Wedge-type clutch

A clutch and wedge-type technology, applied in the field of clutches, can solve problems such as unsuitable application, energy consumption, and unsuitable use of variable speed transmission systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in further detail below according to accompanying drawing and embodiment:

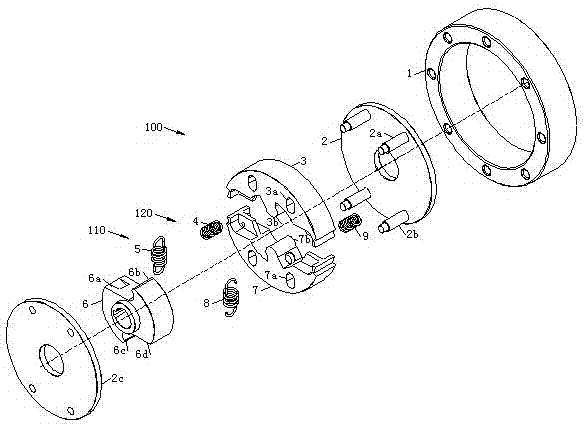

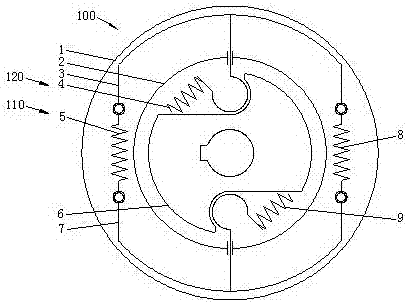

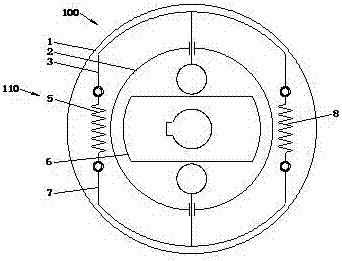

[0058] Such as figure 1 , figure 2 As shown, the sprag clutch 100 of the present invention includes a driving cam 6 , a driven element 1 , at least one centrifugal sprag 3 , at least one reset device 110 and an intermediate support 2 . The driving cam 6, the intermediate support 2 and the driven element 1 are arranged on the same axis, the intermediate support 2 is hinged to the driving cam 6, the intermediate support 2 and the driven element 1 are arranged radially apart from each other, and a plurality of centrifugal wedges 3 surround the intermediate support 2 The axis of the drive cam 6 and the driven element 1 are arranged in turn, and each centrifugal wedge 3 is respectively movable and installed on the middle bracket 2, and the driving cam 6 pushes the centrifugal wedge 3 to move radially, so that the centrifugal wedge 3 and The driven element 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com