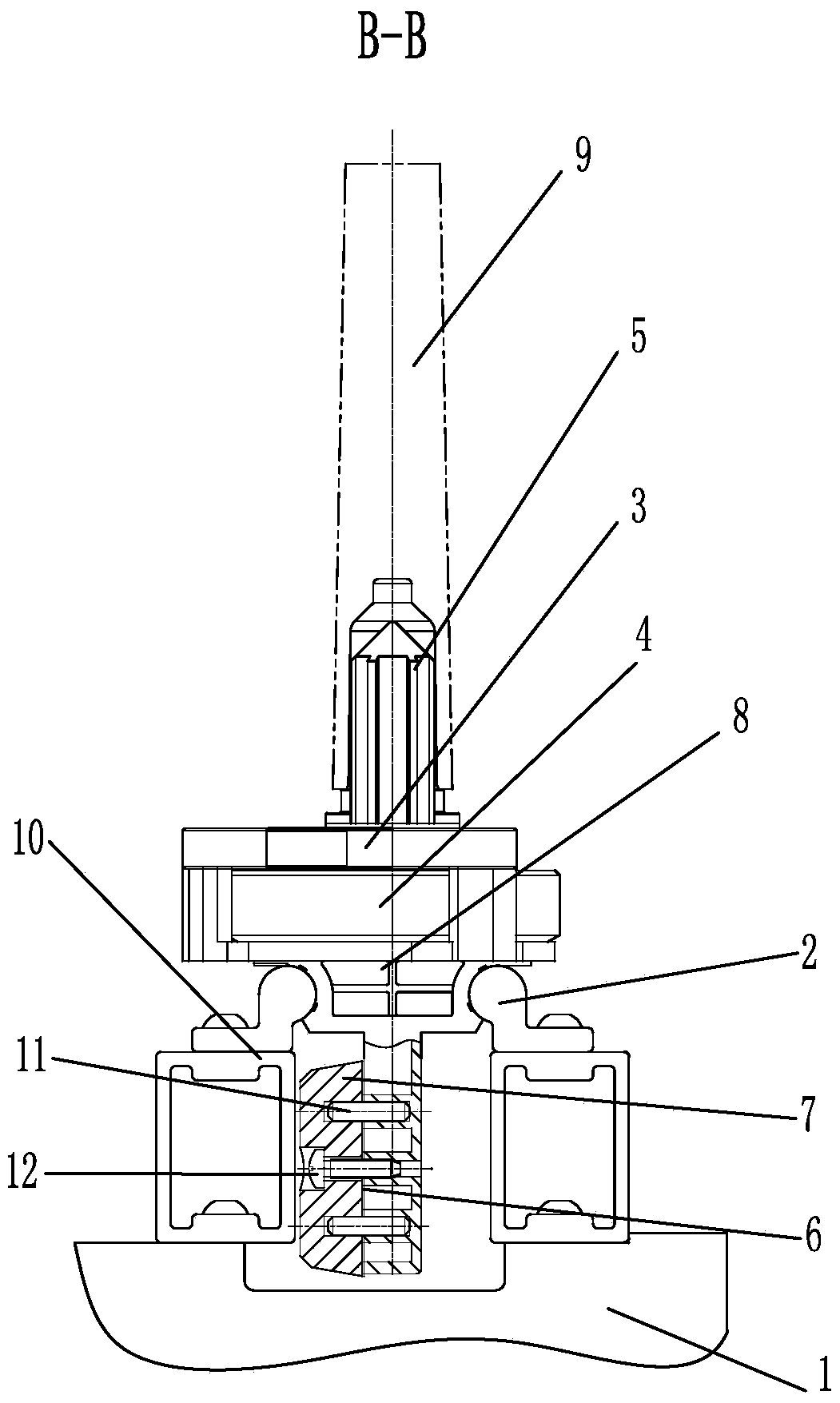

Rope supporting tensioning device and crane with same

ActiveCN103318791AReduce frictional contact areaReduce frictionWinding mechanismsCranesEngineeringConductor Coil

The invention provides a rope supporting tensioning device and a crane with the same. The device comprises two oppositely arranged first mounting bases (10) and a tensioning mechanism (20). The tensioning mechanism (20) is arranged between the two first mounting bases (10) and comprises a carrier roller component (21) and a compression component (22). Two ends of the carrier roller component (21) are in one-to-one corresponding connection with the two first mounting bases (10), and the carrier roller component (21) is provided with a rope winding cambered surface extending along the axial direction of the carrier roller component (21) and arranged in a radial movable mode relative to the two first mounting bases (10) to tension a hoisting rope (31) wound on the rope winding cambered surface. The compression component (22) is arranged on the first mounting bases (10) and in drive connection with the carrier roller component (21). By means of the device and the crane with the same, the phenomenon that the steel wire rope leaps and jumbles easily on a winding cylinder and a pulley can be changed, abrasion to the hoisting rope is reduced, and the service life of the hoisting rope is increased.

Owner:ZOOMLION HEAVY IND CO LTD

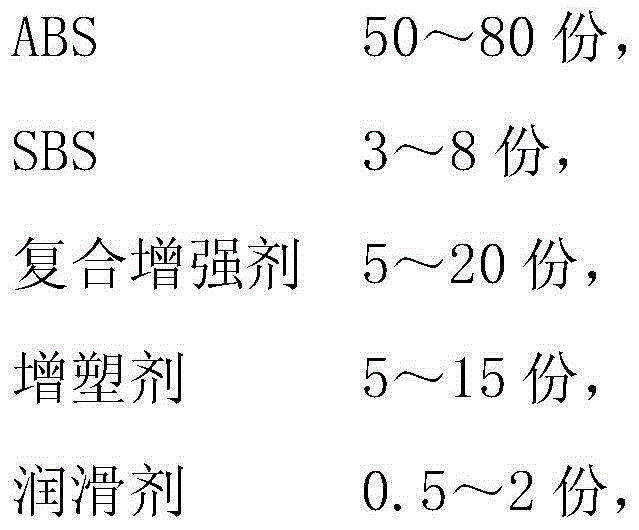

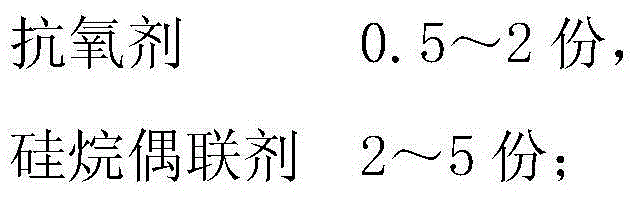

ABS composite material for plastic toys and preparation method thereof

The invention provides an ABS composite material for plastic toys, wherein the ABS composite material comprises the following components in parts by weight: 50-80 parts of ABS, 3-8 parts of SBS, 5-20 parts of a composite reinforcing agent, 5-15 parts of a plasticizer, 0.5-2 parts of a lubricant, 0.5-2 parts of an antioxidant, and 2-5 parts of a silane coupling agent, wherein the composite reinforcing agent is prepared by mixing ceramic micro-beads and glass fibers with the weight ratio of 2:1. The invention also discloses a preparation method of the ABS composite material for the plastic toys. The ABS composite material for the plastic toys has relatively good shock-resisting and wear-resisting properties.

Owner:SUZHOU WILDER IND & TRADE

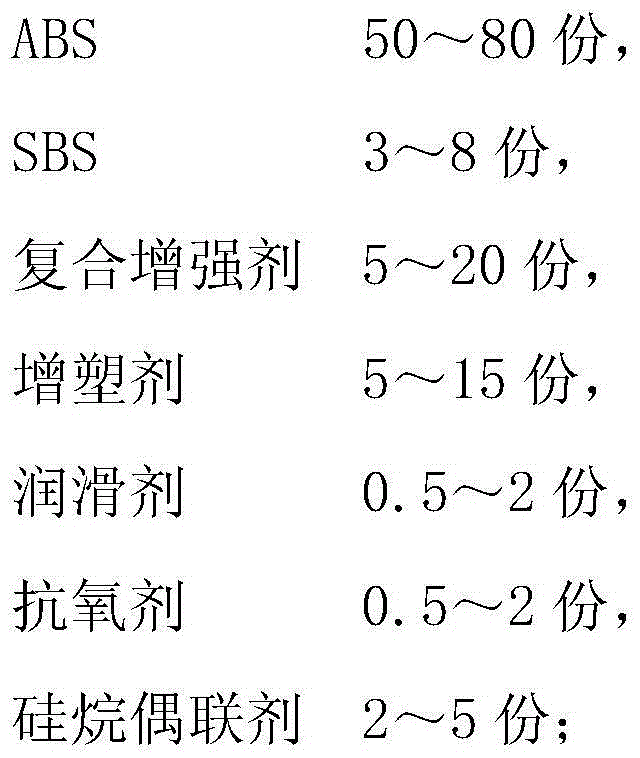

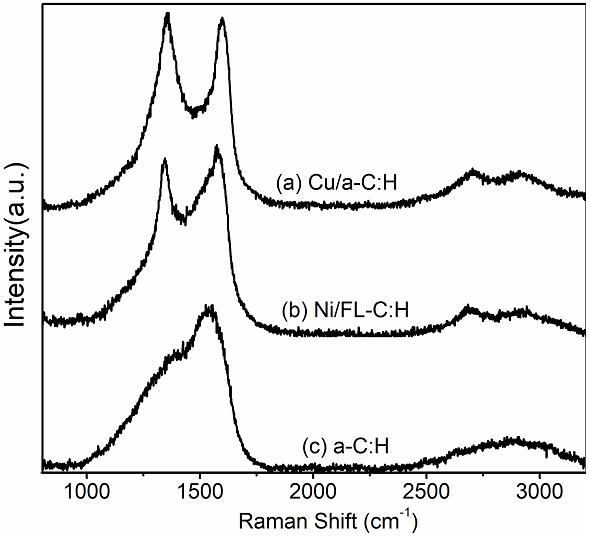

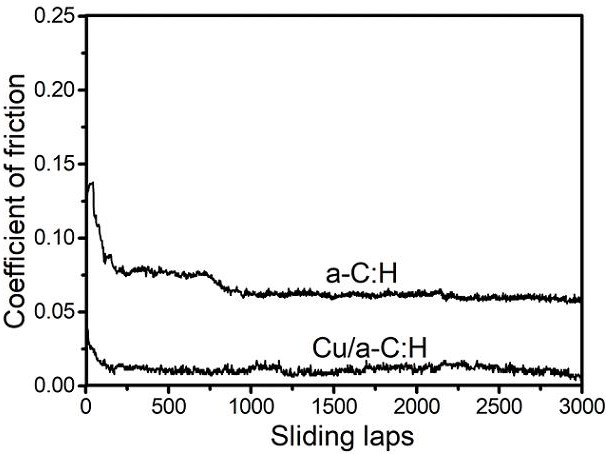

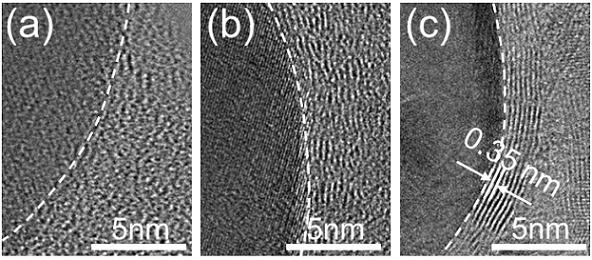

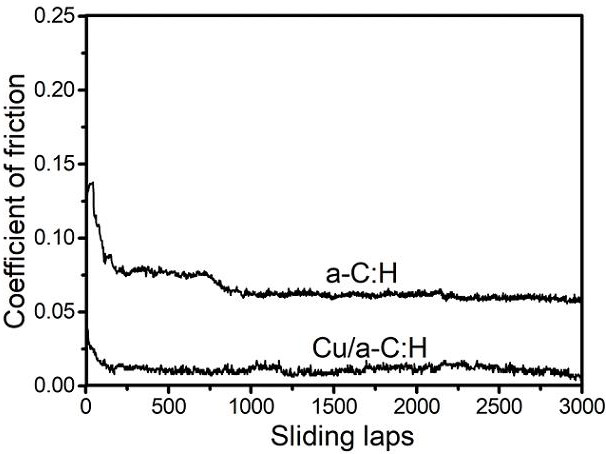

Friction catalysis design method for realizing ultralow friction of carbon film

ActiveCN112210417AReduce frictional contact areaReduce frictionMaterial nanotechnologyGrapheneCarbon filmPtru catalyst

The invention relates to a friction catalysis design method for realizing ultralow friction of a carbon film, which comprises the following steps: adding metal nanoparticles into absolute ethyl alcohol, and carrying out ultrasonic dispersion to obtain a metal nanoparticle solution; then spin-coating the surface of the carbon-based film with the metal nanoparticle solution to obtain a metal nanoparticle coating; and finally, adopting mechanical friction stirring, promoting the carbon-based film abrasive dust and the metal nanoparticles to be mixed, and the ball-like particle coating with the embedded metal nanoparticles wrapped with the graphene is obtained. Metal nanoparticles are introduced into a carbon-based film friction interface as a catalyst, and the problems of high friction coefficient, environmental sensitivity and the like in a single friction process are improved through a friction catalysis synergistic effect.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

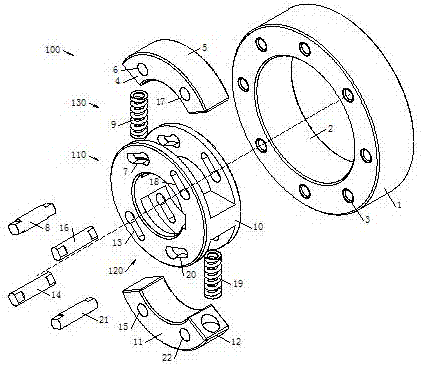

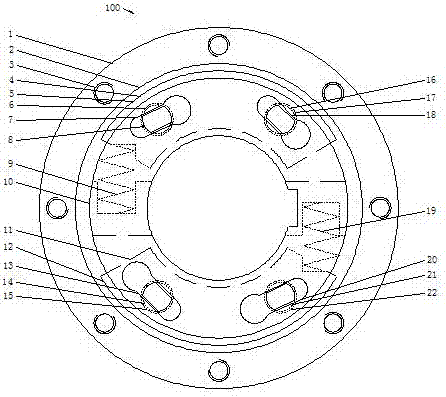

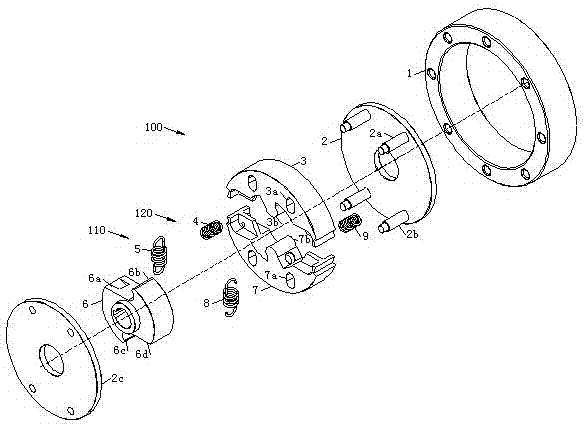

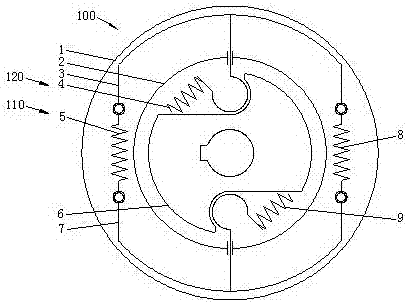

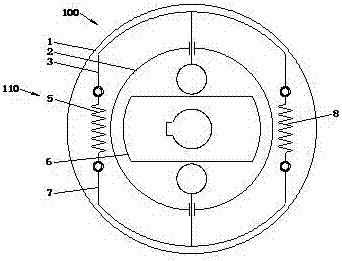

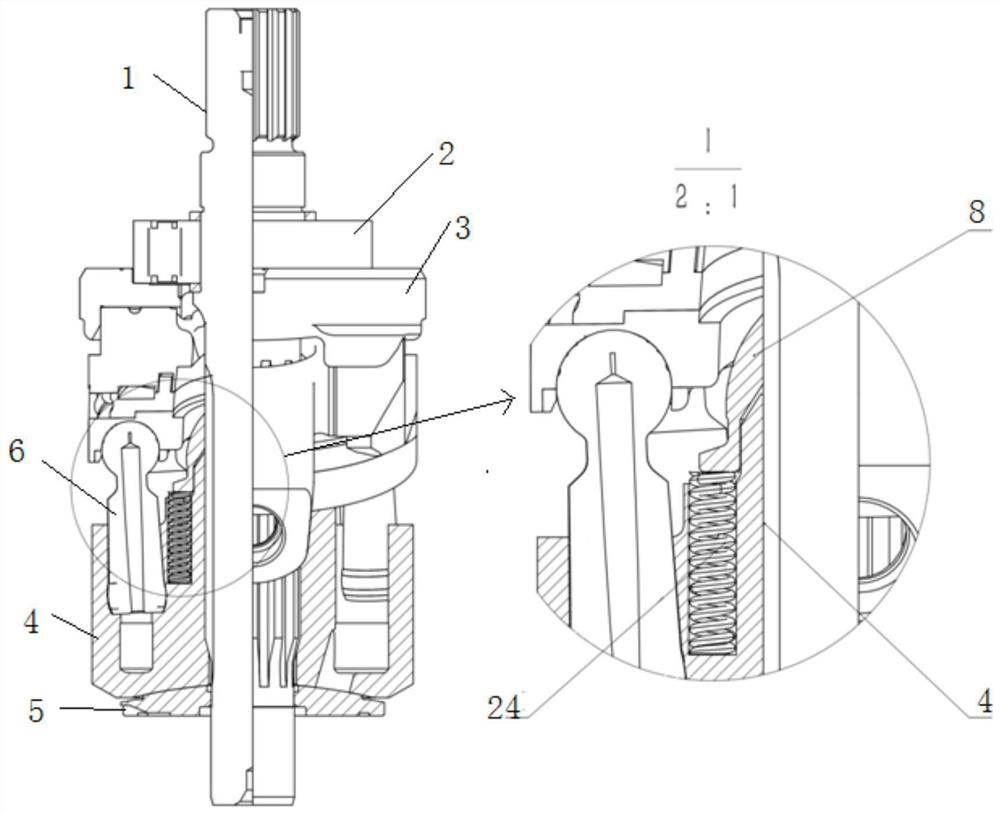

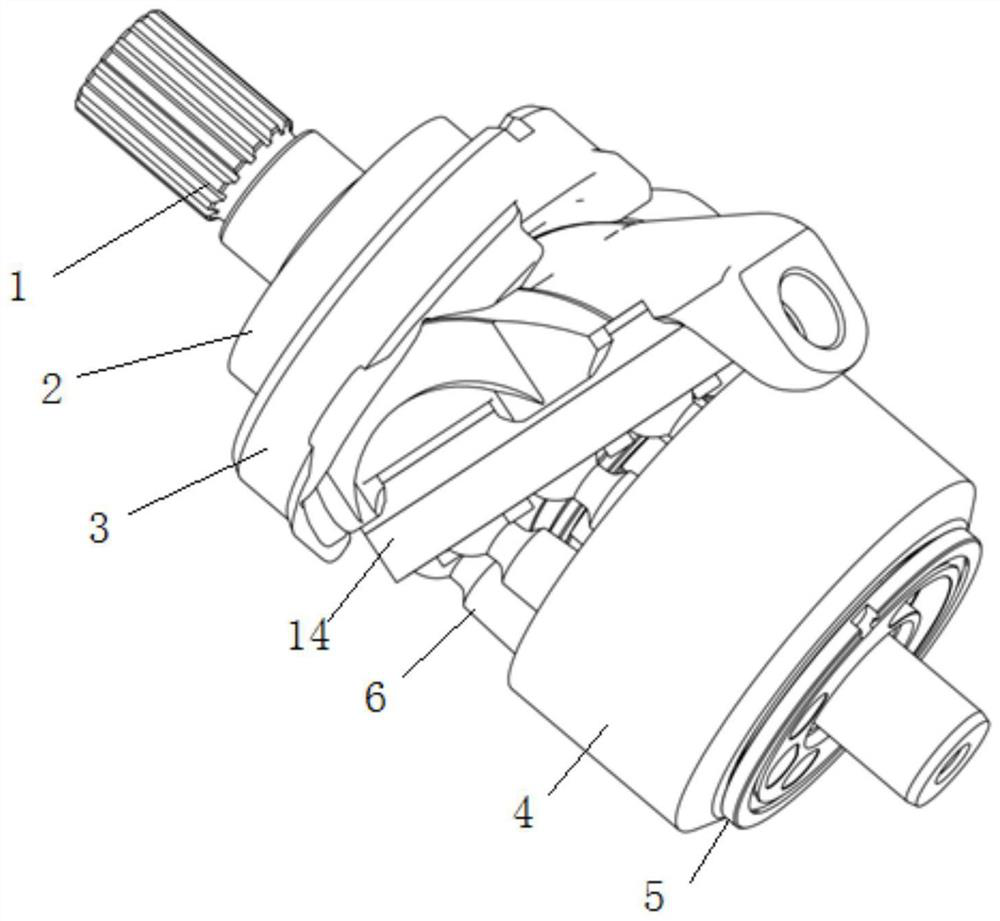

Wedge block type clutch

InactiveCN106931053AReduce frictional contact areaReduce volumeGearingGearing detailsAutomatic transmissionCentrifugation

The invention discloses a wedge block type clutch which comprises a driving cam, a driven element, a plurality of centrifugal wedge blocks, at least one reset device and radial extending stroke sets the same as the centrifugal wedge blocks in number. The driven element is arranged on the driving cam in a sleeving manner, the radial extending stroke sets are symmetrically arranged on the driving cam, the centrifugal wedge blocks are movably installed on the radial extending stroke sets, and the reset device applies pushing force to the centrifugal wedge blocks to enable the centrifugal wedge blocks and the driven element to keep the non-contact state all the time; and through tiny centrifugal force, the centrifugal wedge blocks are in contact with the driven element, then the radial extending stroke sets push the centrifugal wedge blocks to apply the pushing force in the radial direction, and therefore large torque can be transmitted under the low rotating speed condition. The wedge block type clutch is high in loading capacity and good in impact resistance, and high performance of the single / double-direction clutch can be achieved. The wedge block type clutch can be used for power transmission between a prime motor and a working machine or between a driving element and the driven element in the machine, the separation function and the field of mechanical transmission such as automatic transmissions.

Owner:郭克亚

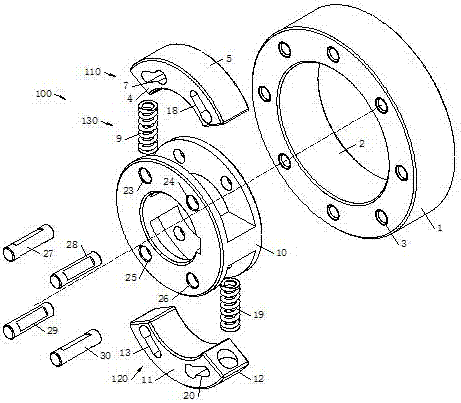

Wedge-type clutch

InactiveCN107035787AChange the way of forceIncrease frictionGearingGearing detailsMechanical power transmissionAutomatic transmission

The invention discloses a wedge-type clutch. The clutch comprises a driving cam, a driven element, at least one centrifugal wedge, at least one reset device and a middle support, wherein the middle support is hinged with the driving cam; the middle support and the driven element are mutually spaced for a certain distance in the radial direction; a plurality of centrifugal wedges are sequentially arranged between the driving cam and the driven element around an axis of the middle support; each centrifugal wedge is respectively movably arranged on the middle support; the centrifugal wedges are driven by the driving cam to radially move to ensure that the centrifugal wedges are in contact with the driven element and torque is transmitted; and the reset devices are used for continuously applying an acting force on the centrifugal wedges to ensure that the centrifugal wedges and the driven element are kept in a non-contact state. The clutch disclosed by the invention is strong in load capability and good in impact resistance and can have excellent performances of both one-way / two-way clutches; and the cultch disclosed by the invention can be used for realizing the power transmission and separation functions between prime motors and working machines or between driving elements and driven elements in machines and can be used in the mechanical drive fields of automatic transmissions and the like.

Owner:郭克亚

Chain

Owner:吴国平

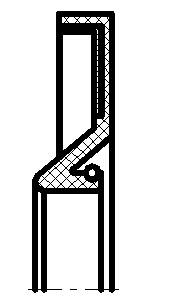

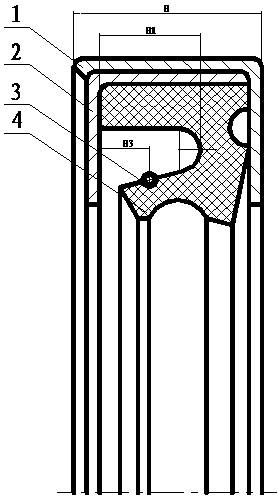

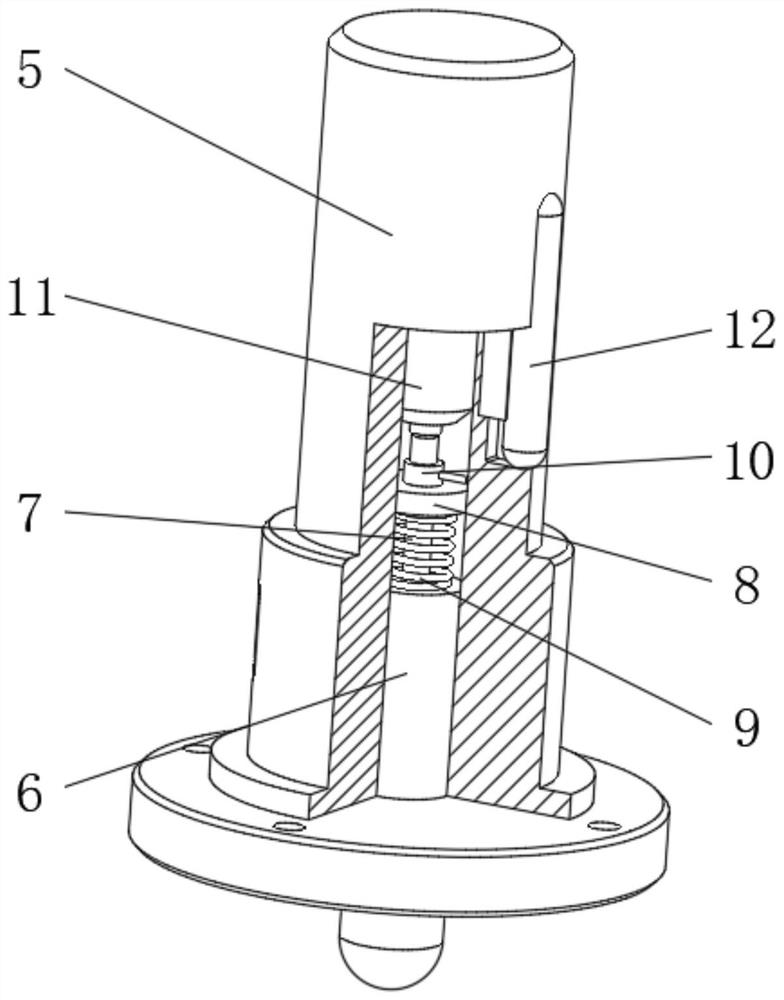

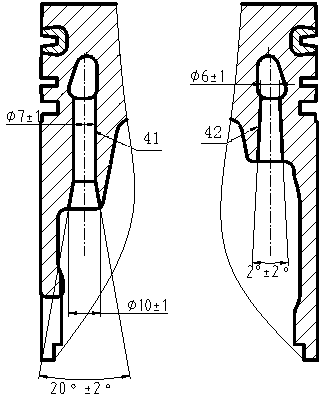

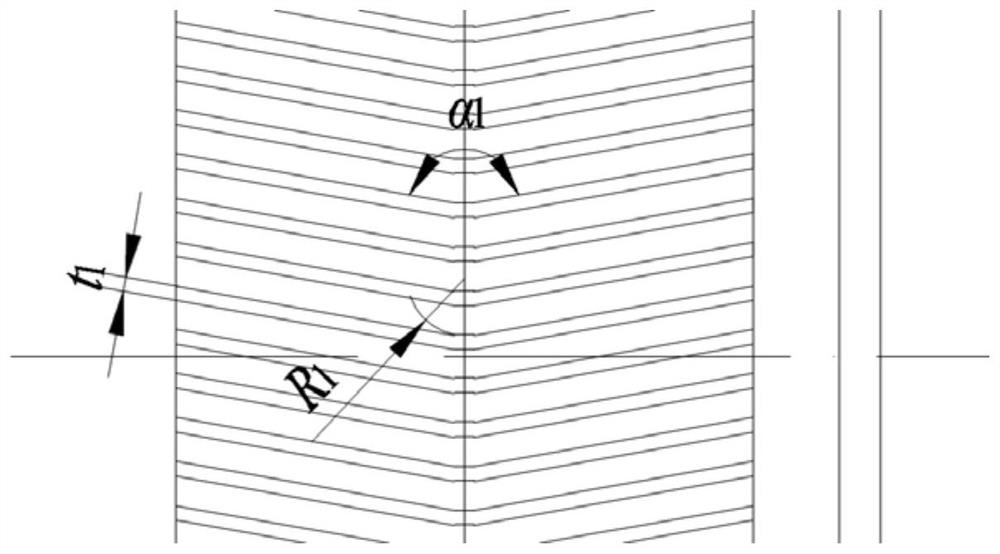

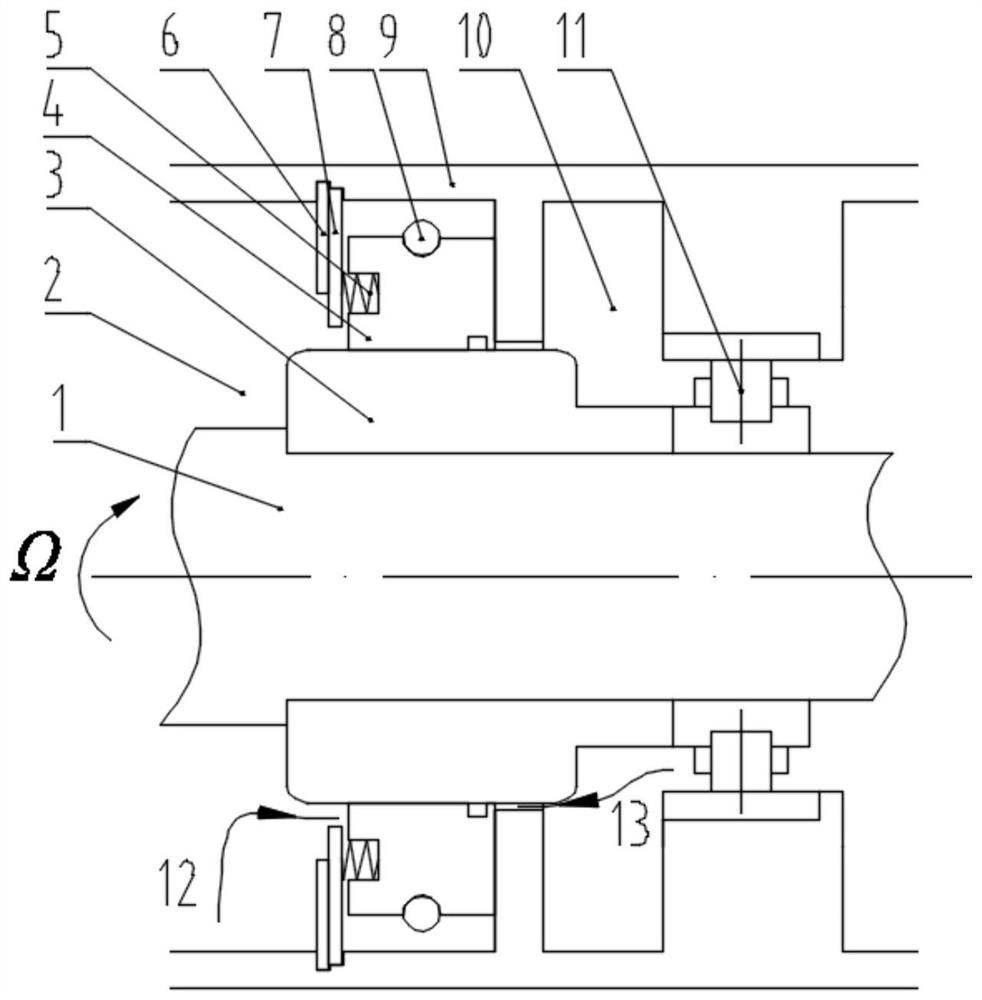

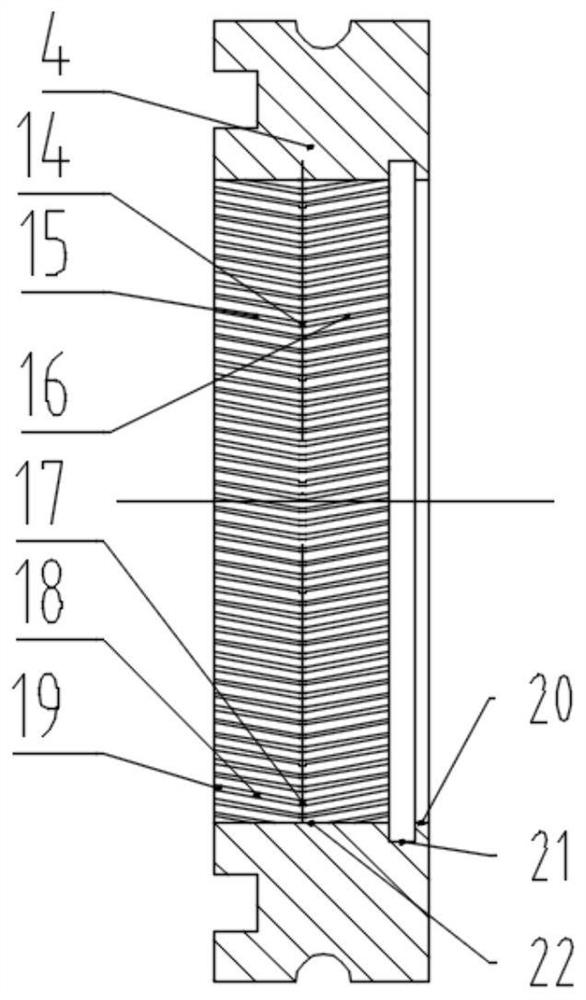

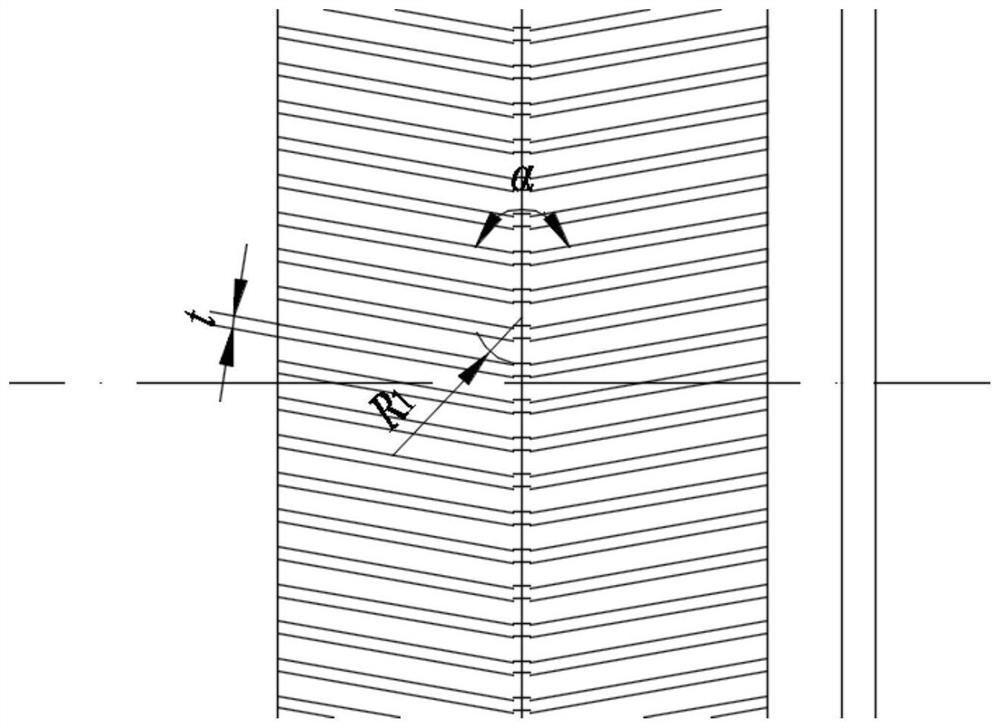

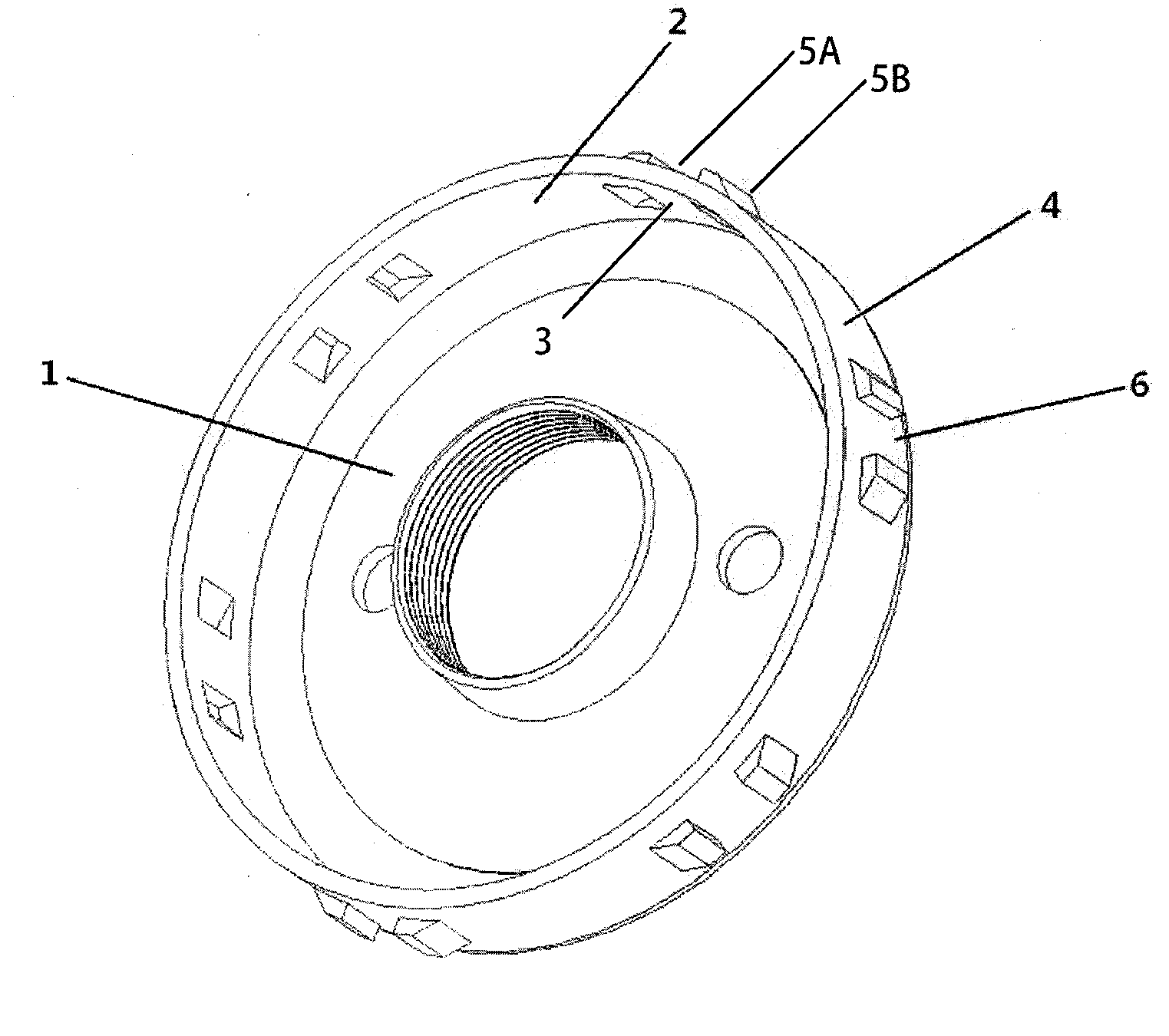

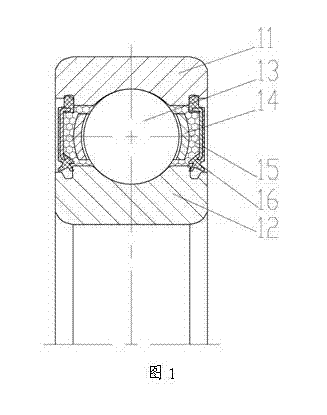

Method for designing combined sealing device used in low speed and heavy load conditions of bearing

InactiveCN102562817AImprove operating conditionsExtended service lifeBearing componentsLow speedClassical mechanics

The utility model relates to a method for designing a combined sealing device used in low speed and heavy load conditions of a bearing. The half section of a sealing ring (4) is shaped like a Chinese character 'jiu' with one stroke to the left, and composed of a horizontal support (5), an inclined vertical support (6) and a beveled lip (7) which are naturally connected through three semicircular arcs R1, R2 and R3, a locking spring (3) is assembled in a semicircular groove of the sealing ring, then the sealing ring is installed into a left bracket-shaped inner casing (2), the end of the semicircular arc R2 is outward, and finally, a right bracket-shaped outer casing (1) is buckled outside the inner casing (2) at the end of the semicircular arc R2, and sealed for preventing the inner casing (2) from falling out of the outer casing (1). The sealing ring is clamped in a door-shaped structure including the outer casing and the inner casing to form the combined sealing device, therefore, a favorable guarantee is provided for maintaining the stiffness of the skeleton of the sealing ring, and the inclined vertical support and the beveled lip are in contact with the shaft shoulder of the inner ring, therefore, the dustproof and antifouling effect is better, the frictional contact area is reduced, and abrasion is reduced.

Owner:LUOYANG BEARING SCI & TECH CO LTD

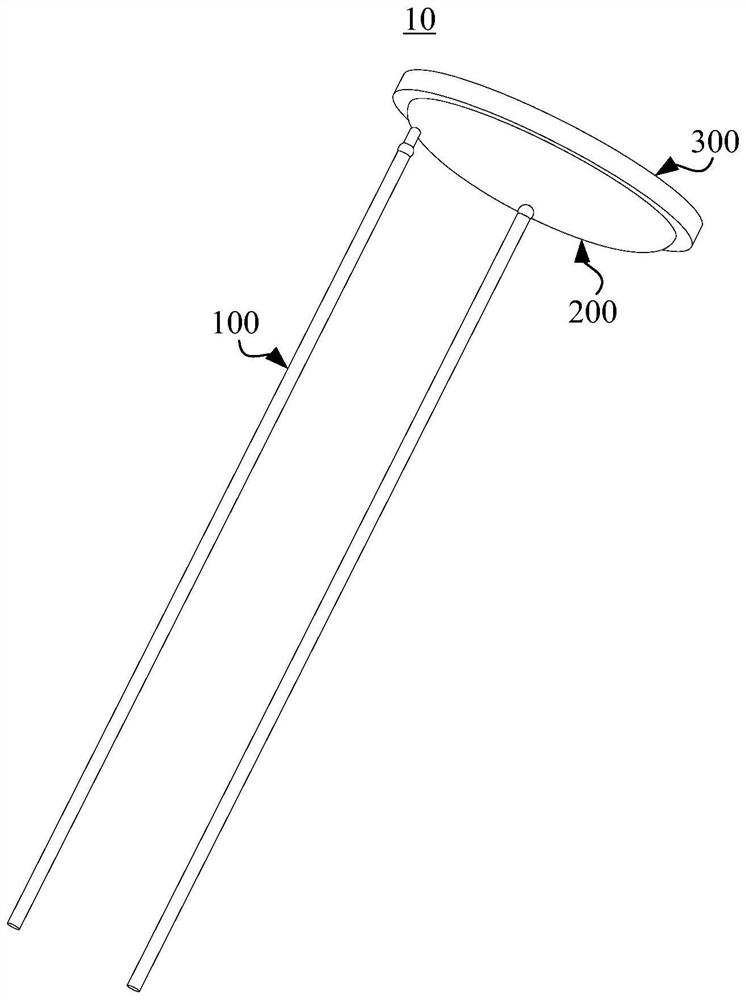

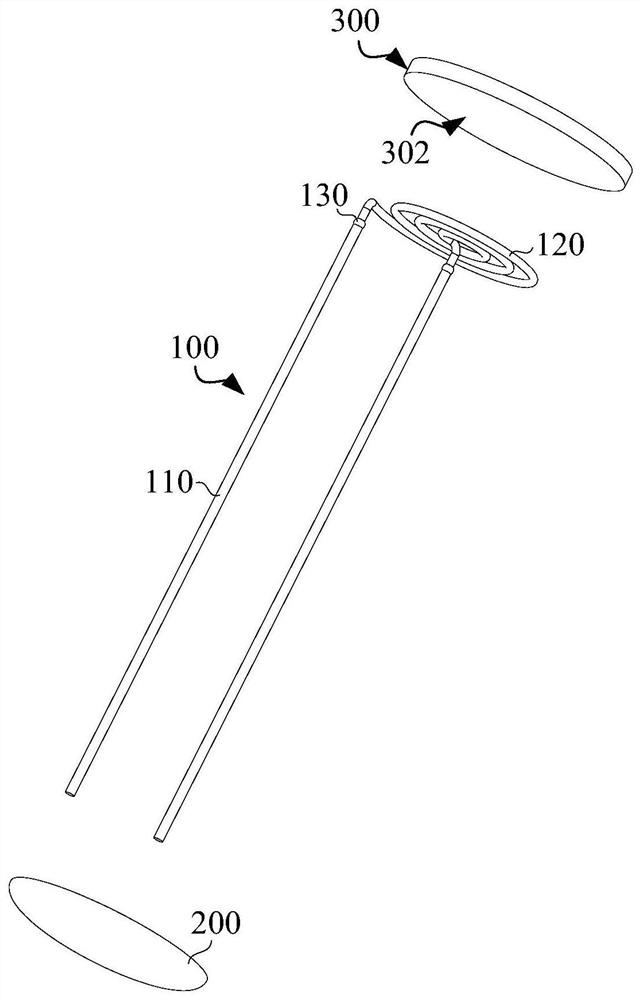

Mechanical sensing type edge finder

InactiveCN112296759AAvoid the problem of large precision errorsImprove detection accuracyMeasurement/indication equipmentsEngineeringStructural engineering

The invention relates to the technical field of spindle cutter position detection equipment, and discloses a mechanical sensing type edge finder. The edge finder comprises a mounting bottom ring, a fixed connecting rod and a clamping sleeve rod; the clamping sleeve rod is fixedly mounted at the top of the mounting bottom ring through the fixed connecting rod; a rotary touch rod is fixedly mountedin the mounting bottom ring through a disc spring; a touch connecting rod is movably sleeved with the bottom of an inner cavity of the clamping sleeve rod; and the bottom end of the touch connecting rod makes contact with the top end of the rotary touch rod. According to the mechanical sensing type edge finder, a touch elastic block is arranged to be matched with a conductive connecting rod and apressure spring on the touch connecting rod, two sets of series switches can be formed between a storage battery and a light alarm on the edge finder, the light alarm can be triggered to give an alarmonly when all the switches are turned on, when the edge finder is not clamped and mounted on a machine tool spindle, the touch elastic block is not triggered due to the fact that the touch elastic block is not extruded, and no loss is caused to the current of the storage battery when the edge finder is not use.

Owner:张彬

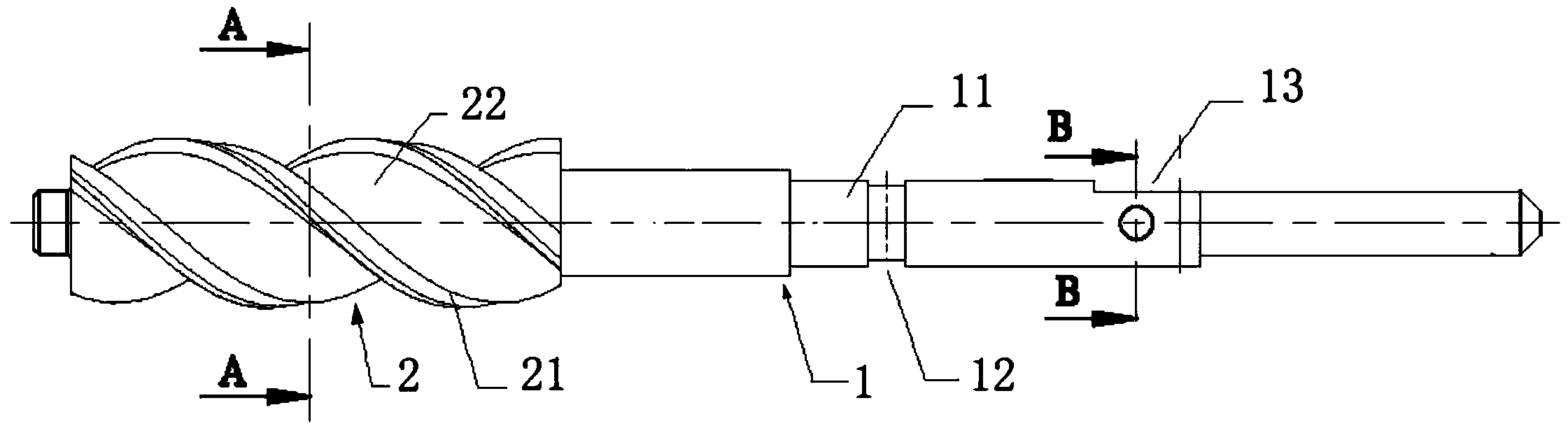

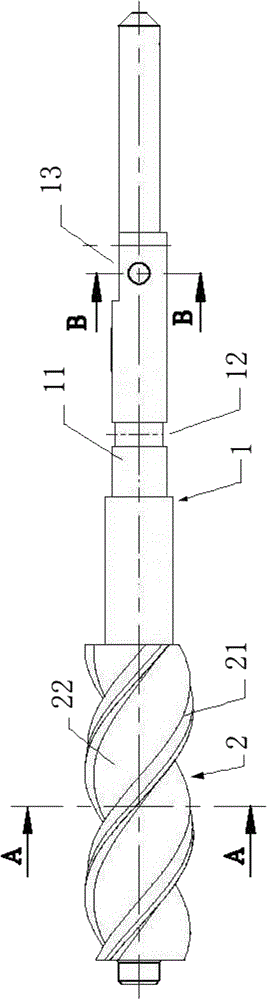

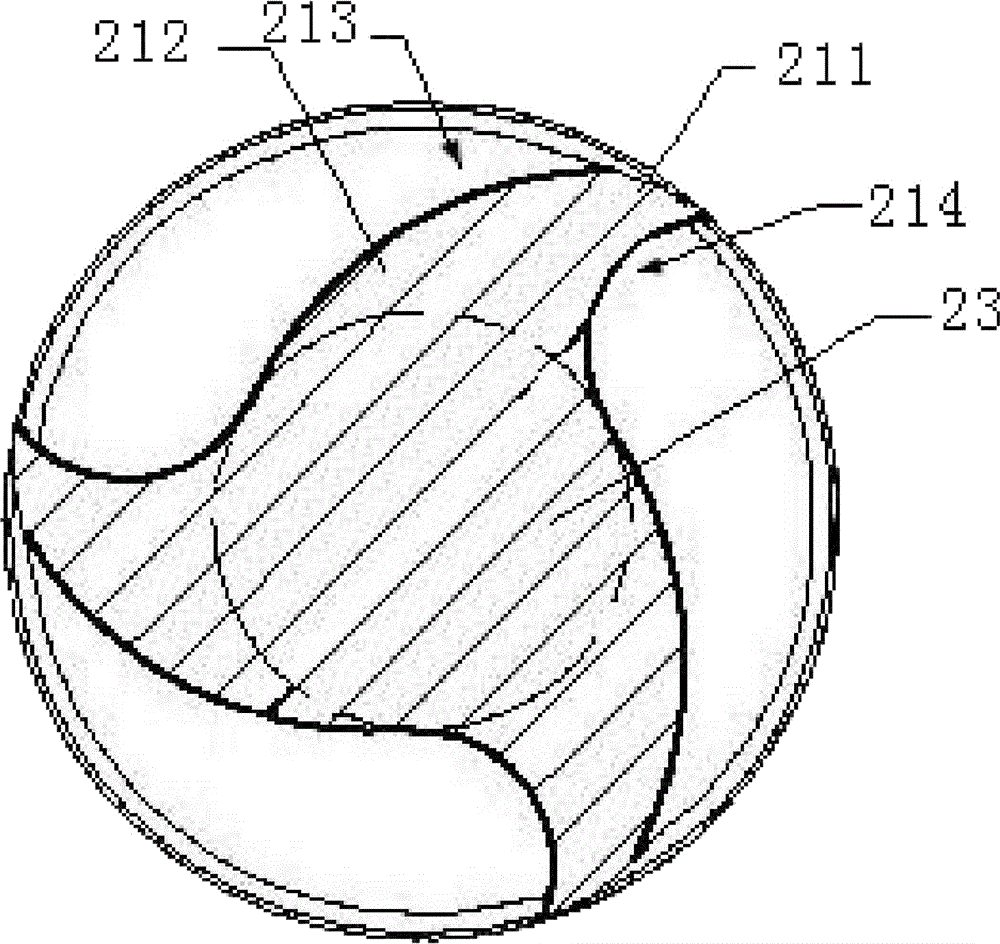

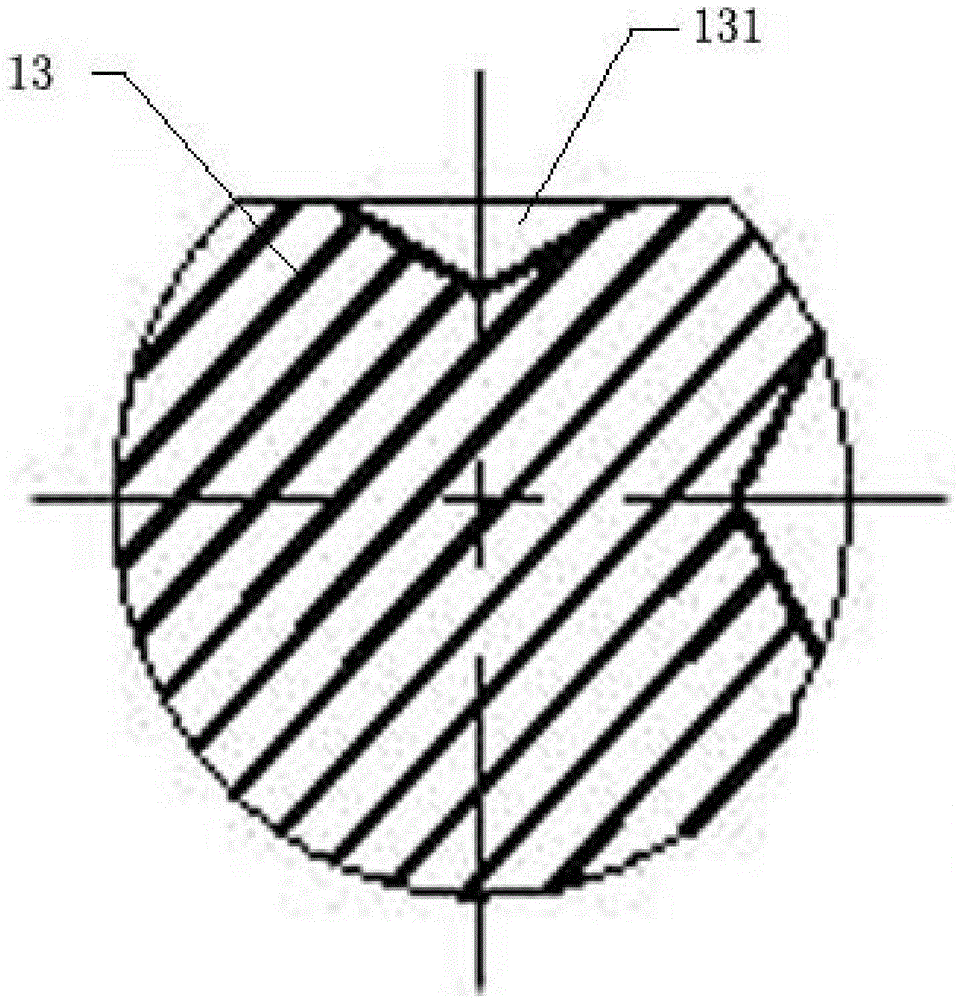

Cutting tool for hard gelatin traditional Chinese medicine processing machine

The invention discloses a cutting tool for a hard gelatin traditional Chinese medicine processing machine. The cutting tool comprises a cutting handle and a cutting head, wherein the cutting head is columnar and comprises a cutting core and three or four cutting edges uniformly and spirally arranged at the outer edge of the cutting core; scrap containing space is formed between each two adjacent cutting edges; each cutting edge comprises an edge point and an edge root, the edge point comprises a cutting side face and a non-cutting side face, the direction of the cutting side face is opposite to the spiral direction of the cutting edge, and the direction of the non-cutting side face is as the same as the spiral direction of the cutting edge; a first edge belt and a second edge belt are arranged on the cutting side face of each edge point, a first relief angle formed by the intersecting of the first edge belt and the horizontal plane is 11-13 degrees, a second relief angle formed by the intersecting of the second edge belt and the horizontal plane is 27-29 degrees, a front angle formed by the intersecting of the non-cutting side face and a vertical face at an outer point of the edge point is 9-11 degrees, and a bearing mounting section and a transmission part mounting section are mounted in the middle of the cutting handle. By utilizing the cutting tool, the powder of the cut hard gelatin traditional Chinese medicine is in a flocculent flake shape, is immediately dissolved into water and is smoothly discharged under the premises that the rigidity and strength are sufficient.

Owner:HARBIN YIWEN DINGSHENG INVESTMENT MANAGEMENT ENTERPRISE LLP

Heating element, manufacturing method thereof, atomization assembly and atomization device

PendingCN113455732AReduce tanglingQuick and accurate installationTobaccoHeating elementCeramic materials

The invention provides a heating element, a manufacturing method of the heating element, an atomization assembly and an atomization device. The heating element comprises a heating body, a bonding body and a ceramic body, wherein the bonding body is respectively bonded with the heating body and the ceramic body. The heating element is advantaged in that the heating element is fixed to the ceramic body through the bonding body, winding of the heating element is omitted, and installation difficulty of the heating element is lowered; 2, connection between the heating body and the ceramic body is realized through the bonding body so that a problem of powder falling on the ceramic body is effectively reduced; and 3, in the process of forming the heating element, the heating element is directly bonded on the surface of the ceramic body through the bonding body, so the manufacturing process of the heating element is simple, difficulty of the manufacturing process of the heating element is reduced, the heating element does not need to be manufactured by adopting a specific mold, production cost of the mold is saved, and manufacturing cost of the heating element is reduced.

Owner:SHENZHEN AEROSOL TECH RES CO LTD

Gripper with guided cleaning function

ActiveCN110181310AStable movement without shakingReduce wastePositioning apparatusMaintainance and safety accessoriesNumerical controlMachine tool

The invention discloses a gripper with a guided cleaning function and belongs to the field of machine tool grippers. The gripper comprises a substrate. An open slot is formed in the substrate in a penetrating manner, clamping cavities are formed in the positions, on two sides of the open slot, of the substrate, the clamping cavities are formed toward the opening of one side of the open slot, a lever is arranged in each clamping cavity, one end of each lever is connected to a clamping block while the other end of each lever is connected to a guide wheel, a tension spring is connected between each clamping block and the wall of the corresponding clamping cavity, a driving cavity is formed in the substrate of one side, deviated from the open lot, of each clamping cavity, a hydraulic driving mechanism is arranged in each driving cavity, and the output end of each hydraulic driving mechanism is rigidly connected to the corresponding clamping block. The gripper can effectively solve the problem that the processing quality of a workpiece is affected as a result of severe wear of a clamping structure of a clamping block of an existing numerically controlled machine tool for a long time.

Owner:CHONGQING HONGGANG CNC MACHINE TOOL

Rope fixture type shearing resisting, dip angle changing and mutual inlaying barricade block and rope fixing method

InactiveCN103572778AIncrease alkalinityImprove permeabilityArtificial islandsUnderwater structuresArchitectural engineeringStructural engineering

The invention relates to a rope fixture type shearing resisting, dip angle changing and mutual inlaying barricade block and a rope fixing method, and belongs to the field of civil engineering, marine traffic engineering and municipal engineering. Two side end surfaces of the block are convex arc-shaped, and the middle part is provided with a semicircular penetrated long hole; a concave body back edge is arranged at the upper part of one end of the block, and a convex body back edge capable of being inlaid with the concave body back edge is arranged at the lower part of the end of the block; a grid winding pole is arranged in the convex body back edge of the block, and is wound with a reinforced grid. In order to overcome the defect that the reinforced soil barricade block surface layer and the barricade reinforced soil interface are laid to form weak layers due to simple clamping of reinforced materials between blocks, the grid winding pole is arranged at the lower part of the block body back edge; the integrality and the stability of the reinforced soil and the surface layer of the block are effectively reinforced through different winding and laying manners of reinforced soil grids inlaid through filling soil to the positions behind walls. The block can be produced and prefabricated in factories conveniently. The barricade is constructed easily and conveniently, and the barricade construction period can be effectively shortened. At the same time, the block can be recycled, so that the material is saved, and the engineering construction cost is reduced.

Owner:HOHAI UNIV

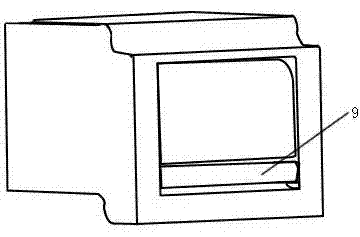

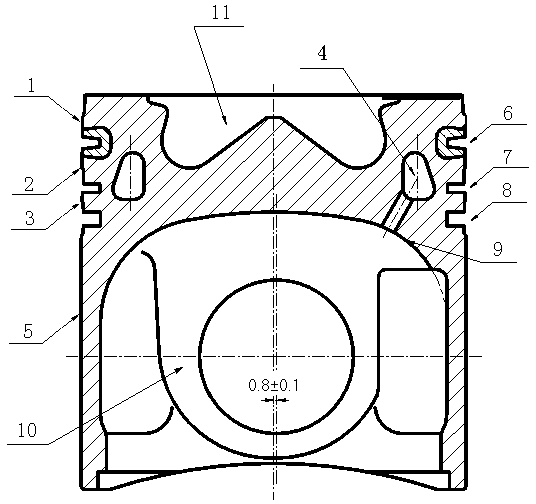

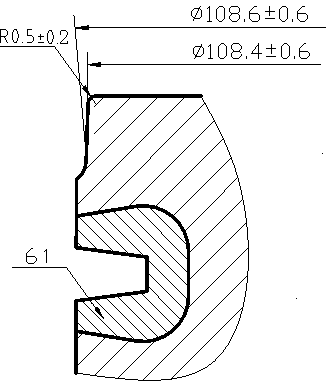

Pressurizing oil-saving type piston of diesel engine

ActiveCN102444496BReduce weightReduce the overall heightMachines/enginesPistonsFriction reductionCombustion chamber

The invention discloses a pressurizing oil-saving type piston of a diesel engine, which comprises a piston pin boss, a skirt portion and a head portion, wherein the head portion is composed of a piston top end and a ring groove, the ratio of the total height of the piston to the cylinder diameter is from 1.024 to 1.028, the ratio of the height of a piston junk to the cylinder diameter is from 12.6% to 12.8%, and the largest point gap between the head portion of the piston and the inner diameter of the cylinder is 2.2mm. A top end combustion chamber in a shape of a w-shaped pit is arranged at the head portion of the piston, a cooling oil cavity composed of a cooling oil channel, an oil inlet hole and an oil outlet hole is arranged in the head portion of the piston below the top end combustion chamber, and the oil inlet hole and the oil outlet hole are located at two ends of the cooling oil channel and communicated with a cavity inside the piston. The skirt portion is a variable elliptic type surface with the middle portion protruding outwards and both the ellipticity and the diameter variable. The pressurizing oil-saving type piston of the diesel engine can reduce inertia force of reciprocating movement, friction contact area and invalid friction work loss and can reduce clearance of cylinder matching by means of optimizing piston structure, and achieve the purposes of improving valid power and reducing consumption of fuel oil and lubricating oil and environment pollution.

Owner:石家庄金刚内燃机零部件集团有限公司

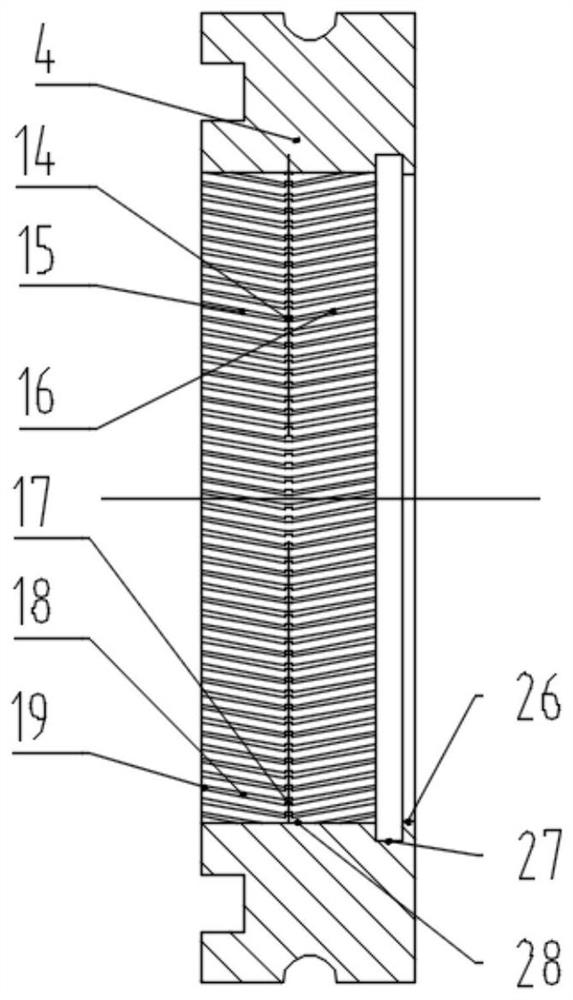

Bearing cavity non-contact trend graphite sealing structure

ActiveCN111927634AExtended service lifeImprove running line speedGas turbine plantsTurbine/propulsion lubricationAviationEngineering

The invention discloses a bearing cavity non-contact trend graphite sealing structure and relates to the field of engine bearing cavity sealing. The bearing cavity non-contact trend graphite sealing structure is especially suitable for efficient sealing of aero-engine bearing cavity grease. Specific to the defects of high friction consumed work and friction heat, low working linear speed and the like of contact type graphite sealing, a reversed fishbone-shaped dynamic pressure groove is formed in the inner circumferential face of a graphite sealing ring, a fishbone-shaped dynamic pressure groove is formed in the outer circumferential face of a sealing runway, through the improved graphite structure, the contact area of a rotor and a stator is reduced, graphite sealing has a trend to a non-contact effect on the basis that sealing performance is improved, operation life is prolonged, and the use edge is expanded. A method is simple and clear and is easy to achieve, and the bearing cavitynon-contact trend graphite sealing structure has high application prospects.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Rope tensioning device and crane with same

ActiveCN103318791BReduce frictional contact areaReduce frictionWinding mechanismsCranesEngineeringPulley

The invention provides a rope supporting tensioning device and a crane with the same. The device comprises two oppositely arranged first mounting bases (10) and a tensioning mechanism (20). The tensioning mechanism (20) is arranged between the two first mounting bases (10) and comprises a carrier roller component (21) and a compression component (22). Two ends of the carrier roller component (21) are in one-to-one corresponding connection with the two first mounting bases (10), and the carrier roller component (21) is provided with a rope winding cambered surface extending along the axial direction of the carrier roller component (21) and arranged in a radial movable mode relative to the two first mounting bases (10) to tension a hoisting rope (31) wound on the rope winding cambered surface. The compression component (22) is arranged on the first mounting bases (10) and in drive connection with the carrier roller component (21). By means of the device and the crane with the same, the phenomenon that the steel wire rope leaps and jumbles easily on a winding cylinder and a pulley can be changed, abrasion to the hoisting rope is reduced, and the service life of the hoisting rope is increased.

Owner:ZOOMLION HEAVY IND CO LTD

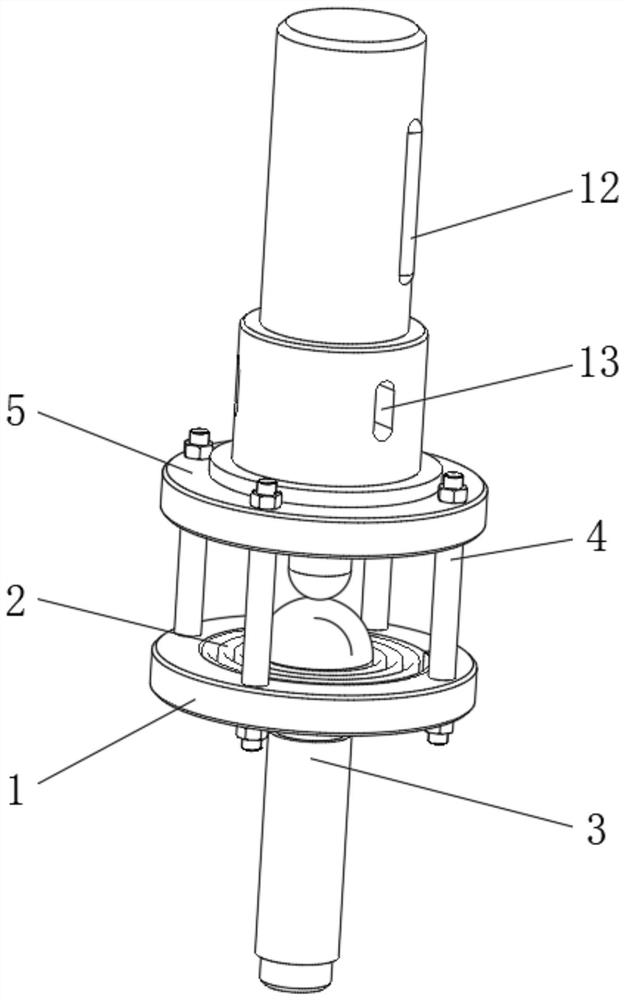

Anti-spin system for the head of a cone crusher

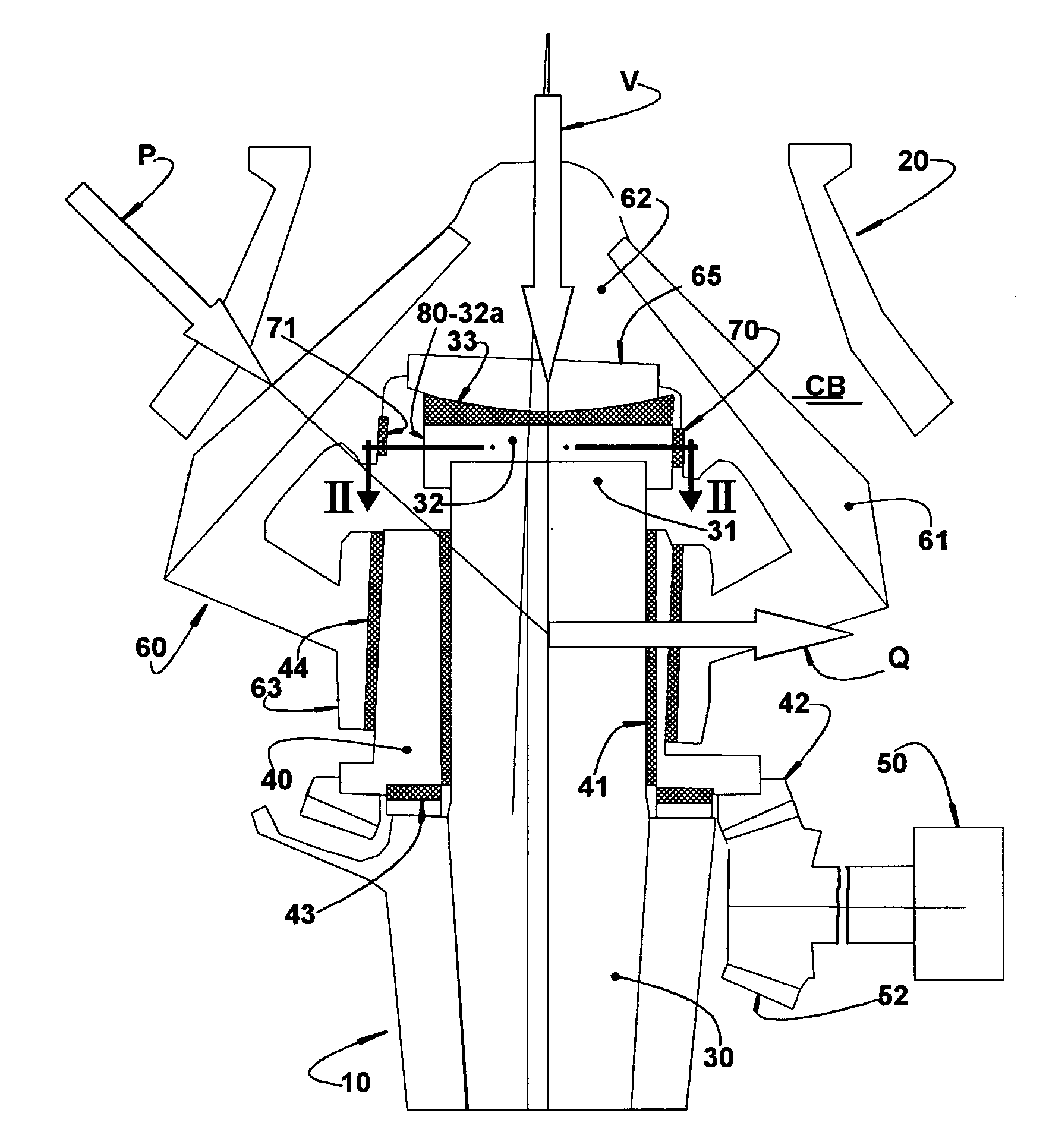

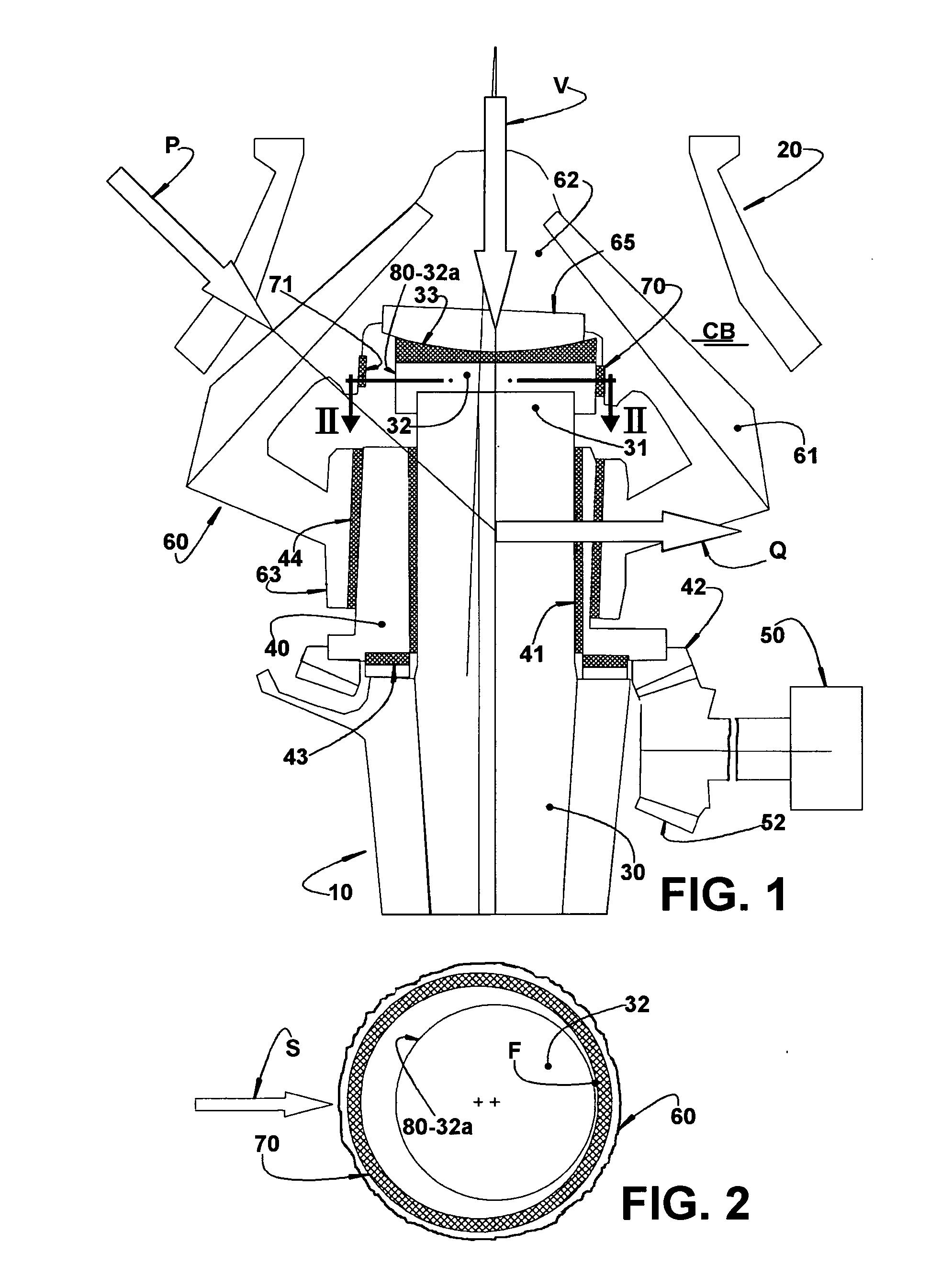

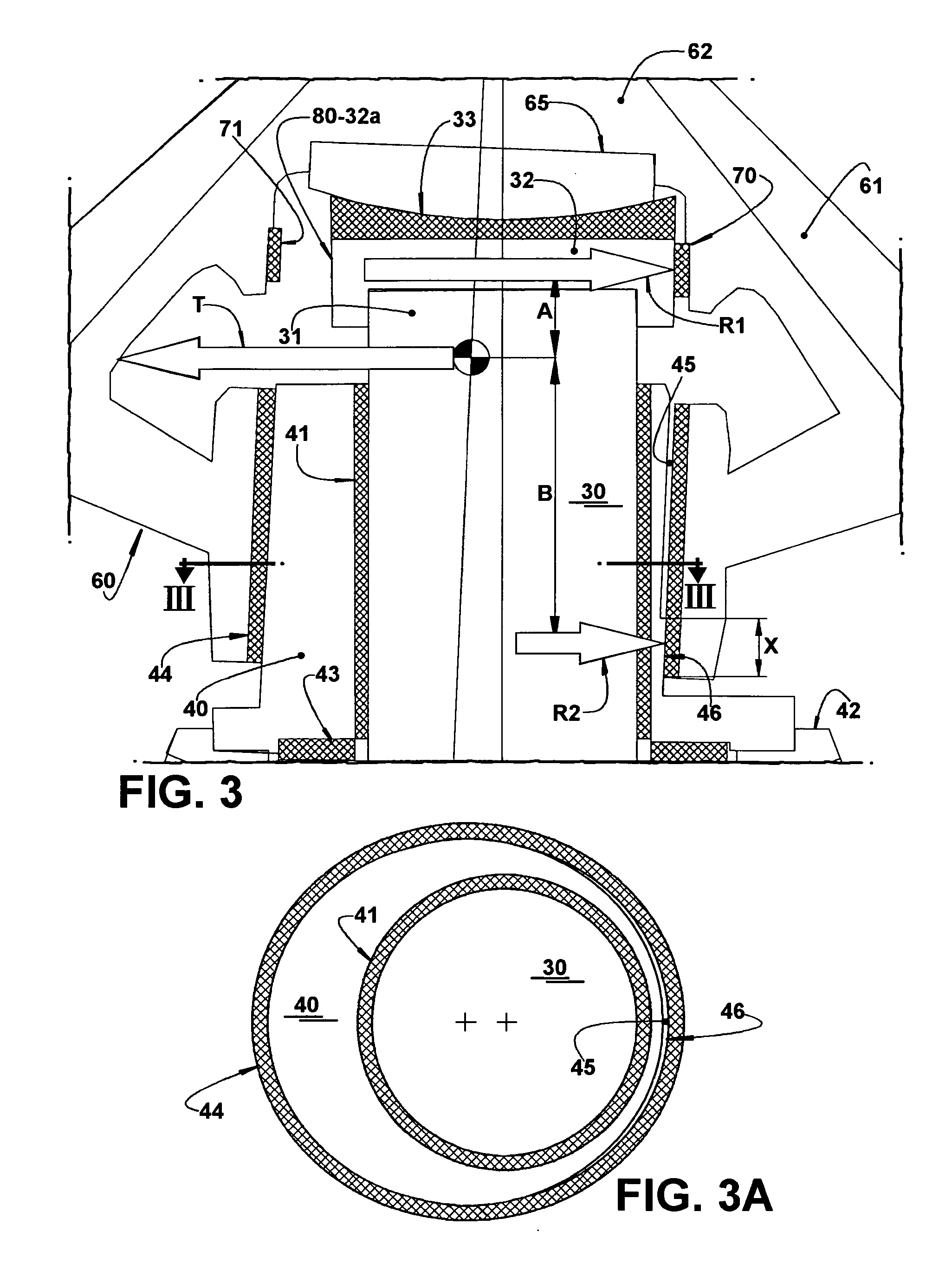

ActiveUS20120061499A1Prevent rotationReduce resistanceGrain treatmentsWet separationSpin systemEngineering

The anti-spin system is applied to a cone crusher having a structure (10) carrying an upper housing (20) and a vertical axle (30); an eccentric element (40) to be rotated around the vertical axle (30); and a cone head (60) disposed inside the upper housing (20) and being axially and rotatively supported on the structure (10) and radially supported around the eccentric element (40). The anti-spin system comprises a braking bush (70) carried by the cone head (60) or by the structure (10), and an annular shoe (80) carried by the other of said parts, which are pressed against each other, by action of the inertial centrifugal force acting on the cone head (60), upon “no-load” operation of the crusher, to generate a friction force opposite and superior to that generated between the cone head (60) and the eccentric element (40) and to prevent the latter from rotatively dragging the cone head (60).

Owner:METSO BRASIL IND E COMML LTDA

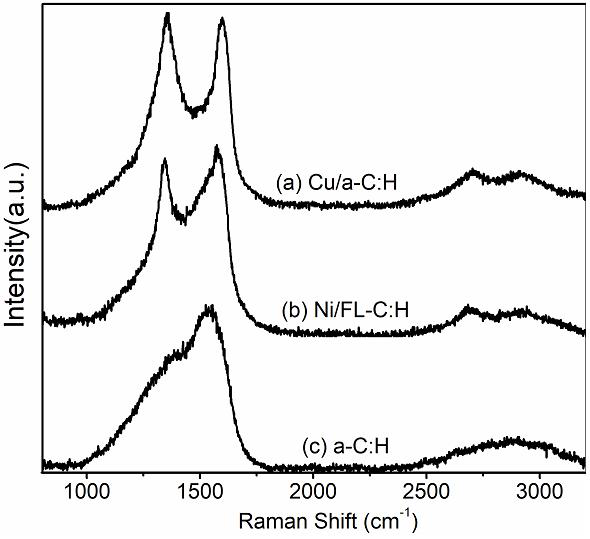

A Tribocatalytic Design Method for Realizing Ultra-low Friction of Carbon Thin Films

ActiveCN112210417BReduce frictional contact areaReduce frictionMaterial nanotechnologyGrapheneCarbon filmAnhydrous ethanol

The invention relates to a method for designing friction catalysis to realize ultra-low friction of a carbon film. The method refers to: first adding metal nanoparticles into absolute ethanol, ultrasonically dispersing to obtain a metal nanoparticle solution; and then spin-coating the metal nanoparticle solution On the surface of the carbon-based film, a metal nanoparticle coating is obtained; finally, mechanical friction stirring is used to promote the mixing of carbon-based film wear debris and metal nanoparticles, and a ball-like particle coating with embedded metal nanoparticles and coated graphene is obtained. . The invention introduces the metal nano-particles as a catalyst into the friction interface of the carbon-based film, and improves the problems of high friction coefficient and environmental sensitivity in a single friction process through the synergistic effect of friction and catalysis.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

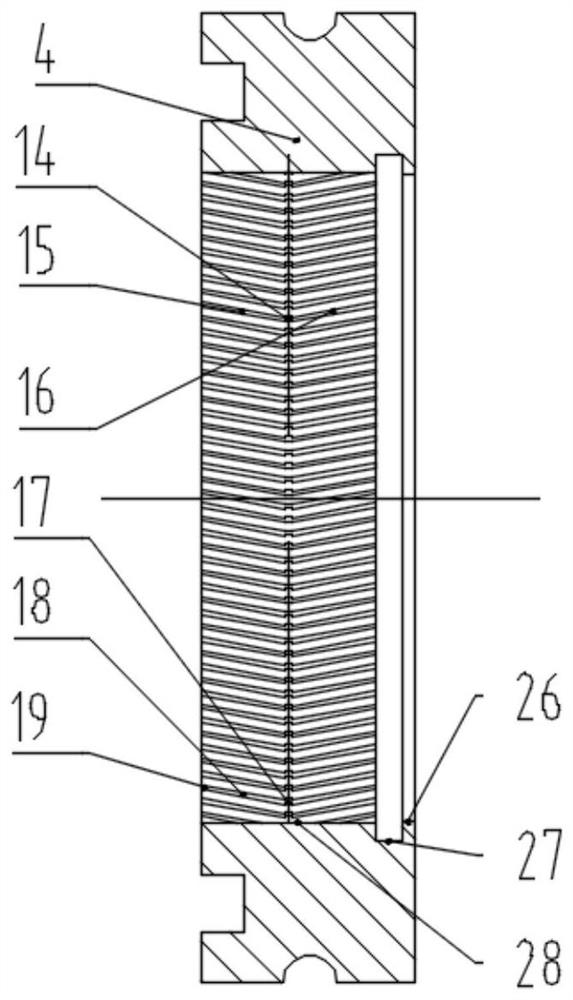

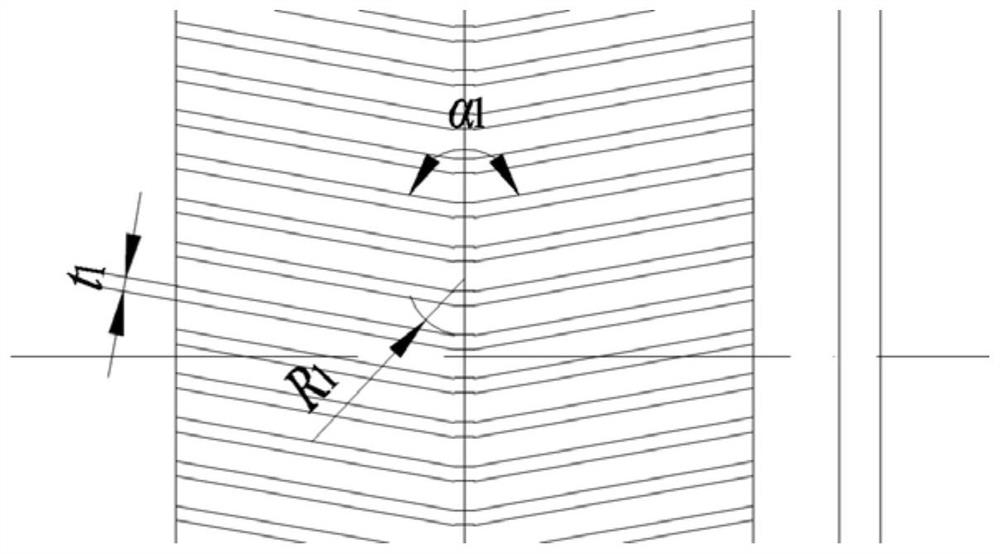

A graphite sealing structure with anti-herringbone dynamic pressure groove

ActiveCN111927633BBroaden the boundaries of useReduce frictional contact areaGas turbine plantsTurbine/propulsion lubricationEngineeringGraphite

The invention discloses a graphite sealing structure with an anti-herringbone dynamic pressure groove, relates to the field of engine bearing cavity sealing, and is particularly suitable for high-efficiency sealing of lubricating oil in the bearing cavity of an aeroengine. The structure is mainly to open an annular inner groove on the inner peripheral surface of the graphite sealing ring, and the annular inner groove divides the inner peripheral surface of the graphite sealing ring into a main sealing surface and a secondary sealing surface, and one side of the secondary sealing surface communicates with the outside of the bearing cavity , The anti-herringbone dynamic pressure groove connected to the annular inner groove on the other side. When the rotor runs at high speed, pressure can be generated in the anti-herringbone dynamic pressure groove to improve the sealing performance of the graphite seal; at the same time, the anti-herringbone dynamic pressure groove reduces the contact area between the graphite sealing ring and the sealing track, reducing Frictional power consumption and frictional heat are conducive to improving the life of graphite seals; in addition, it can increase the operating line speed and broaden the use boundary of graphite seals. The invention has simple structure and convenient processing, and is a sealing structure with great application prospects.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

A cutting tool for hard glue traditional Chinese medicine cooking machine

Owner:HARBIN YIWEN DINGSHENG INVESTMENT MANAGEMENT ENTERPRISE LLP

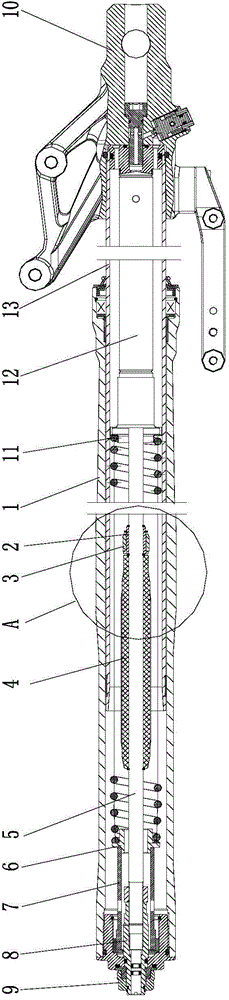

Blade guide rolling device for static frequency detection of large blades

ActiveCN105414922BAvoid damageRestricted freedom of movementMachine part testingMetal working apparatusEngineeringFrequency detection

The invention provides a blade guiding rolling device for static frequency detection of large blades. The blade guiding rolling device is capable of solving the problems of difficult frequency detection mounting of existing huge and superheavy blades and easy damage of roots of blades during frequency detection mounting. The blade guiding rolling device comprises a guiding assembly and a rolling assembly; the guiding assembly comprises two guide blocks; the two guide blocks are mounted on two side surfaces of a top opening of a wheel slot of a frequency detector, respectively, and arranged to extend in a length direction of the wheel slot; the rolling assembly extending in the length direction of the wheel slot is mounted on a bottom surface of the wheel slot of the frequency detector.

Owner:WUXI TURBINE BLADE

Low-noise mild type damping assembly

ActiveCN104482107AIncreased compression damping forceGuaranteed comfortSpringsShock absorbersLow noiseRelative motion

The invention discloses a low-noise mild type damping assembly which comprises a damping spring and a damper module. The damper module comprises a damping drum and a piston module, the piston module comprises a piston and a piston rod, the damping spring sleeves the piston rod, the middle of the piston rod located between the damping spring and the piston rod is sleeved with a guide sleeve, and the guide sleeve is axially limited on the piston rod. The middle of the piston rod is provided with the guide sleeve structure and is just the part where the spring is easily deviated from the center line to be deformed, the collision and friction of the spring and the piston rod can be avoided in use, the piston rod and the spring are protected, the smoothness of relative motion of the piston rod and the spring is guaranteed, the noise of a damper is reduced, and the comfort and smoothness are improved.

Owner:CHONGQING LONCIN ENGINE

Multifunctional brake disc of electric vehicle

ActiveCN102352900BEasy to disperseReduce frictional heatBraking drumsCycle brakesEngineeringElectric cars

Owner:TAICANG CENTURY PORT GARMENT CO LTD

Integrated light chain board

The invention relates to the technical field of transmission parts, in particular to an integrated light chain board. The integrated light chain board comprises an inner chain board and a chain roller. The inner chain board and the chain roller are integrally formed in a thermoplastic mode with high-wear-resisting epoxy resin. Reinforcing particles adopted in the high-wear-resisting epoxy resin is nano-SiC. The diameter of the nano-Sic ranges from 50 nanometers to 80 nanometers. Polyacrylamide is added into the epoxy resin. The two sides of the chain roller are in a concave shape. A chain assembled by the chain board is simple in structure, convenient to use, low in mass and high in strength; due to the concave design in the middle of the chain roller, the frictional contact area between the chain roller and a chain wheel is reduced, flexibility of the chain during operation is improved, and the service life of the chain is prolonged.

Owner:TIANJIN KAIRUI METAL PROD

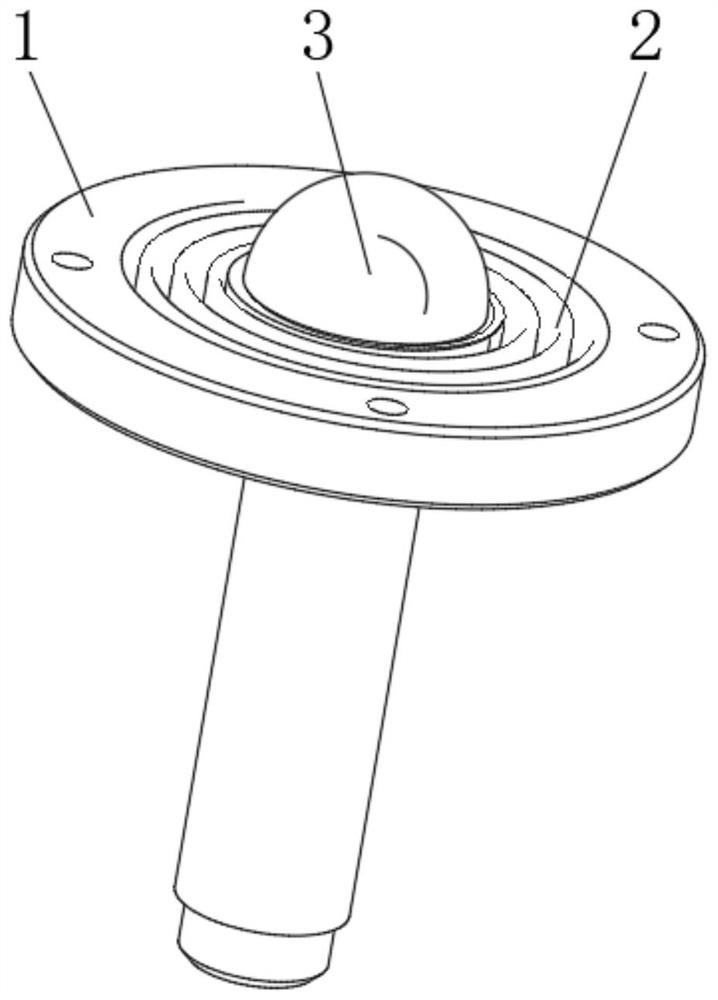

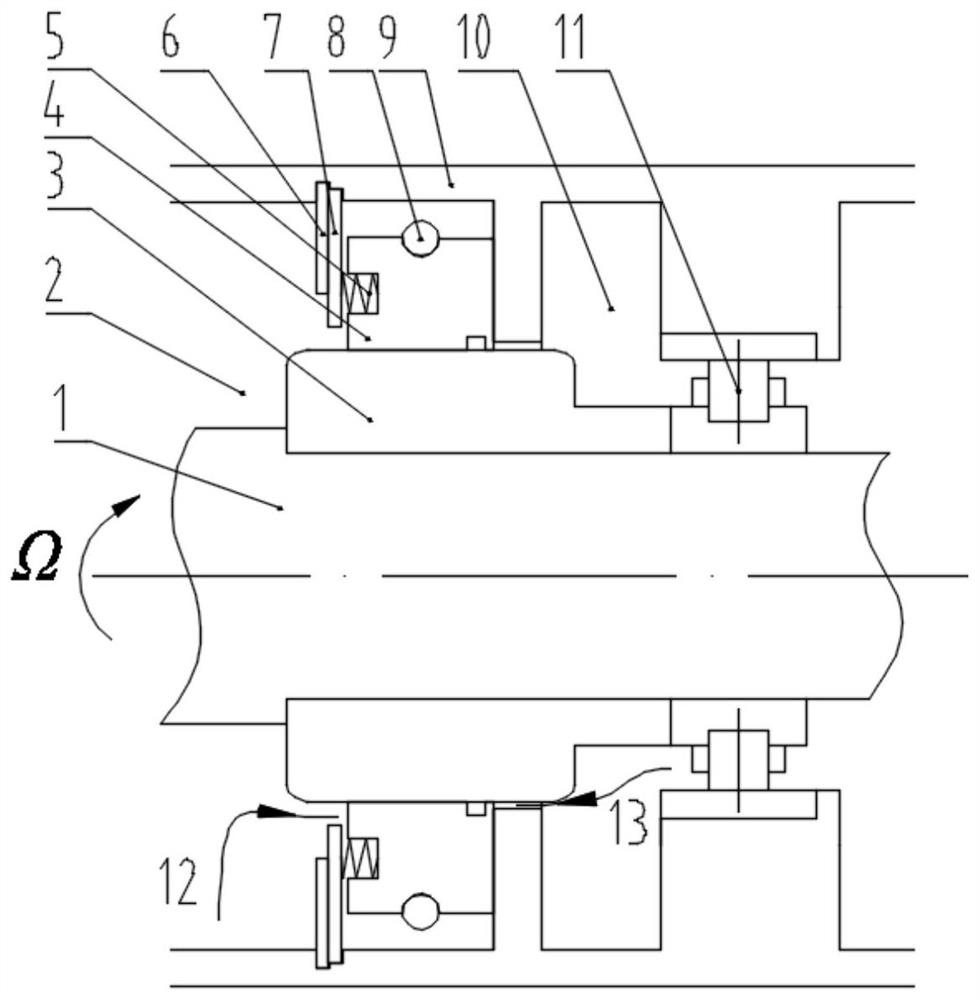

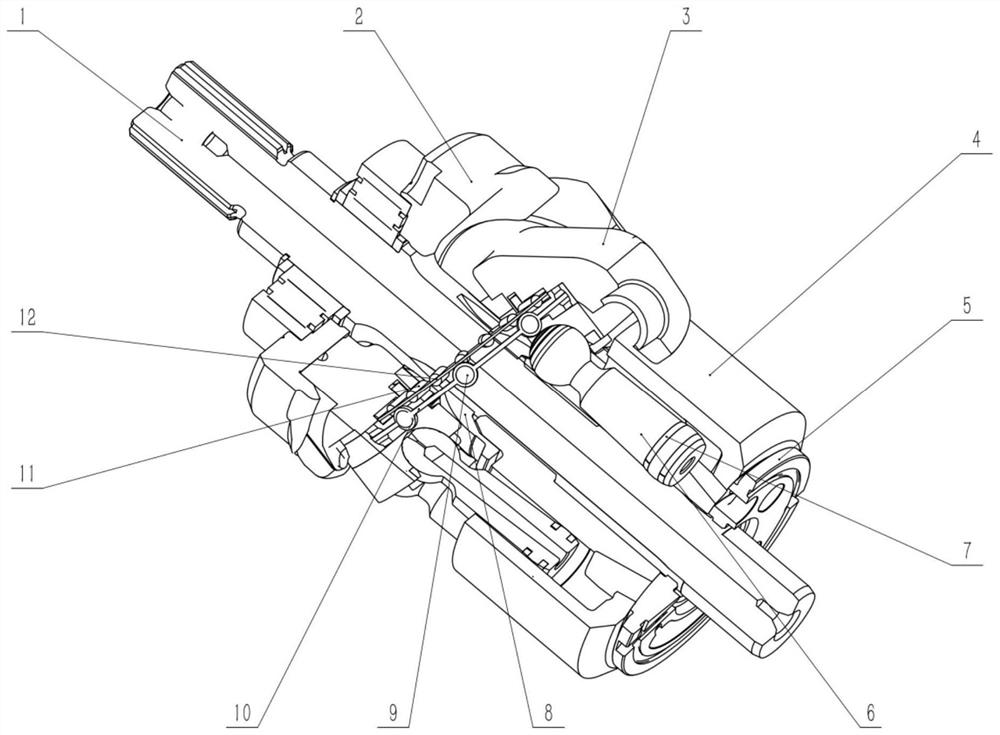

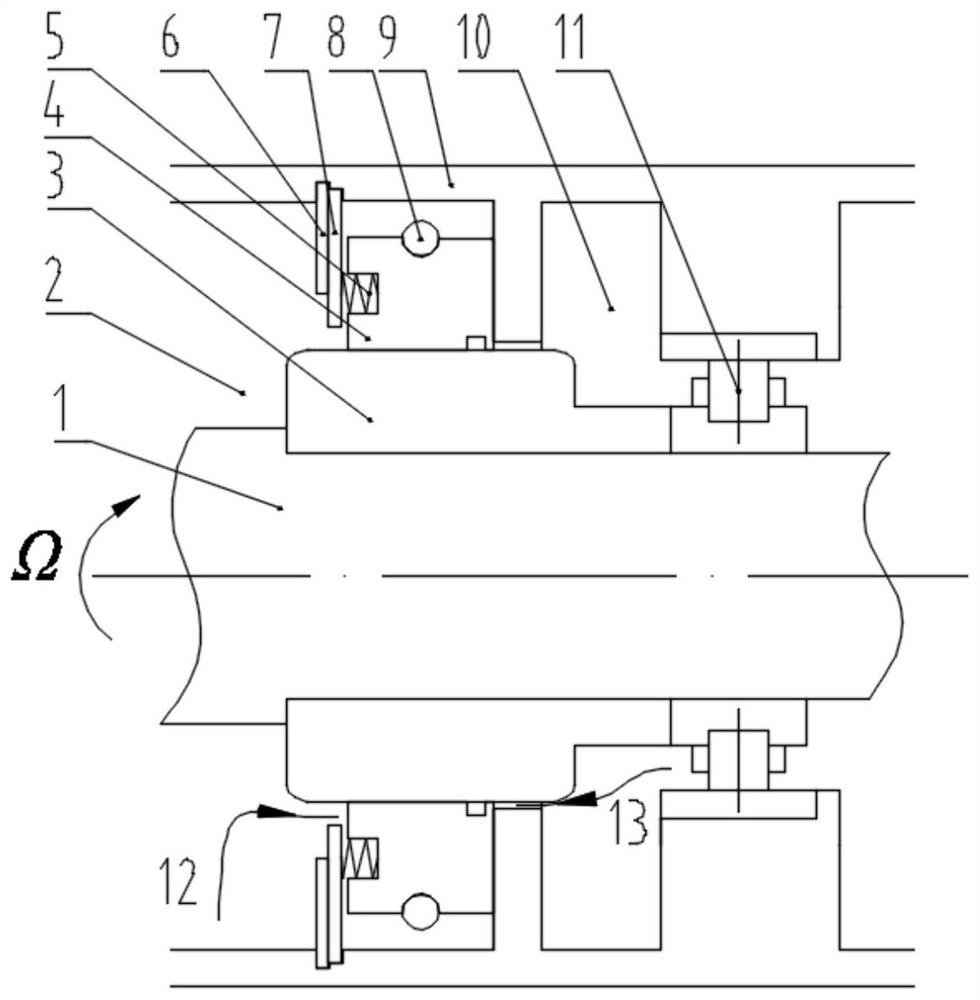

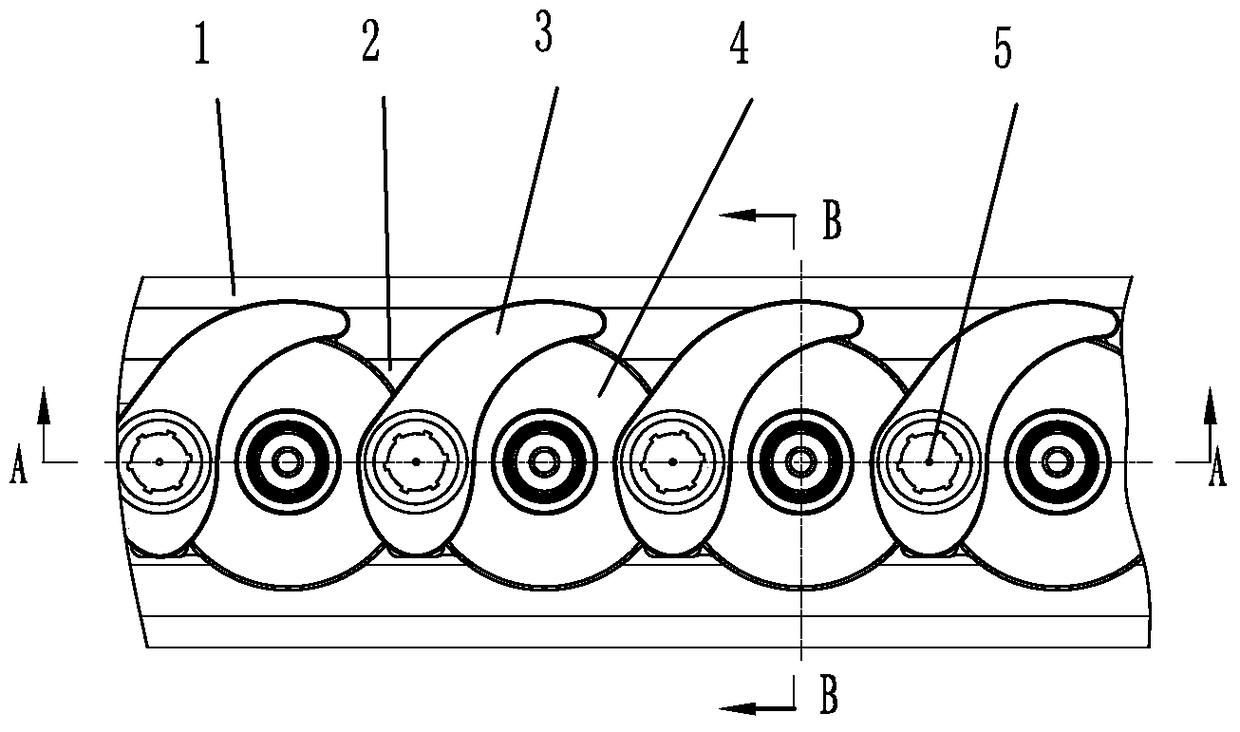

Floating swash plate follower ball hinge conical plunger variable pump/motor rotation assembly

ActiveCN111692063BExtended service lifeEasy to replace and maintainPositive-displacement liquid enginesMulti-cylinder pumpsEngineeringStructural engineering

The present invention disclosed a floating diagonal disk hinge hinge hinge hinge pump / motor rotation component, including floating diagonal and cone plunged rotation components.The front -end ball head and the rotating ball nest of the cone plunger are hinged. The back end only has the spherical area area and the pillar wall of the cylinder body.The principle of force solves the problem of friction and wear caused by the huge side force and torque caused by the traditional fixed oblique disk -type axial plunger pump.The inner plate of the floating diagonal disk is fixed with the rotating plate. The rotating disc is driven by the hinge of the cone -shaped plunger ball. Due to the support of the bottom roller and the side roller, the rotation disc and the inner disc renewal movement, so that the rotation and inner discs will turn around, thereby the rotation movement, thereby the rotation movement.The sliding movement of the original sliding boots and the sliding boots and the sliding boots and the slash plate converted into the rolling movement between the side roller and the bottom roller, which achieved the purpose of reducing the loss of the sub -friction power loss of heavy -duty skate boots.

Owner:HEFEI UNIV OF TECH

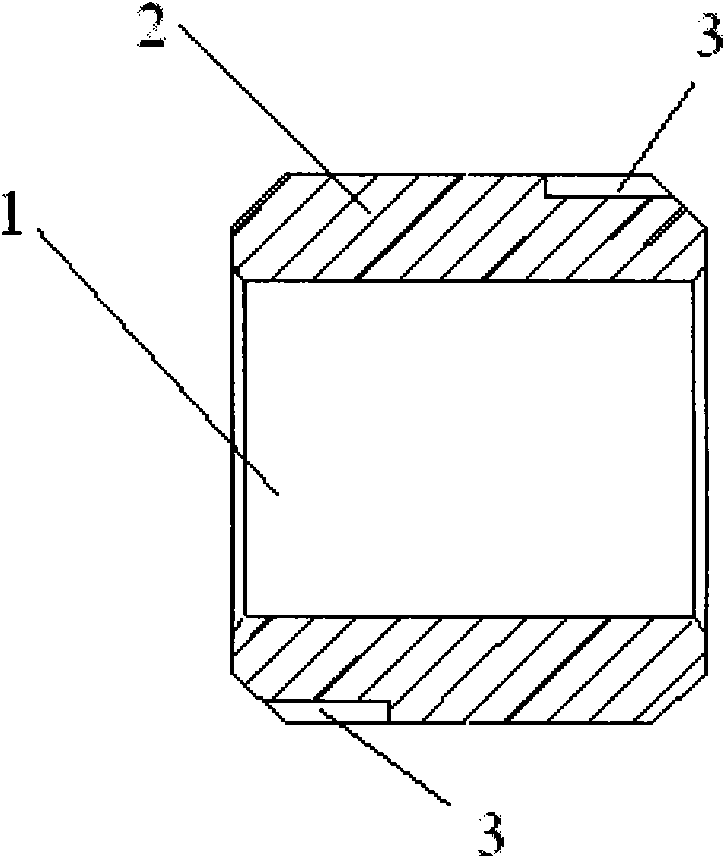

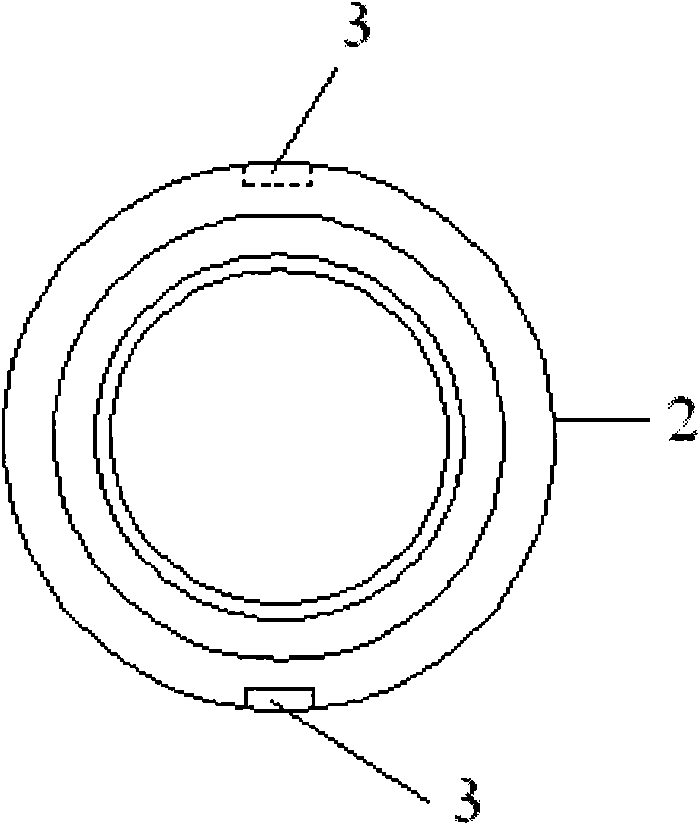

Powder metallurgy oil-free lubricating bearing and method for preparing same

ActiveCN101576122BImprove rotation efficiencyReduce running noiseBearing componentsOil freeMaterials science

The invention discloses a powder metallurgy oil-free lubricating bearing and a method for preparing the same. The powder metallurgy oil-free lubricating bearing comprises a shaft body provided with anaxial central hole, and the outer surface of the shaft body is provided with an oil storage tank. The preparation method comprises the following steps: (1) evenly mixing Cu-Sn powder and C powder forforming, wherein the weight portion of all components is that: C is 0.5 to 3.0 portion, Cu is 85 to 93 portions and Sn is 5 to 13 portions; (2) controlling the temperature to between 650 and 730 DEGC, and performing sintering; (3) orderly performing finishing and cleaning; (4) performing vacuum oil immersion; and (5) performing deoiling treatment. The product has high precision and good dimension stability. Because the internal diameter tolerance of the product is controlled at 8u, and the axiality of the product is less than 0.05mm, and the matching gap between the product and the shaft issmall, so that the friction contact area is small, the rotating efficiency of a fan is improved, the operating noise of the fan is reduced, and the service life of the fan is prolonged.

Owner:扬州保来得科技实业有限公司

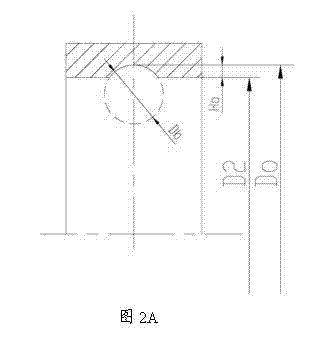

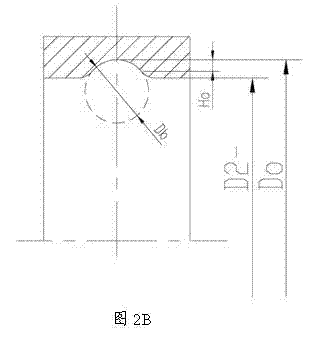

Low-friction implementation method for radial ball bearing and shallow groove radial ball bearing

InactiveCN103697067AReduce frictionReduce frictional contact areaBearing componentsRolling resistance optimizationFriction reductionBall bearing

The invention relates to a shallow groove radial ball bearing which comprises an outer ring, an inner ring, balls embedded between an outer ring groove and an inner ring groove, and retainers for uniformly isolating the balls along the circumferential direction, wherein a groove depth coefficient, namely, a ratio of the depth of the groove of the outer ring or / and the inner ring to the radius of each ball is smaller than that of a corresponding deep groove ball bearing; the reduction of the depth of the groove is generally implemented by adjusting the diameter of a stop edge of a ferrule or a chamfer at a groove edge. According to the shallow groove radial ball bearing, the groove depth is reduced, and the containment friction area of a ferrule groove to each ball is diminished; the shallow groove radial ball bearing is very favorable for the reduction of the energy consumption of the bearing, starting of friction torque, running of the friction torque, temperature rising, improvement of the running sensitivity and the like and is an important measure for a friction reduction design, a sensitivity design and a green design of a rolling bearing; the shallow groove radial ball bearing has very important engineering practical significance.

Owner:SHANGHAI F&S BEARING TECH

A bearing cavity non-contact graphite sealing structure

ActiveCN111927634BExtended service lifeImprove running line speedGas turbine plantsTurbine/propulsion lubricationAviationGraphite

The invention discloses a non-contact graphite sealing structure for a bearing cavity, relates to the field of engine bearing cavity sealing, and is particularly suitable for high-efficiency sealing of lubricating oil in the bearing cavity of an aeroengine. Aiming at the shortcomings of the contact graphite seal, such as high frictional power consumption, high frictional heat, and low working line speed, the present invention provides an anti-herringbone dynamic pressure groove on the inner peripheral surface of the graphite sealing ring, and a fishbone type dynamic pressure groove on the outer peripheral surface of the sealed runway. The bone-shaped dynamic pressure groove uses the improved graphite sealing structure of the present invention to reduce the contact area of the rotor and stator, and make the graphite seal tend to be non-contact on the basis of improving the sealing performance, prolong the operating life, and expand the use boundary. The method is simple and clear, easy to implement, and is a very promising sealing structure.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Tray fixed conveying device for collective doffing of spinning frame

The invention relates to a tray fixing and conveying device used for integrated doffing of a spinning machine. A conveying guide rail comprises a double-guide rail structure which is provided with a convex arc-shaped limit surface at the inner side and an arc-shaped supporting surface at the top, a tray structure comprises more than two tray supports, trays and tray pressing plates, a sliding seat of each tray support is arranged on double guide rails, the inner concave cambered surface of each sliding seat is matched with and limited by the convex arc-shaped limit surface on the double guide rails, the arc-shaped supporting surface of the double guide rails supports the sliding seats of the tray supports, at least one pollution discharge channel is formed on the inner concave cambered surface of each sliding seat, the trays are accordingly placed on respective tray supports, a first locating column and a second locating column on each tray support and a first locating column on an adjacent tray support are limited in the horizontal direction, each tray pressing plate is arranged on a respective corresponding tray support by virtue of a connecting piece, and a depositing stand pipe is arranged on each tray pressing plate. The tray fixing and conveying device provided by the invention is reasonable in structure, better fixation property of the trays can be guaranteed, abrasion is small, and operation is stable and reliable.

Owner:常州市同和纺织机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com