Low-friction implementation method for radial ball bearing and shallow groove radial ball bearing

A centripetal ball and low-friction technology, applied to bearing components, shafts and bearings, rolling resistance optimization, etc., can solve problems such as high power consumption, high torque, and large temperature rise, and achieve reduced startup and friction torque and improved sensitivity , the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

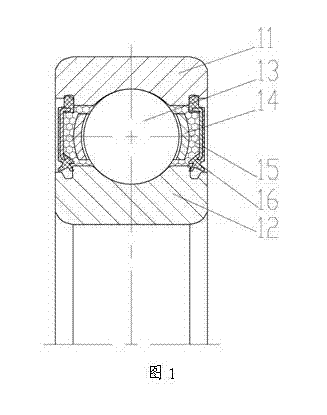

[0045] Example 1, a shallow groove radial ball bearing 6302 in a low temperature rise application

[0046] This occasion has a particularly high requirement on temperature rise, and the existing deep groove ball bearing 6302 cannot meet the requirements of the main engine through various technical measures. Therefore, it is necessary to use the corresponding shallow groove radial ball bearing 6302, and only the outer ring adopts a shallow groove design. The following table is the actual size comparison.

[0047] Technical parameters (nominal value)

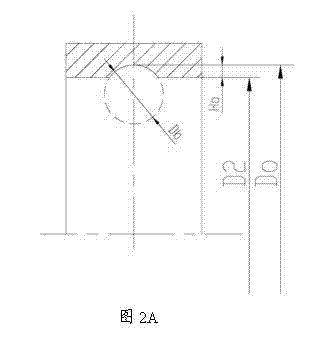

[0048] D. 2 / mm

[0049] Shallow groove radial ball bearing 6302 only has a shallow groove design on the outer ring. Compared with deep groove ball bearing 6302, the rib diameter of the shallow groove outer ring is significantly increased, the groove diameter is slightly increased, and the groove depth is changed from the original 1.509mm Reduced to 1.188 mm, the groove depth coefficient dropped from the orig...

Embodiment 2

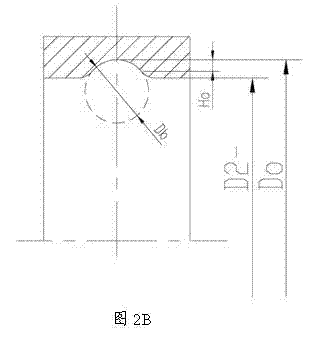

[0050] Embodiment 2, shallow groove radial ball bearing 6204 for a low energy consumption occasion

[0051] The deep groove ball bearing 6204 was originally used in this occasion, and the power consumption could not meet the requirements of the main engine. Although it was improved, the effect was not good. The use of the radial ball bearing 6204 with both the outer ring and the inner ring with shallow grooves solved this problem better. The realization method of the shallow groove is not to change the ring groove diameter and the ring rib diameter of the current deep groove ball bearing 6204, but to adopt the chamfering method of the groove edge. The actual parameters are shown in the following table.

[0052]

[0053]

[0054] The shallow groove radial ball bearing 6204 realizes the shallow groove design of the outer ring and the inner ring by chamfering the groove edge, and the deep groove ball bearing 6204 outer ring groove depth coefficient and inner ring groove dept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com