Vanadium-titanium magnetite blast furnace smelting method

A technology for vanadium titanomagnetite and blast furnace smelting, which is applied in the field of blast furnace smelting, can solve the problems of increasing the inactive area of the hearth, the difficulty of hot air blowing through the center of the hearth completely, and the thickness of the furnace wall, so as to avoid slag iron. The effect of poor fluidity, improvement of gas and liquid permeability of material column, and improvement of metallurgical properties of slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A blast furnace smelted with vanadium-titanium magnetite as the main raw material, after an emergency shutdown of the blast furnace, the gas flow distribution was unstable, and due to improper adjustment measures, the furnace condition further deteriorated, resulting in long-term abnormality of the blast furnace condition, resulting in severe economic losses.

[0026] After analyzing and judging in many aspects, it is shown that serious central accumulation and edge bonding have occurred in the furnace, and the method of the present invention is used to recover the furnace condition.

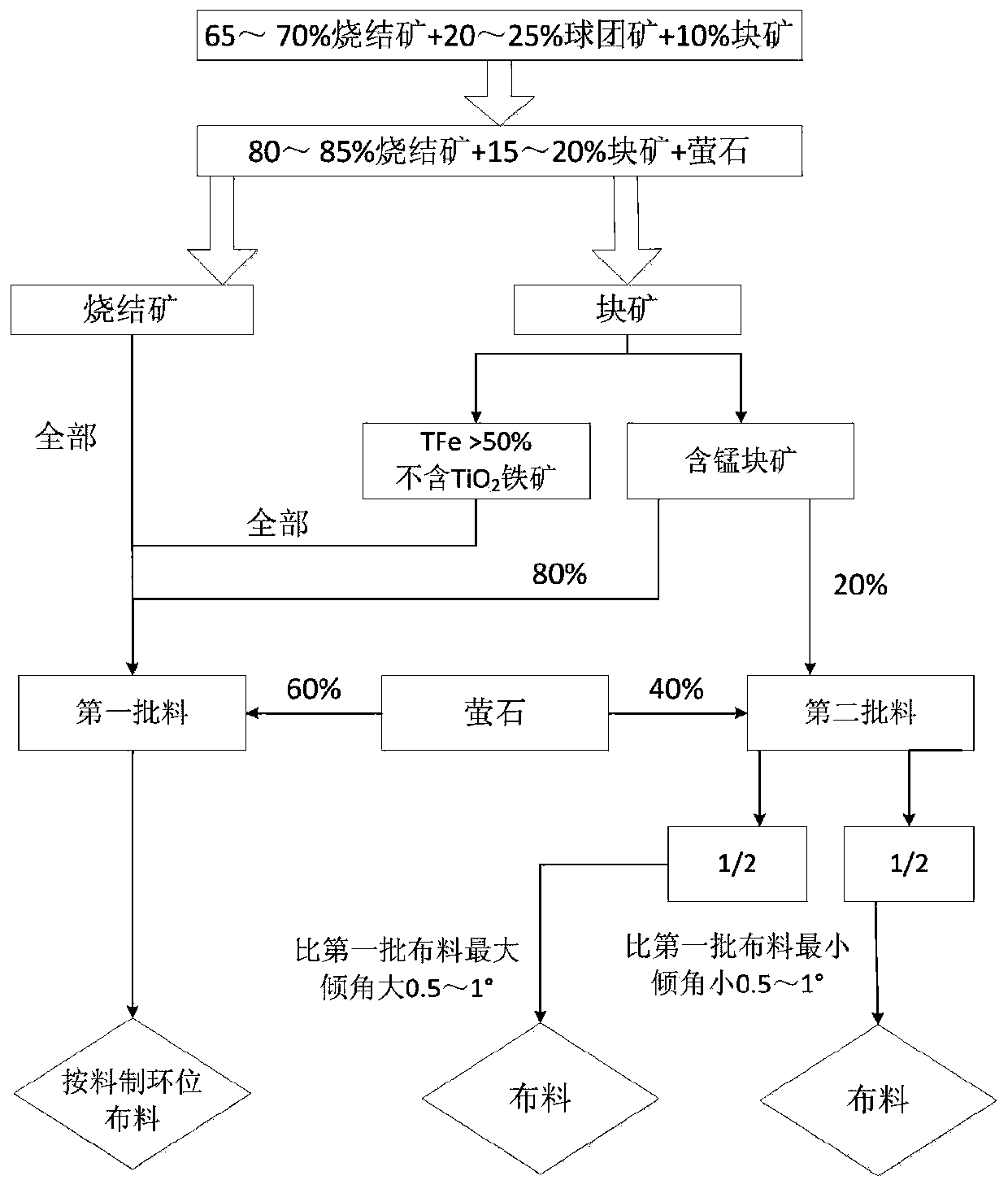

[0027] Ore distribution adjustment: stop using high TiO 2 content of vanadium-titanium pellets, the mass ratio of vanadium-titanium sintered ore is increased to 80% to 85%, and the mass ratio of lump ore is increased to 15% to 20%. The lump ore is divided into two parts, one part does not contain TiO 2 And the iron ore with an iron grade ≥ 50% is a part of manganese-containing lump ore;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com