A Method for Adjusting Furnace Charge Structure Before Ironmaking Blast Furnace Shutdown

A technology for structural adjustment and iron-making blast furnace, which is applied in the field of iron ore blast furnace smelting. It can solve the problems affecting the recovery process of furnace conditions and index optimization, the slow recovery of hearth temperature, and the increase of iron-bonded matter, so as to shorten the recovery of furnace conditions. Time, reduce the difficulty of tapping, improve the effect of fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

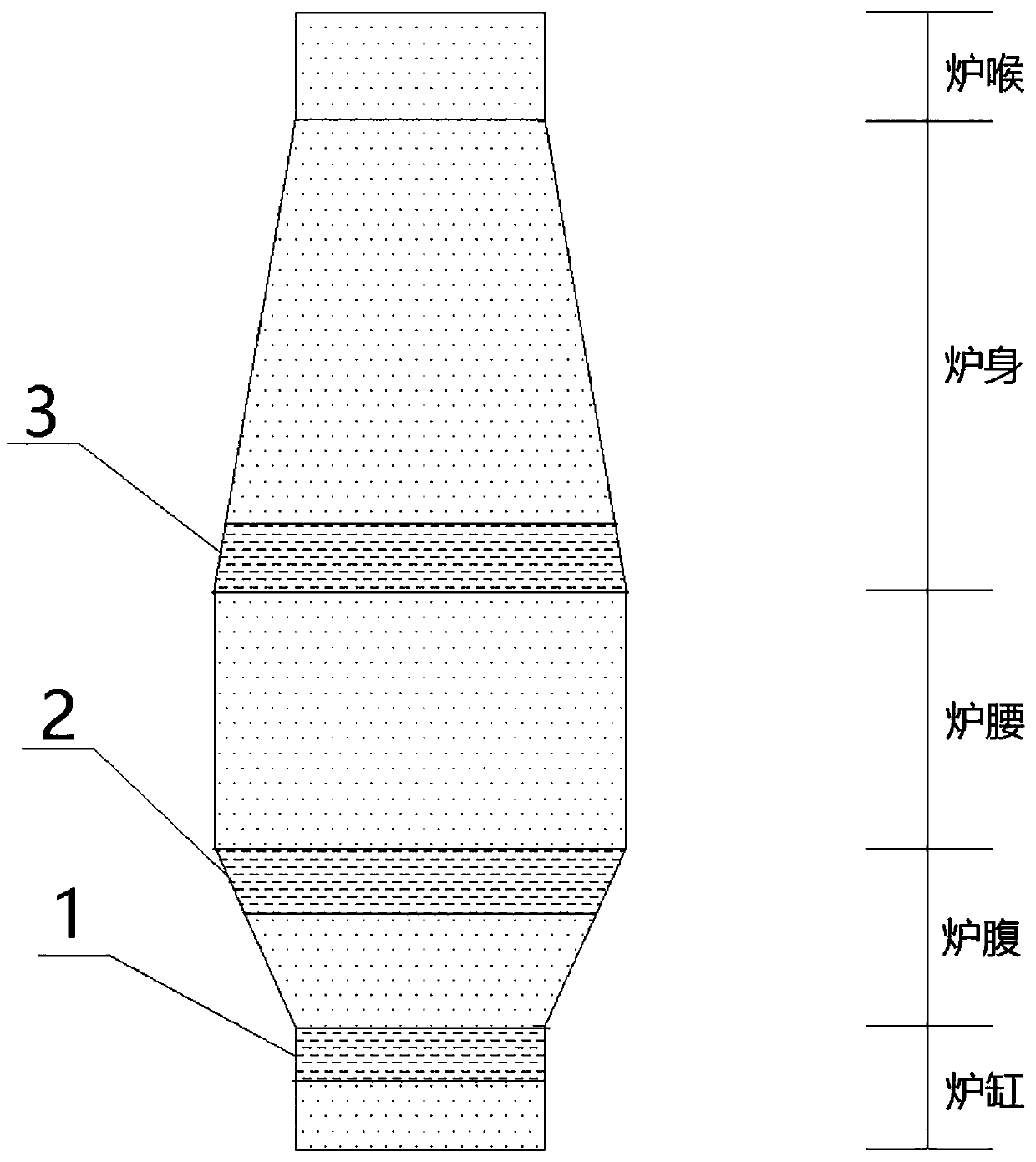

[0021] Effective volume 2500m 3 Before shutting down the blast furnace, adjust the charge structure, the specific steps are as follows:

[0022] 1) Calculation of net coke layer parameters: Before the blast furnace shuts down, pre-position the blast furnace hearth, the upper part of the bosh and the lower part of the furnace body respectively, and determine the relationship between the blast furnace throat material surface and the blast furnace hearth, upper part of the furnace belly and lower part of the furnace body respectively. Volume V between pre-positioning 预1 =2440.53m 3 、 V 预2 =1764.16m 3 、 V 预3 =1514.91m 3 , to determine the air volume Q of coke consumption per ton of blast furnace 焦 =2650m 3 / t, the quality G of coke in each batch of normal material 焦 =13.5t / batch, the volume V of each batch of normal material 料 =48.9m 3 / batch, blast furnace hourly air volume Q 风 =270000m 3 / h, through the formula H=(V 预 *Q 焦 *G 焦 ) ÷ (V 料 *Q 风 ), the time taken ...

Embodiment 2

[0030] Effective volume 1800m 3 Before shutting down the blast furnace, adjust the charge structure, the specific steps are as follows:

[0031] 1) Calculation of net coke layer parameters: Before the blast furnace shuts down, pre-position the blast furnace hearth, upper bosh, and lower shaft Volume V between pre-positioning 预1 =1629.39m 3 、 V 预2 =1230.28m 3 、 V 预3 =1053.03m 3 , to determine the air volume Q of coke consumption per ton of blast furnace 焦 =2700m 3 / t, the quality G of coke in each batch of normal material 焦 =9.8t / batch, the volume V of each batch of normal material 料 =35m 3 / batch, blast furnace hourly air volume Q 风 =210000m 3 / h, through the formula H=(V 预 *Q 焦 *G 焦 ) ÷ (V 料 *Q 风 ), the time taken for the first net coke expected layer 1 to be lowered from the blast furnace throat material level to the pre-positioning of the blast furnace hearth is H 1 H 2 H 3 =3.8h;

[0032] 2) Setting process of net coke prediction layer: H before blas...

Embodiment 3

[0039] Effective volume 450m 3 Before shutting down the blast furnace, adjust the charge structure, the specific steps are as follows:

[0040] 1) Calculation of net coke layer parameters: Before the blast furnace shuts down, pre-position the blast furnace hearth, the upper part of the bosh and the lower part of the furnace body respectively, and determine the relationship between the blast furnace throat material surface and the blast furnace hearth, upper part of the furnace belly and lower part of the furnace body respectively. Volume V between pre-positioning 预1 =417.31m 3 、 V 预2 =300.32 m 3 、 V 预3 =245.11m 3 , to determine the air volume Q of coke consumption per ton of blast furnace 焦 =2800m 3 / t, the quality G of coke in each batch of normal material 焦 =4.5t / batch, the volume V of each batch of normal material 料 =16.2m 3 / batch, blast furnace hourly air volume Q 风 =72000m 3 / h, through the formula H=(V 预 *Q 焦 *G 焦 ) ÷ (V 料 *Q 风 ), the time taken for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com