Transmission type material loosening device for sintering machine

A transmission type and sintering machine technology, which is applied in the field of sintering machines, can solve problems such as inability to give full play to the role of intensified sintering production, the cleaning effect cannot meet the requirements, and the site environment is complex, and achieve continuous and stable air permeability, easy maintenance, and labor-intensive low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further illustrate the present invention, the specific implementation of the motor-chain drive type sintering and loosening device according to the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

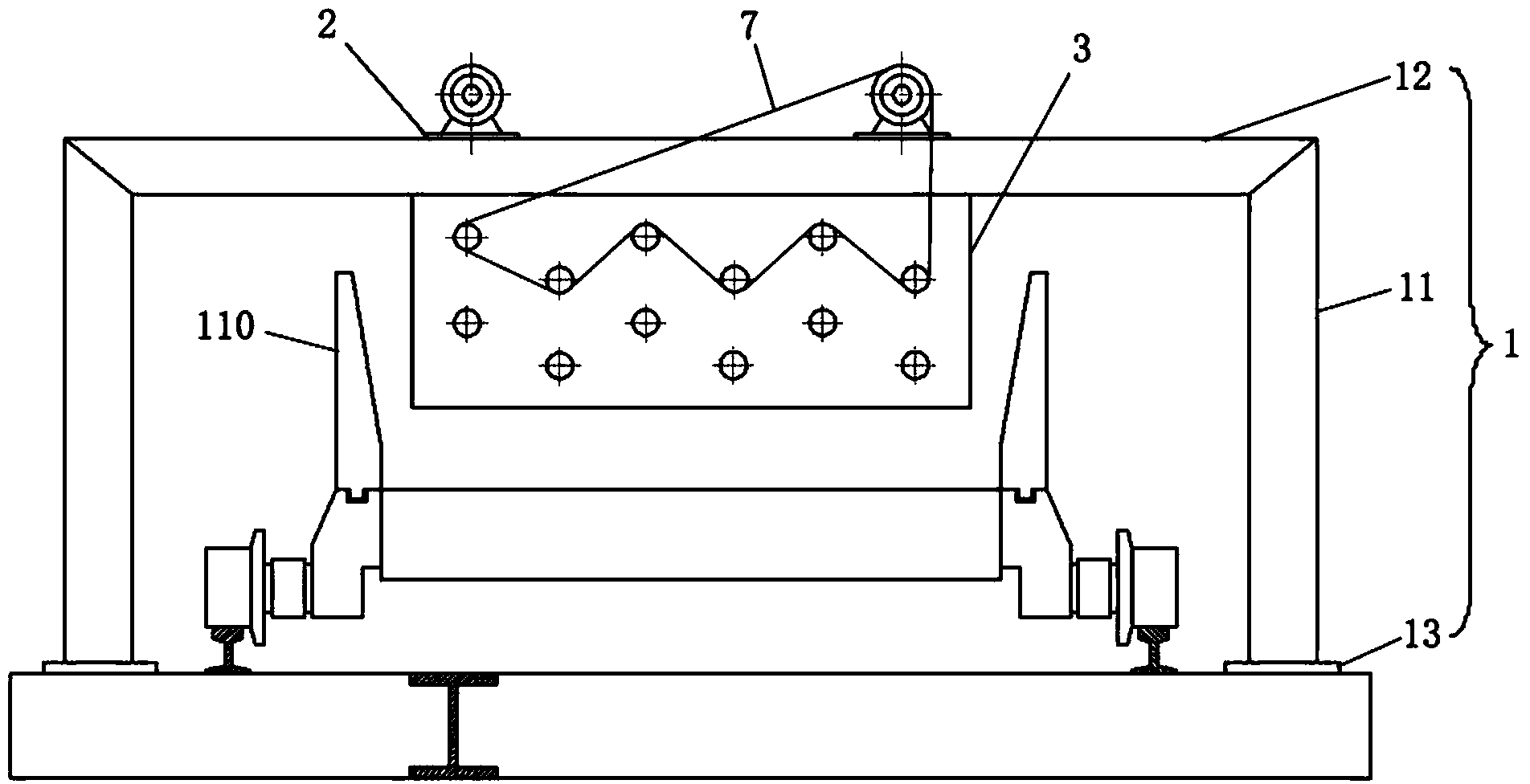

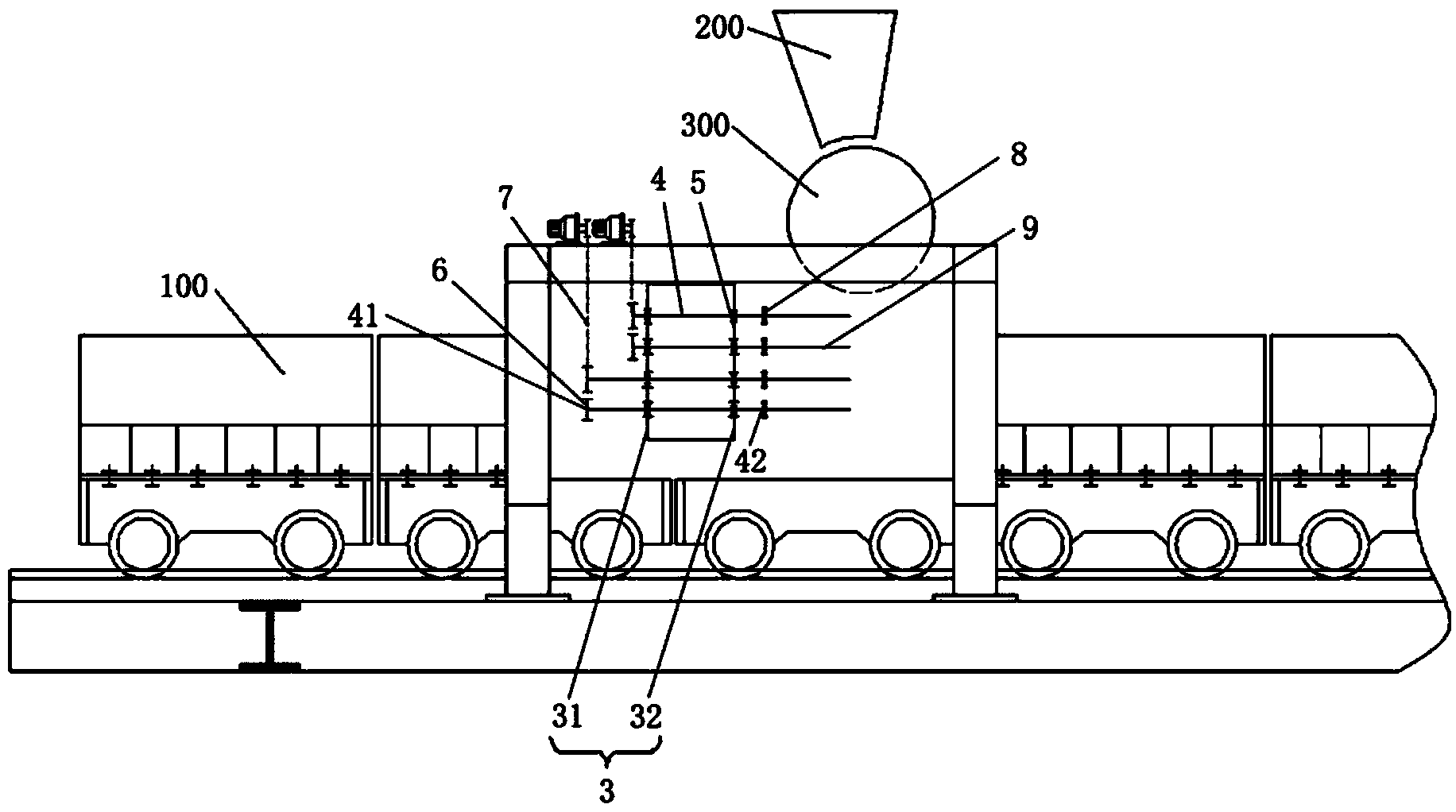

[0017] figure 1 is a schematic front view showing a transmission type loosening device for a sintering machine according to an embodiment of the present invention, wherein a set of motor-reducer assemblies 2 drives two rows of loosening rods 9 through a chain 7 . figure 2 is shown to remove figure 1 A schematic side view of the transmission loosening device of the fence 110 of the trolley 100 in .

[0018] In general, if figure 2 As shown, the transmission loosening device is arranged below the mixed material ore tank 200 and the round roller feeder 300 , and straddles the width direction of the trolley 100 . When the mixture fell, the mixture was loosened by the rotation of the loosening rod 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com