Wedge block type clutch

A clutch and wedge-type technology, applied in the field of clutches, can solve problems such as unsuitable application, energy consumption, and unsuitable use of variable speed transmission systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

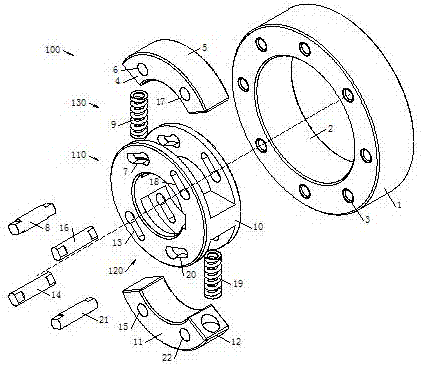

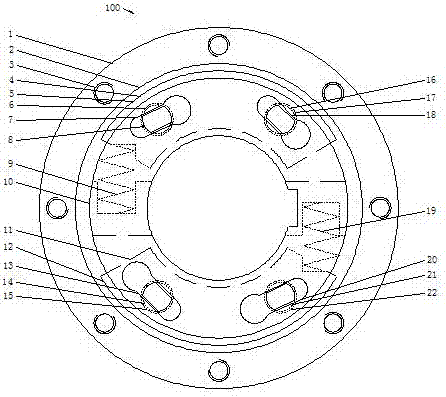

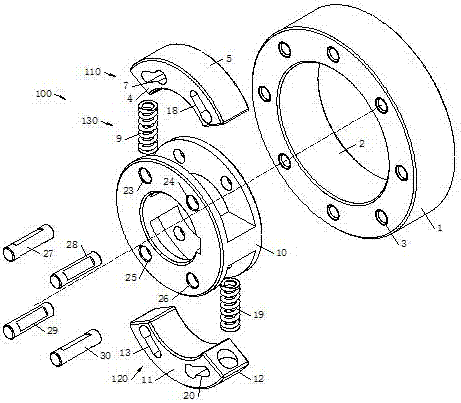

[0056] The present invention will be described in further detail below according to accompanying drawing and embodiment:

[0057] Such as figure 1 , figure 2 As shown, the sprag clutch 100 of the present invention includes a driving cam 10, a driven element 1, a plurality of centrifugal sprags 4, at least one reset device 130, and radial thrust groups 110 having the same number as the centrifugal sprags 4. The pushing group 110 includes at least one pushing device 7 , and the centrifugal wedge 4 includes at least one friction arc surface 5 . The driving cam 10 and the driven element 1 are radially apart from each other and arranged on the same axis, the driven element 1 is sleeved on the driving cam 10, or the driving cam 10 is sleeved on the driven element 1, and the base circle of the driving cam 10 The radial thrust group 110 with the same number as the centrifugal wedge 4 is arranged in turn around its axis, and the thrusts of the first thrust device 7 and the second th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com