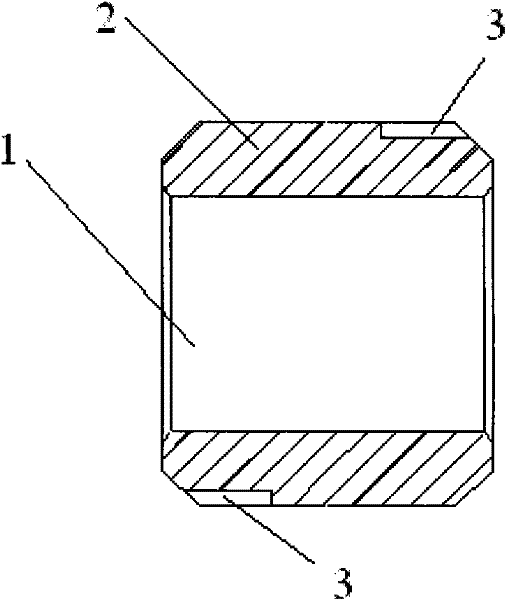

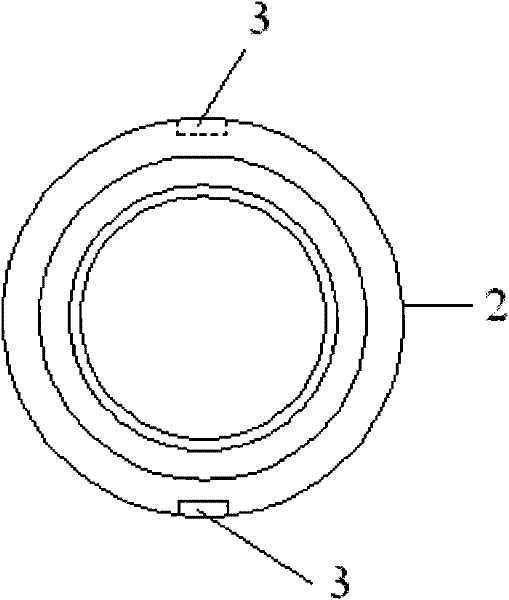

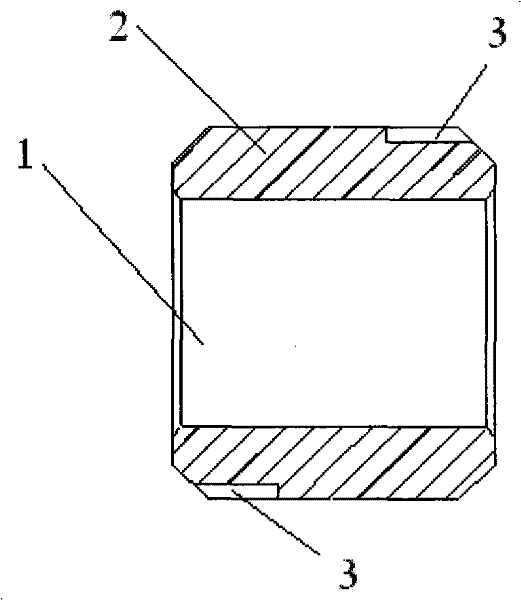

Powder metallurgy oil-free lubricating bearing and method for preparing same

An oil-free lubrication, powder metallurgy technology, used in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of high bearing scrap rate, increase friction noise, shaft core wear, etc., achieve small friction contact area, increase rotation Efficiency and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] After mixing Cu powder, Sn powder and C evenly, put them into a molding machine for molding; the parts by weight of each component are: C: 0.5, Cu: 86.5, Sn: 13; then put it into a mesh belt firing furnace Carry out sintering, the sintering temperature is 650°C; the sintered products are subjected to finishing and cleaning processes in turn; under vacuum conditions, the oil-immersed fluorinated oil process is carried out; finally, deoiling treatment is carried out to prepare powder metallurgy oil-free lubricating bearings.

[0025] After testing, the prepared powder metallurgy oil-free lubricating bearing has radial crushing force: 110kgf; material radial crushing strength: 60MPa; friction coefficient: 0.020; outer diameter eccentricity: 0.05mm; end face eccentricity: 0.05mm .

Embodiment 2

[0027] After mixing Cu powder, Sn powder and C evenly, put them into a molding machine for molding; the parts by weight of each component are: C: 3.0, Cu: 92, Sn: 5; then put them into a mesh belt firing furnace Carry out sintering, the sintering temperature is 730°C; the sintered products are subjected to finishing and cleaning processes in turn; under vacuum conditions, the oil-immersed fluorinated oil process is carried out; finally, deoiling treatment is carried out, that is, powder metallurgy oil-free lubricating bearings are prepared.

[0028] After testing, the prepared powder metallurgy oil-free lubricating bearing has radial crushing force: 130kgf; material radial crushing strength: 150MPa; friction coefficient: 0.010; outer diameter eccentricity: 0.03mm; end face eccentricity: 0.04mm .

Embodiment 3

[0030] After mixing Cu powder, Sn powder and C evenly, put them into a molding machine for molding; the parts by weight of each component are: C: 2.0, Cu: 85; Sn: 13; then put it into a mesh belt firing furnace Carry out sintering, the sintering temperature is 730°C; the sintered products are subjected to finishing and cleaning processes in turn; under vacuum conditions, the oil-immersed fluorinated oil process is carried out; finally, deoiling treatment is carried out, that is, powder metallurgy oil-free lubricating bearings are prepared.

[0031] After testing, the prepared powder metallurgy oil-free lubricating bearing has radial crushing force: 170kgf; material radial crushing strength: 230MPa; friction coefficient: 0.008; outer diameter eccentricity: 0.02mm; end face eccentricity: 0.01mm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| crushing strength | aaaaa | aaaaa |

| crushing strength | aaaaa | aaaaa |

| crushing strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com