Patents

Literature

105results about How to "Eliminate sticking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

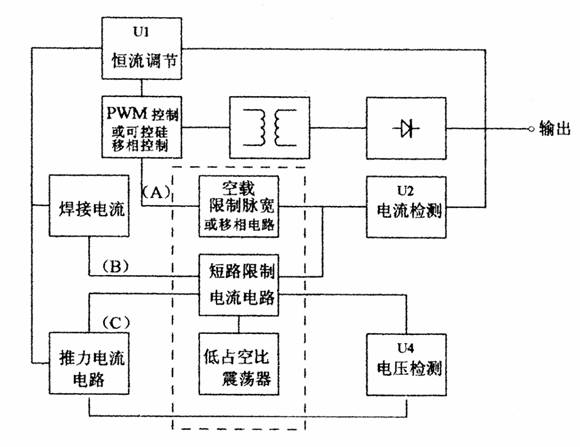

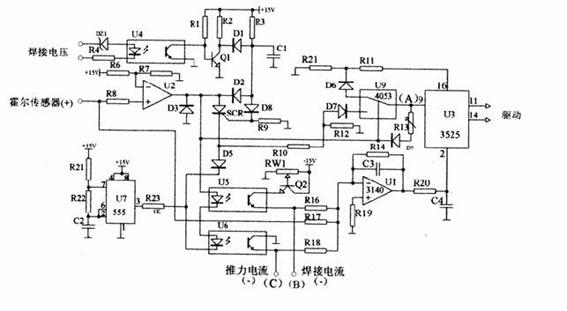

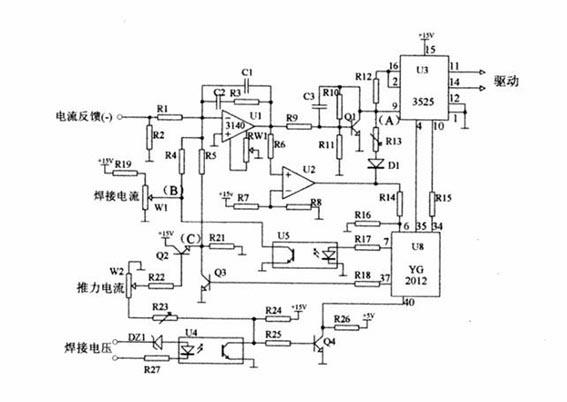

Touch arc striking electric welding machine and electric welding touch arc striking control method

InactiveCN102672308AEliminate overshoot currentEliminate stickingArc welding apparatusWelding power supplyElectric current flow

The invention belongs to the field of electric welding, and particularly relates to a touch arc striking electric welding machine and an electric welding touch arc striking control method. By applying pulse current of low frequency and low duty ratio during short circuit of the electric welding machine, frequent overshoot current of the electric welding machine is eliminated, the reliability of a welding power source is greatly improved, and a welding rod adhesion phenomenon is eliminated to easily strike arc.

Owner:刘裕国

Production method of vanadium nitride

ActiveCN101948977AFacilitate the reduction reactionReduce water contentNitrogen-metal/silicon/boron binary compoundsMetallurgyVanadium nitride

The invention relates to a production method of vanadium nitride. The production method includes that: powdery vanadium oxide, carbon powder and catalyst are mixed and pressed into raw material spheres, the surface of raw material sphere is wrapped with vanadium nitride superfine powder and is added into a vertical furnace continuously, meanwhile nitrogen is introduced into the vertical furnace to be taken as reaction gas, material is heated to 1200-1600 DEG C, reduction and nitridation reactions are taken place on the material in the temperature range, time duration is less than 40-60min, and the material is cooled to certain temperature under protective atmosphere and then is taken out the furnace, thus obtaining the vanadium nitride product. The invention can solve the problem of bonding while discharging which is caused by the vertical furnace; and the invention has the advantages that production cycle is short, utilization ratio of energy and gas is high, production efficiency is high, production mode is flexible, product quality is high, and production cost is low.

Owner:江阴市中赢有色金属新材料有限公司

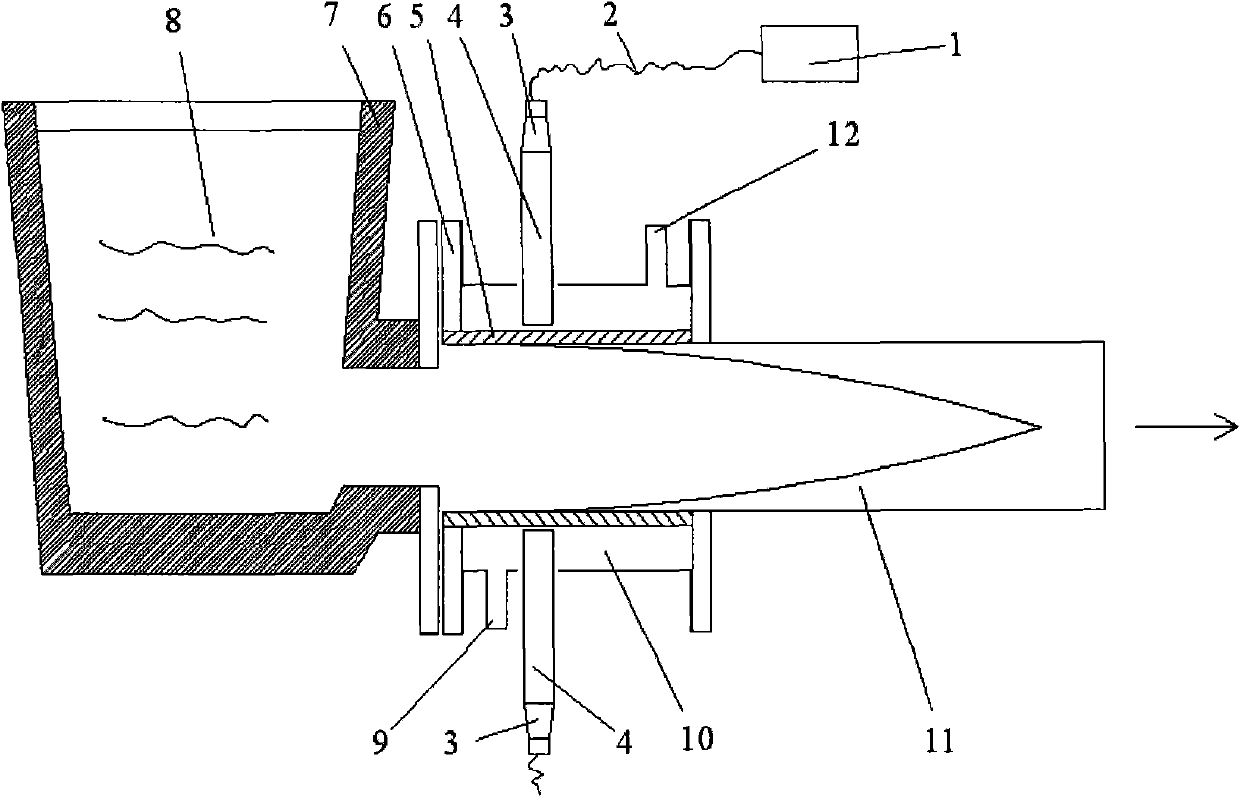

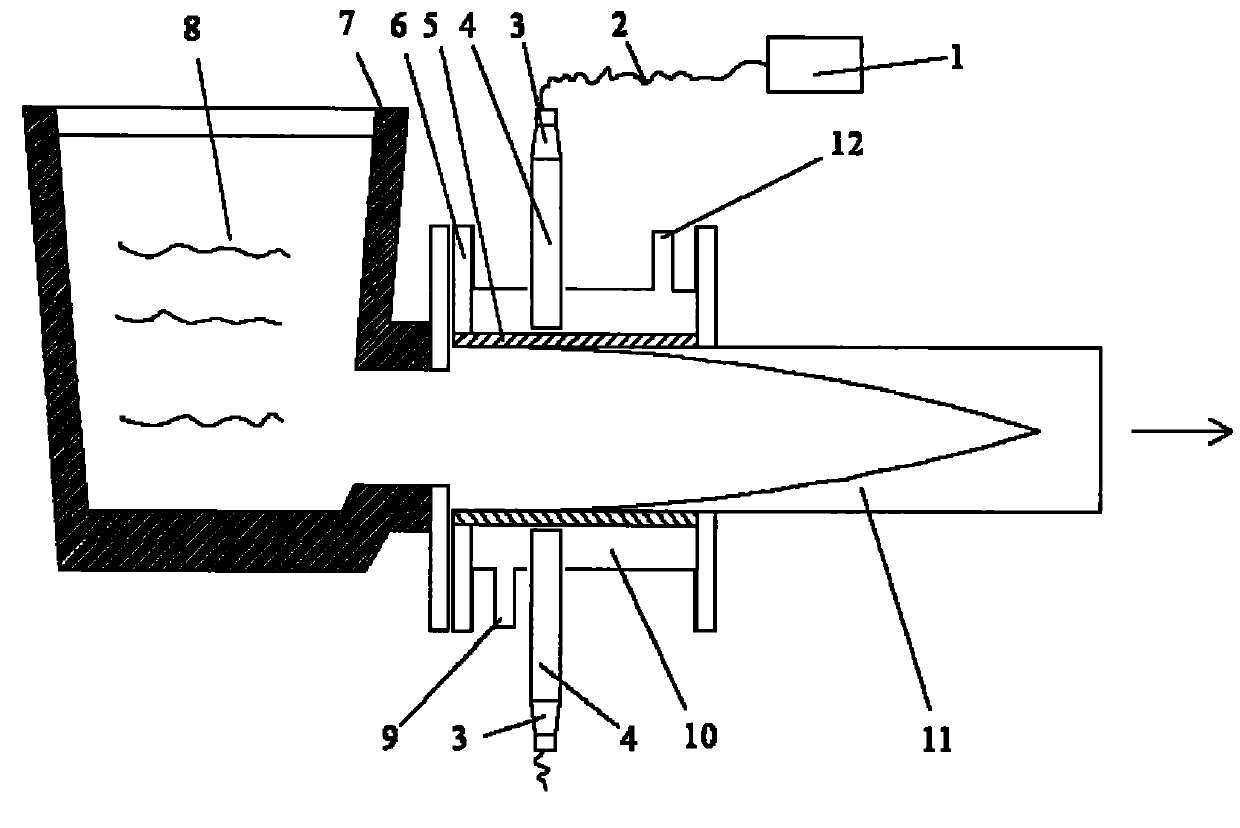

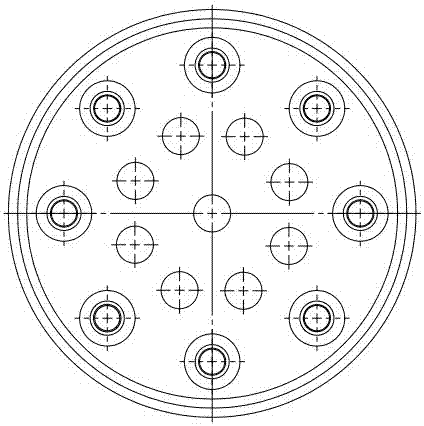

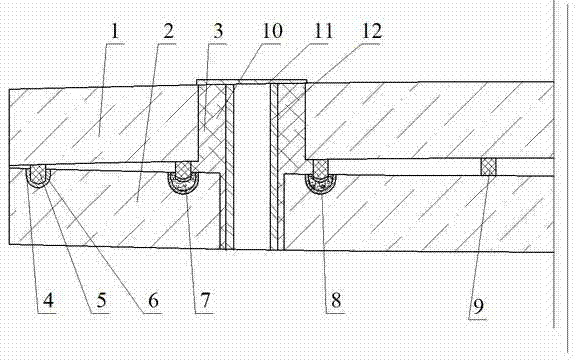

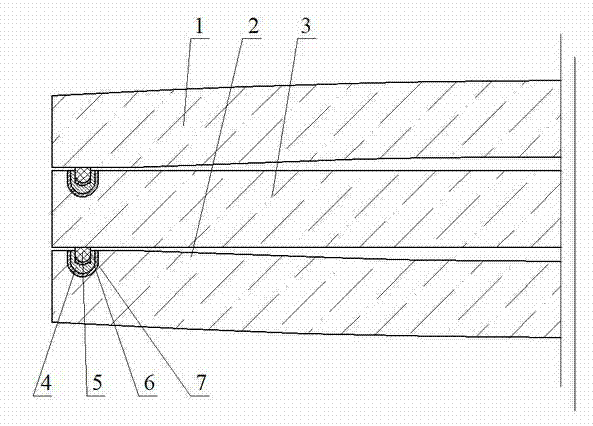

Continuous casting crystallizer device using ultrasonic vibration

InactiveCN101905295AEliminate stickingEliminate surface defectsUltrasonic vibrationUltrasonic guided wave

The invention provides a continuous casting crystallizer device using ultrasonic vibration, which belongs to the technical field of metallurgical casting. The device of the invention comprises a trough, a crystallizer, a crystallizer copper plate, ultrasonic guide rods, an energy converter and an ultrasonic power supply, wherein the crystallizer is directly connected with the trough; the ultrasonic guide rod is arranged on each reverse side of the crystallizer copper plate and connected with the energy converter; the energy converter is connected with the ultrasonic power supply; the ultrasonic guide rod passes through a cooling water tank and is vertically connected with the crystallizer copper plate; and the length of the ultrasonic guide rod is an integral multiple of the wavelength or half-wavelength of the used ultrasonic. The vibration mode of the ultrasonic vibration crystallizer provided by the invention breaks through the traditional mechanical vibration limit, and the continuous casting crystallizer device using the ultrasonic vibration is favorable for promoting the production of deflect-less continuous casting blanks without surface defects such as vibration marks and improving the quality of the casting blanks and steel.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

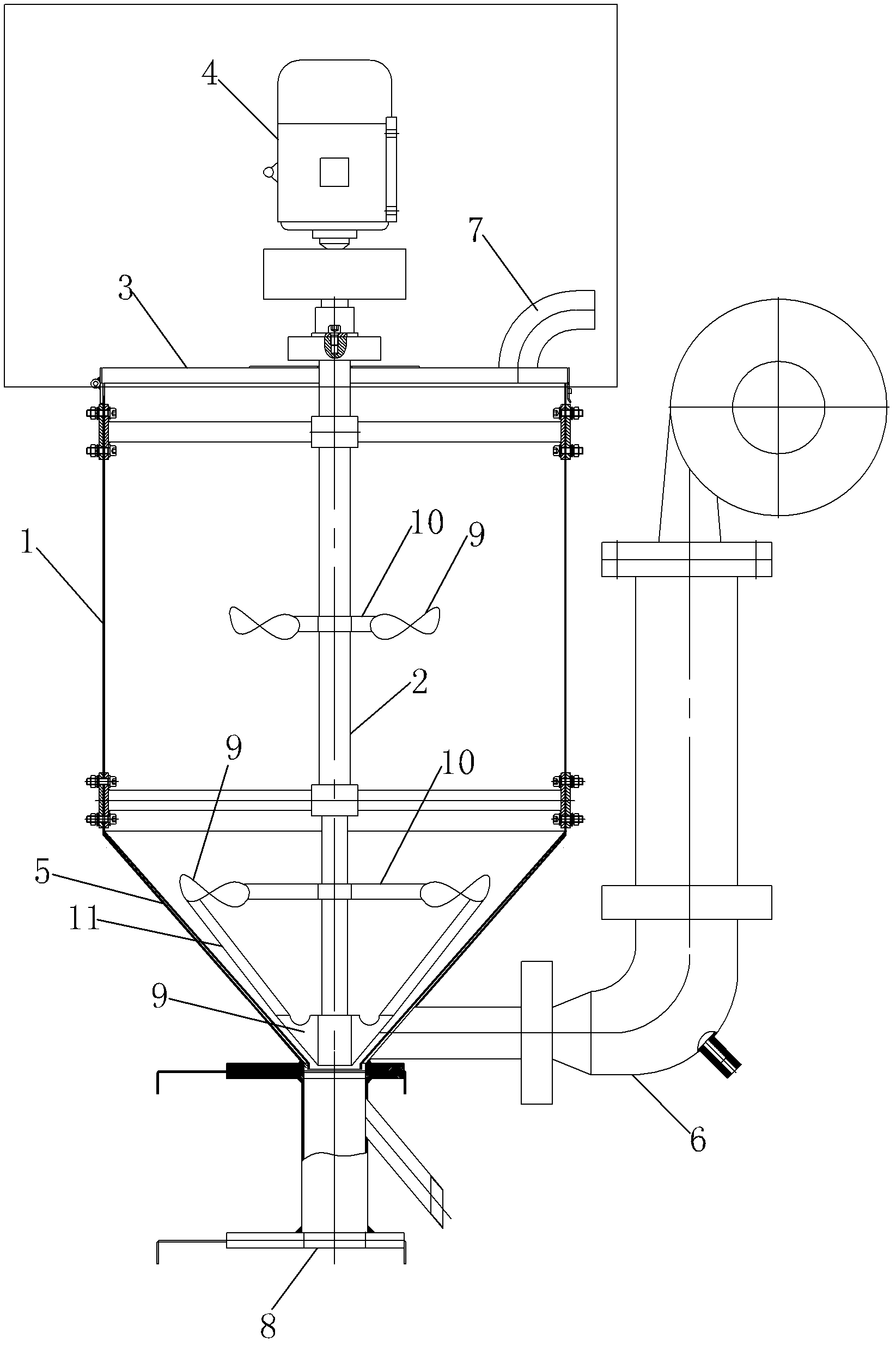

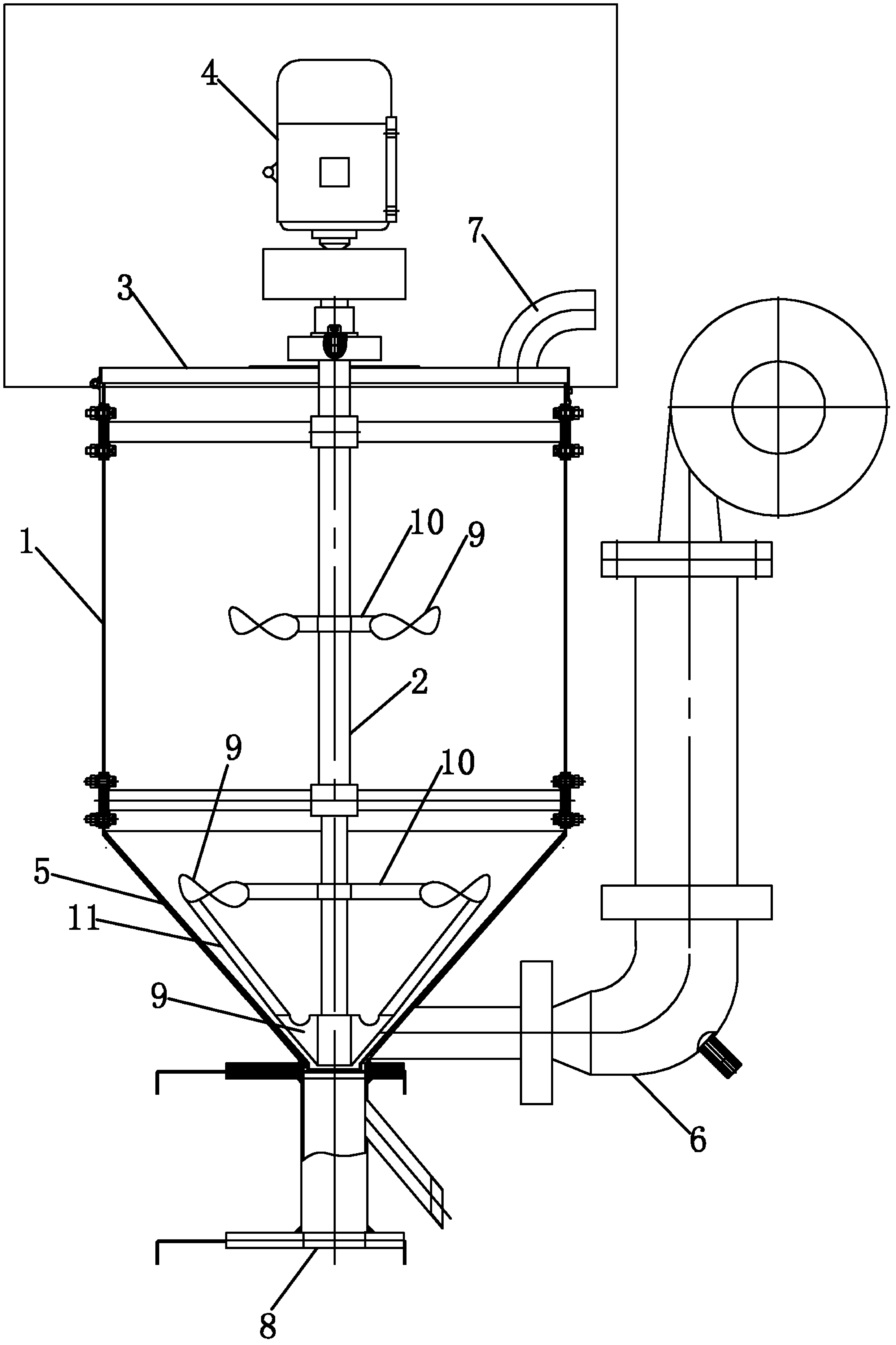

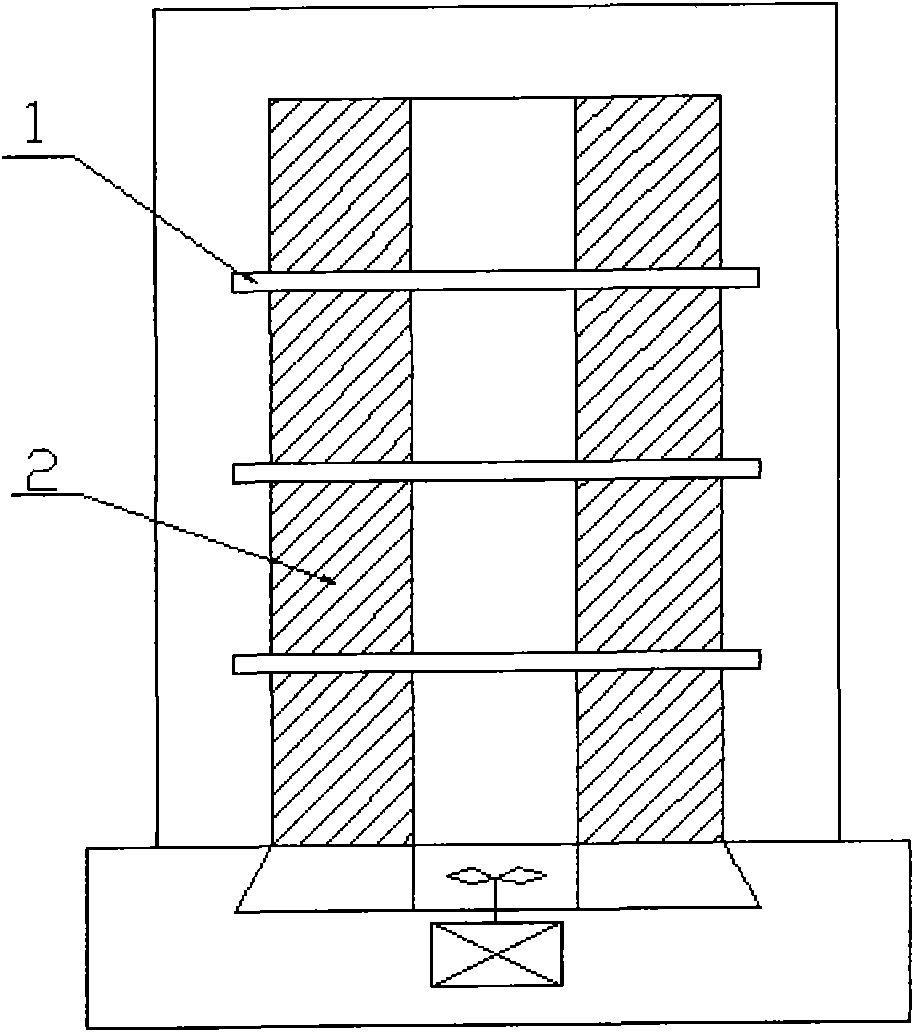

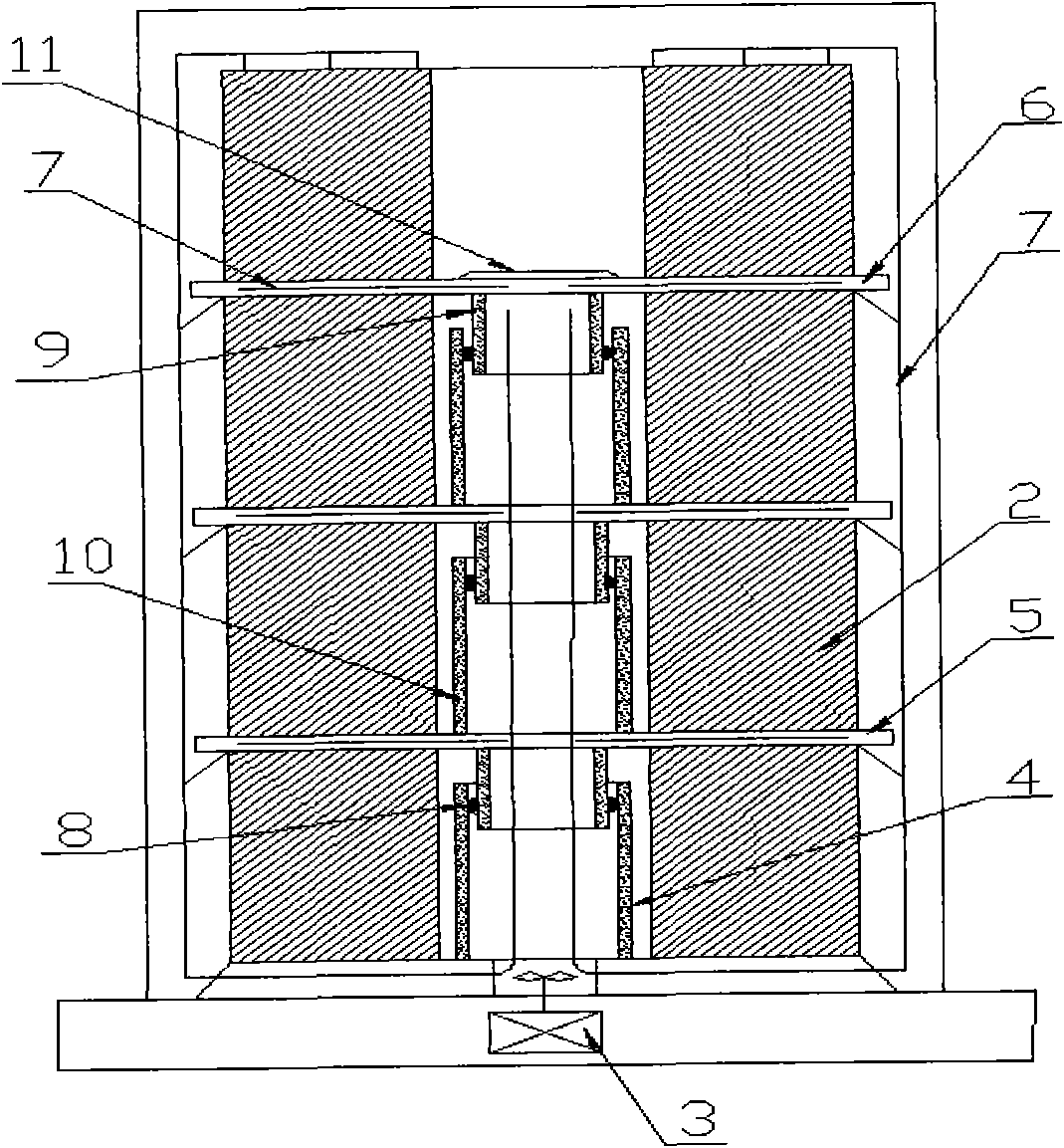

Master-batch drying device

The invention discloses a master-batch drying device. The master-batch drying device comprises a drying barrel, wherein a stirring paddle is vertically arranged in the drying barrel; a barrel cover is arranged at the upper part of the drying barrel; a motor is fixedly arranged on the barrel cover of the drying barrel, and is connected with the stirring paddle by a speed reducer; the lower part of the drying barrel is connected with a conical filter mesh; the side wall of the lower part of the conical filter mesh is connected with an air channel which is internally provided with a heating pipe; an exhaust port is formed in the barrel cover; a discharging port of the bottom part of the conical filter mesh is provided with a sieve mesh; the stirring paddle extends to the interior of the conical filter mesh; and multiple layers of stirring blades are distributed on the stirring paddle. The master-batch drying device has the characteristics that the stirring paddle is arranged in the drying barrel and the conical filter mesh, the stirring blades on the stirring paddle are divided into an upper group, a middle group and a lower group, and the two-layer stirring blades in the conical filter mesh can enhance vertical and lateral flowing of the master batches in the filter mesh so as to guarantee the drying quality of the master batches.

Owner:ZHEJIANG WELONG NEW MATERIAL

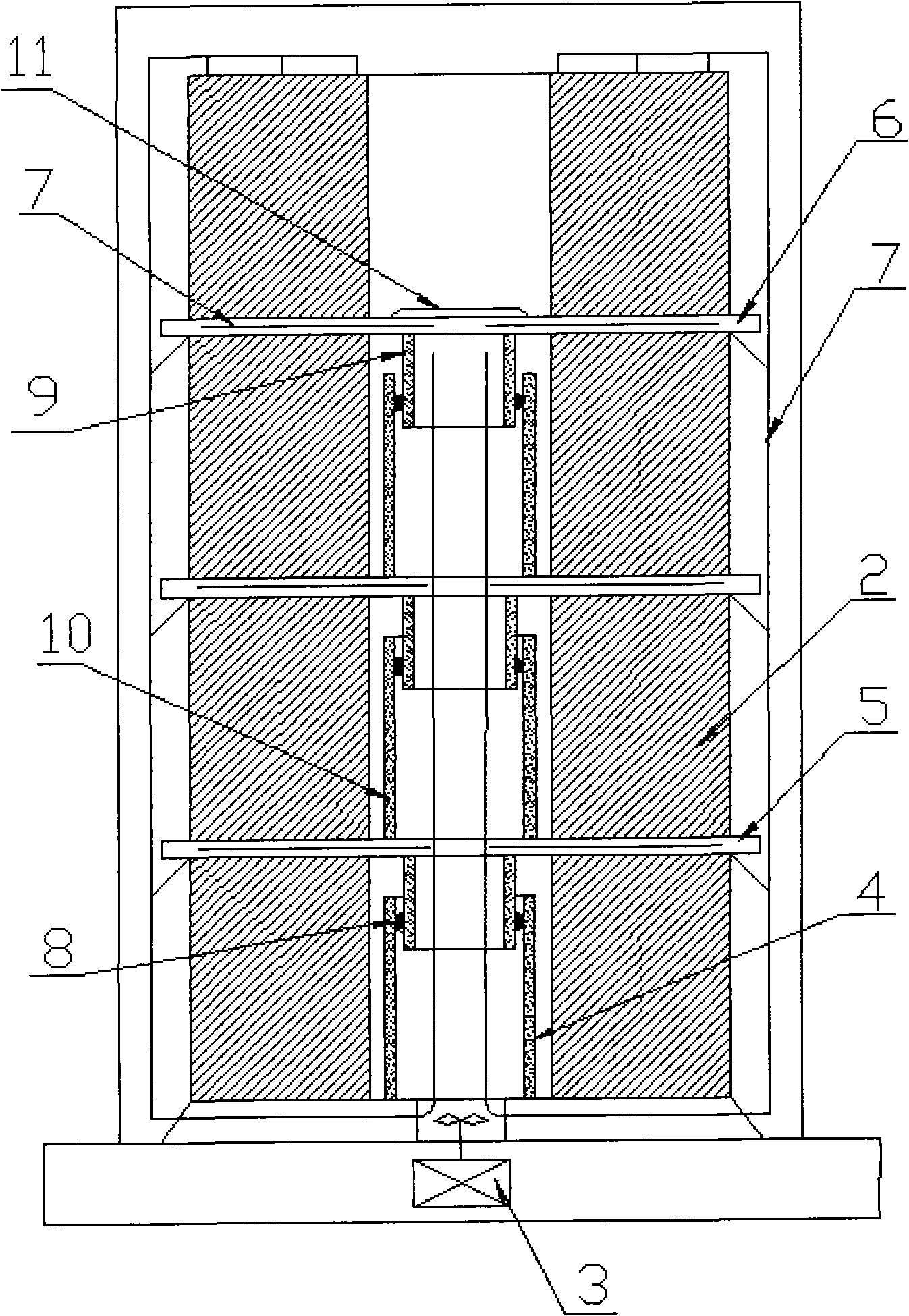

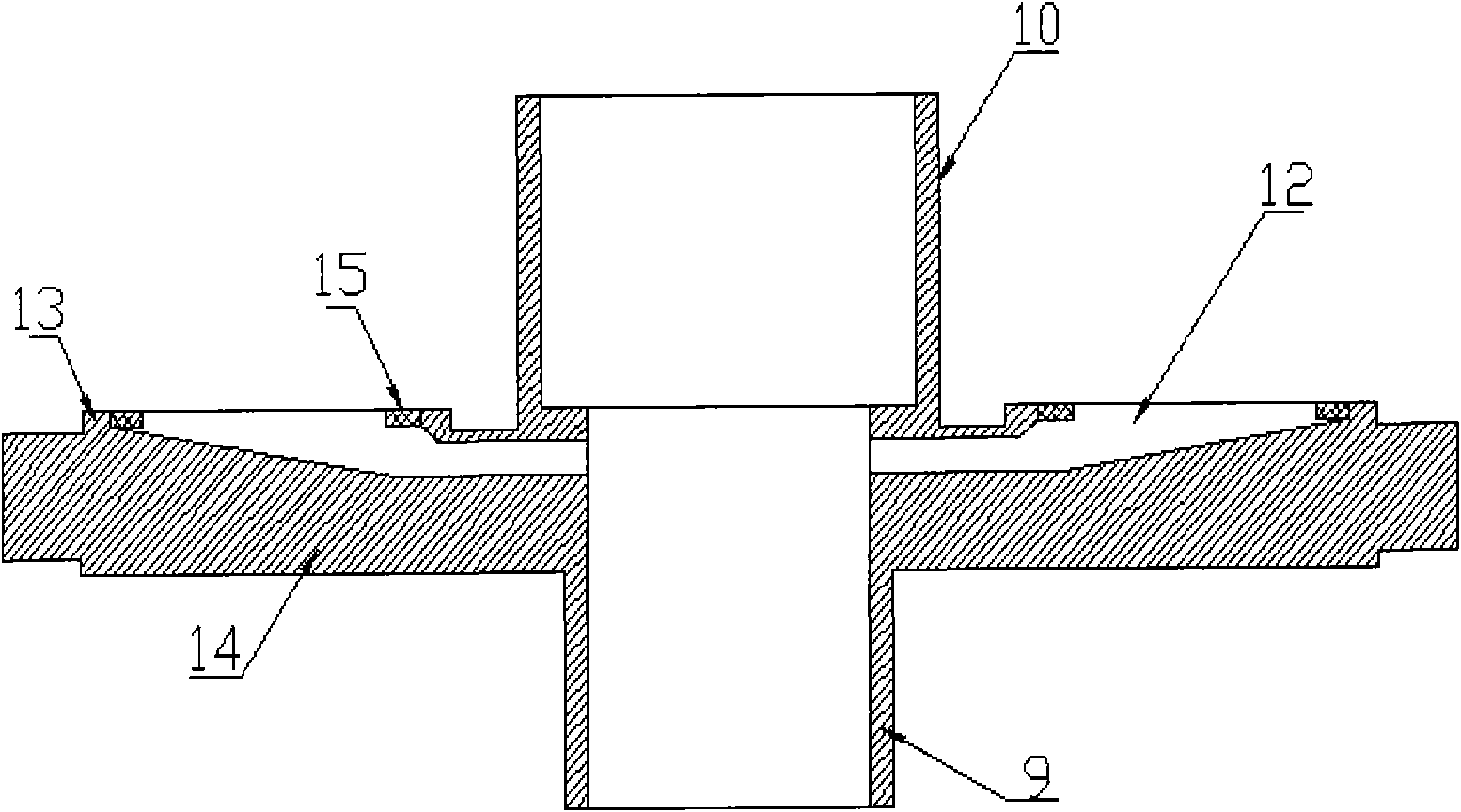

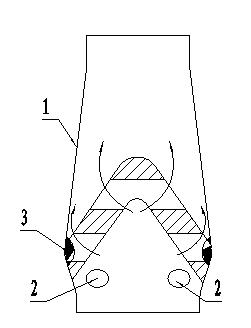

High-efficiency annealing furnace capable of avoiding bonding of cold-rolled strip steel and operating method thereof

InactiveCN101886166AGood thermal cycle performanceEliminate stickingFurnace typesHeat treatment furnacesShielding gasStrip steel

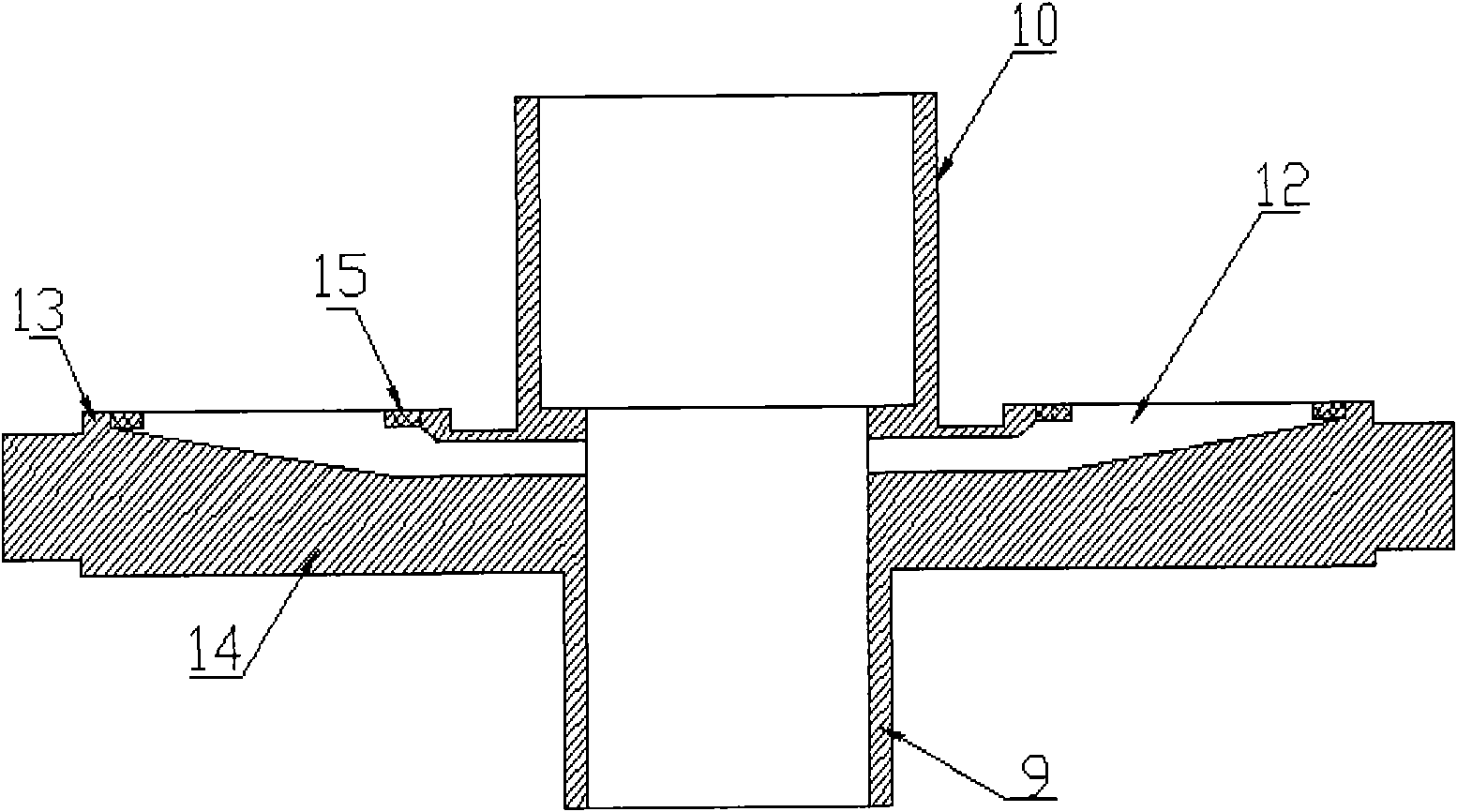

The invention discloses a high-efficiency annealing furnace capable of avoiding bonding of cold-rolled strip steel and an operating method thereof. The high-efficiency annealing furnace comprises a high power blower, a segment of independent flow guide tube, guide plates provided with upper flow guide tubes and lower flow guide tubes, a guide plate only provided with a lower flow guide tube, and a sealing ring. The annealing furnace is characterized in that the independent flow guide tube (4) is positioned at the core of a first cold-rolled steel coil on a furnace platform and sleeves a reserved air port of the blower on the furnace platform in a ring manner; the upper part of the independent flow guide tube (4) is connected with the lower flow guide tubes (9) of the guide plates (5) provided with the upper flow guide tubes and the lower flow guide tubes through the heat resistant sealing ring (8); the upper flow guide tubes and the lower flow guide tubes of the guide plates (5) provided with the upper flow guide tubes and the lower flow guide tubes are sequentially connected through the heat resistant sealing ring (8); and the guide plate (6) at the upmost end is only provided with the lower guide tube (9) and is arranged between two top steel coils. In the invention, the adopted heat cycle path is as follows: a heating mantle (a cooling mantle), an inner cover, protective gas in the furnace after completing warming (cooling) convection in the middle part, outer rings of the steel coils, and heat radiation of the cores of the steel coils, thus strengthening the convection effect in the middle part and reducing the phenomenon of unbalanced inner temperature and outer temperature.

Owner:SHANDONG IRON & STEEL CO LTD

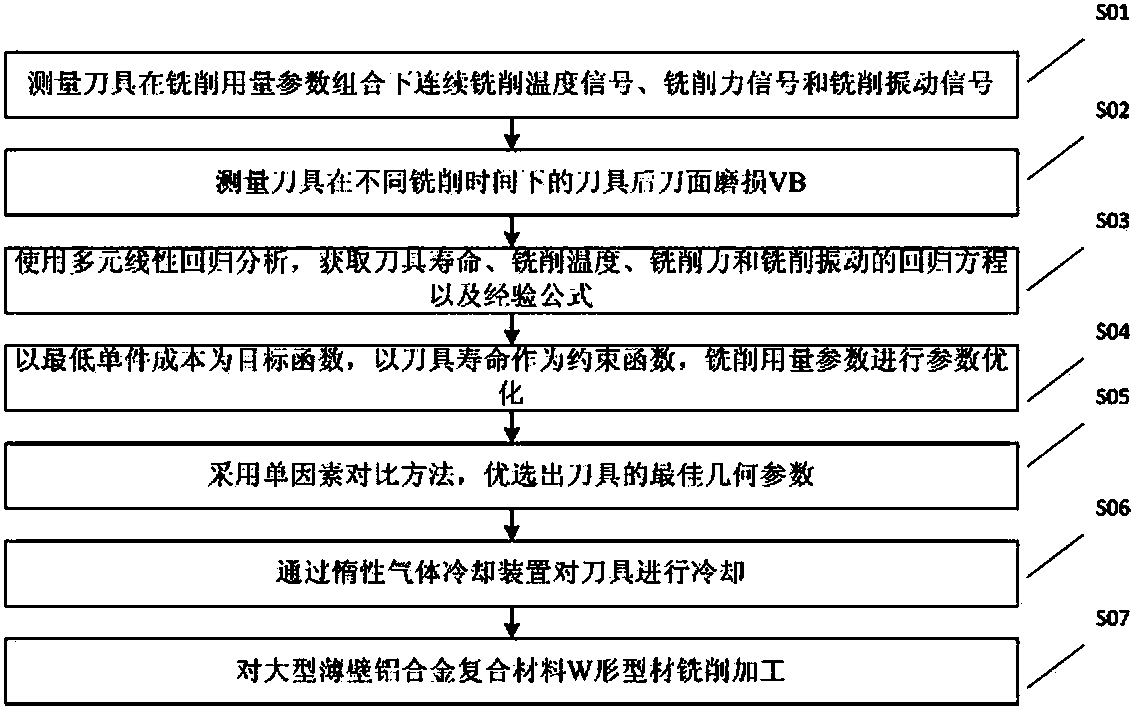

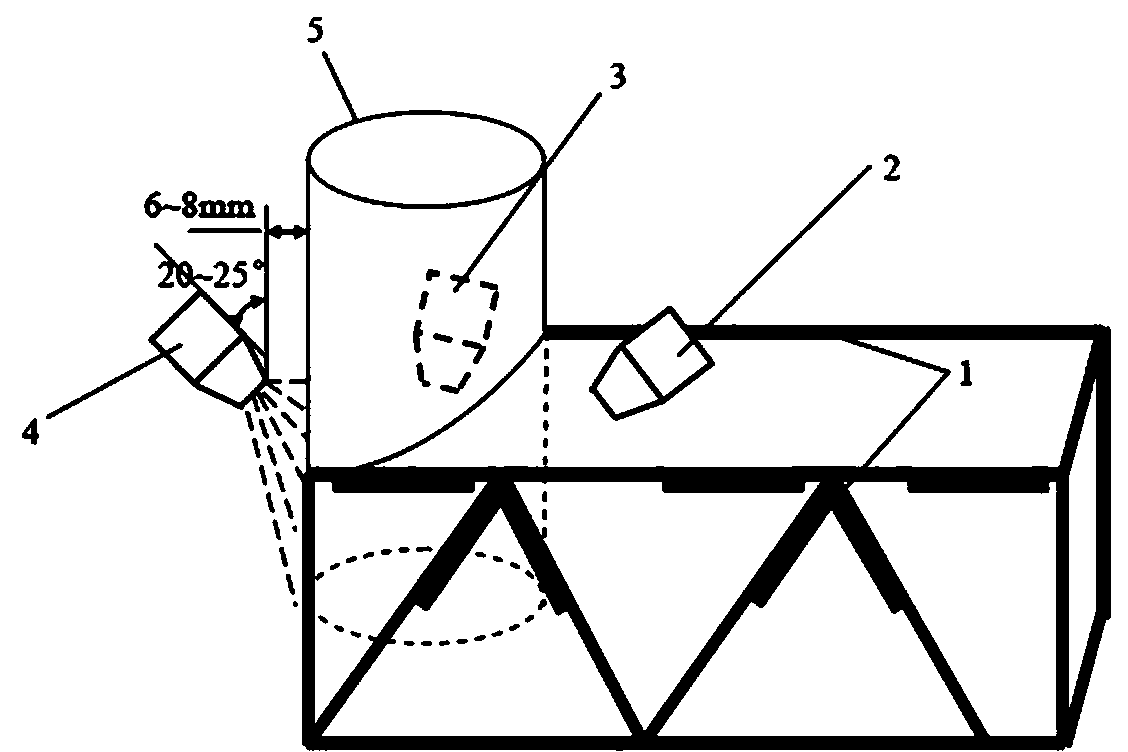

Method for milling and machining W-shaped proximate matter of large-scale thin-wall aluminum alloy composite material

ActiveCN104070217AReduce wear rateSuppresses severe bond failuresMilling equipment detailsProduction rateMetallurgy

The invention discloses a method for milling and machining a W-shaped proximate matter of a large-scale thin-wall aluminum alloy composite material. The method comprises the following steps: (S01) measuring continuous milling temperature signals, milling force signals and milling vibration signals of a cutter under a milling amount parameter combination; (S02) measuring the wear of the rear cutter surface of the cutter at different milling time; (S03) acquiring regression equations and empirical formulae of the cutter life, the milling temperature, the milling force and the milling vibration; (S04) optimizing milling amount parameters; (S05) preferably selecting optimal geometric parameters of the cutter; (S06) cooling the cutter by virtue of an inert gas cooling device; (S07) milling and machining the W-shaped proximate matter of large-scale thin-wall aluminum alloy composite material by virtue of the inert gas cooling device, the cutter with the optimized geometric parameters in the step (S05) and the optimized optimal milling amount parameter combination in the step (S04). According the method, the process parameter combination is optimized, so that the wear rate of the cutter is reduced, a serious bonding failure condition of the cutter is restrained, the production cost is lowered, and the productivity is increased.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

Method for blowing furnace washing agent by using air inlet of blast furnace

The invention discloses a method for blowing a furnace washing agent by using the air inlet of a blast furnace, and aims to rapidly solve the problems of adhesion on the lower part of the blast furnace and hearth accumulation. The method comprises the following steps of: feeding high-pressure fluidized furnace washing agent powder into a coal dust blowing pipeline according to the proportion; and blowing the furnace washing agent powder and the coal dust into the hearth of the blast furnace together from the air inlet by a blast furnace coal blowing device, wherein 2.0 to 15kg of the furnace washing agent is added into one ton of Fe; and the furnace washing agent powder is fluorite powder, manganese mineral powder or mixture of the two. In the method of the invention, the furnace washing agent and the coal dust are blown into the furnace together from the air inlet of the blast furnace, so that the furnace washing agent directly acts on a high-viscosity slag accumulation part; and by improving the fluidity of the slag and reacting the slag with graphite carbon, the adhesion of the slag to the furnace wall on the lower part and the hearth accumulation are reduced and eliminated, the hearth center is activated, and proper operation furnace profile is maintained.

Owner:HEBEI IRON AND STEEL

Self-adhesion modularized crystalline silicon solar cell component

ActiveCN102569467AHigh degree of freedom in constructionReduce processPhotovoltaic supportsRoof covering using slabs/sheetsPolyethylene terephthalateCrystalline silicon

The invention discloses a self-adhesion modularized crystalline silicon solar cell component, which is formed by laminating toughened glass, thermosol, a crystalline silicon cell sheet, thermosol, TPT (Tedlar / Polyethylene Terephthalate / Tedlar) and a self-adhesion adhesive layer in sequence. The self-adhesion modularized crystalline silicon solar cell component provided by the invention can be mounted on a roof of light steel structure; the irradiation of sunlight can be received to the greatest extent to generate power by combining the crystalline silicon solar cell component and the roof of light steel structure for use; the heat load of the roof in summer can be reduced by considering the roof bearing load and the wind load of the roof of light steel structure and storage of the original water proofing function; and the combination of the solar power generation function and the building water proofing function is realized.

Owner:南通金丝楠膜材料有限公司

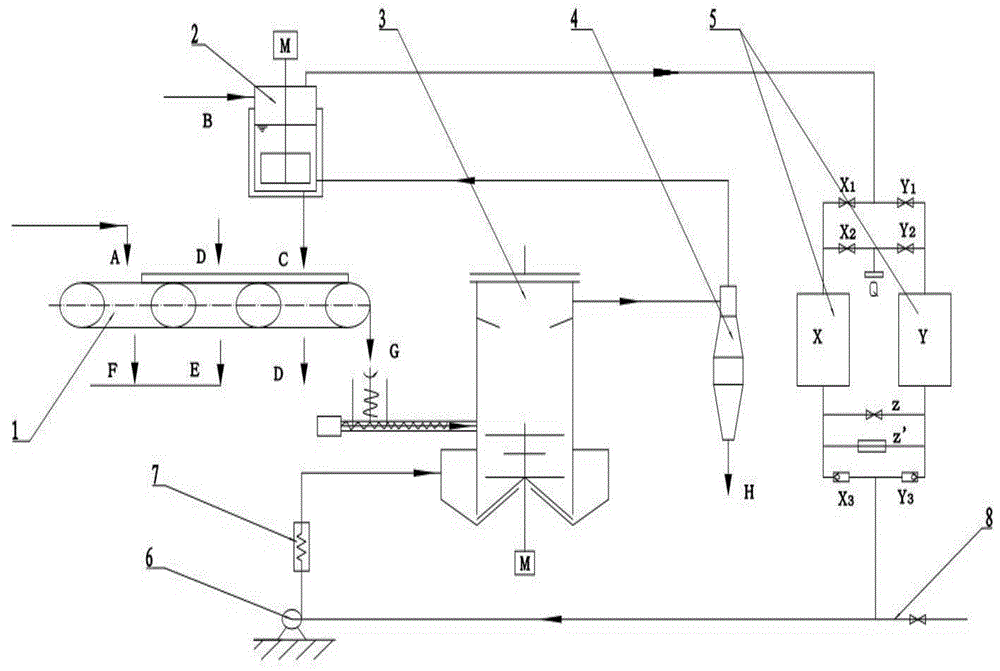

Rotary flash drying apparatus and drying method

ActiveCN106267950ASave energyFlexible adjustment of moisture contentCombination devicesDrying solid materials with heatBelt filterProduct gas

The invention provides a rotary flash drying apparatus. The rotary flash drying apparatus comprises a belt filter, a rotary flash drying device, a cyclone separator, a washing water heating tank, a gas drying device and a fan, wherein the gas outlet of the cyclone separator is connected with the gas inlet of the washing water heating tank; the gas outlet of the washing water heating tank is connected with the gas inlet of the gas drying device; the liquid outlet of the washing water heating tank is connected with a washing water pipeline of the belt filter; the gas outlet of an adsorption tower is connected with the gas inlet of the fan through a pipeline; and the gas outlet of the fan is connected with the gas inlet of the rotary flash drying device. The invention also provides a drying method. According to the invention, closed circulation is employed and no tail gas is discharged in the whole process; high-temperature air-flow containing dust and located at the outlet of the cyclone separator enters the washing water heating tank for heating washing water, so most heat is recovered; and low-temperature gas discharged from the washing water heating tank is dried by the adsorption tower, then heated by an air heater and then reused, so low-temperature waste heat of the gas is completely used.

Owner:CHINA PETROLEUM & CHEM CORP +1

Freezing-disintegrating process of boswellia carterii and myrrh

ActiveCN1813852ASolve the softening bondFinished product quality is stablePlant ingredientsMyrrhMedicine

The present invention discloses a freeze-pulverizing process of frankincense and myrrh. It is characterized by that on the basis of original low-temperature pulverization technique said invention adopts fractionally-freezing and fractionally-pulverizing method, so that it can make the effective components of medicinal material be fully released, and can make the quality of medicinal material fine powder be greatly raised.

Owner:九寨沟天然药业股份有限公司

Pure titanium seamless pipe cross rolling piercing method

ActiveCN104889163AEliminate stickingSolve the sticking problemMetal rolling arrangementsMicrometerSurface roughness

The invention discloses a pure titanium seamless pipe cross rolling piercing method which includes the steps: hot spraying a zirconium oxide coating with the thickness of 0.2-0.4mm on a working surface of a guide plate of a cross rolling piercing machine by the aid of plasma; grinding the zirconium oxide coating with surface roughness of 0.9-1.5 micrometers; smearing boron nitride lubricants on a working surface of a front guide plate of the cross rolling piercing machine; setting the ellipticity of a pure titanium seamless pipe cross rolling piercing hole pattern to be 1.09-1.2. By the method, piercing and sizing can be performed on a hot rolling mill comprising the cross rolling piercing machine, so that a high-precision pure titanium seamless pipe is directly produced on a production process line, and the problems of easiness in adhesion and low yield of guide plates of a cross rolling piercing machine in the prior art are solved.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

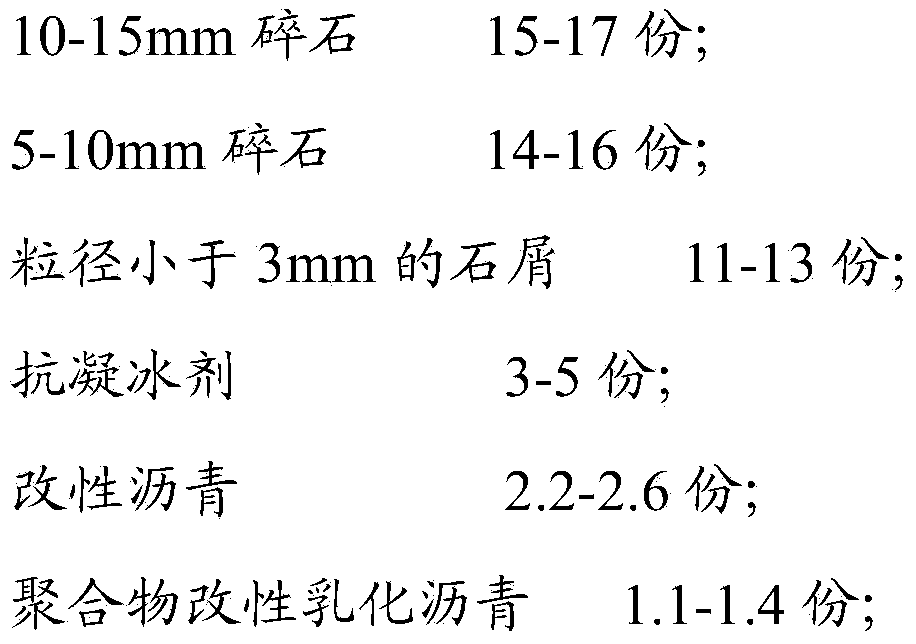

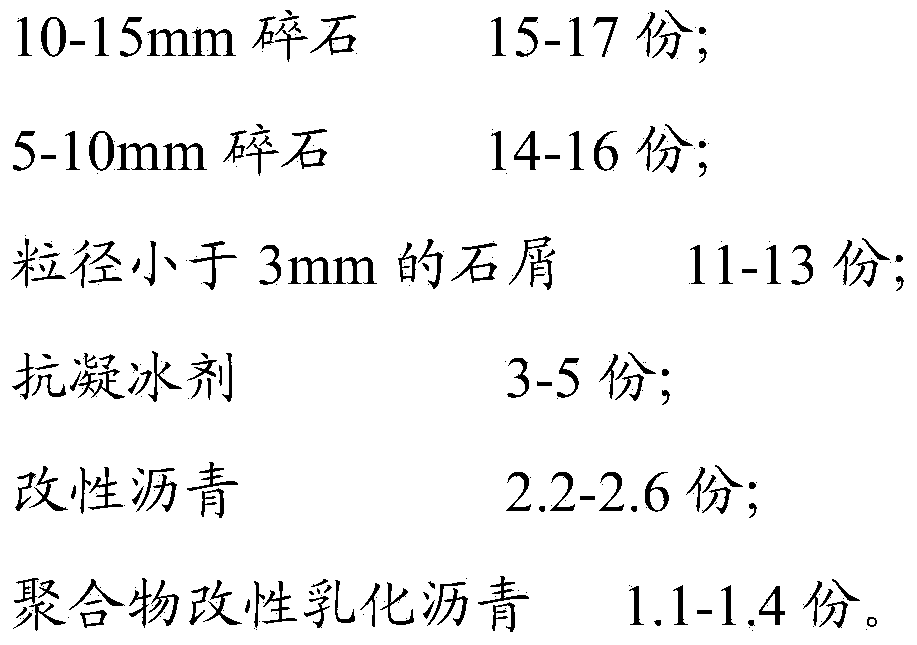

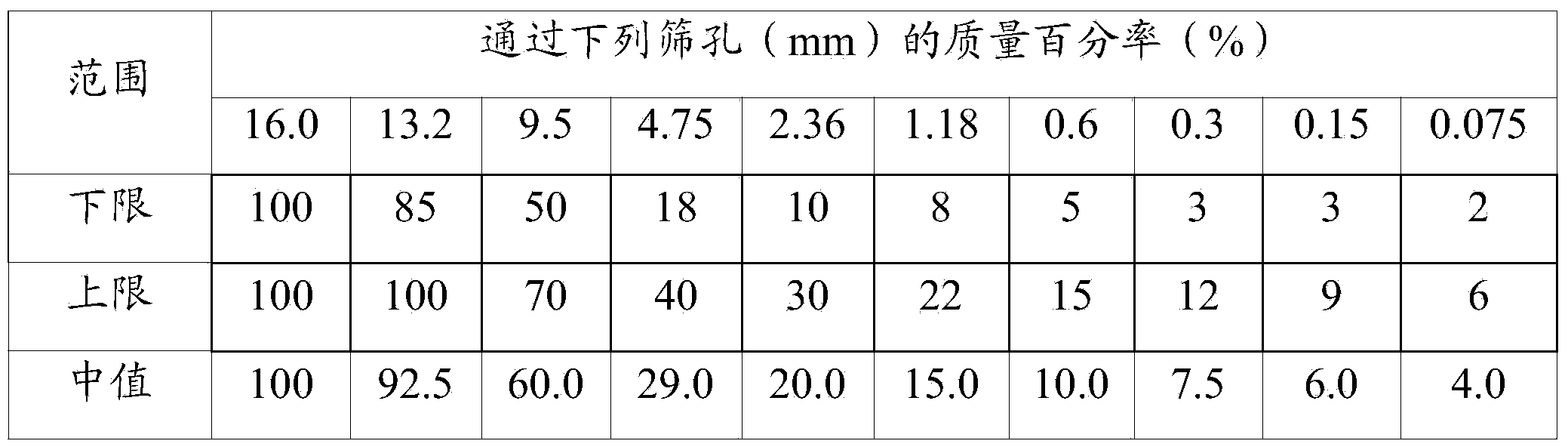

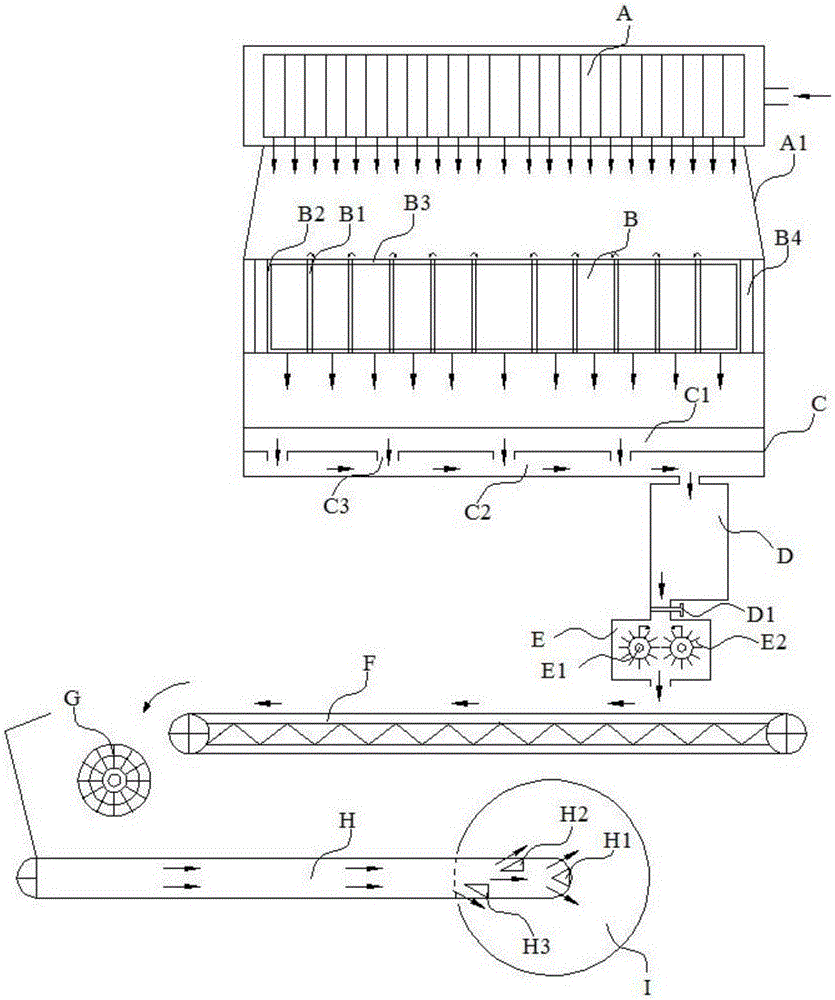

Ice condensation resistant ultra-thin wearing course pavement and preparation method thereof

ActiveCN104032639ADelayed snow and icingEnsure driving safetyIn situ pavingsSnowpackPolymer modified

The invention discloses an ice condensation resistant ultra-thin wearing course pavement and a preparation method thereof. The ice condensation resistant ultra-thin wearing course pavement is prepared from the following raw materials in parts by weight: 15-17 parts of 10-15 mm gravels, 14-16 parts of 5-10 mm gravels, 11-13 parts of stone chips of which the particle size is smaller than 3 mm, 3-5 parts of ice condensation resistant agents, 2.2-2.6 parts of modified asphalt, and 1.1-1.4 parts of polymer modified emulsified asphalt, wherein the content of sodium chloride in the ice condensation resistant agents is 50-60%, and the solid content of the polymer modified emulsified asphalt is greater than or equal to 65%. According to the invention, ice condensation resistant ultra-thin wearing courses are paved on the pavement, so that the ice point of water in the surface of the pavement is reduced, snow accumulation and icing on the pavement are delayed, a new solution is put forward for solving the problem of the congelation of the pavement in winter is restrained, and safe running on the pavement is ensured.

Owner:广州新粤交通技术有限公司

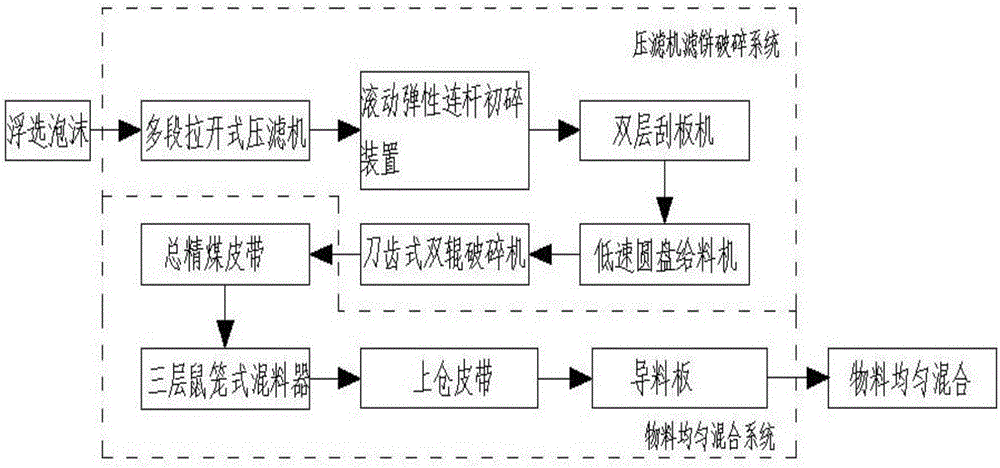

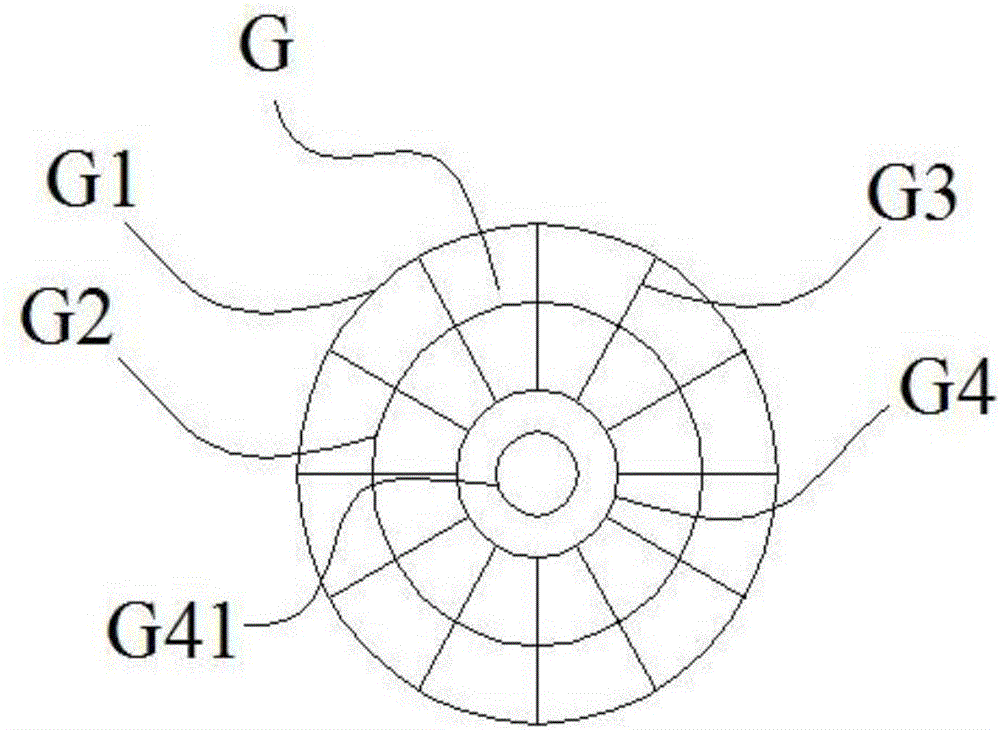

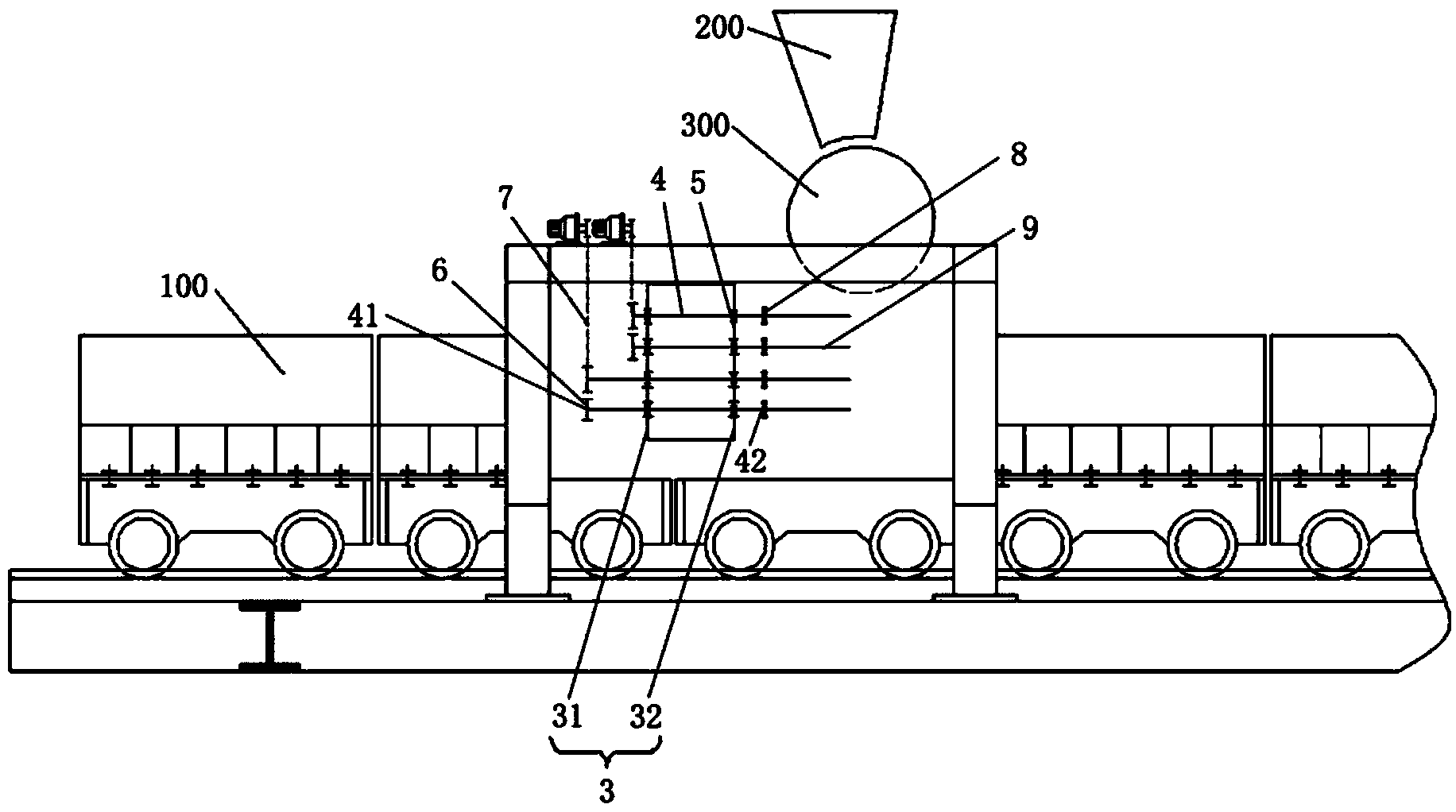

System and method for uniformly mixing filter-press coal-clay briquette and reselected coarse coal

PendingCN106731930AReduce the probability of accumulationAvoid accumulationFlow mixersMixing methodsLow speedDischarge rate

The invention relates to the technical field of uniform mixing of flotation concentrate and reselected fine coal, and particularly relates to a system and method for uniformly mixing filter-press coal-clay briquette and reselected coarse coal. The system comprises working systems as follows: a filter cake of a multi-segment open filter press shocks a rolling elastic connecting rod primary crushing device by virtue of self-weight to complete primary crushing; the primarily crushed material enters a double-layer scrapper; an upper layer of the double-layer scrapper is used for storing the material and a lower layer is used for continuously transporting the material through a scraper blade; the material enters a low-speed disk feeder and controls the discharge rate through adjusting the rotating speed and the opening degree of a feed opening; the material is crushed through a cutter tooth-type double-roll crusher and then falls to a total fine coal belt; a three-layer squirrel-cage mixer is arranged at the inclined lower part of a discharge end of the total fine coal belt to achieve uniform material mixing; and a guide plate is arranged at the discharge end of an upper warehouse belt to play a role in dispersing blanking points. The system is reasonable in process layout, equipment selection and structural design; the material is mixed uniformly; and the effect is reliable and stable.

Owner:ANHUI UNIV OF SCI & TECH

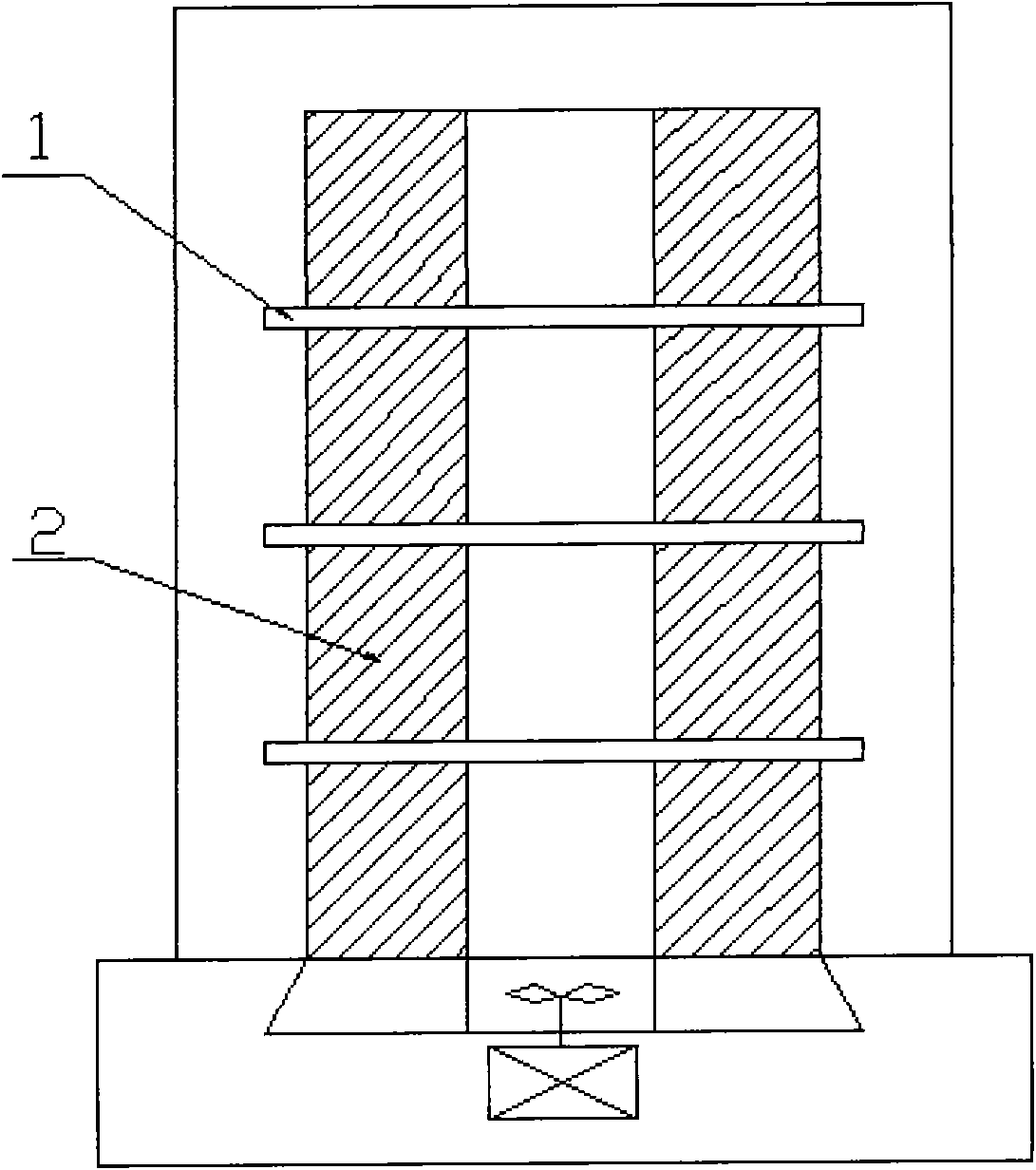

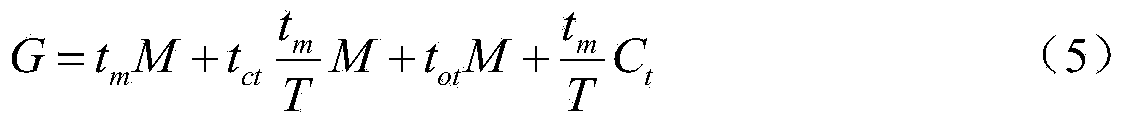

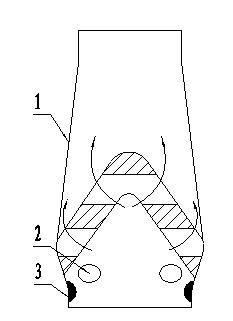

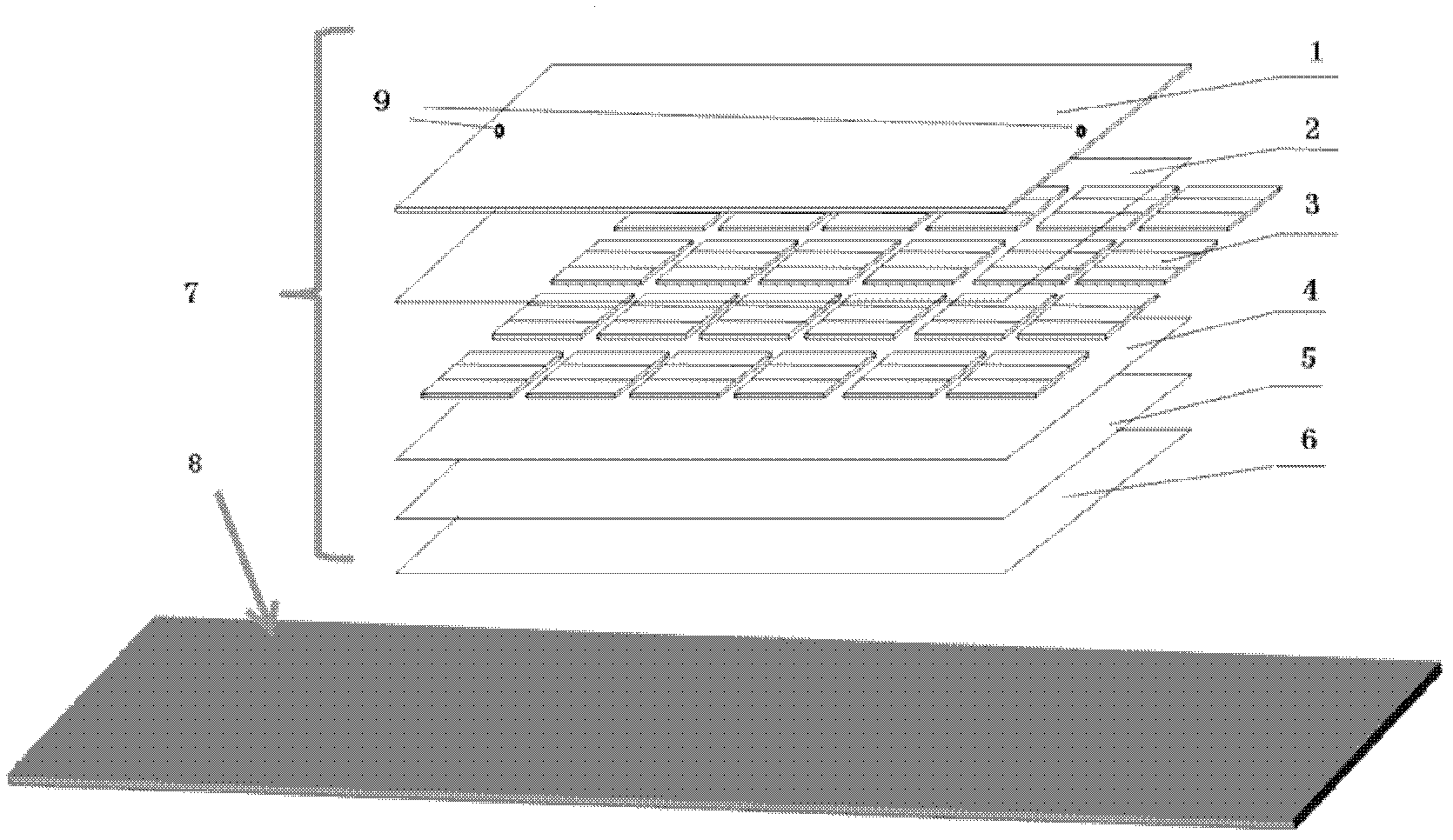

Direct strong convection board used for hood-type annealing furnace and automatically suitable for cold-rolling strip steel bandwidth and working method thereof

InactiveCN101892377AGood thermal cycle performanceEliminate stickingFurnace typesHeat treatment furnacesShielding gasStrip steel

The invention relates to a direct strong convection board used for a hood-type annealing furnace and automatically suitable for a cold-rolling strip steel bandwidth and a working method thereof. The direct strong convection board comprises a flow guide pipe and a flow guide plate with a flow guide channel. The direct strong convection board is characterized by the thermal cycle paths of sequentially passing through a heating hood, an inner hood, protective gas inside a furnace after middle temperature rising and convection, an outer ring of a steel coil and a core part of a thermal radiation steel coil in the heating process and sequentially passing through a cooling hood, the inner hood, the protective gas inside the furnace after middle temperature decreasing and convection, the outer ring of the steel coil and the core part of the thermal radiation steel coil in the cooling process. The direct strong convection board fulfills the aims of enforcing middle convection effect and reducing the unbalance of inner and outer temperatures.

Owner:SHANDONG IRON & STEEL CO LTD

Sunscreen powder and preparation method thereof

PendingCN109394556AGood dispersionNot suitable for reunionCosmetic preparationsToilet preparationsZincRutile

The invention relates to sunscreen powder and a preparation method thereof. The sunscreen powder sequentially comprises a substrate, an ultraviolet shielding layer and an optional inorganic light stabilizing layer from the inside to the outside. The substrate is in the form of a sheet, the particle size is less than or equal to 10 mum, and the radius-thickness ratio is more than or equal to 30. The ultraviolet shielding layer includes a titanium dioxide layer and a zinc oxide layer, and the rutile structure of the titanium oxide is not less than 60%. The sunscreen powder has the advantages ofgood dispersibility, good sunscreen effect and good stability.

Owner:林一中

Vetrified tiles high-efficiency purifying clay

The invention provides a vitrified brick high-efficiency purification mastic belonging to the technical field of building materials. The components A and B are mixed according to the weight ratio of 1:0.5, stirred evenly, and then directly applied to the back of the vitrified brick or bonded to the base layer. Vitrified tiles can be pasted. The high-efficiency purification cement for vitrified bricks of the present invention can resist, alleviate and eliminate various stress impacts, and realize permanent and firm bonding between vitrified bricks, adhesive cement and bonding base. The zeolite powder, diatomaceous earth and sepiolite fiber contained in the cement can absorb, decompose and eliminate formaldehyde, indoor odor and harmful substances in the air. It also has the function of adjusting indoor humidity and improving the living environment.

Owner:郭太宗

Fast-steam-heating electric rice cooker

InactiveCN107007131ANo spillageHigh speedMultiple-unit cooking vesselsEgg-cookersRice dishesProcess engineering

The invention discloses a domestic-use fast-steam-heating electric rice cooker and a domestic-use fast-steam-heating soybean milk machine. An ordinary electric rice cooker and an ordinary soybean milk machine have the following shortcomings that the cooking speed is slow, nutrition loss is much, the rice taste is poor, rice easily sticks to a pan or overflows from the pan, and pan washing is troublesome. The domestic-use fast-steam-heating electric rice cooker is same as the ordinary electric rice cooker in use method, however, the principle of the electric rice cooker is that the rice is not cooked but steamed, at the same time, congee cooking and other traditional functions of the electric rice cooker are retained, and the function of an egg steamer is added to the electric rice cooker. When the fast-steam-heating electric rice cooker is under the same rated power condition, the rice steaming time is saved by more than half, both rice steaming and bun steaming take only 15 min, more nutrients of the rice are retained, the rice taste is good, and rice does not stick to the pan or overflow from the pan.

Owner:雍占锋

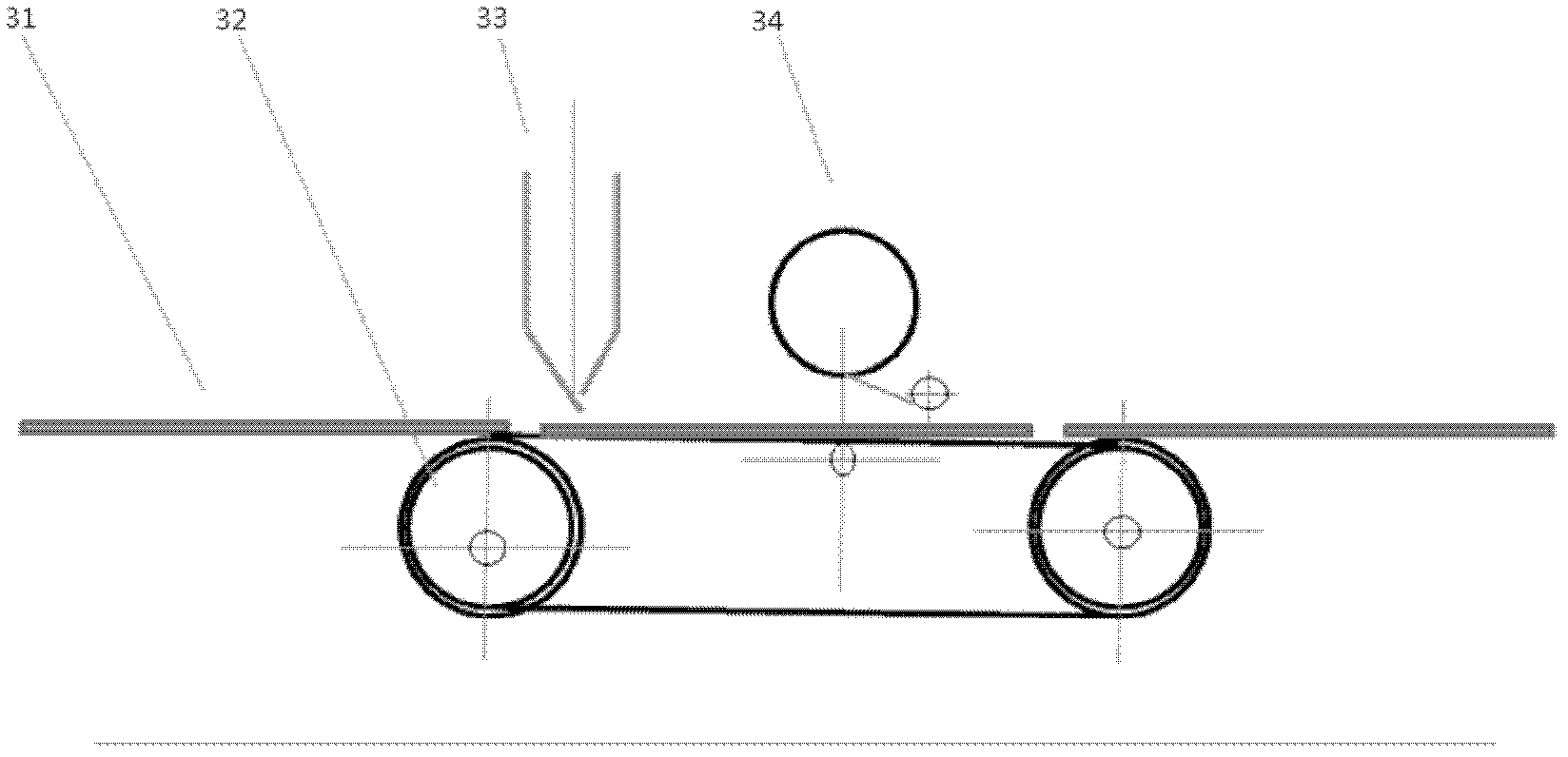

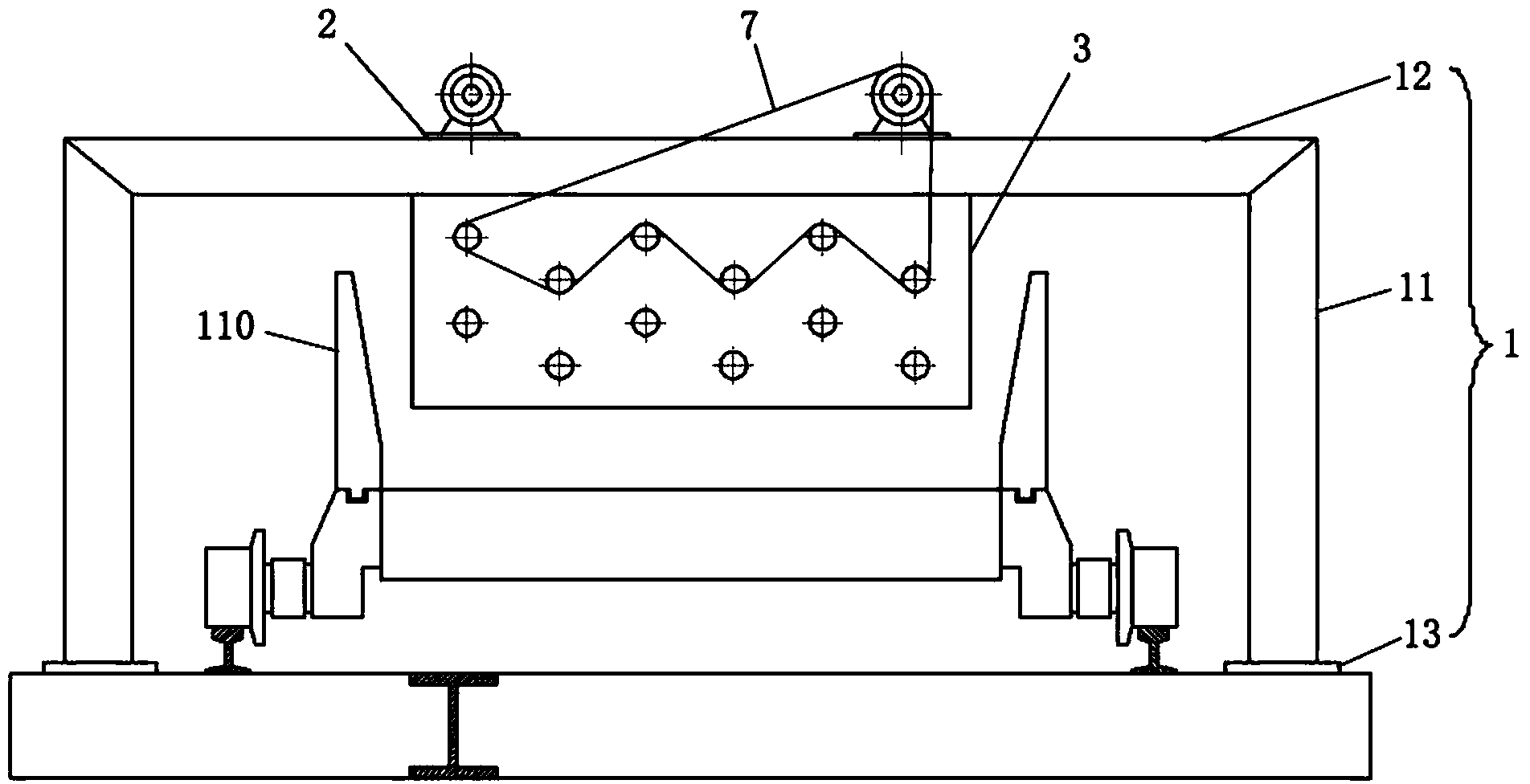

Transmission type material loosening device for sintering machine

ActiveCN103983112AContinuous and stable breathabilityImprove breathabilityFurnace typesEngineeringMotor speed

The invention provides a transmission type material loosening device for a sintering machine. The transmission type material loosening device comprises a machine frame, a motor-speed reducer assembly, a supporting frame, a material loosening bar, a driving chain wheel, a driven chain wheel and a chain, wherein the machine frame strides a sintering machine trolley and is provided with an upper end platform, the motor-speed reducer assembly is fixed to the platform of the machine frame, the upper end of the supporting frame is fixed to the lower surface of the upper end platform, one end of the material loosening bar is supported by the supporting frame, the other end of the material loosening bar is inserted into a mixture, the driving chain wheel is arranged on an output shaft of the motor-speed reducer assembly, the driven chain wheel is connected with one end of the material loosening bar, and the chain connects the driving chain wheel with the driven chain wheel and drives the material loosening bar to rotate through the motor-speed reducer assembly. According to the transmission type material loosening device for the sintering machine, the mixture accumulated on and adhering to the material loosening device can be automatically removed, the phenomenon that the mixture is accumulated on and adheres to the material loosening device is eliminated, and therefore the yield and quality of agglomerates are increased, and sintering solid fuel consumption is lowered.

Owner:攀钢集团西昌钢钒有限公司

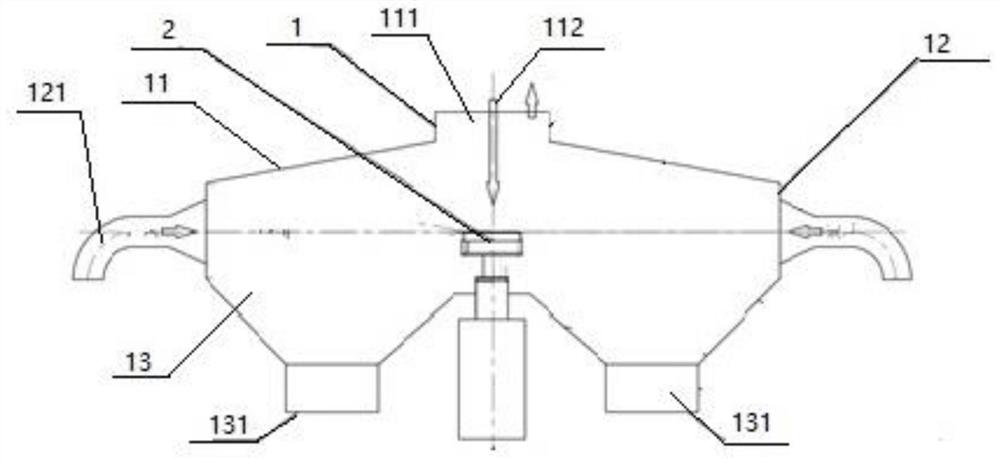

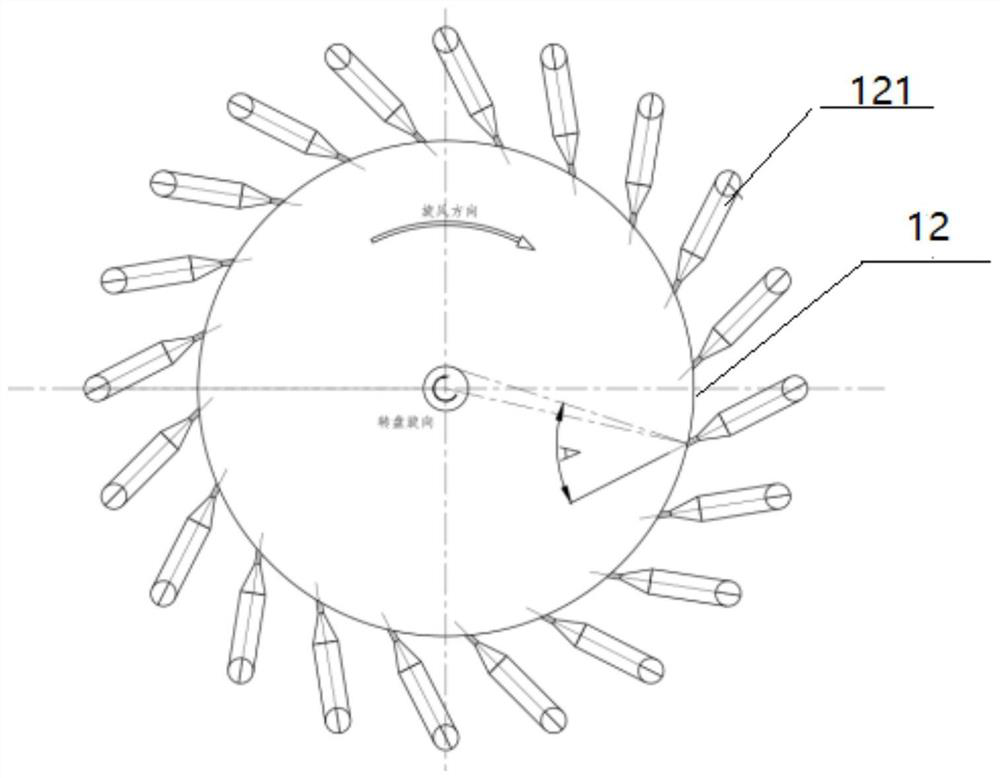

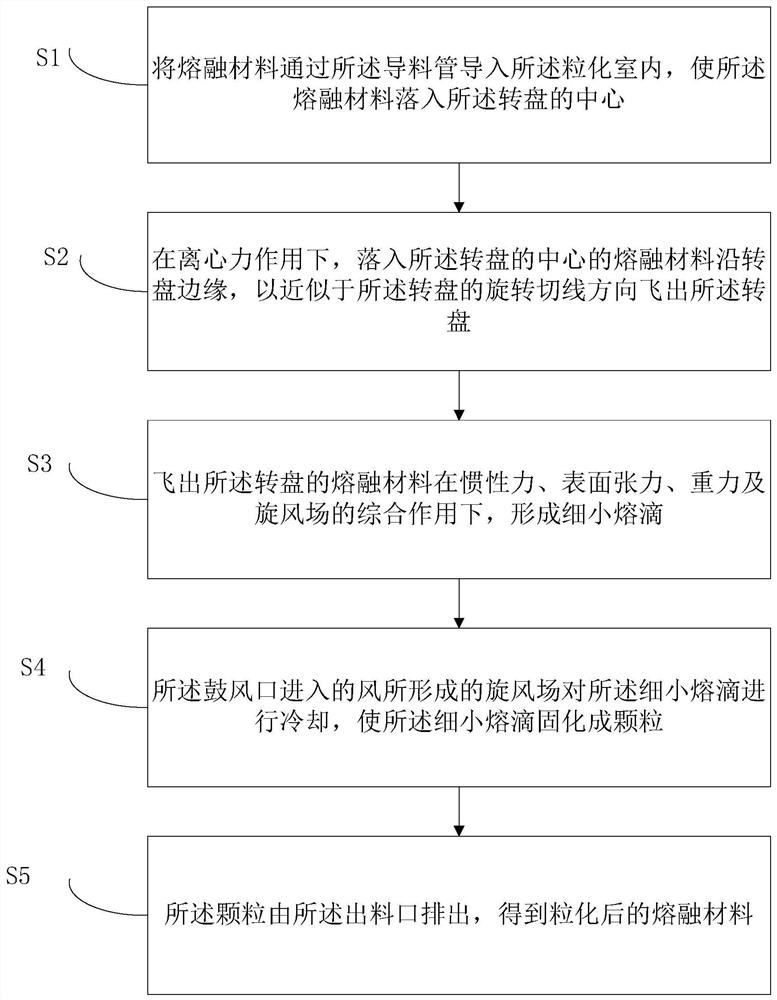

Granulating device and granulating method for molten material

The invention provides a granulating device and a granulating method for a molten material. The granulating device comprises a granulating chamber, the granulating chamber comprises a tip cone structure, a middle ring section connected with the bottom end of the tip cone structure and a lower cone section connected with the bottom end of the middle ring section; an air outlet is formed in the top end of the tip cone structure, and a material guide pipe is arranged in the air outlet; at least one group of blower nozzles are arranged on the outer side wall of the middle ring section, and each group of blower nozzles at least comprises two blower nozzles which are symmetrically arranged; a rotating disc is arranged in the middle ring section, and the center of the rotating disc is opposite to the bottom of the material guide pipe; and the lower cone section comprises a lower cone structure arranged on the periphery of the lower portion of the rotary disc, and a discharging port is formed in the bottom of the lower cone structure. By utilizing the invention, the problem that the existing granulation equipment is huge can be solved; and large-particle-size particles or large blocks are easy to generate, so that the phenomena of product accumulation, remelting and the like are caused.

Owner:北京中冶设备研究设计总院有限公司

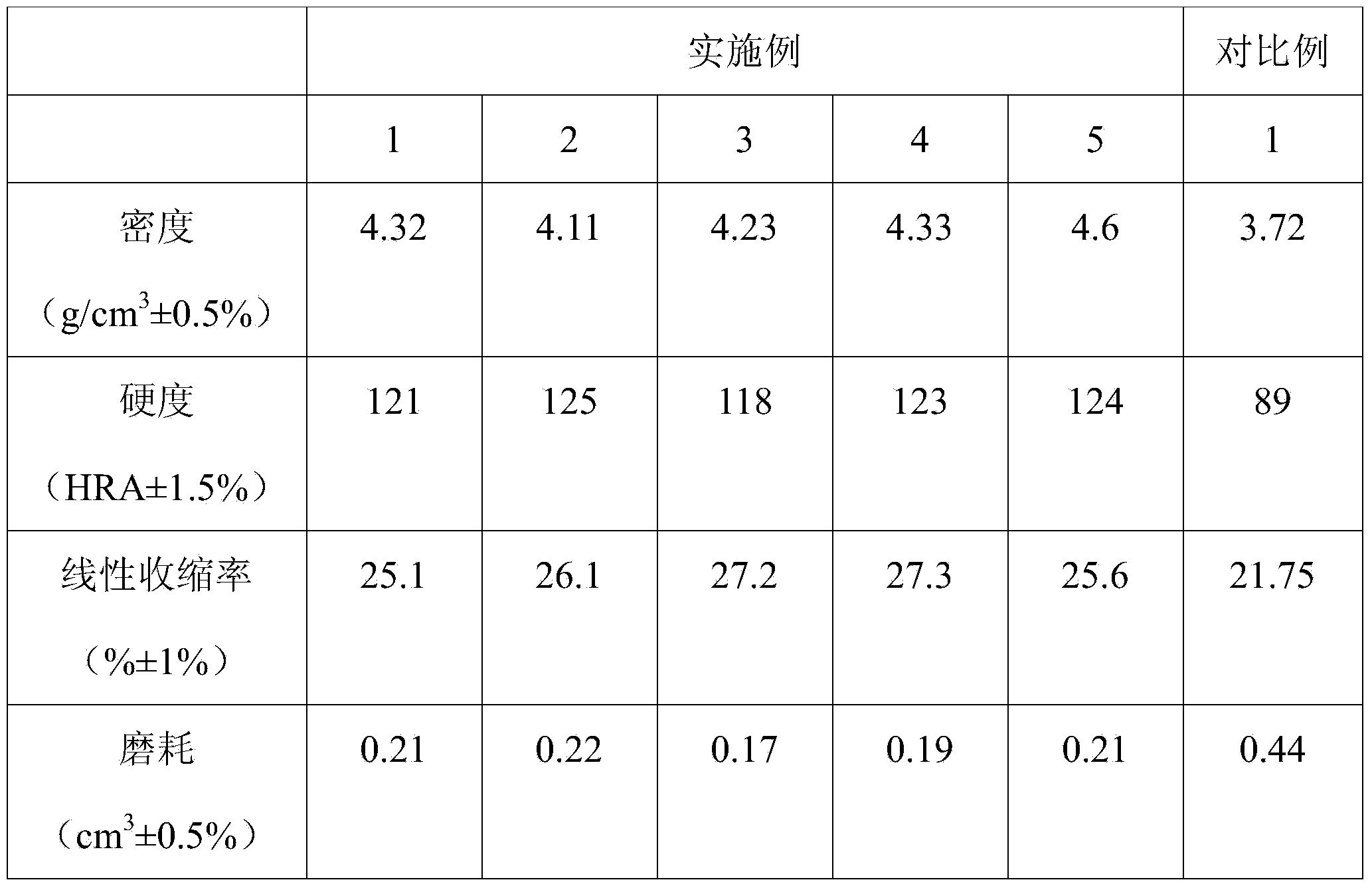

Alumina ceramic material and preparation method thereof

The invention provides an alumina ceramic material which uses high-alumina fly ash, light calcium carbonate and magnesium carbonate as raw materials. The preparation method comprises the following steps: firstly, performing pre-desilicification and acid activation pretreatment on the high-alumina fly ash to improve the alumina content in the high-alumina fly ash; then, ball-milling the high-alumina fly ash, the light calcium carbonate, the magnesium carbonate, water, a dispersing agent and a binding agent, drying, and grinding, so as to obtain powder; sieving and deironing the powder, adding a release agent, uniformly mixing, then pressing into a green body, and performing pressurization high-temperature sintering on the green body, so as to obtain the alumina ceramic material. According to the method, no other additional aluminium sources are needed, and the sintering temperature is obviously reduced during the preparation process, so that the cost is reduced; moreover, the method is high in parameter controllability and high in repeatability, and the prepared products are good in consistency, high in abrasion resistance and high in stability.

Owner:江苏龙欧新型建材科技有限公司

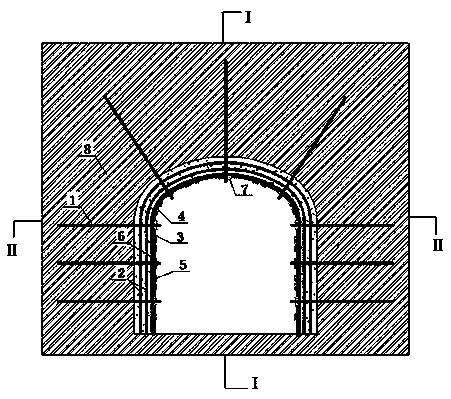

Fractured rock mass roadway combined active and passive support method

InactiveCN110500115AStop fallingGuaranteed long-term stabilityUnderground chambersTunnel liningRebarWire mesh

The invention discloses a fractured rock mass roadway combined active and passive support method. The fractured rock mass roadway combined active and passive support method comprises the steps that the mine rock joint fissure fracture development condition is observed on site, the thickness of concrete is determined, and a drilling position of an anchor rod hole is arranged and marked; according to a calculation result, peripheral anchor rod holes are drilled, resin anchor rods are fixed into the anchor rod holes through an anchoring agent, the depth of anchor rods entering mine rock is 2-3m,and the anchor rods exposes from the surface of a roadway by 0.5-1m; steel wire meshes are inserted to exposed rod bodies of the anchor rods from being closely attached to the mine rock every other 0.1-0.2m in a penetrating mode, and at least more than two layer of steel wire meshes are formed; steel plates are fixed to anchor rod positions of the outer layers of the steel wire meshes from bottomto top, and meanwhile, geotechnical cloth is laid on the inner surfaces of the steel plates; during construction, the steel plates are fixed while the concrete is poured in surrounding space of the steel plates layer by layer until construction of a whole roadway cross section is completed; and the steel plates are connected and reinforced through steel bars between the longitudinal direction andthe transverse direction. The fractured rock mass roadway combined active and passive support method is simple in process, high in safety, and saved in engineering materials.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

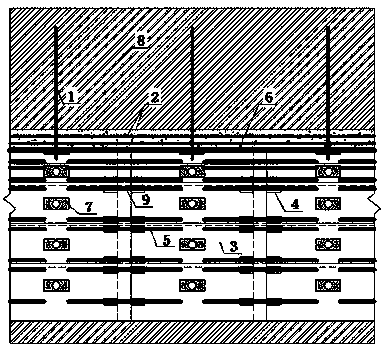

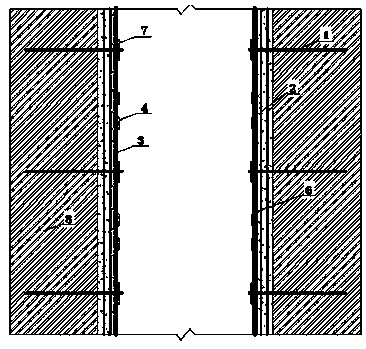

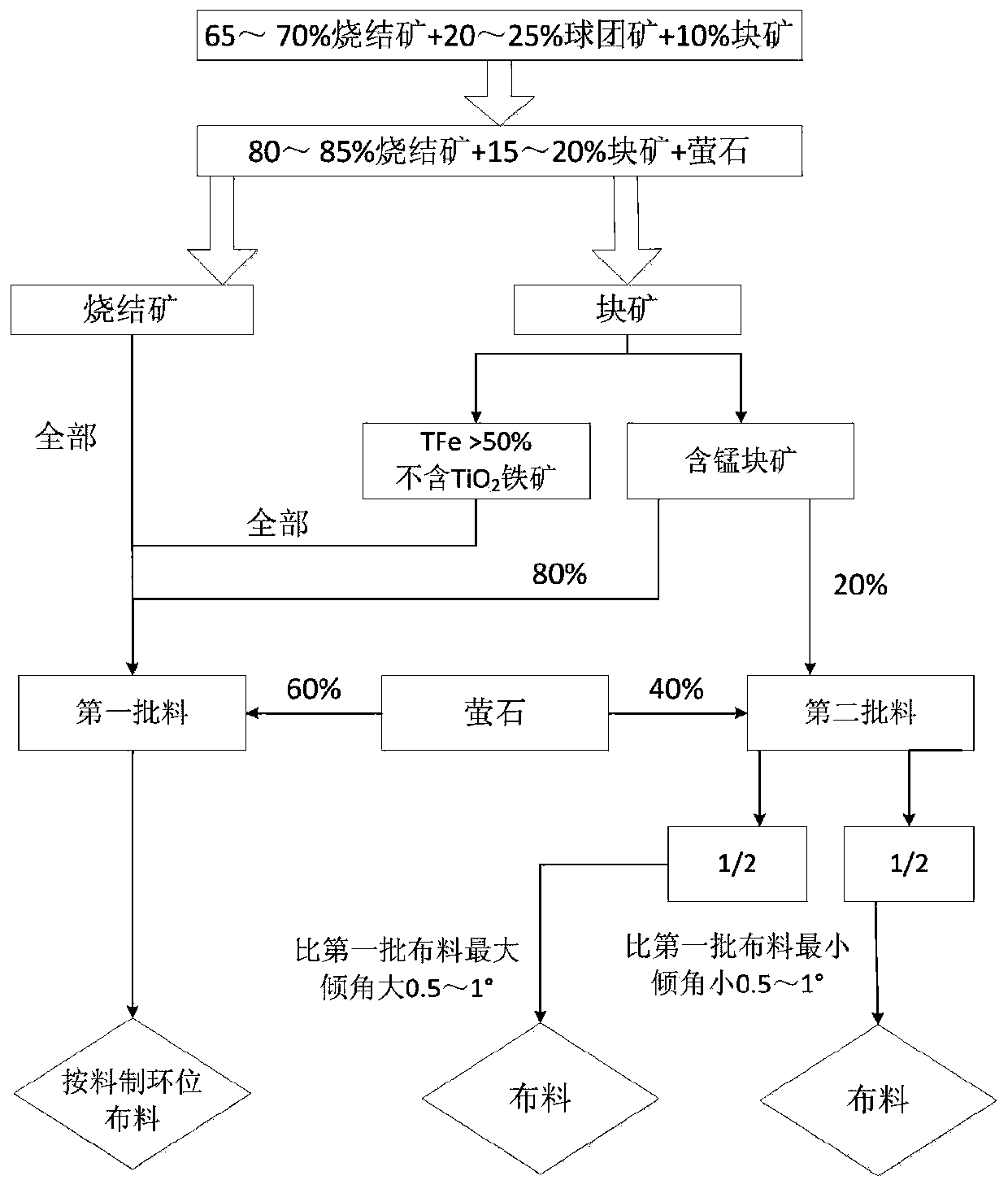

Vanadium-titanium magnetite blast furnace smelting method

ActiveCN110724776AImprove breathability and liquid permeabilityImprove metallurgical performanceBlast furnace detailsBlast furnace smeltingTitanomagnetite

The invention discloses a vanadium-titanium magnetite blast furnace smelting method, and belongs to the technical field of blast furnace smelting. The vanadium-titanium magnetite blast furnace smelting method is provided to eliminate the situation that furnace conditions of vanadium-titanium magnetite blast furnace smelting is not smooth. By adjusting magnetite distribution, a slagging system, a heat system and an air supply system, the fluidity of slag iron is improved, the working state of a furnace cylinder is stabilized, the gas permeability and liquid permeability of a material column areimproved, reasonable distribution of blast furnace gas flow is promoted, and rapid recovery of the furnace conditions of a blast furnace is promoted.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

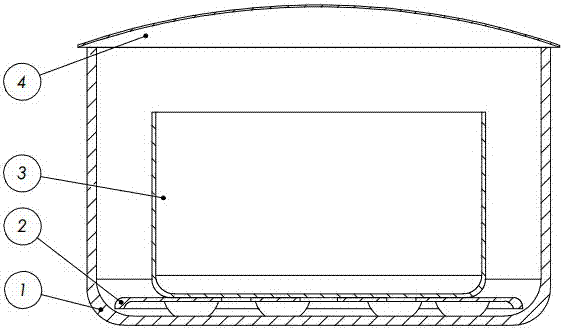

High-temperature-sheet-combination convex vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

InactiveCN104743825AShorten the timeSolve productivityGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

High-temperature-sheet-combination convex vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The convex vacuum glass comprises upper glass and lower glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; peripheries of the upper glass and each air extracting hole are provided with sealing strips; corresponding positions of the periphery of the lower glass and each air extracting hole are provided with the sealing grooves; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace; each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace; and a sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Method for preventing indoor swimming pool with concrete structure from being eroded by chlorine gas

Owner:林州建总建筑工程有限公司 +1

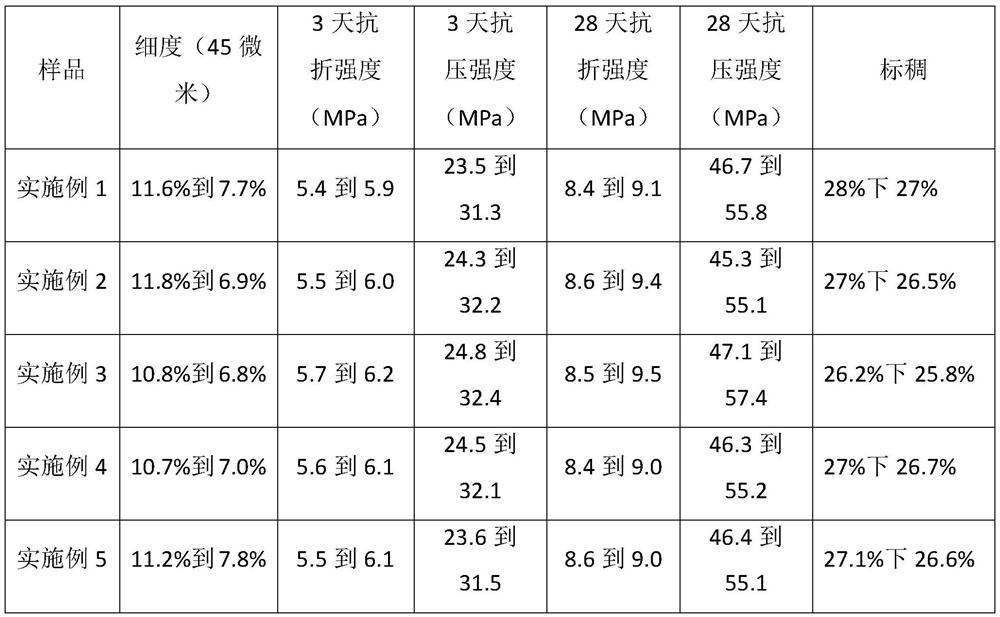

Mineralized material used in cement grinding process

The invention is suitable for the technical field of cement grinding aids, and provides a mineralized material used in a cement grinding process, the mineralized material is composed of the following substances by mass: 2-5% of sodium sulfate, 4-7% of sodium thiosulfate, 0-3% of sodium sulfite, 1-3% of maleic anhydride dimer acid triethanolamine ester, 1-3% of ethylene glycol, and 79-92% of fly ash. By determining proper substances and content, promoting early hydration of cement and greatly improving the early hydration rate of cement particles, the early strength is improved, the hydration durability is considered, the later hydration of the cement is promoted through sodium thiosulfate, maleic anhydride dimer acid triethanolamine ester and ethylene glycol, the strength of cement paste is improved, and the cement paste can also wrap the surface of cement particles to form a protective film to eliminate bonding and adsorption agglomeration, the maleic anhydride dimer acid triethanolamine ester can form an oxidation protection film on the metal surface to retard the corrosion of steel bars so that the machine-hour yield of a mill is increased, the comprehensive performance of the product is improved, the power consumption of cement grinding is reduced, and the damage to the cement concrete caused by excessive chloride ions is avoided.

Owner:山西天润恒德新材料有限公司

Low-liquid-level boiling pot

ActiveCN108784315AEasy to add waterImprove space utilizationMultiple-unit cooking vesselsEgg-cookersWater boilSteaming

The invention discloses a low-liquid-level boiling pot. Water boiling in the pot applying a low-liquid-level boiling technology can save a quarter of coal gas and time, the rice steaming time can be shortened by one half or above, the time of rice steaming is only 15-20 minutes same as that of steamed bread steaming, and steamed rice retains more nutrition, has good taste, does not stick to the pot and does not spill out of the pot, and the steamed rice spilling out of the pot is a main reason causing the damage of an electric cooker and gas stove. The low-liquid-level boiling pot overcomes the disadvantages of being slow in speed, much in nutrition loss and poor in taste, easily sticking to the pot, spilling out of the pot and cleaning the pot troublesomely and the like of ordinary electric cookers, soybean milk machines, water jugs, steamers and steam boxes.

Owner:雍占锋

Metal-welded convex double-vacuum-layer glass provided with edges sealed by sealing grooves and manufacturing method thereof

Metal-welded convex double-vacuum-layer glass provided with edges sealed by sealing grooves is disclosed. The convex double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: peripheries of the upper surfaces of the upper glass and the middle glass are provided with sealing strips; corresponding positions of the peripheries of the upper surfaces of the middle glass and the lower glass are provided with the sealing grooves; after the three sheets of glass are rapidly heated, the peripheries of the three sheets of glass are welded under elevated pressure by metal solder in a vacuum furnace; and two vacuum layers are formed among the upper glass, the lower glass and the middle glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

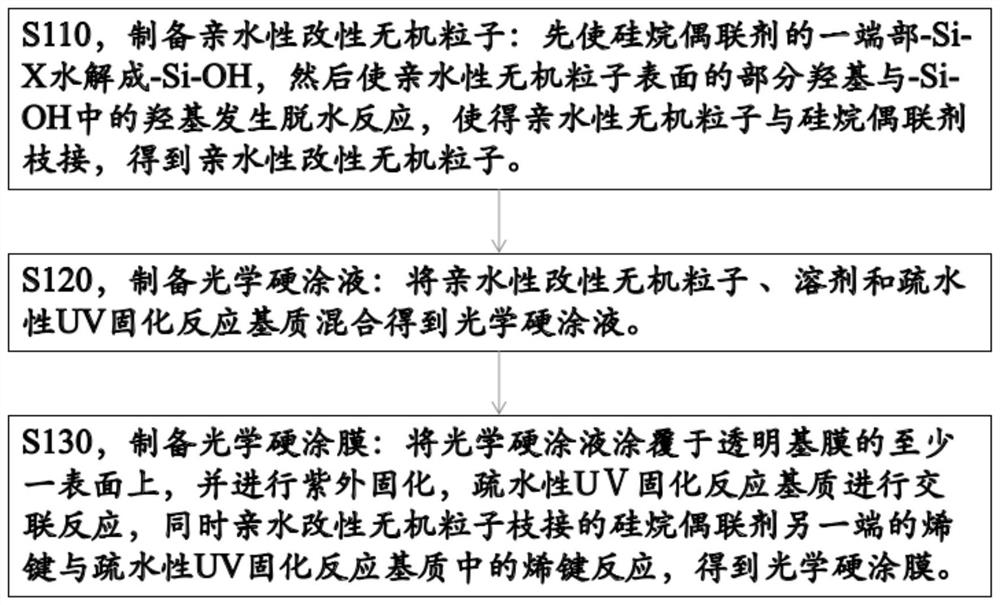

Preparation method of optical hard coating film

ActiveCN113583284AEliminate stickingGuaranteed scratch resistancePolyurea/polyurethane coatingsEpoxy resin coatingsSilanesUltraviolet

The invention relates to a preparation method of an optical hard coating film, and belongs to the technical field of optical hard coating films. The preparation method comprises the steps of hydrolyzing -Si-X at one end part of a silane coupling agent into -Si-OH, and then carrying out dehydration reaction on part of hydroxyl groups on the surfaces of hydrophilic inorganic particles and hydroxyl groups in -Si-OH so as to enable the hydrophilic inorganic particles to be grafted with the silane coupling agent to obtain the hydrophilic modified inorganic particles; mixing the hydrophilic modified inorganic particles, a solvent and a hydrophobic UV curing reaction matrix to obtain an optical hard coating liquid; and coating at least one surface of a transparent base film with the optical hard coating liquid, carrying out ultraviolet curing, enabling a hydrophobic UV curing reaction matrix to be subjected to a cross-linking reaction, meanwhile, enabling an olefinic bond at the other end of the hydrophilic modified inorganic particle grafted silane coupling agent to react with an olefinic bond in the hydrophobic UV curing reaction matrix, and obtaining the optical hard coating film. The optical hard coating film prepared by the preparation method is relatively good in toughness, scratch resistance and adhesion resistance.

Owner:NINGBO HUGHSTAR ADVANCED MATERIAL TECH

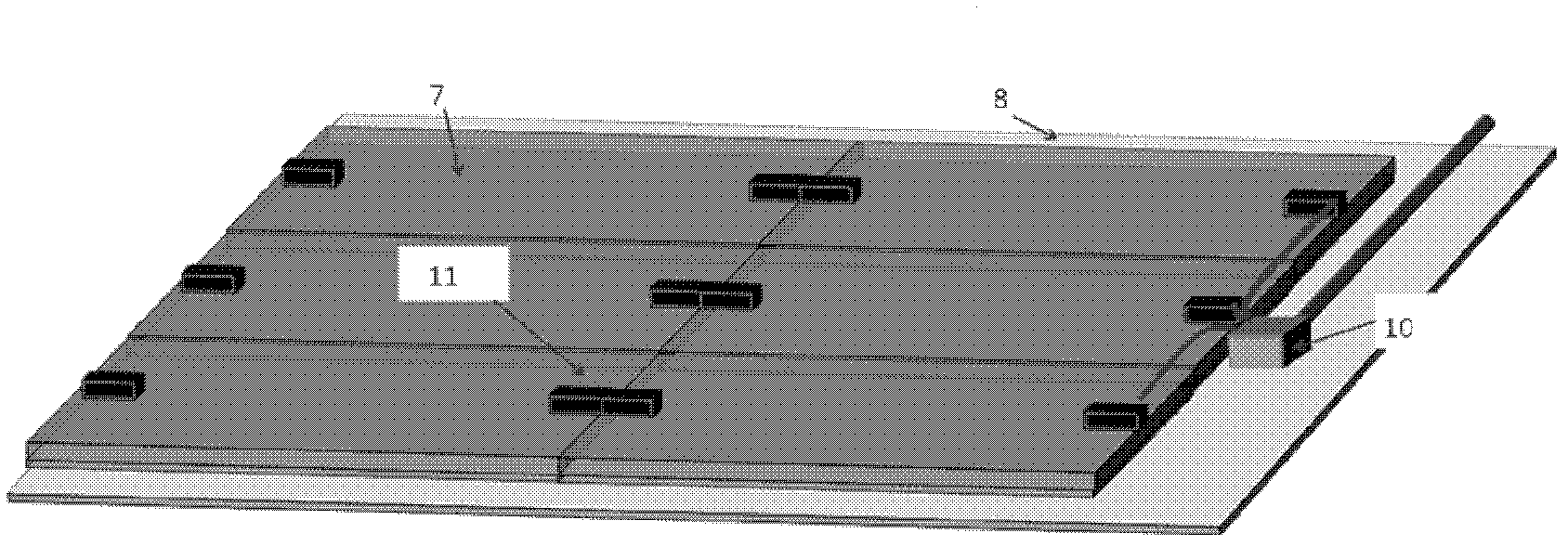

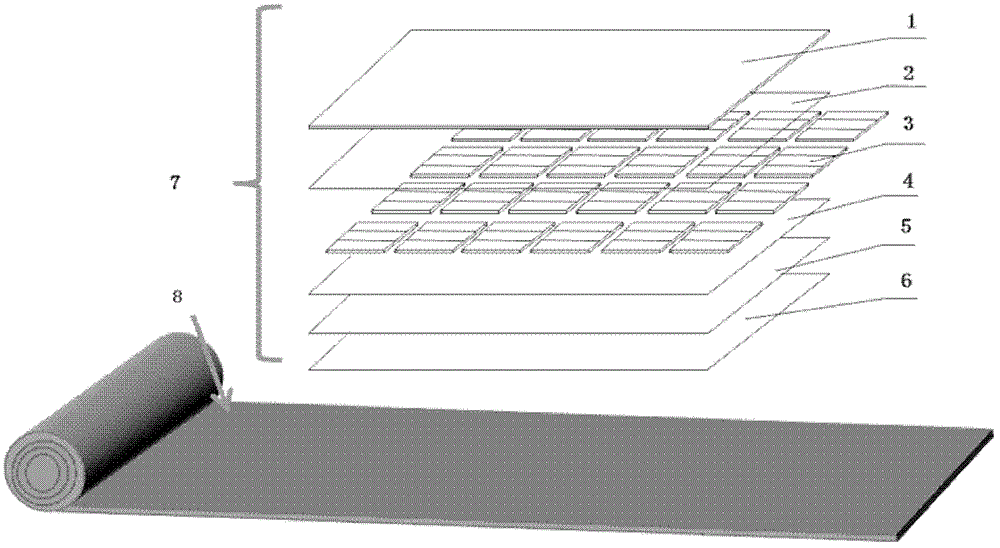

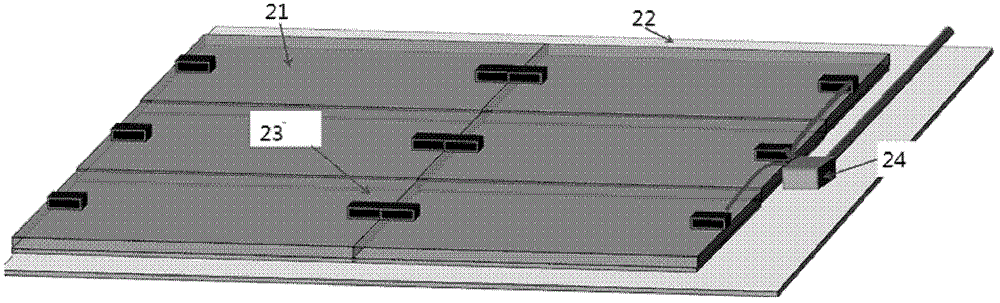

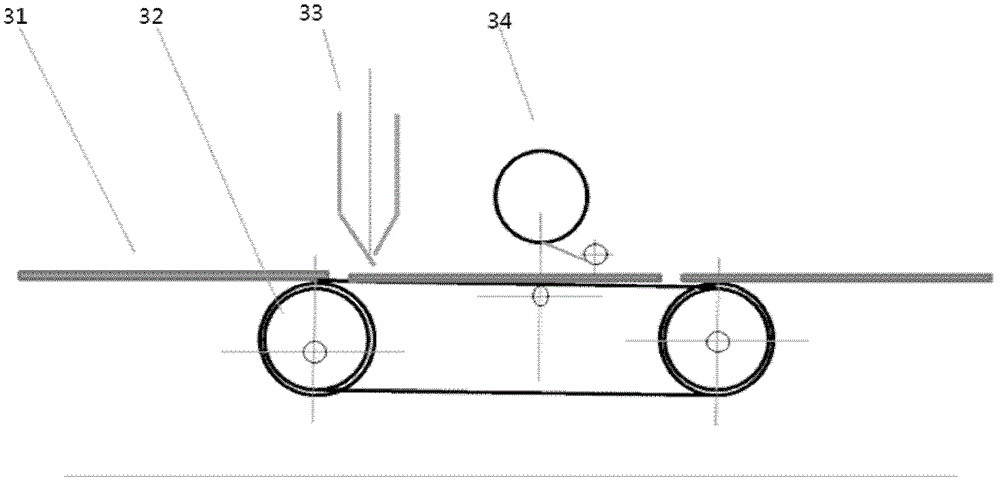

A self-adhesive modular crystalline silicon solar power generation waterproof integrated board system and its preparation method

ActiveCN102709358BFlexibleHigh degree of freedom in constructionRoof covering using slabs/sheetsRoof covering using tiles/slatesComputer moduleEngineering

The invention discloses a waterproof integrated pressure-sensitive-adhesive modularized crystalline silicon solar power generation board system which consists of a pressure-sensitive-adhesive crystalline silicon solar panel component module and a waterproof coil layer assorted with the pressure-sensitive-adhesive crystalline silicon solar panel component module. An adhesive layer composed of creepage adhesive is arranged at the bottom of the pressure-sensitive-adhesive crystalline silicon solar panel component module, TPT (tedlar / PET / tedlar) is covered on the adhesive layer, and a crystalline silicon battery cell and toughened glass are sequentially arranged on the TPT and are adhered with the same by hot-melt adhesive. Products of the waterproof integrated pressure-sensitive-adhesive modularized crystalline silicon power generation board system are material-saving, energy-saving and environment-friendly during production and construction, and be applicable to flat roofs and curved roofs simultaneously. The waterproof integrated pressure-sensitive-adhesive modularized crystalline silicon power generation board system has flexibility of flexible film solar cells and low cost which fails to be qualified by the flexible film solar cells. Mounting process can be simplified and economy and convenience are achieved. Further, the waterproof integrated pressure-sensitive-adhesive modularized crystalline silicon power generation board system can be processed and completed directly in a factor, can be paved by adhesives during construction, and photovoltaic utilization can be effectively popularized.

Owner:南通金丝楠膜材料有限公司

Composite thermal insulating mortar and preparing method thereof

The invention relates to a complex thermal- insulting sand grout. It comprises nanometer and sub- nanometer inert oxide, titanium oxide, aluminum oxide, calcium oxide, magnesium and thermal- insulting filler. The invention is characterized by better thermal- insulating, water proof and flame- resistant effect, convenient and fast operation and low production cost. The product is suited to be used on external wall, and can apparently improve the thermal- insulting and water proof performance for buildings.

Owner:毕文学

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com