Floating swash plate follower ball hinge conical plunger variable pump/motor rotation assembly

A technology of conical plunger and rotating components, applied in the direction of pumps, multi-cylinder pumps, machines/engines, etc., can solve the adverse effects of the overall transmission efficiency of the pump control transmission system, the large friction power loss between the plunger pair and the slipper pair, It has not completely solved the problems, so as to solve the problem of severe friction and wear, reduce frictional power loss, and facilitate maintenance and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

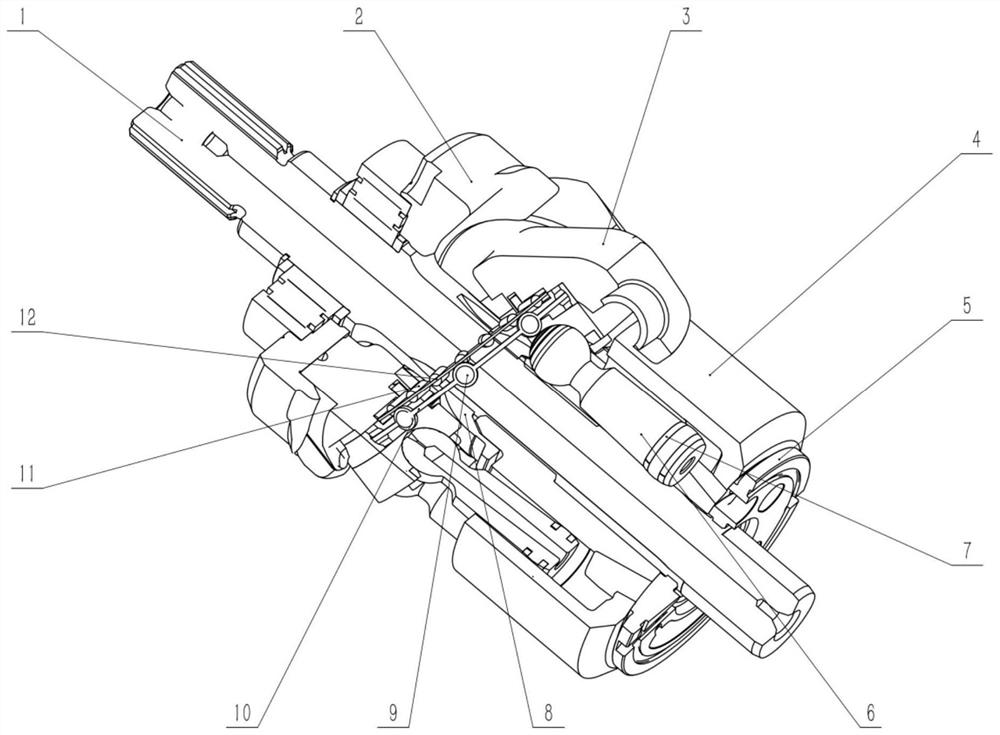

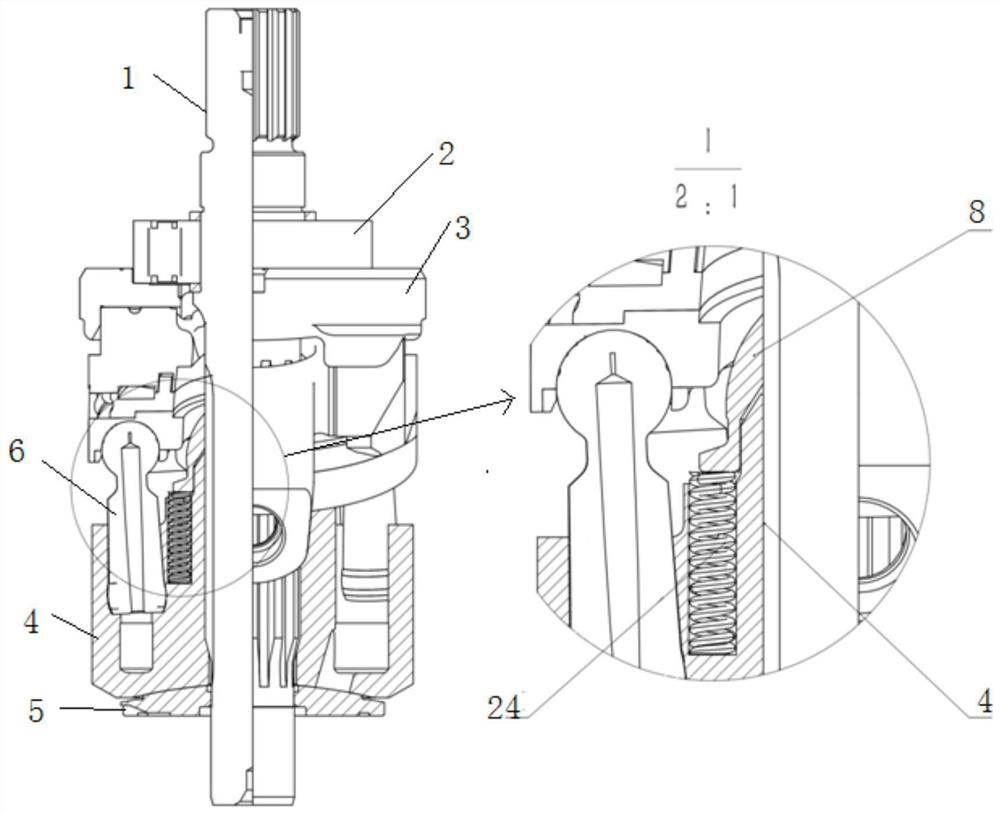

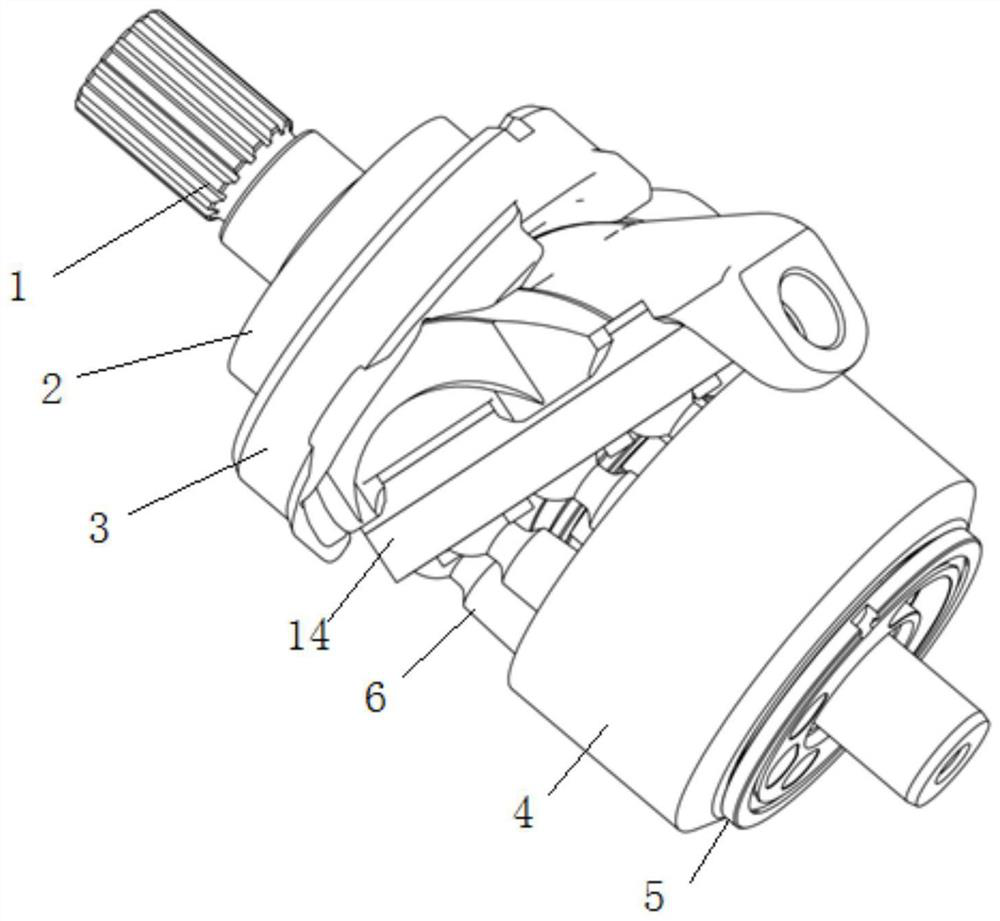

[0030] Such as figure 1 As shown, a through-shaft floating swash plate follower ball hinge joint tapered plunger variable pump / motor rotation assembly includes a floating swash plate assembly and a tapered plunger rotation assembly:

[0031] Such as Figure 5-10As shown, the design of the floating swash plate assembly is based on the special-shaped bearing structure formed by the cylindrical roller thrust bearing on the bottom surface and the angular contact ball bearing on the side surface, and is realized in the sealed space formed by the cooperation between the chassis 3 of the floating swash plate and the inner plate 15. The hydrostatic support structure together with the special-shaped bearing structure constitutes a hybrid support, which is characterized by: including inner disc 15, side balls 9, side cage 10, bottom roller 11, bottom cage 12, side cover 16 and floating swash plate chassis 3 The composition, applied to the swash plate axial piston pump / motor, can be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com