Rope tensioning device and crane with same

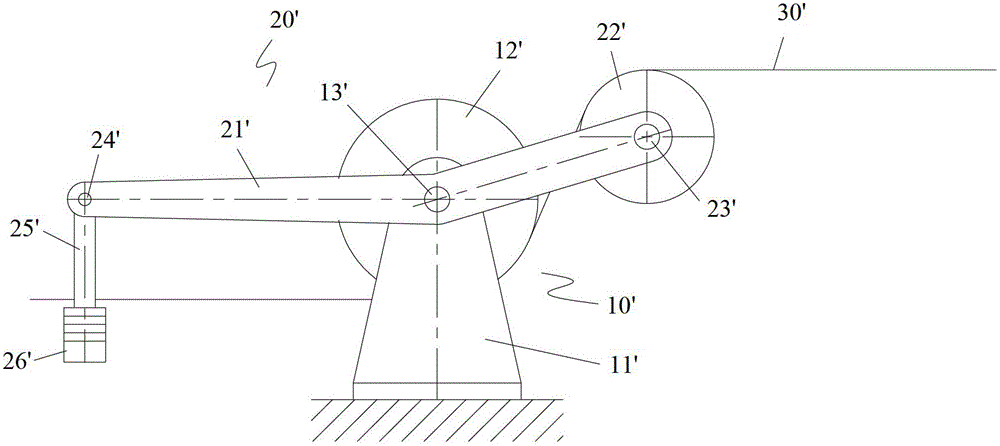

A tensioning device and tensioning mechanism technology, applied in cranes, hoisting devices, spring mechanisms, etc., can solve the problems of large frictional contact area, increased frictional force, and easy wear of the lifting rope 30'. The effect of slowing down friction, reducing friction contact area and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

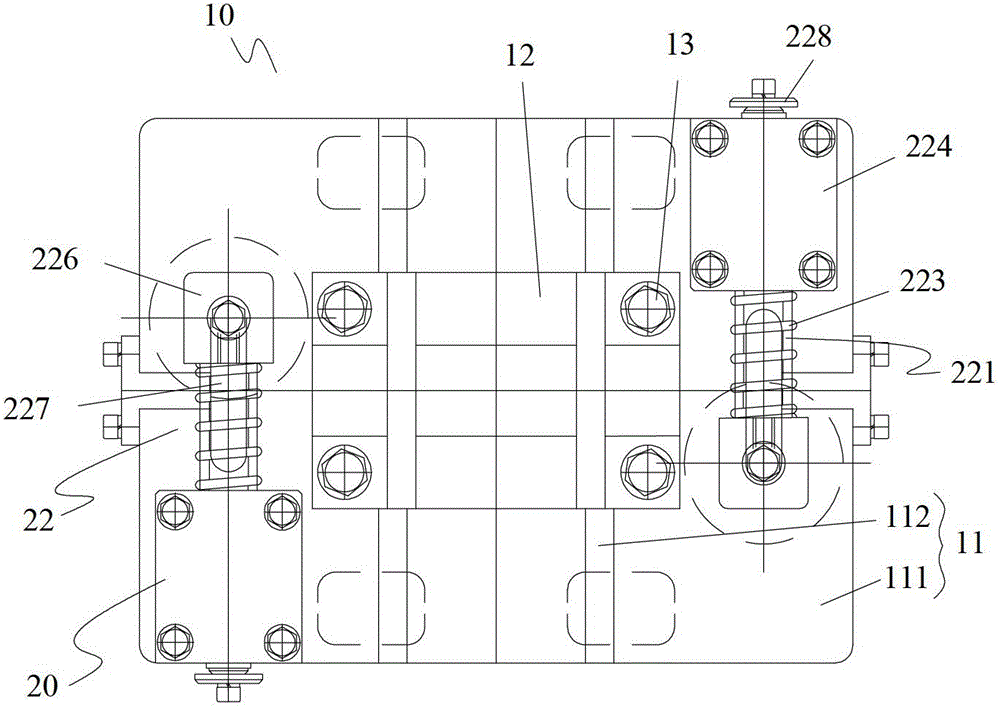

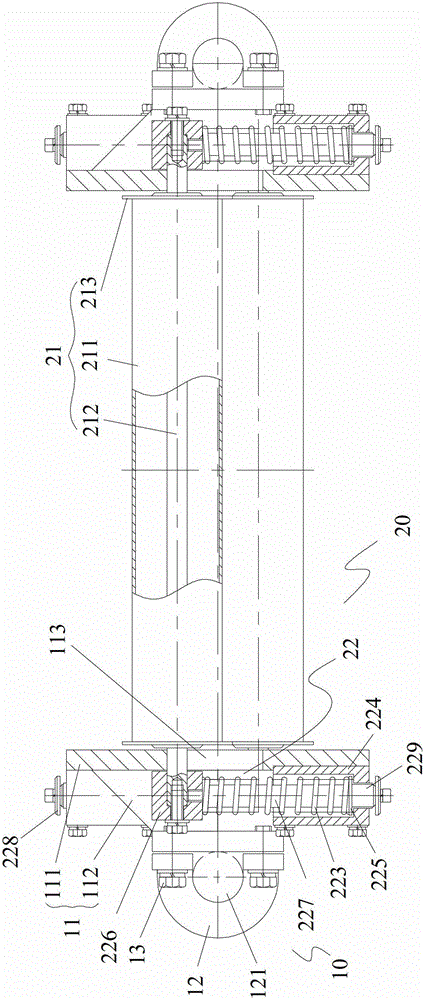

[0028] Such as Figure 2 to Figure 4 As shown, according to the embodiment of the present invention, a kind of rope tensioning device is provided, including a first mounting base 10 and a tensioning mechanism 20, wherein there are two first mounting bases 10, and the two first mounting bases 10 are opposite to each other. Arrangement: The tension mechanism 20 is arranged between the two first mounts 10, the tension mechanism 20 includes an idler assembly 21 and a pressing assembly 22, and the two ends of the idler assembly 21 are connected to the two first mounts 10 respectively. A corresponding connection, and can move radially relative to the two first mounting bases 10, the idler roller ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com