Plastic forming method of internal hexagonal hole of long and thin rod

A plastic forming, hexagonal hole technology, applied in the direction of connecting components, threaded fasteners, bolts, etc., can solve the problems of female mold rupture, reduced production efficiency, hexagonal punch pull-off, etc., to reduce the life of the mold and improve the life of the mold. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A plastic forming method for an inner hexagonal hole of a slender rod, comprising the following steps:

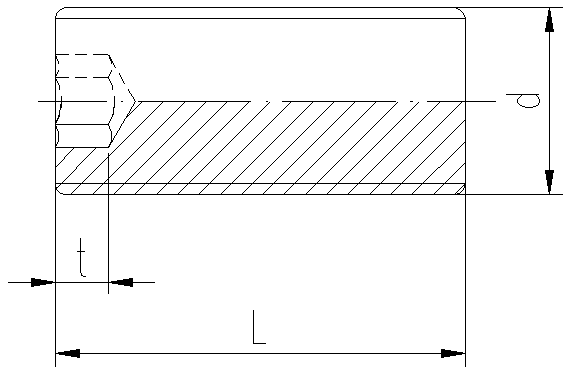

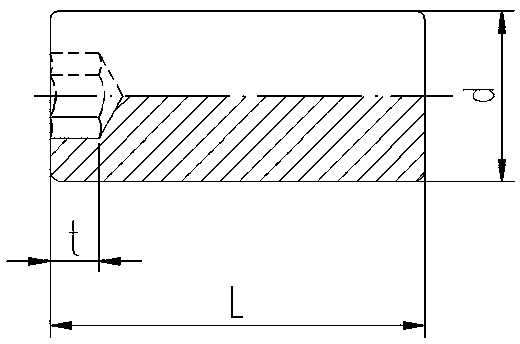

[0029] (1) Cutting (see Figure 5 , 6 ): Determine the raw material diameter d0 according to the specifications of the final workpiece, then calculate and determine the blanking length L0 according to the volume of the workpiece and the determined raw material diameter, and cut off;

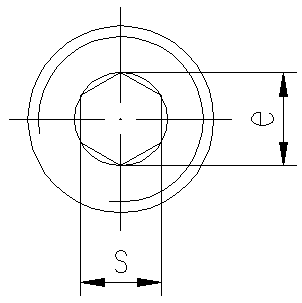

[0030] (2) End face shaping (see Figure 7 , 8 ): Automated production with a three-station cold heading machine, as the first station, determine the shaping size according to the size of the final workpiece, prefabricate the mouth spot spot and chamfer, and the prefabricated mouth spot spot size is in accordance with the final workpiece mouth spot spot size Make sure that the diameter size D and angle a are the same as the final product size, the depth t1 is about 0.25~0.35 hexagonal compared to the width S, and the chamfer size is consistent with the final product chamfer size;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com