Centrifugal force controlled planet gear stepless transmission

A technology of continuously variable transmissions and planetary gears, applied to gear transmissions, belts/chains/gears, components with teeth, etc., which can solve the problems of high maintenance and repair costs, small metal belt carrying capacity, discontinuous transmission ratio, etc. low maintenance cost, high rotation efficiency and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

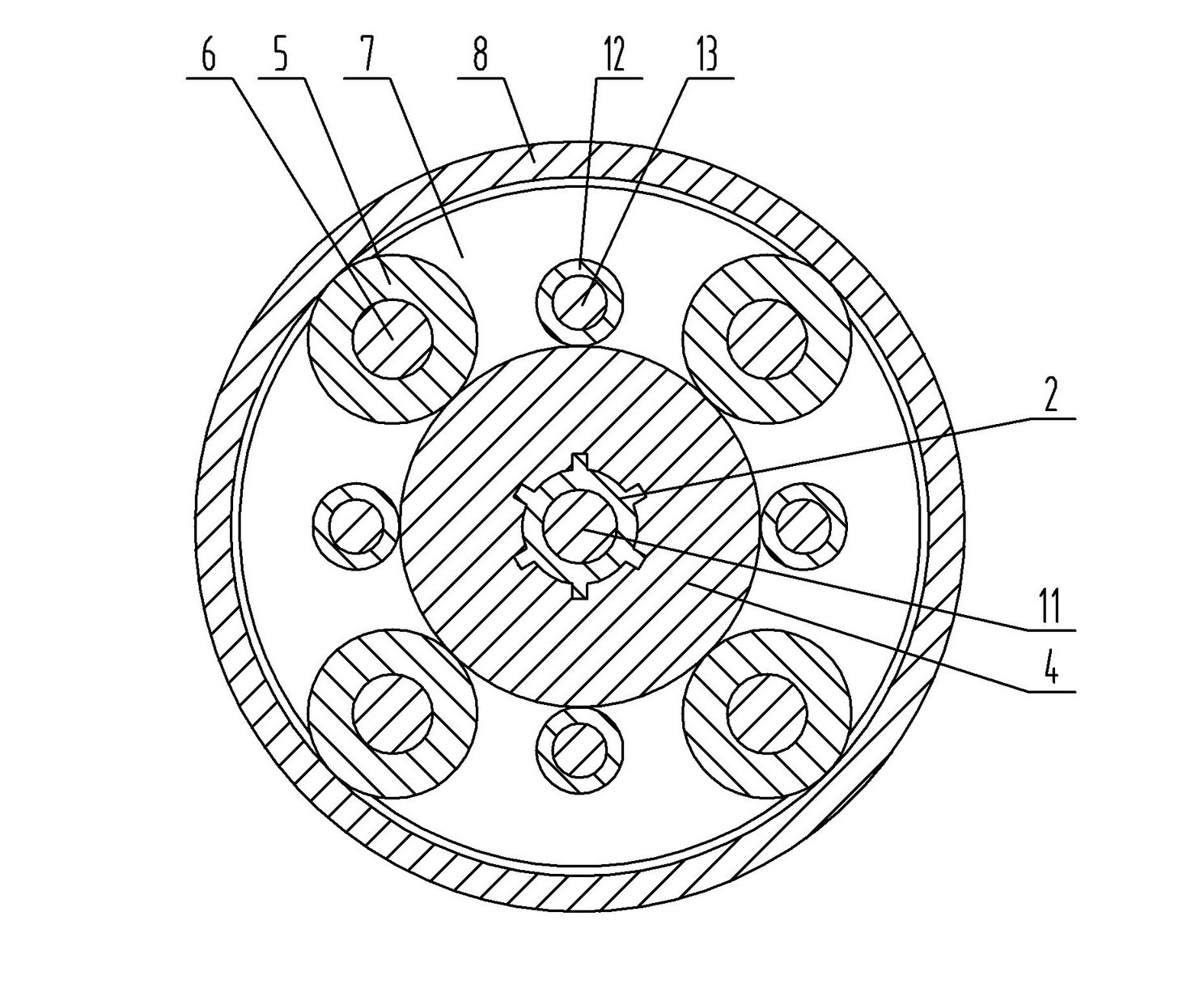

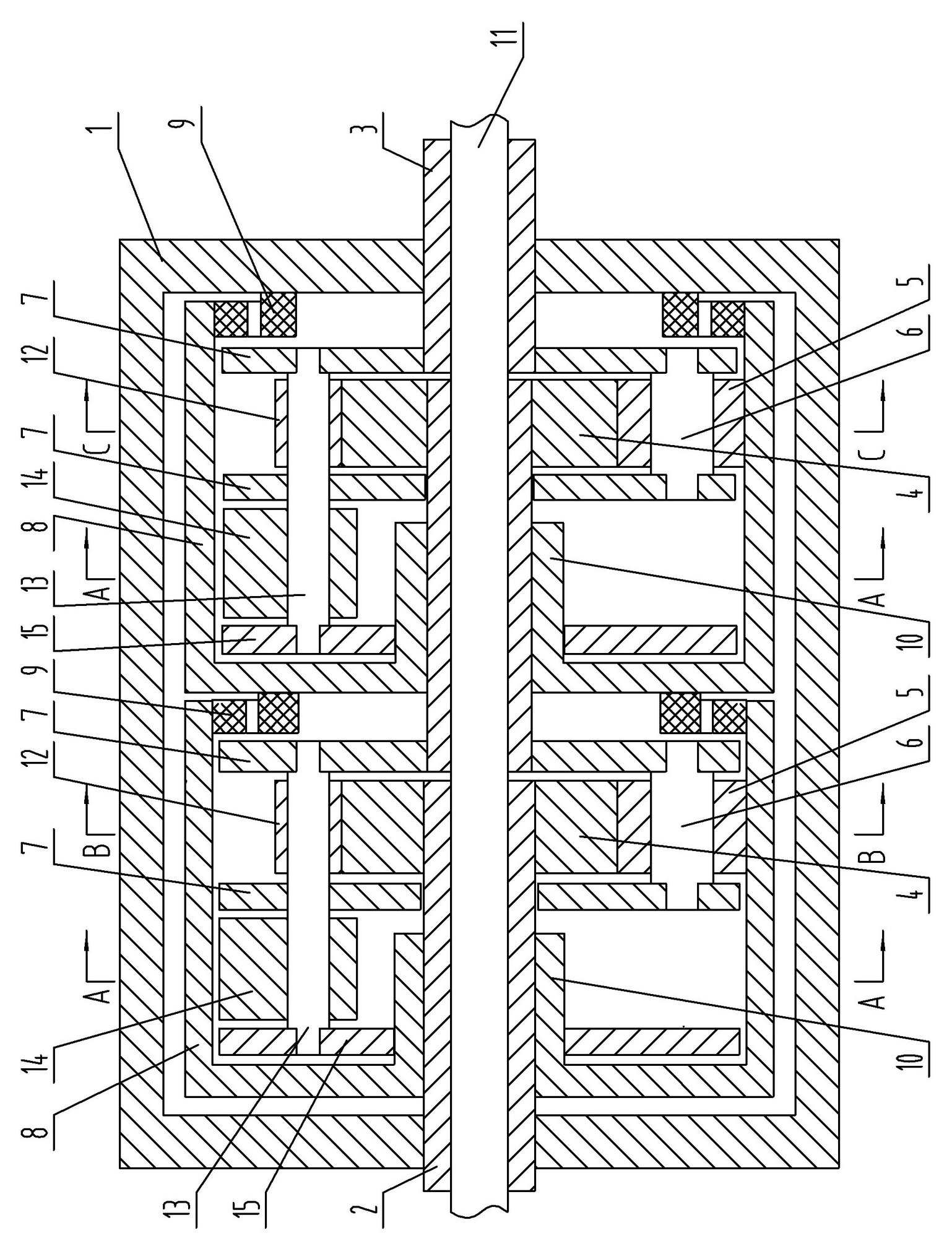

[0026] see figure 2 , Figure 4 to Figure 6 , among the figure, the centrifugal force control planetary gear continuously variable transmission of the present invention comprises casing 1, the transmission unit and overrunning clutch 9 that are installed on the casing 1, and transmission unit comprises input shaft 2, output shaft 3, large planetary gear 5, asteroid Gear 12, sun gear 4, ring gear barrel 8 and planetary gear carrier 7, the transmission unit has at least one stage, a common intermediate shaft 11 is installed in the casing 1, the input shaft 2 and output shaft 3 of each transmission unit They are all set on the outer surface of the intermediate shaft 11, the input shaft 2 and the output shaft 3 are separated from each other, the central gear 4 is fixed on the outer surface of the input shaft 2, and two pairs of large planetary gears 5 are on the two mutually perpendicular sides of the central gear 4. The diameters are arranged along the same circle, and the two ...

Embodiment 2

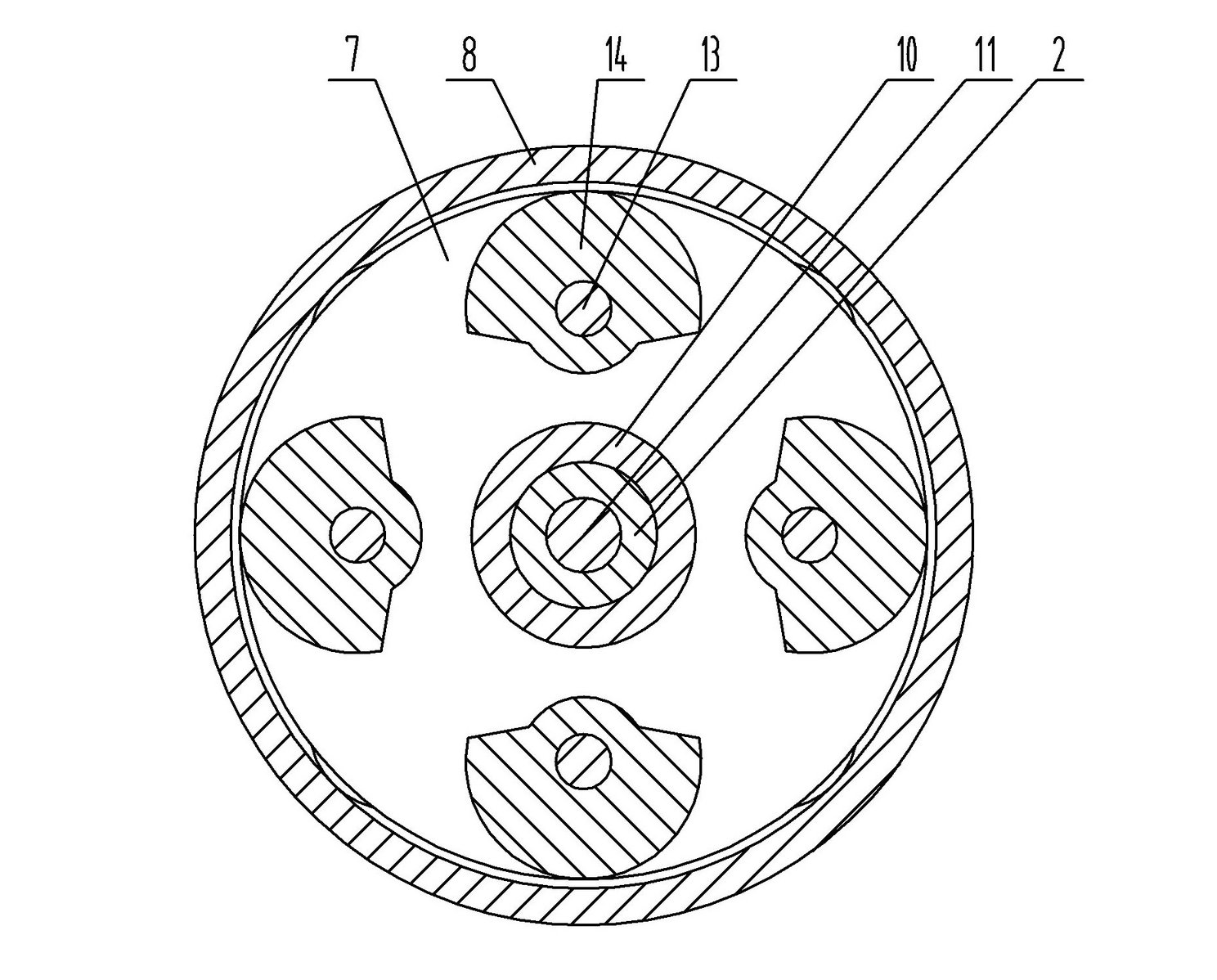

[0030] see figure 1, in the figure, the meaning of the same numbered part of this embodiment is the same as that of Embodiment 1 and will not be repeated. The difference is that the transmission unit is single-stage, and the input shaft 2 and the sun gear 4 are connected by splines.

Embodiment 3

[0032] see image 3 , in the figure, the meanings of the same numbers in this embodiment and Embodiment 1 are the same and will not be repeated. The difference is that the transmission unit is three-stage, and the output shaft 3 of the first-stage transmission unit is also the second-stage transmission The input shaft 2 of the unit is splined to the sun gear 4 of the second-stage transmission unit, and the output shaft 3 of the second-stage transmission unit, which is also the input shaft 2 of the third-stage transmission unit, is connected to the third-stage transmission unit. Spline connection between the sun gear 4 of the first stage transmission unit, spline connection between the input shaft 2 of the first stage transmission unit and the sun gear 4 of the first stage transmission unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com