A blast furnace smelting method based on high theoretical combustion temperature and low fuel ratio

A theoretical combustion temperature and blast furnace smelting technology, applied in the field of blast furnace smelting, can solve the problems of blast furnace utilization coefficient and low comprehensive fuel ratio, and achieve the effects of increasing output, improving stability and reducing Si content in pig iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

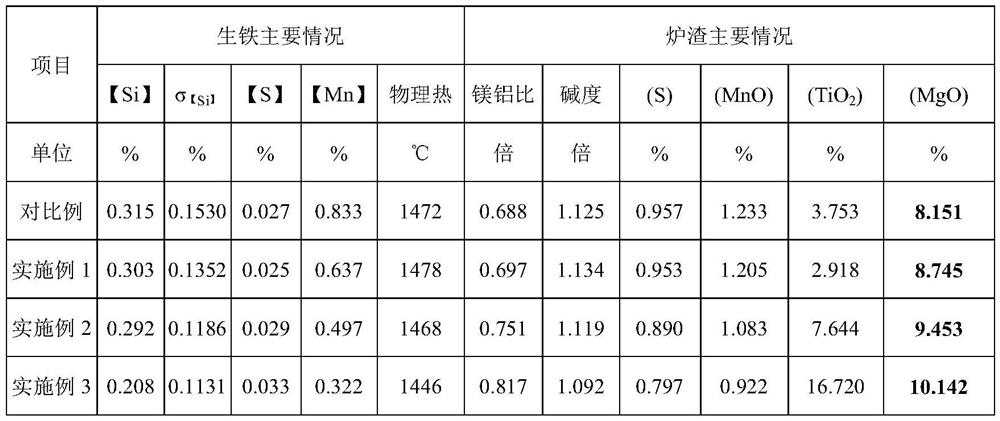

Examples

Embodiment 1

[0036] The blast furnace smelting method based on the high theoretical combustion temperature and low fuel ratio of the present embodiment goes through the following steps:

[0037] A. The ore with the following mass ratio:

[0038] High alkalinity sinter 67%, small particle size high alkalinity sinter 1%, high silicic acid oxidizing pellets 27%, vanadium titanium pellets 0%, natural lump ore 5%, the sum of the above minerals is 100% , and coke with higher ash and sulfur content are sent into the blast furnace according to the coke load of 4.17.

[0039] The coke in this example has a CRI65%.

[0040] The chemical composition of high alkalinity sinter and small particle size sinter is: TFe52.88%, SiO 2 5.40%, CaO12.720%, MgO2.74%, TiO 2 0.364%, S 0.044%, Al 2 o 3 2.095%, MnO0.960%, FeO7.56%. The main physical properties of the sintered ore are: the ISO drum index is 82.0%, and the average particle size is 28 mm; the average particle size of the small-sized sintered or...

Embodiment 2

[0051] The blast furnace smelting method based on the high theoretical combustion temperature and low fuel ratio of the present embodiment goes through the following steps:

[0052] A. The ore with the following mass ratio:

[0053]High alkalinity sinter 64%, small particle size high alkalinity sinter 3%, high silicic acid oxidizing pellets 16%, vanadium titanium pellets 15%, natural lump ore 2%, the sum is 100%, and relatively Coke with high ash and sulfur content is sent into the blast furnace according to the coke load of 4.14.

[0054] The chemical composition of high alkalinity sinter and small particle size sinter is: TFe53.01%, SiO 2 5.532%, CaO12.204%, MgO2.827%, TiO 2 0.801%, S 0.050%, Al 2 o 3 2.107%, MnO0.7510%, FeO7.921%. The main physical properties of the sintered ore are: the ISO drum index is 81.6%, and the average particle size is 26 mm; the average particle size of the small-sized sintered ore is 7 mm.

[0055] The chemical composition of high silici...

Embodiment 3

[0064] The blast furnace smelting method based on the high theoretical combustion temperature and low fuel ratio of the present embodiment goes through the following steps:

[0065] A. The ore with the following mass ratio:

[0066] High alkalinity sinter 60%, small particle size high alkalinity sinter 4%, high silicic acid oxidizing pellets 0%, vanadium titanium pellets 36%, natural lump ore 0%, the sum of the above is 100%, and Coke with higher ash and sulfur content is sent into the blast furnace according to the coke load of 4.17.

[0067] The chemical composition of high alkalinity sinter and small particle size sinter is: TFe52.05%, SiO 2 5.850%, CaO11.86%, MgO3.03%, TiO 2 1.973%, S 0.066%, Al 2 o 3 2.18%, MnO0.45%, FeO7.87%. The main physical properties of the sintered ore are: the ISO drum index is 81.0%, and the average particle size is 26 mm; the average particle size of the small-sized sintered ore is 6 mm.

[0068] The chemical composition of vanadium tita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com