Tray fixed conveying device for collective doffing of spinning frame

A conveying device and spinning frame technology, applied in textiles and papermaking, etc., can solve the problems of large friction area, inconvenient installation and debugging, and large resistance, and achieve the effect of small friction contact area, easy mass production, and low running resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

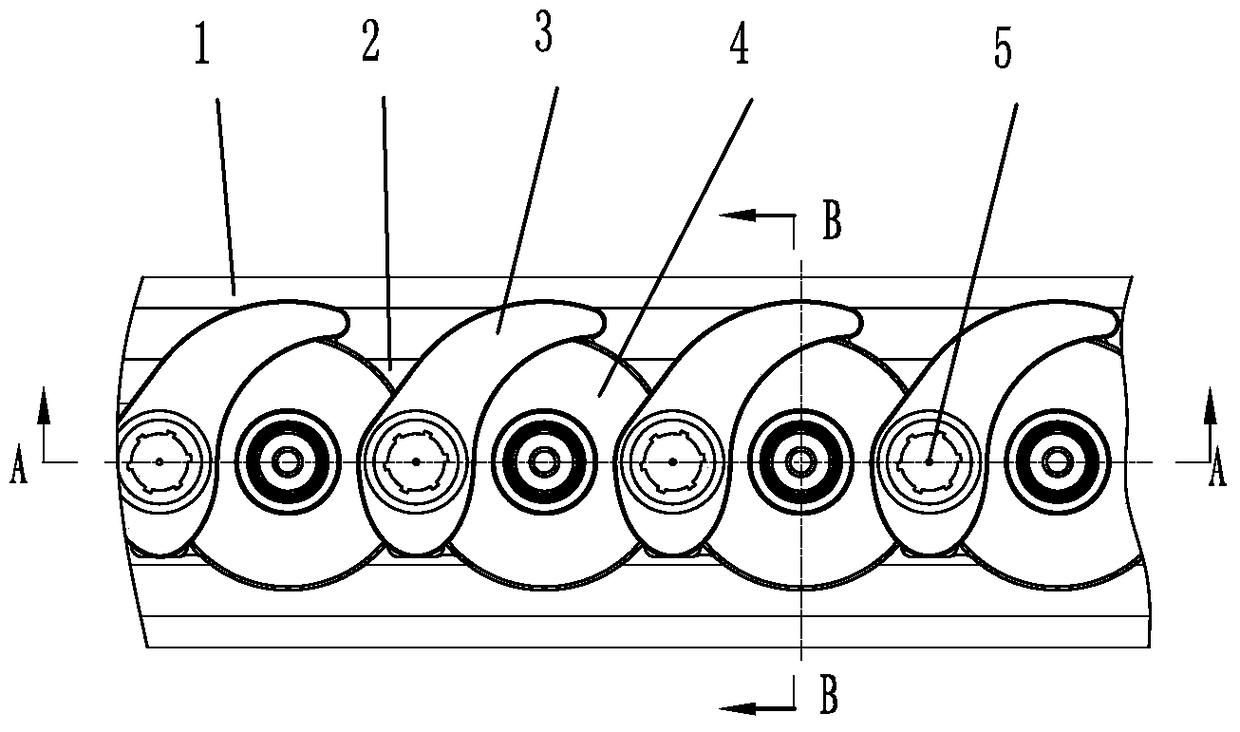

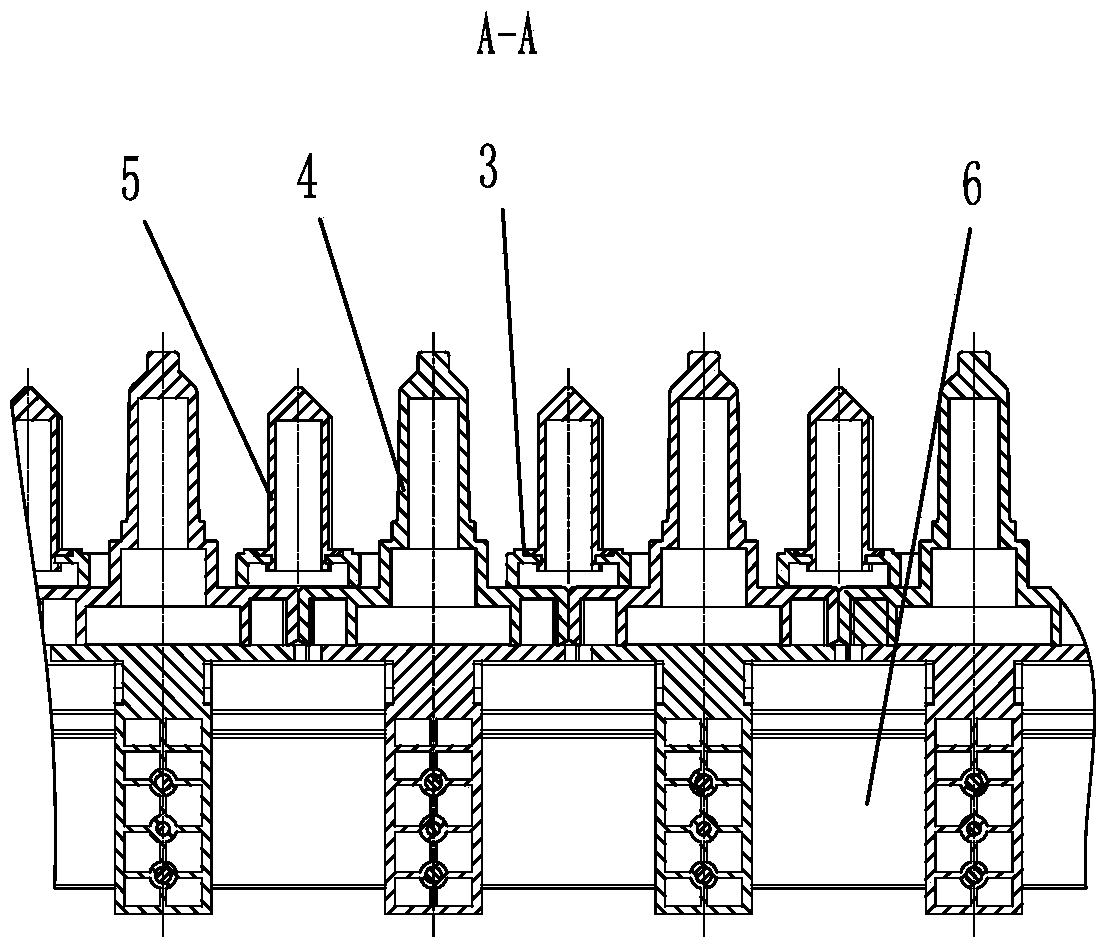

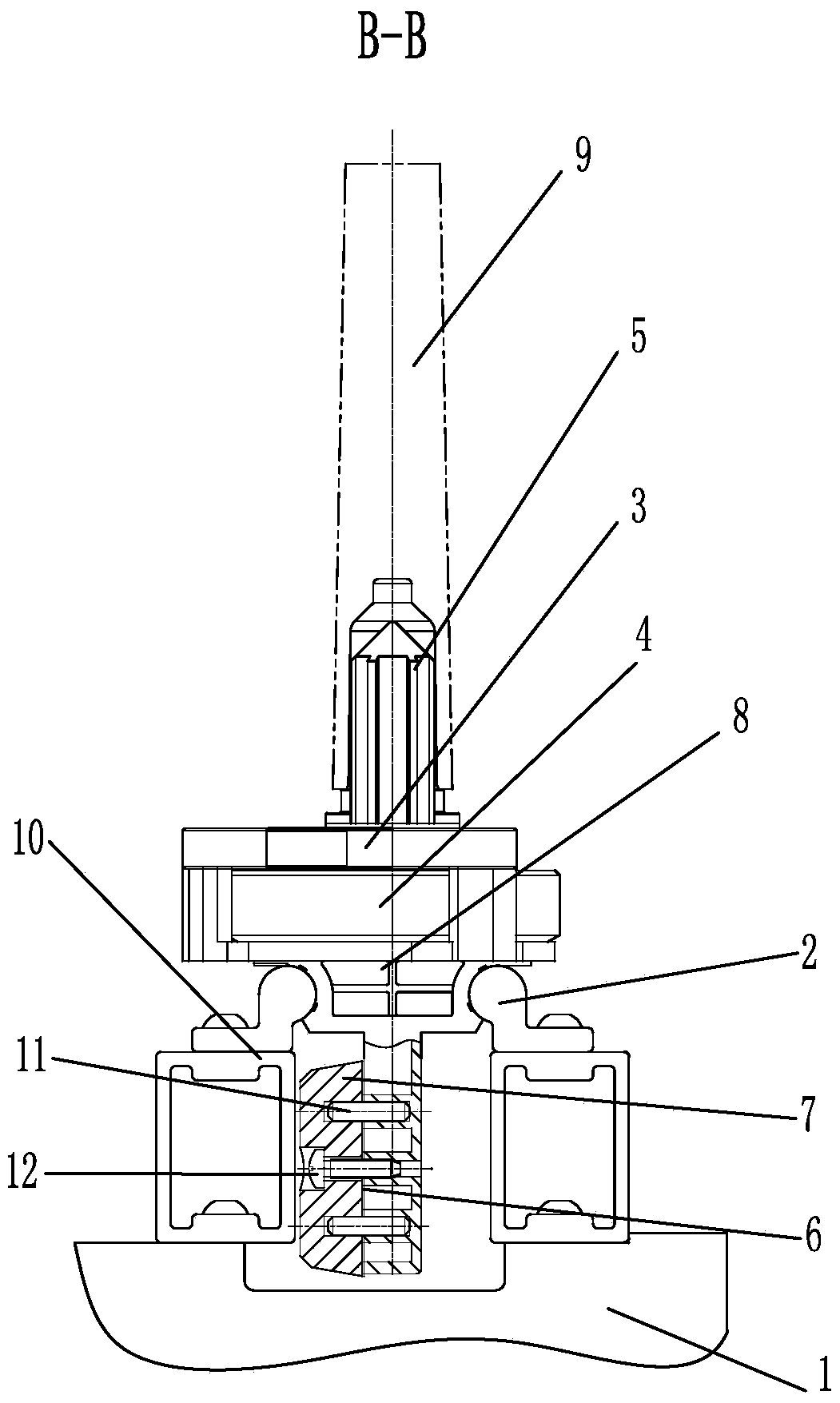

[0024] See Figure 1~5 As shown, the pallet fixing conveying device used for collective doffing of spinning frames in the present invention includes a conveying guide rail 2 and a tray mechanism capable of sliding along the conveying guide rail 2 . See Figure 2-5 As shown, the delivery guide rail 2 of the present invention includes a double guide rail structure with a convex arc-shaped limit surface 2-1 and an arc-shaped support surface 2-2 on the inside, and the delivery guide rail 2 is arranged on the left and right sides of the lower part of the machine. On the upper part of the conveyor guide 2 there is a spindle group directly opposite the left and the right. The convex arc-shaped limiting surface 2-1 of the present invention can be a circular surface or an elliptical limiting surface, and the lower part of the double guide rail of the present invention is installed on the base plate 1 through the rectangular tube 10, and the double guide rail of the conveying guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com