Patents

Literature

218results about How to "Avoid liquidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

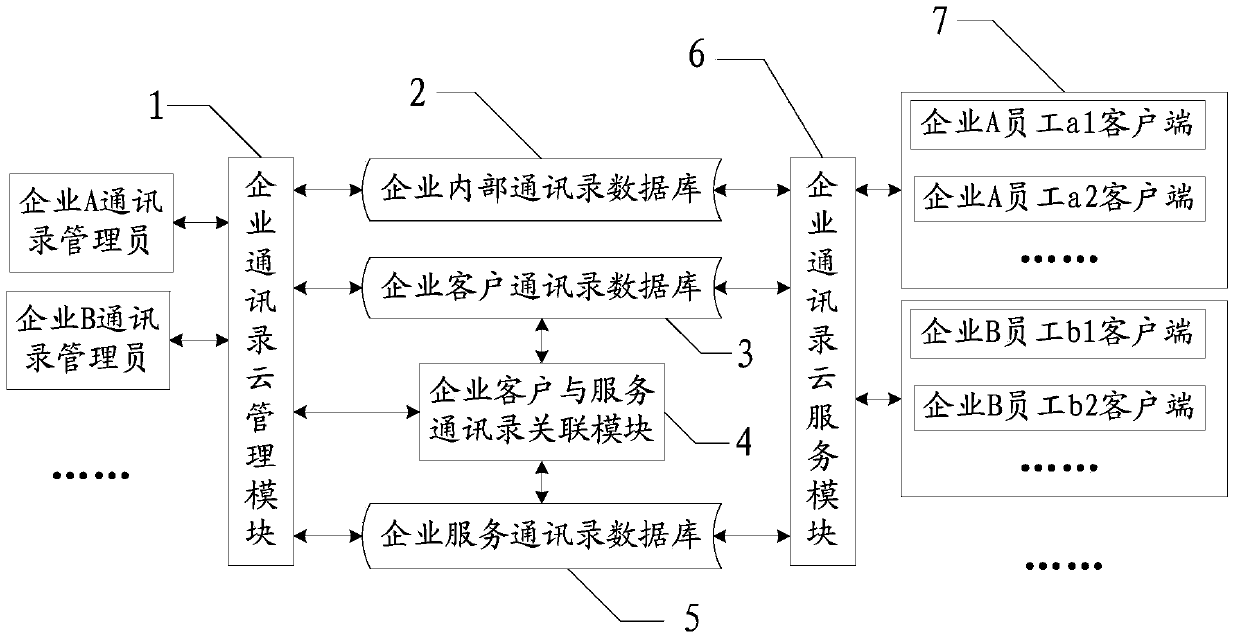

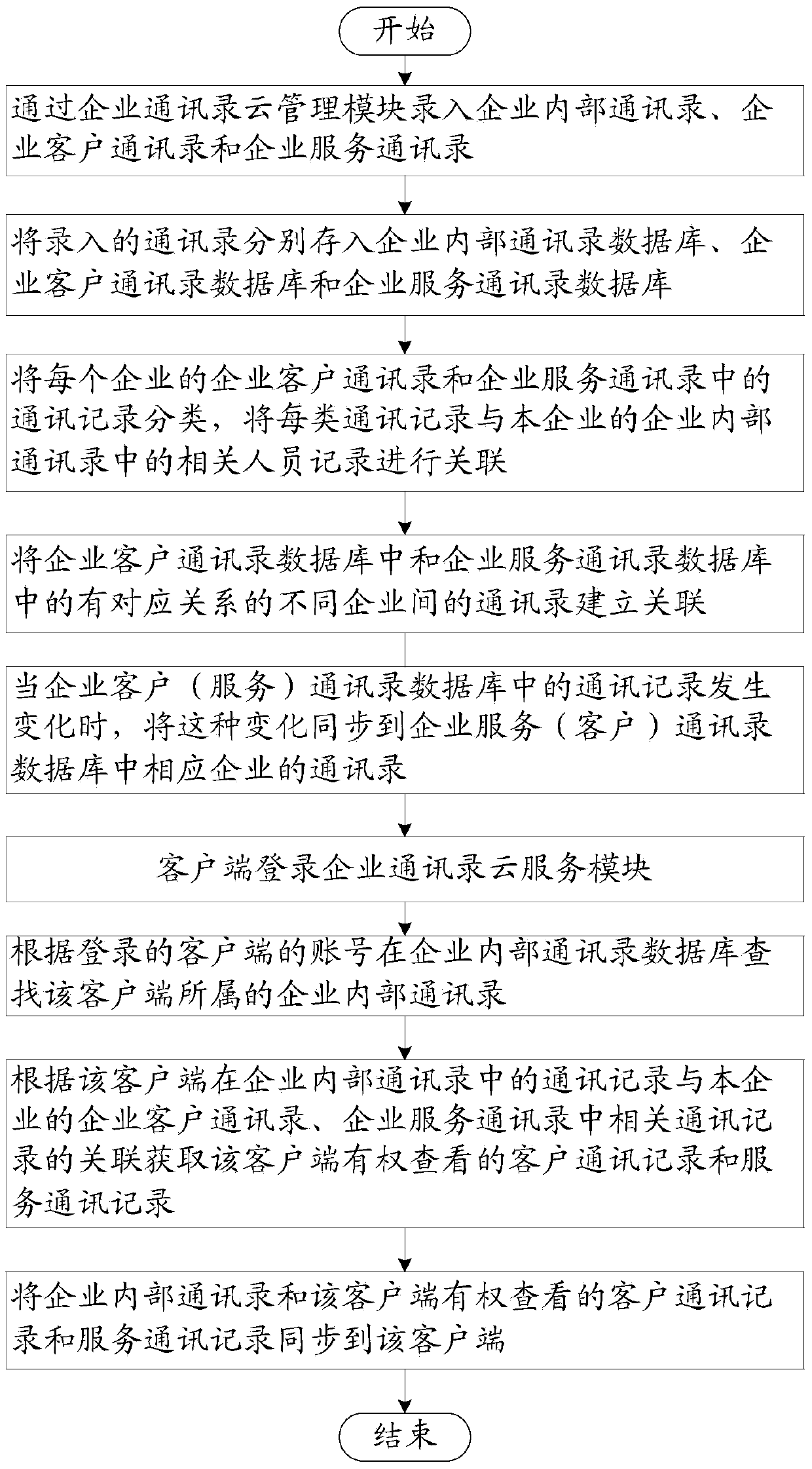

Method and system for realizing automatic correlation of multiple enterprises and multiple contact lists based on cloud computation

ActiveCN103475712AAvoid liquidityFind quicklySubstation equipmentTransmissionEnterprise servicesClient-side

The invention relates to a method and system for realizing automatic correlation of multiple enterprises and multiple contact lists based on cloud computation. The system comprises an enterprise contact list cloud management module, an enterprise internal contact list database, an enterprise client contact list database, an enterprise service contact list database, an enterprise client and service contact list correlation module, an enterprise contact list cloud service module and a plurality of converged communication client sides. According to the method and system, cloud computation, the mobile internet and the converged communication client sides are used for realizing the purpose of providing a contact list service for the enterprises, the enterprise contact list cloud management module is used for conducting classified management on contact lists of each enterprise, the enterprise client and service contact list correlation module is used for realizing the purpose of establishing correlation between contact lists of different enterprises, and the enterprise contact list cloud service module is used for providing a contact list service for all the converged communication client sides. When the contact lists of a certain enterprise change, the other related enterprises can found out the changes timely, and corresponding contact persons can be found quickly, accurately and conveniently.

Owner:北京思特奇信息技术股份有限公司

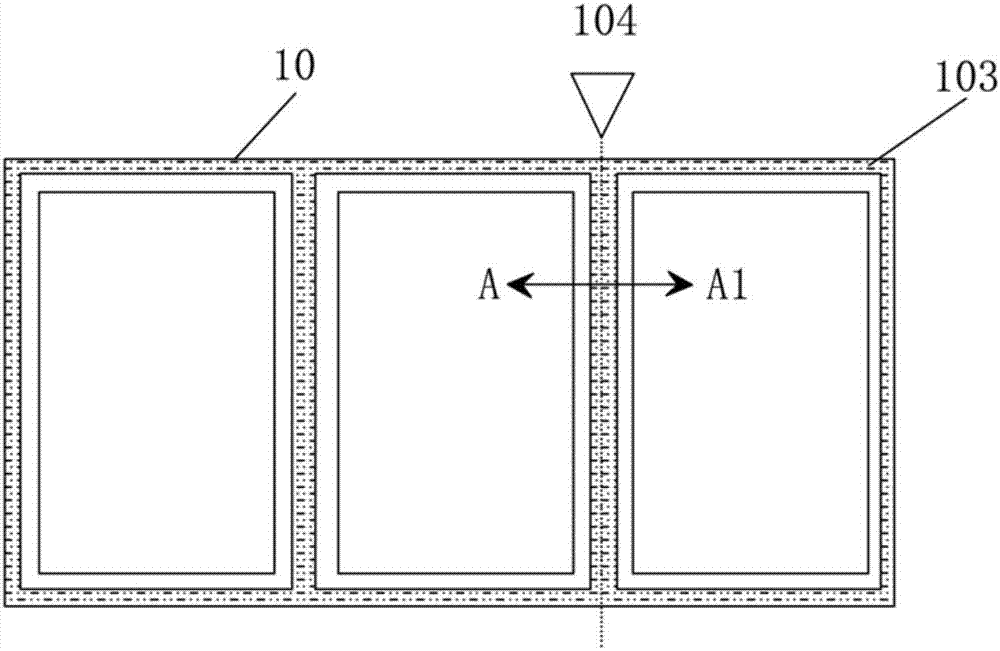

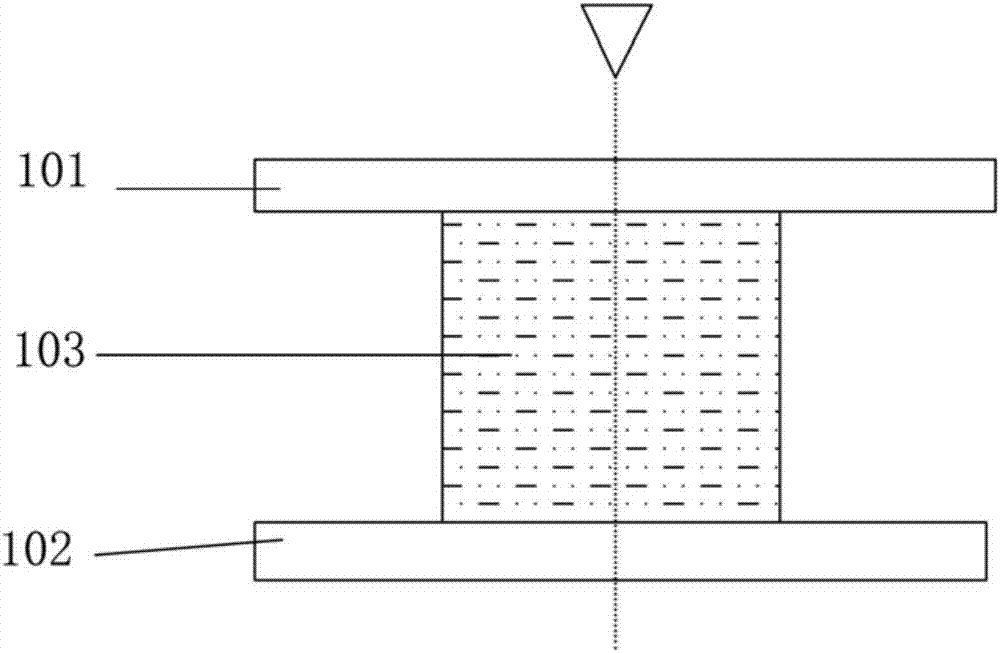

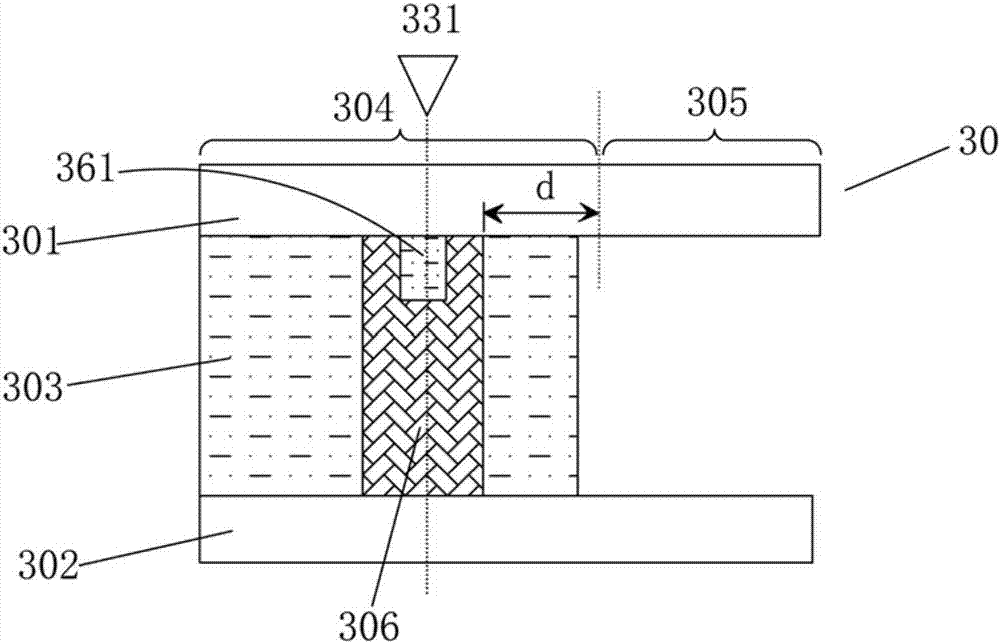

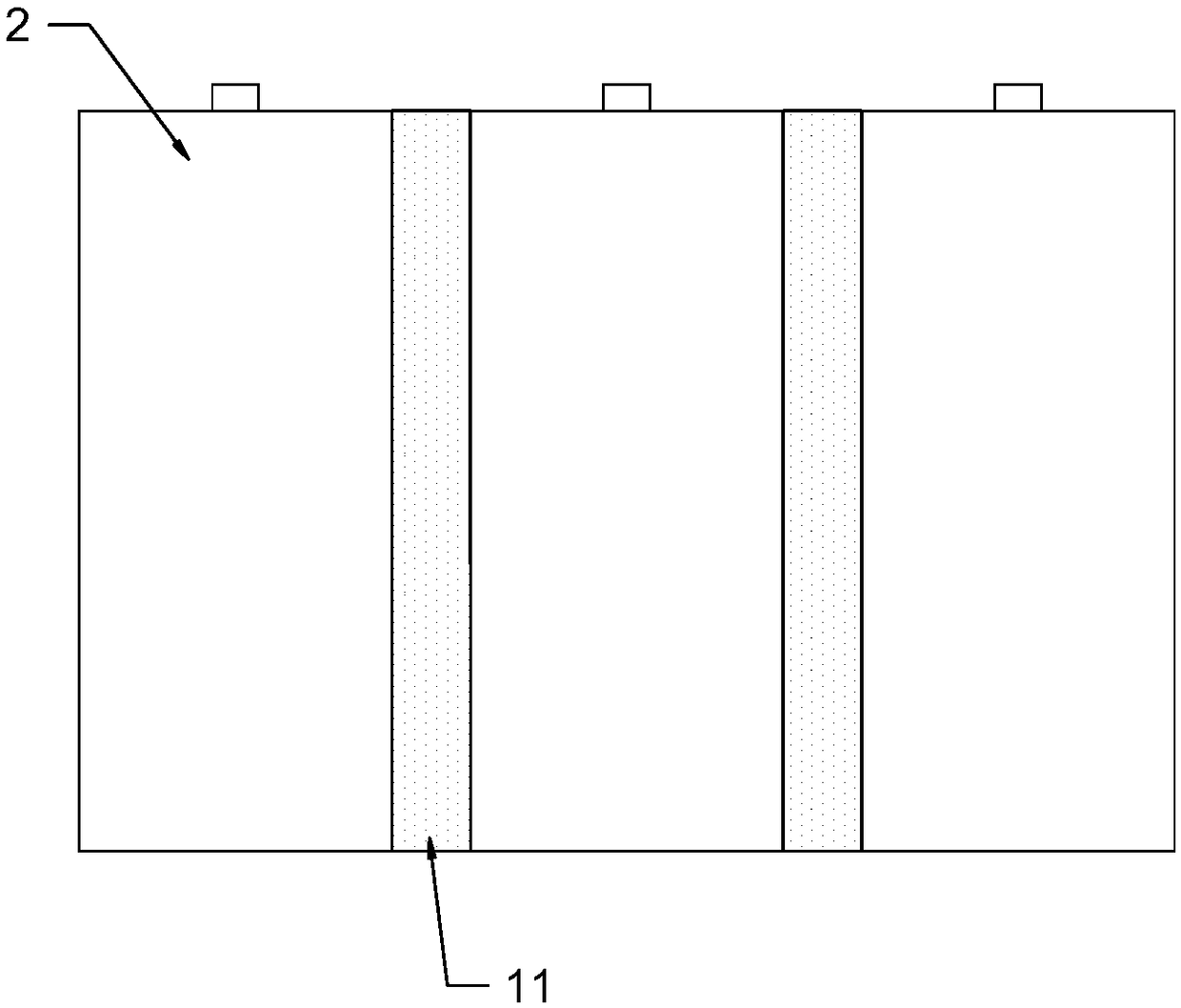

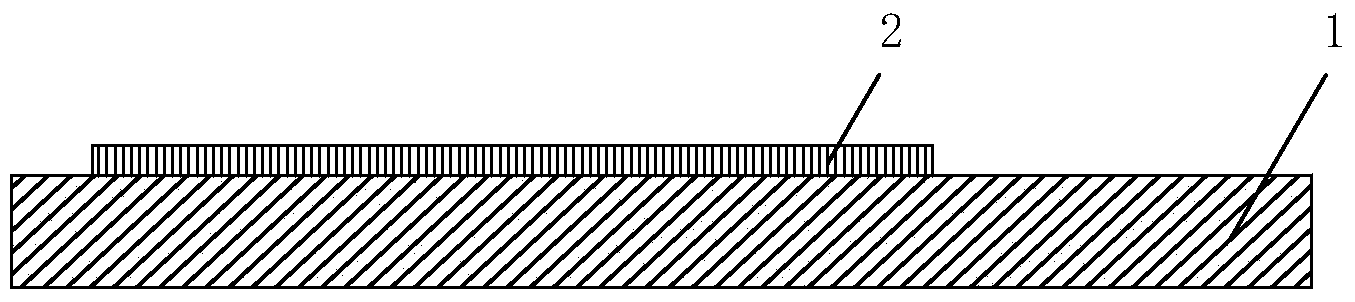

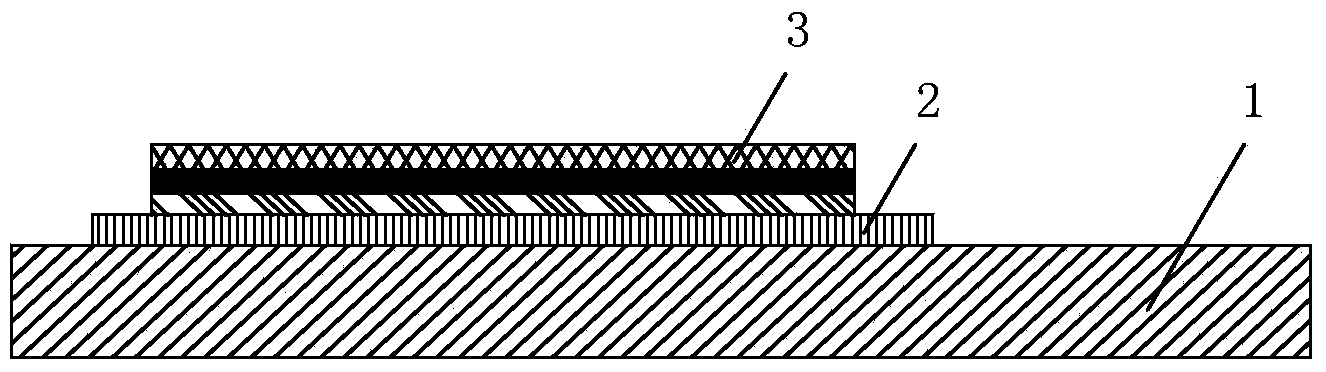

Display panel

ActiveCN106990620AReduce widthPaste effect is goodNon-linear opticsRetaining wallElectrical and Electronics engineering

The invention provides a display panel. The display panel includes a first substrate, a second substrate and frame glue located between the first substrate and the second substrate and further includes a display region and a non-display region, and the frame glue is located in the non-display region and surrounds the display region; the frame glue is internally provided with at least one first retaining wall, the first retaining walls at least partially make contact with the first substrate and the second substrate, the end portions, near the first substrate, of the first retaining walls are provided with grooves with openings facing the first substrate, and first trenches are formed. By forming the first trenches in the first retaining walls, the trench regions are filled in the frame glue coating process, the adhesion between the first retaining walls and the substrates corresponding to the first trenches is improved, the width of the frame glue in the non-display region is reduced, and the narrow bezel design is easily achieved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

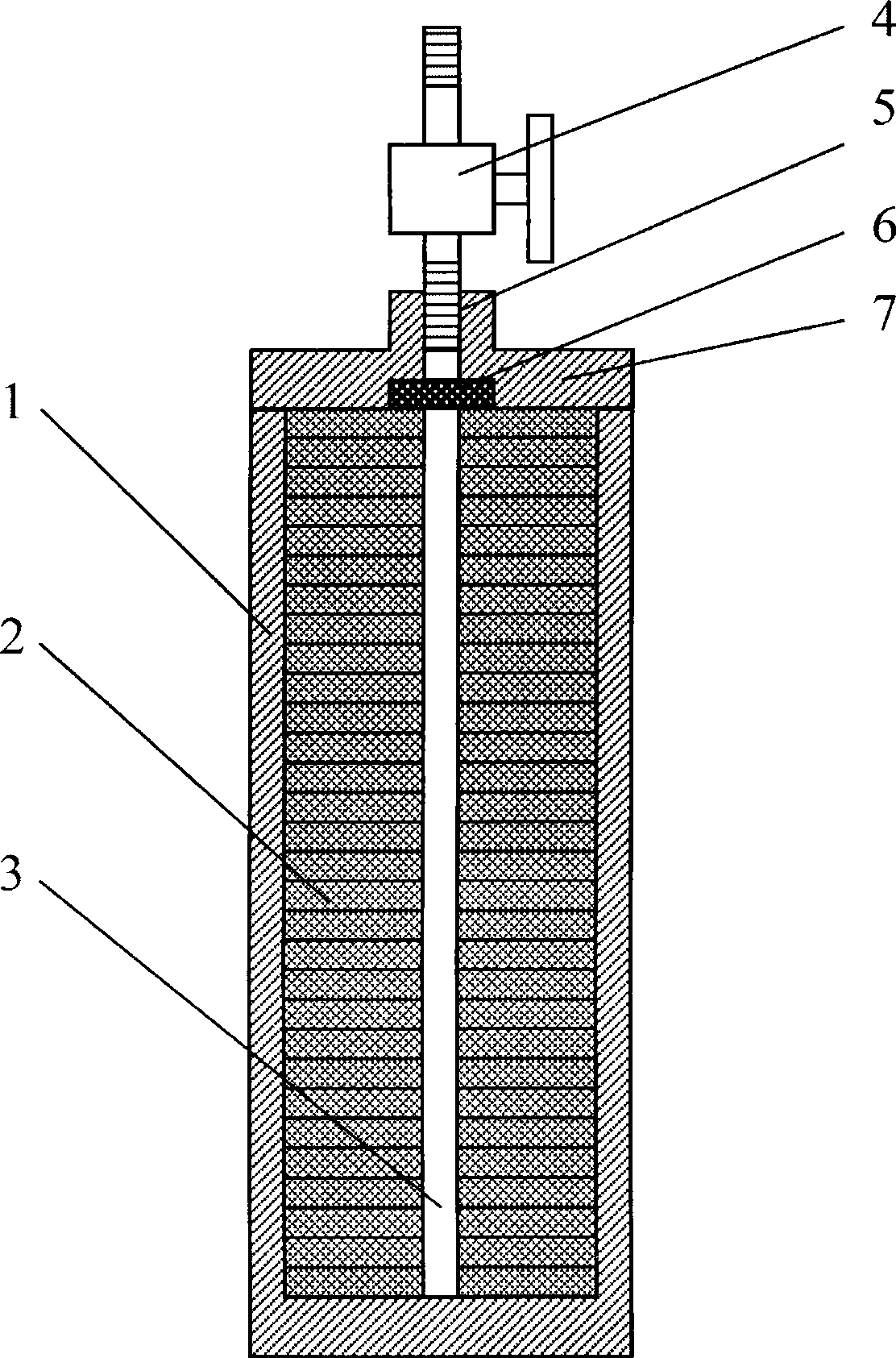

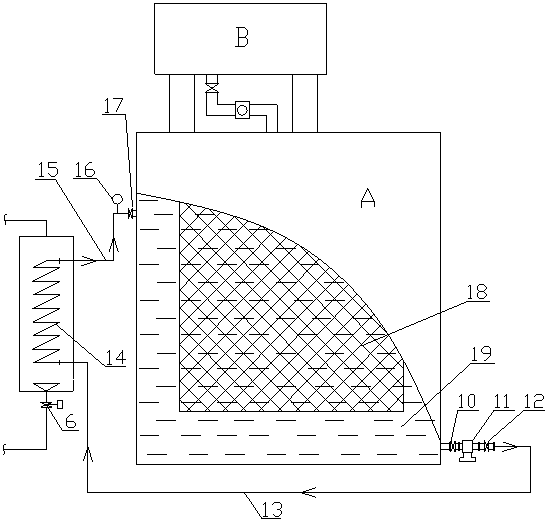

Hydrogen storing apparatus of metal hydrides and manufacturing method thereof

ActiveCN101413624AAvoid deformationAvoid destructionFixed capacity gas holdersHeat transmissionAdhesive

The invention relates to a metal hydride hydrogen storage device and a preparation method thereof; wherein, the device comprises a shell which is filled in superposed hydrogen-storage material sheet which consists of a spumescent metal substrate which absorbs no hydrogen and mixture of hydrogen-storage alloy powder and adhesive which are filled in the gap of the spumescent metal substrate; the hydrogen-storage material sheet is provided with a central hole which is coincident to the central hole of the shell head and is connected with the central hole of the head by a filter sheet which is embedded in the head; the central hole of the head is fixed with a joint pipe which is provided with a valve. The hydrogen storage device can effectively improve the heat transmission performance of the hydrogen storage alloy and hydride powder, effectively prevents the flowing and accumulating of the hydrogen-storage alloy and the hydride, solves the hydrogen absorption expansion problem of the hydrogen storage alloy powder, thus having the advantages of high-efficiency running, safety and reliability and being suitable for the production of meta hydride hydrogen-storage devices applied to various sites.

Owner:ZHEJIANG UNIV

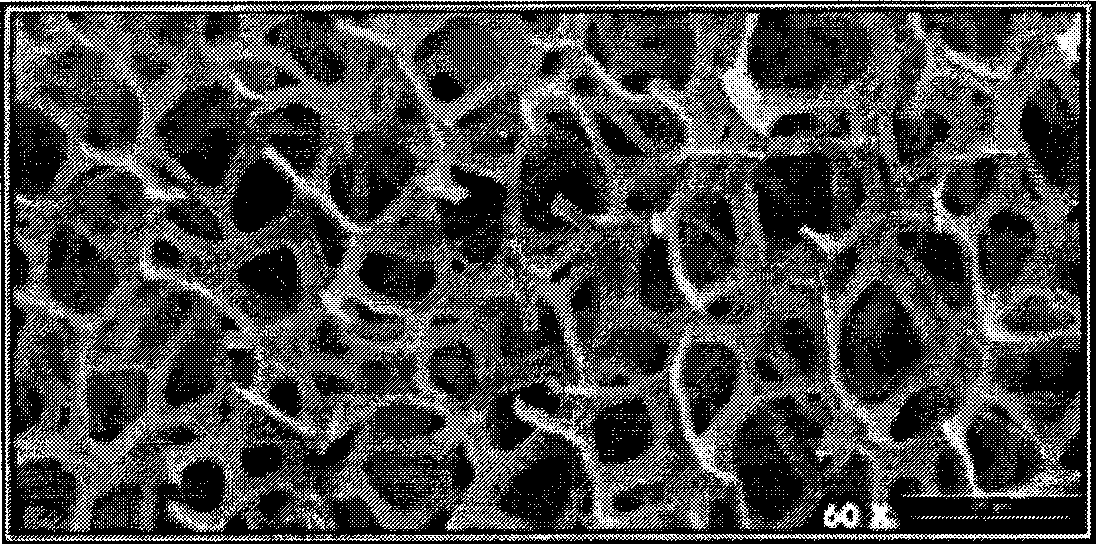

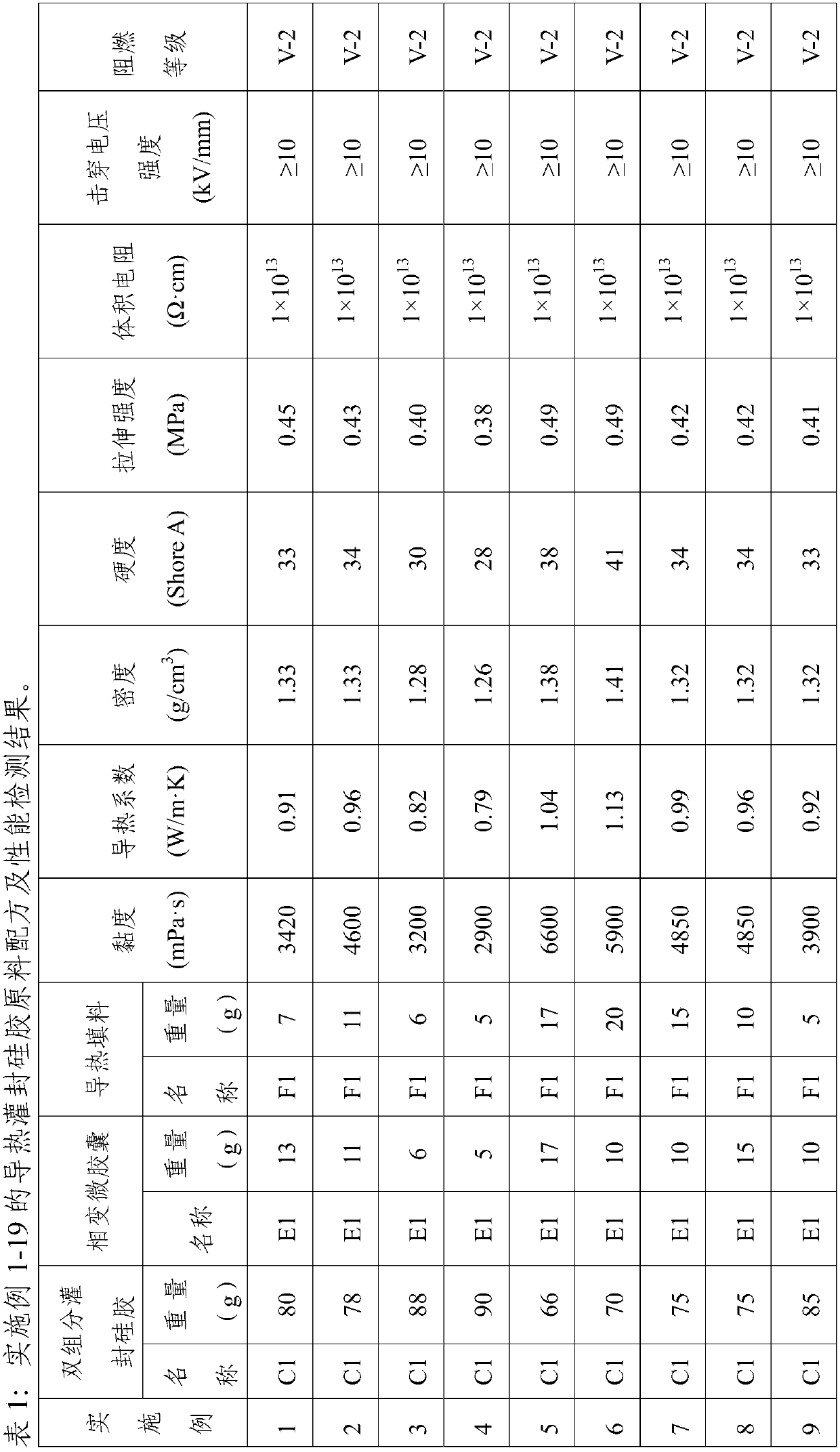

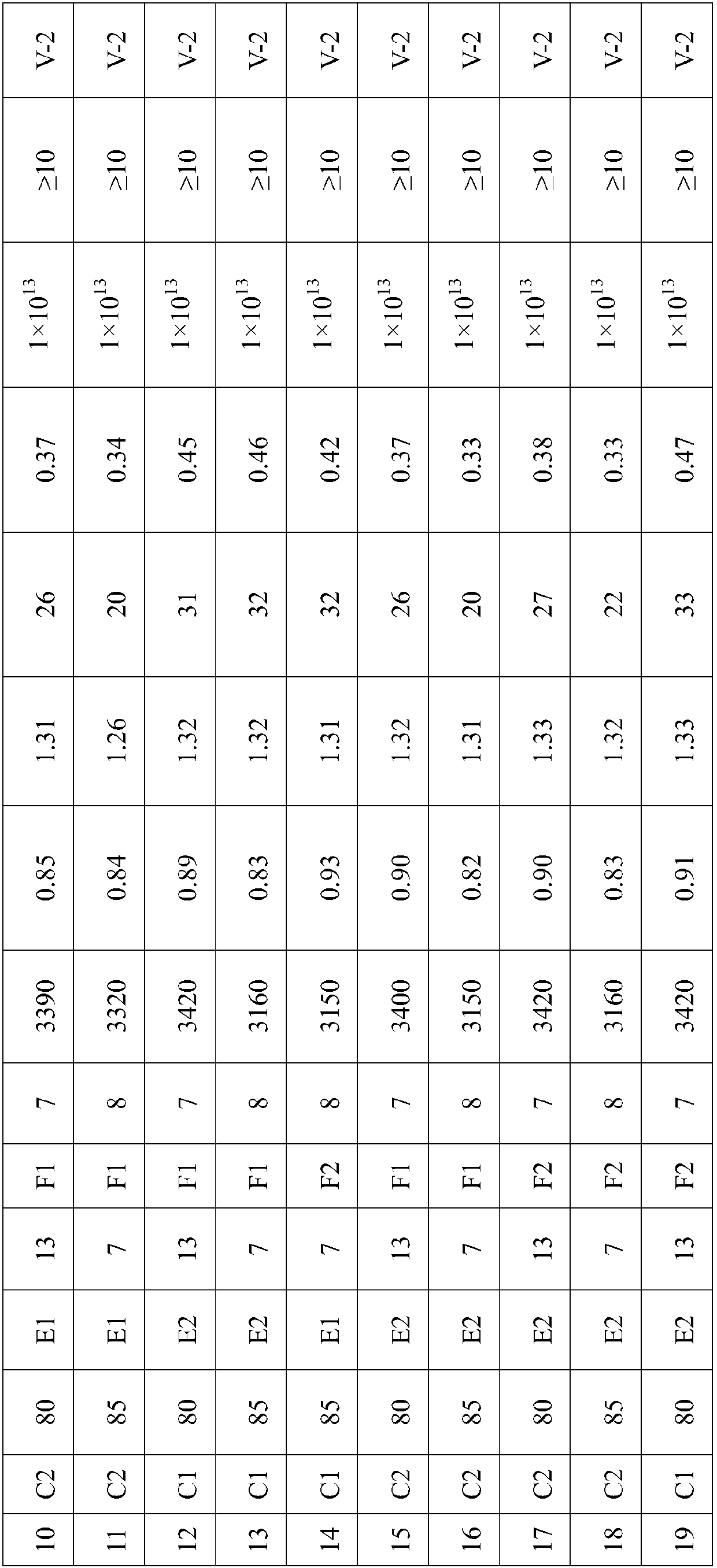

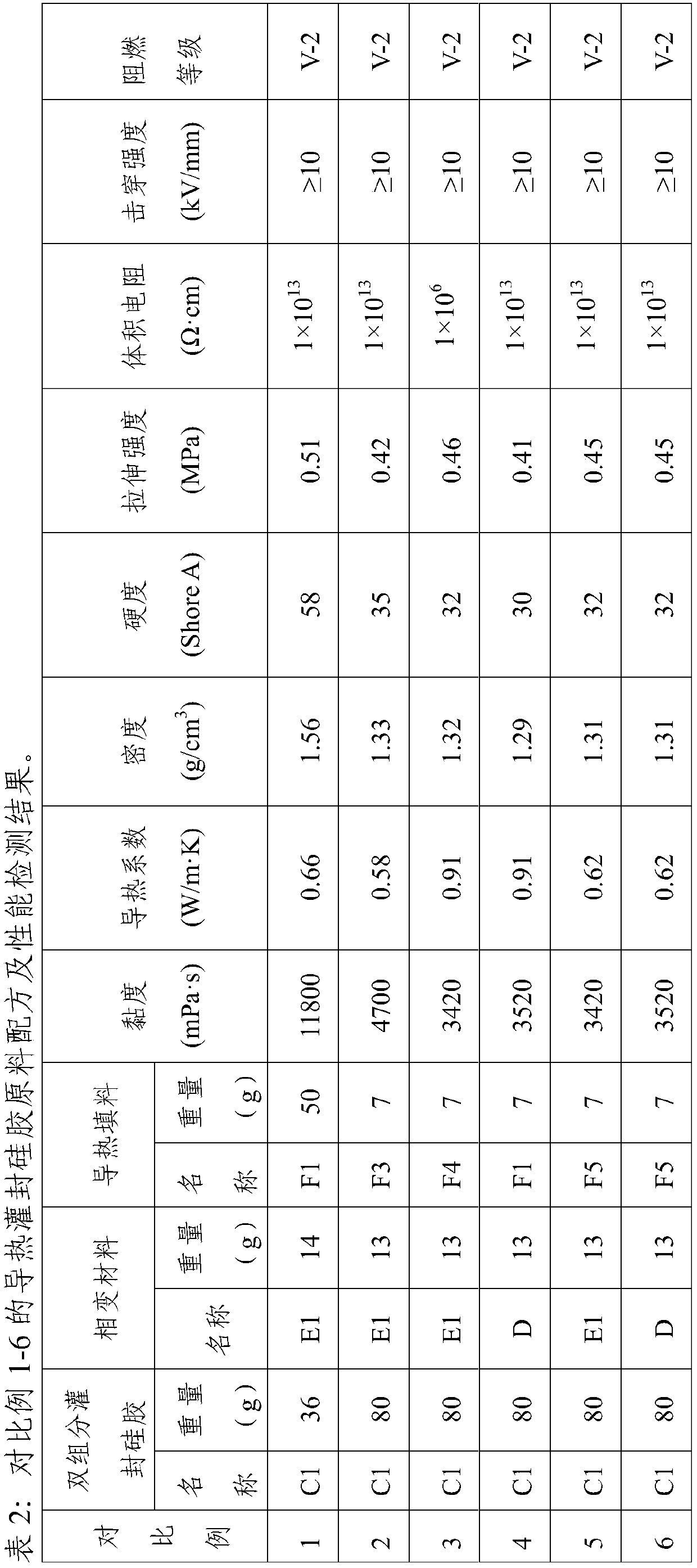

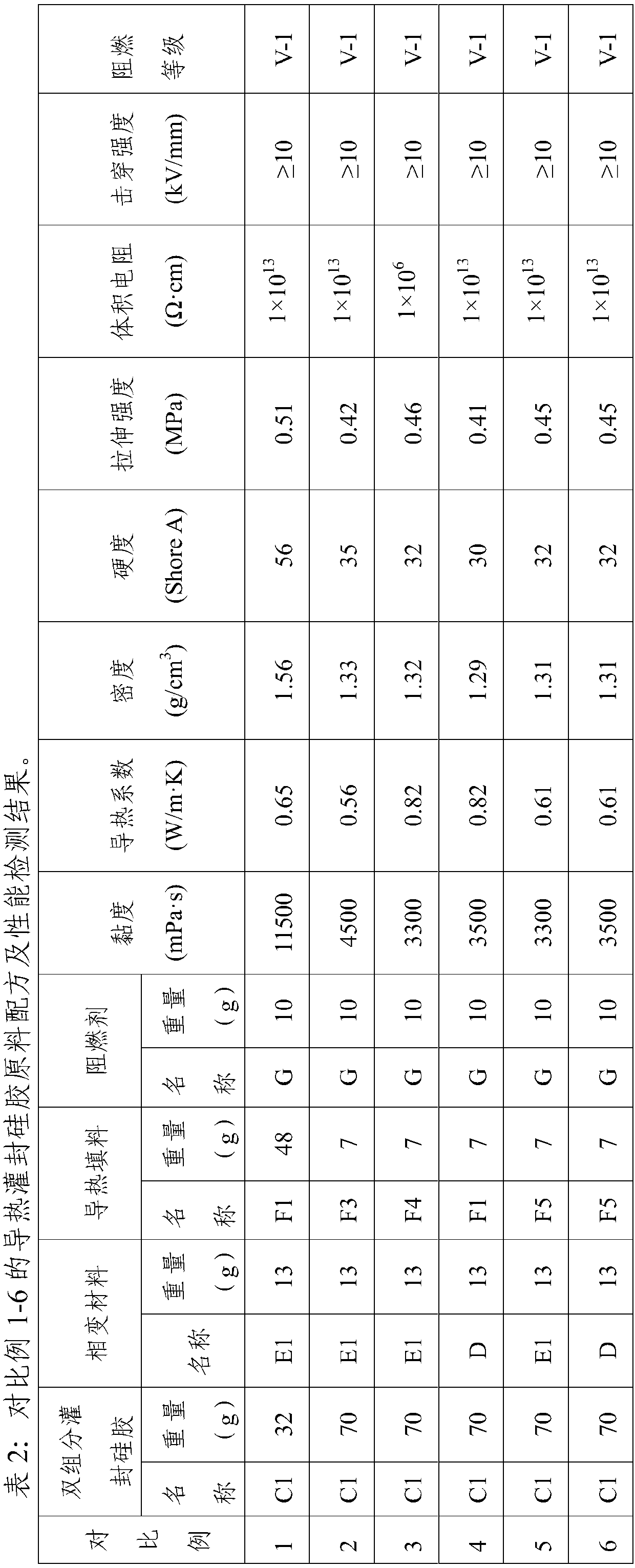

Thermal conduction potting silica gel based on phase-changing microcapsule and preparation method of thermal conduction potting silica gel

ActiveCN107815286AGood dispersionIncrease the amount addedNon-macromolecular adhesive additivesSecondary cellsDispersityTemperature control

The invention relates to thermal conduction potting silica gel based on a phase-changing microcapsule and a preparation method of the thermal conduction potting silica gel. The thermal conduction potting silica gel is prepared from the following components by mass percent: 50 to 90 percent of dual-component potting silica gel, 5 to 25 percent of phase-changing microcapsules and 5 to 25 percent ofsurface-treated thermal conduction filler. The preparation method comprises the following steps: treating the surface of the thermal conduction filler; preparing the thermal conduction composite filler; preparing a component A and a component B in the dual-component potting silica gel; preparing a component A1 and a component B1 in the thermal conduction potting silica gel; and preparing the thermal conduction potting silica gel. According to the preparation method, the surface treatment is performed on the thermal conduction filler in the preparation process, so that the dispersity of the thermal conduction filler in a silica gel matrix is improved, and the thermal conduction performance of the thermal conduction potting silica gel is improved; and by adding the phase-changing microcapsule, the thermal conduction potting silica gel has the heat-storage temperature control performance. The thermal conduction potting silica gel has good thermal conduction performance and heat-storage temperature control performance.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

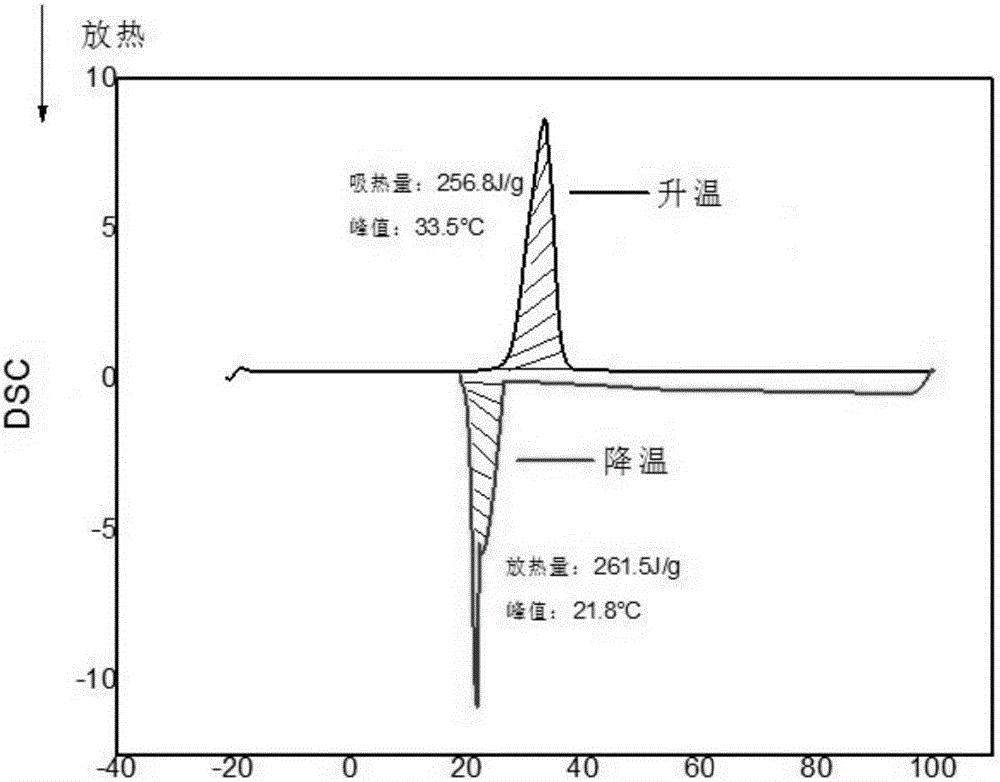

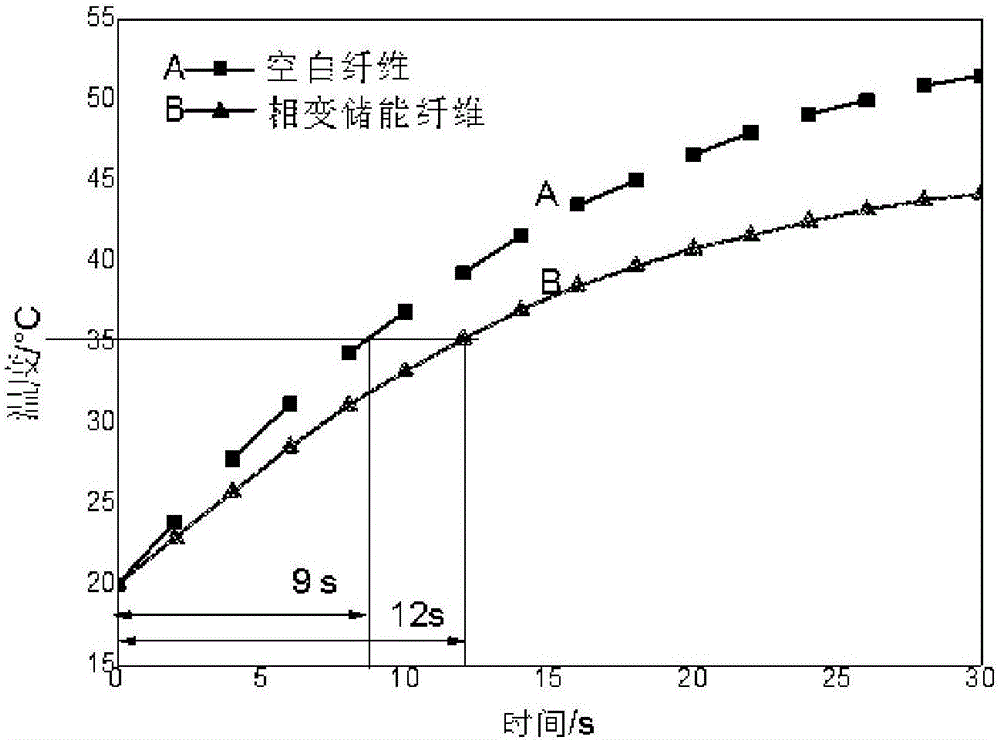

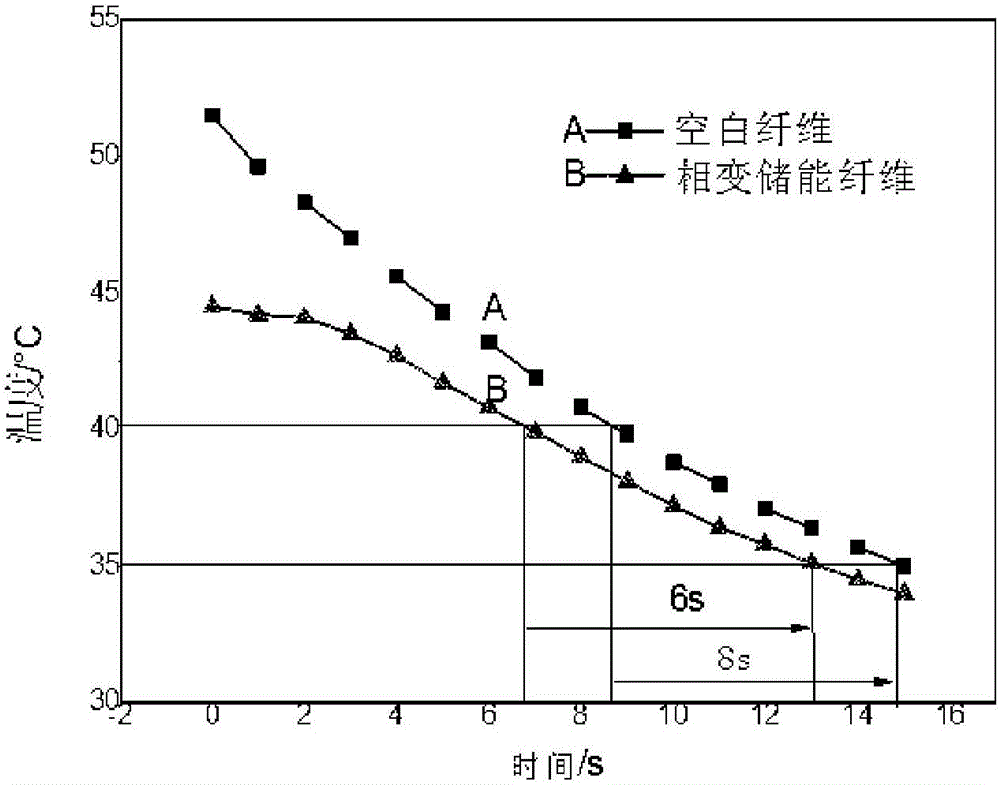

Phase-change energy-storing fiber and preparation method thereof

InactiveCN106801266AIncrease contentAvoid liquidityFilament/thread formingHeat-exchange elementsPhase change enthalpyClay minerals

The invention discloses a phase-change energy-storing fiber. The phase-change energy-storing fiber is of a skin-core structure which comprises a skin layer and a core layer, wherein a skin layer raw material is a thermoplastic polymer; and a core layer raw material is a mixture of the thermoplastic polymer, clay mineral powder and a phase-change material. A preparation method of the phase-change energy-storing fiber comprises the following steps: (1) weighing 2-20 parts of the phase-change material and 5-20 parts of the clay mineral powder in parts by weight, uniformly mixing the weighed phase-change material and clay mineral powder by virtue of ultrasonic oscillation under a vacuum condition, putting the mixture into a vacuum oven so as to obtain a composite phase-change material, and uniformly mixing 60-90 parts of thermoplastic polymer with the prepared composite phase-change material, so as to obtain the core layer raw material; and (2) carrying out melt spinning on the thermoplastic polymer, as skin layer raw material, and the core layer raw material by virtue of a compound spinning machine, so as to obtain the phase-change energy-storing fiber being of the skin-core structure. The preparation method is simple and low in cost, and the prepared phase-change energy-storing fiber has large phase-change enthalpy and a uniform temperature regulation effect.

Owner:WUHAN TEXTILE UNIV

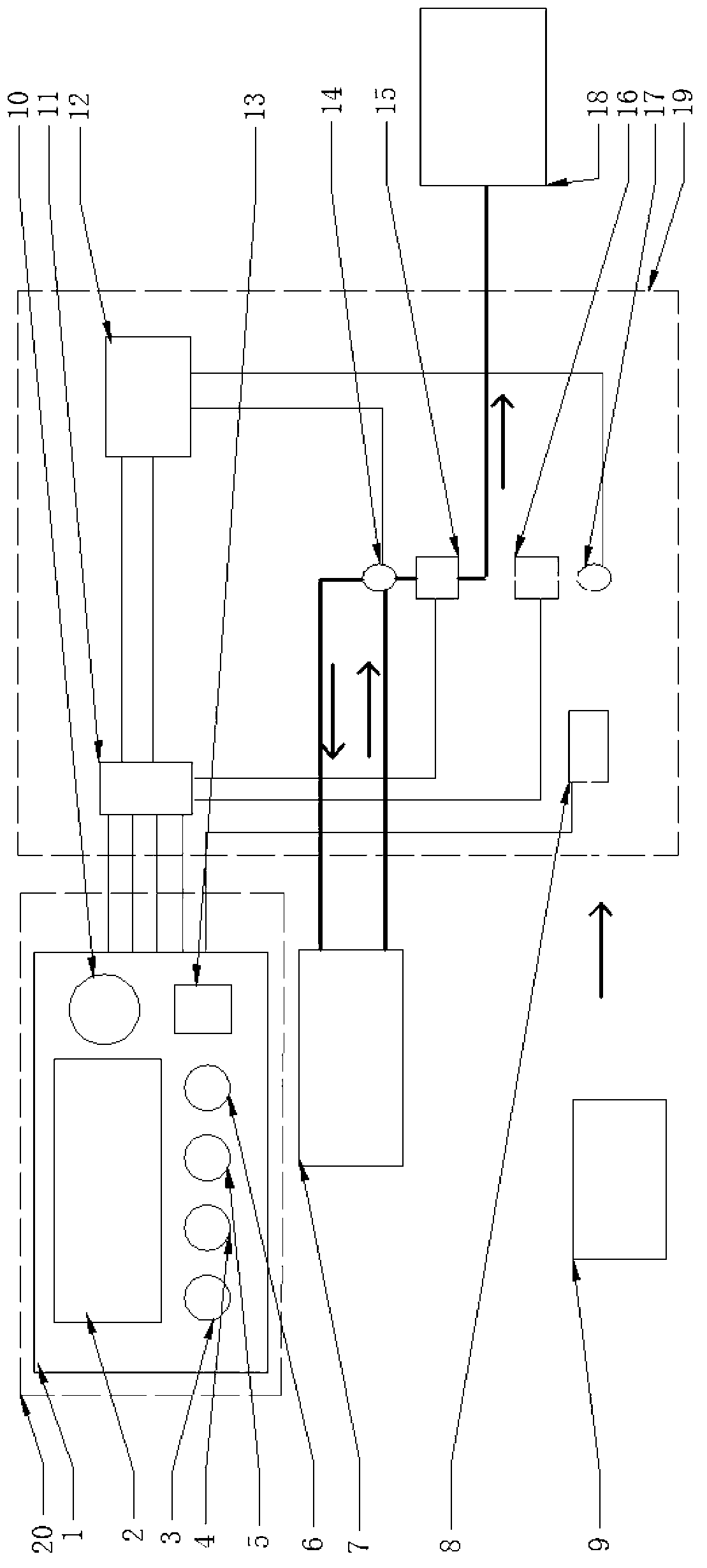

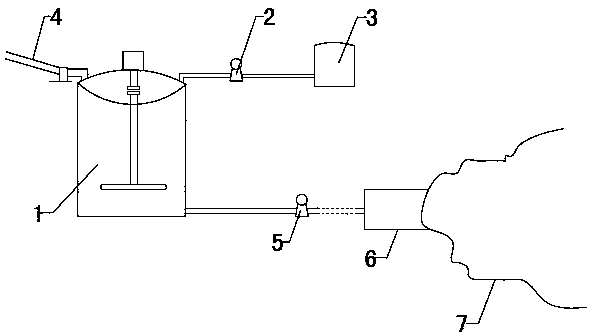

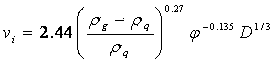

Fracturing pulse sand filling system with ultrahigh flow conductivity and method for operating fracturing pulse sand filling system

The invention relates to a fracturing pulse sand filling system with ultrahigh flow conductivity. The fracturing pulse sand filling system comprises an external control unit, an internal controlled unit, an external fracturing pump truck unit, a sand mixing truck and a fluid storage tank. Fracturing sand-mixed fluid is accommodated in the sand mixing truck, fracturing base fluid is accommodated in the fluid storage tank, the external control unit controls the internal controlled unit, so that the sand-mixed fluid in the sand mixing truck and the base fluid in the fluid storage are alternately pumped into the external fracturing pump truck unit at intervals, and the sand-mixed fluid and the base fluid are finally alternately pumped into underground exploitation cracks at intervals by the external fracturing pump truck unit. The fracturing pulse sand filling system has the advantages that propping agent slugs added with fibers can be injected in a pulse manner under the control of the system, the flow conductivity of the prop cracks is greatly improved, a lag effect due to continuous opening and closing of an existing sand mixing truck is prevented, damage to the sand mixing truck is reduced, and pressure building during propping agent injection can be effectively prevented by the system.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

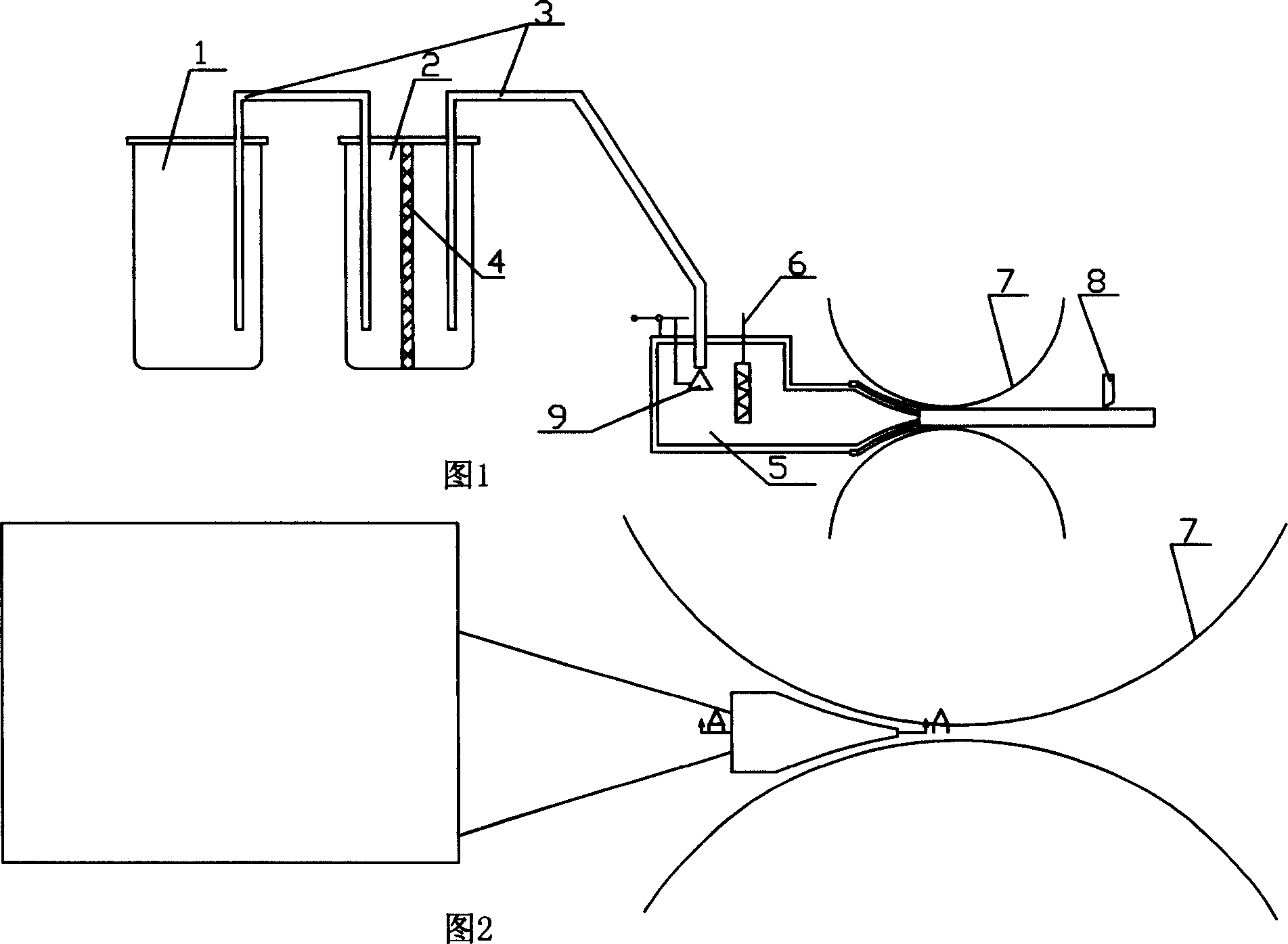

Magnesium alloy twin-roll continuous casting system for manufacturing magnesium alloy plate

A conticasting system with dual Mg-alloy rollers for producing Mg-alloy plate is disclosed. Its technology includes such steps as smelting Mg-alloy, holding temp. delivering to front box with constant temp and level and protecting gas, and flowing in casting-rolling mill. Its apparatus is composed of smelting furnace, temp-keeping heater, delivering system, front box, flowing outlet, casting-rolling mill and shear mechanism. Its advantages are high productivity and high safety.

Owner:FUJIAN HUAMEI NEW TECH DEV

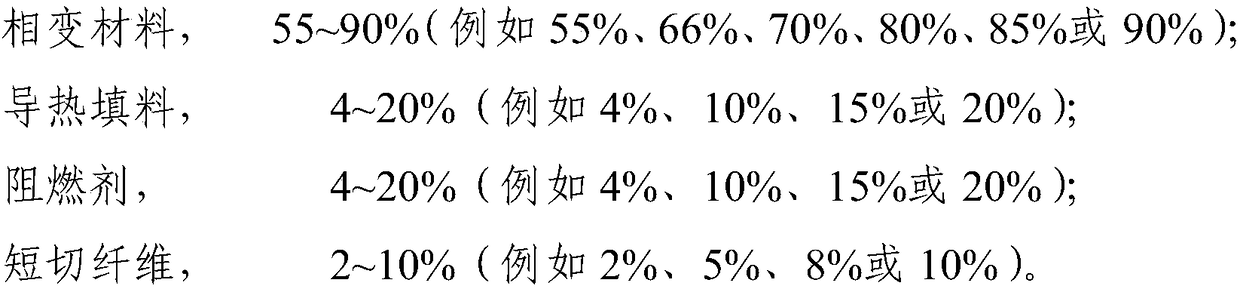

Phase-change-material-based thermal management material, preparation method and applications thereof

ActiveCN108199113AImprove thermal conductivityGood temperature control functionSecondary cellsHeat-exchange elementsFiberPhase-change material

The invention relates to a phase-change-material-based thermal management material, a preparation method and applications thereof, wherein the thermal management material comprises, by mass, 55-90% ofa phase change material, 4-20% of a thermal conduction filler, 4-20% of a flame retardant, and 2-10% of chopped fiber. According to the present invention, by adding an appropriate amount of the chopped fibers, the deformation of the phase change material due to volume expansion or contraction can be effectively prevented, such that the content of the phase change material in the thermal management material can be substantially increased so as to improve the heat storage capacity of the thermal management material and stably regulate and control the temperature.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

A granular composition containing mes

InactiveCN102277238AHigh content of active matter MESImprove liquiditySurface-active detergent compositionsDetergent compounding agentsSulfonateSodium Bentonite

The invention discloses a granular fatty acid methyl ester sulfonate (MES)-containing composite. A method for preparing the granular MES-containing composite comprises the following steps of: mixing the following raw materials including 40 to 90 mass parts of MES, 5 to 60 mass parts of anhydrous sodium sulphate, 0 to 30 mass parts of 4A zeolite, 2 to 20 mass parts of sodium carboxymethyl starch and 0 to 10 mass parts of bentonite uniformly, extruding and granulating under the condition of external protective wind, cooling by dried air at the temperature of between 5 and 30 DEG C to be hardened completely to obtain granules, and sieving by a 10 to 40-mesh screen. The granular MES-containing composite has the characteristics of high content of active matter MES and flowability and small influence on environment, is easy to dissolve, and can be used as the raw materials in many downstream processes.

Owner:杭州迪康生物技术有限公司

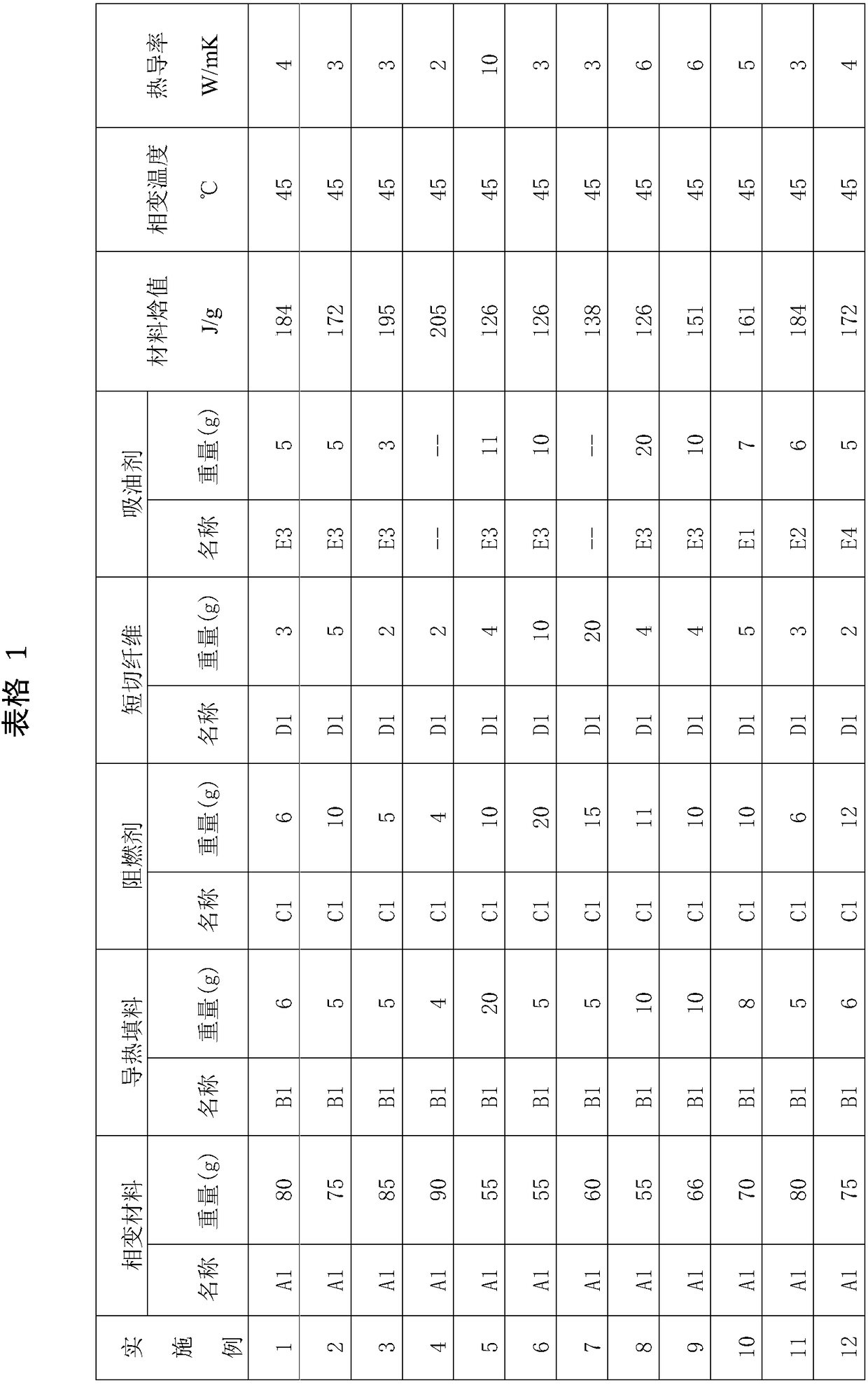

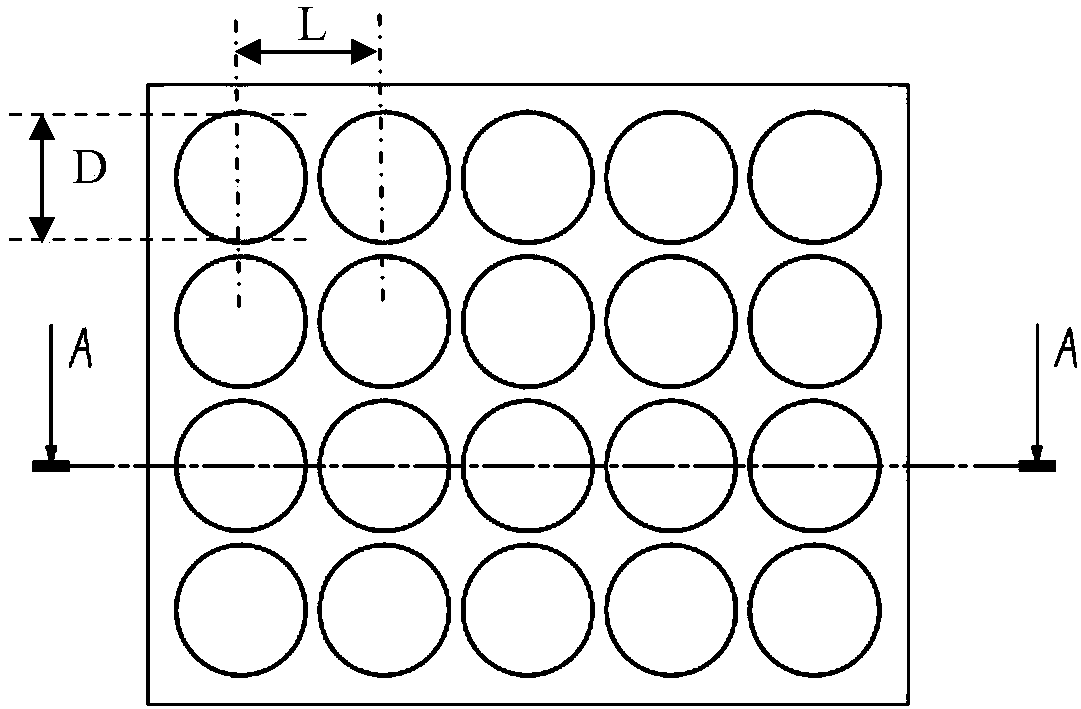

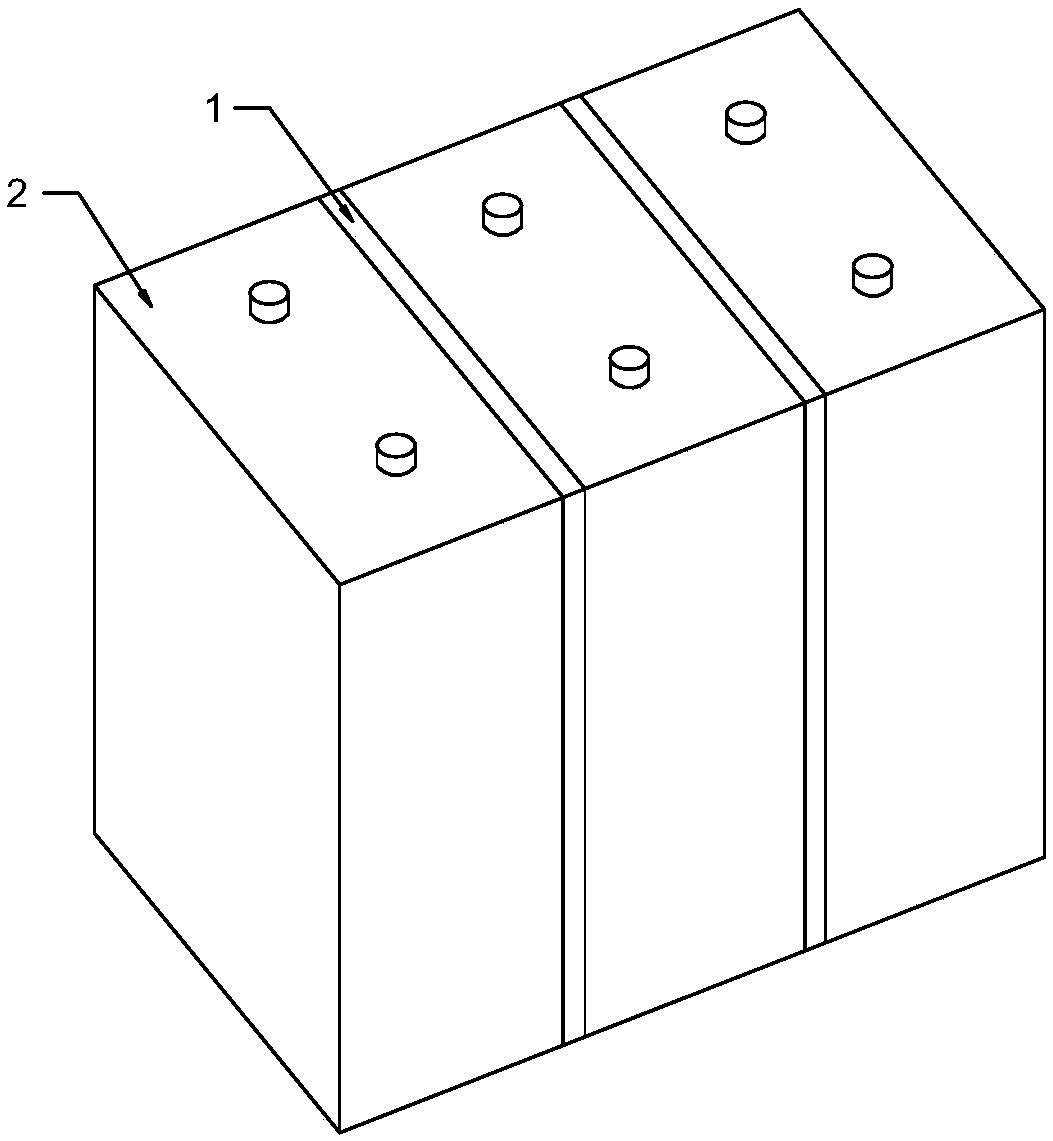

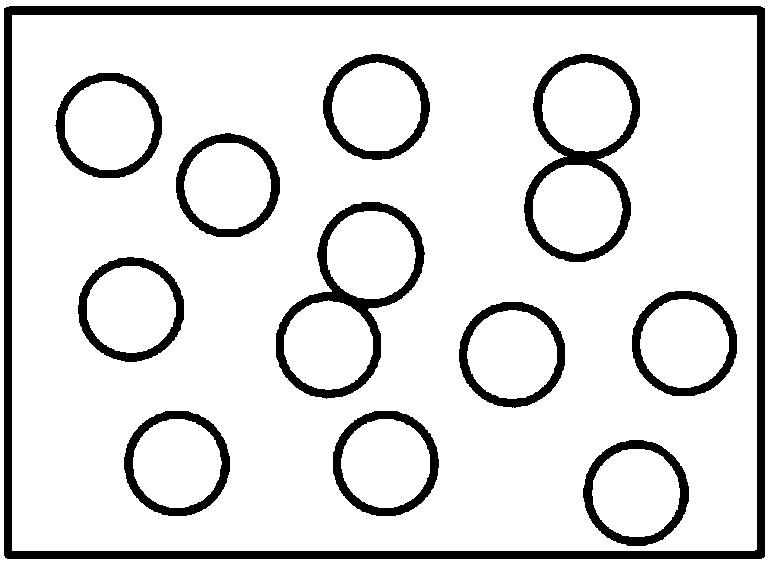

Heat management module for cylindrical batteries and preparation method thereof and battery pack

ActiveCN108288739AImprove thermal conductivityGuaranteed temperature uniformityBattery isolationSecondary cellsFiberHeat management

The invention relates to a heat management module for cylindrical batteries and a preparation method thereof and a battery pack. The heat management module comprises a heat management material mouldedbody; a plurality of cylindrical holes for accommodating the cylindrical batteries are formed in the heat management material moulded body; the heat management material moulded body is prepared froma heat management material by a moulding method; and the heat management material comprises the following components in percent by mass: 55-90% of a phase change material, 4-20% of a heat-conducting filler, 4-20% of a flame retardant and 2-10% of chopped fiber. Through addition of the chopped fiber into the heat management module, an effective enhancing effect can be achieved; the content of the phase change material in the heat management material can be increased to a relatively large extent, and thus the heat storage capacity of the heat management module is improved, so that the heat management module regulates and controls the temperature more stably.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

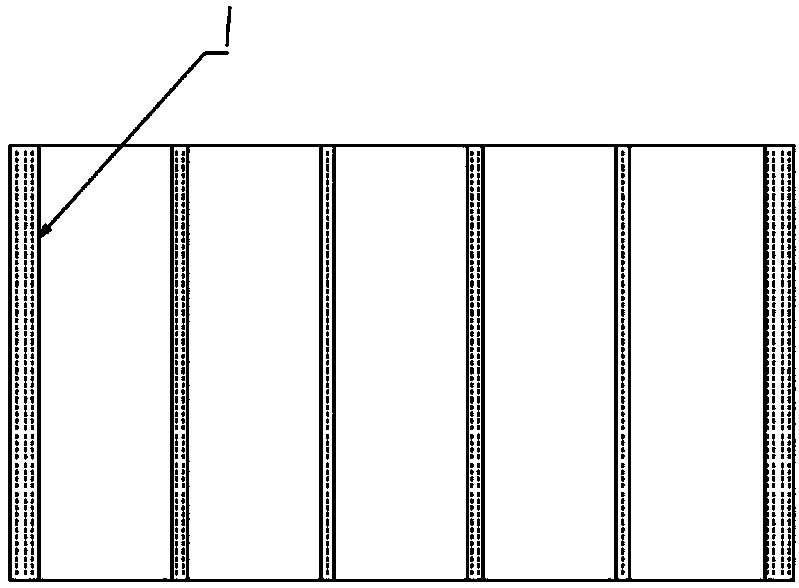

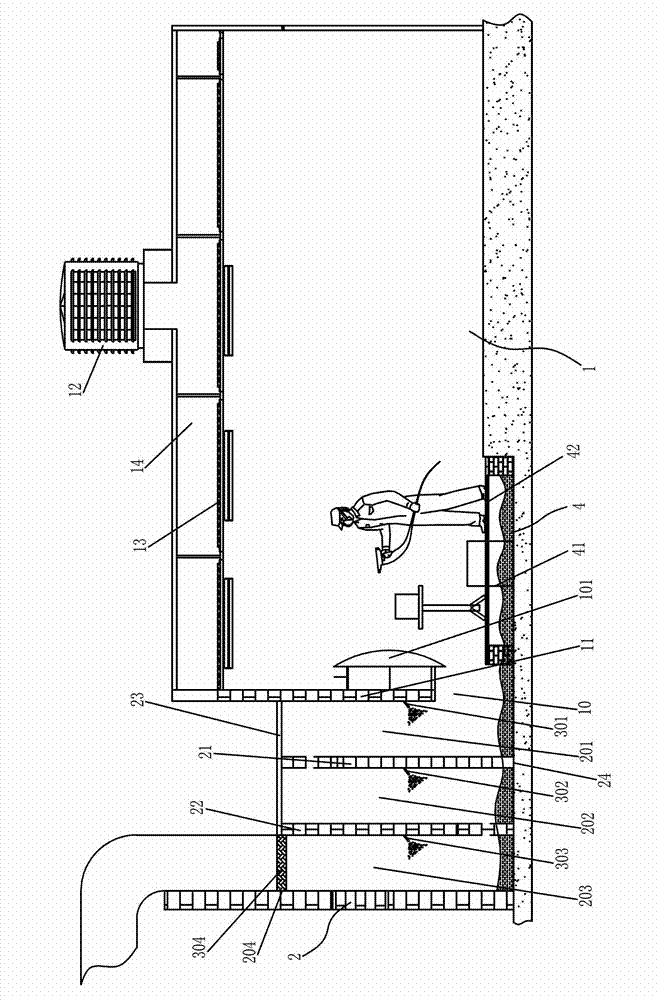

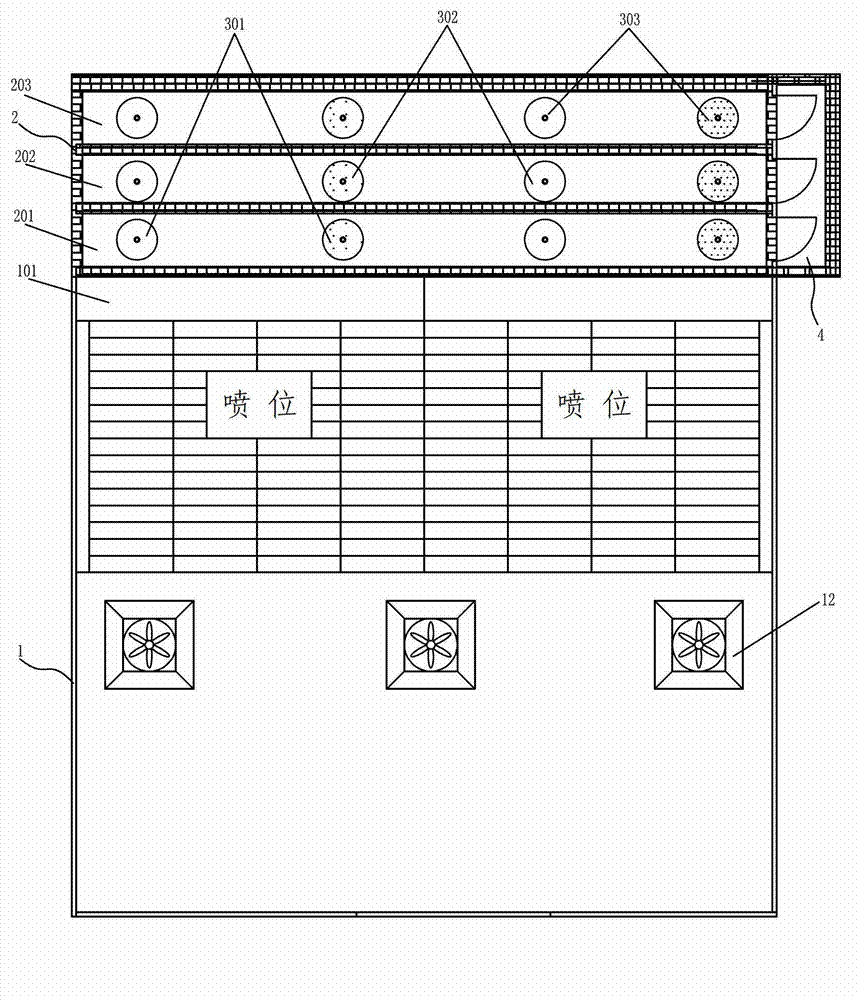

Paint room with paint production waste gas treatment system, and paint production waste gas treatment method

InactiveCN103041945AAvoid liquidityAvoid rising paint mistCombination devicesLiquid surface applicatorsActivated carbon filtrationHuman health

The invention relates to a paint room with a paint production waste gas treatment system, and a paint production waste gas treatment method. The paint production waste gas treatment system comprises a waste gas treatment chamber communicated with a paint room body. A first longitudinal channel communicated with a waste gas outlet at the bottom of the paint room obey, a second longitudinal channel communicated with the top of the first longitudinal channel, a third longitudinal channel communicated with the bottom of the second longitudinal channel, and an exhaust hole arranged at the top of the third longitudinal channel are arranged in the waste gas treatment chamber. A first spray unit is disposed in the first longitudinal channel. A second spray unit is disposed in the second longitudinal channel. A third spray unit is disposed in the third longitudinal channel. Activated carbon filter cotton is disposed at the exhaust hole. three spray treatment procedures and one activated carbon filtering procedure are added to treat the paint production waste gas, so that paint mist and peculiar odors in the paint production waste gas are removed completely, no paint mist or peculiar odors are present in the exhausted gas and pollution of atmospheric environment and threat on human health are avoided.

Owner:东莞市四友机械设备有限公司

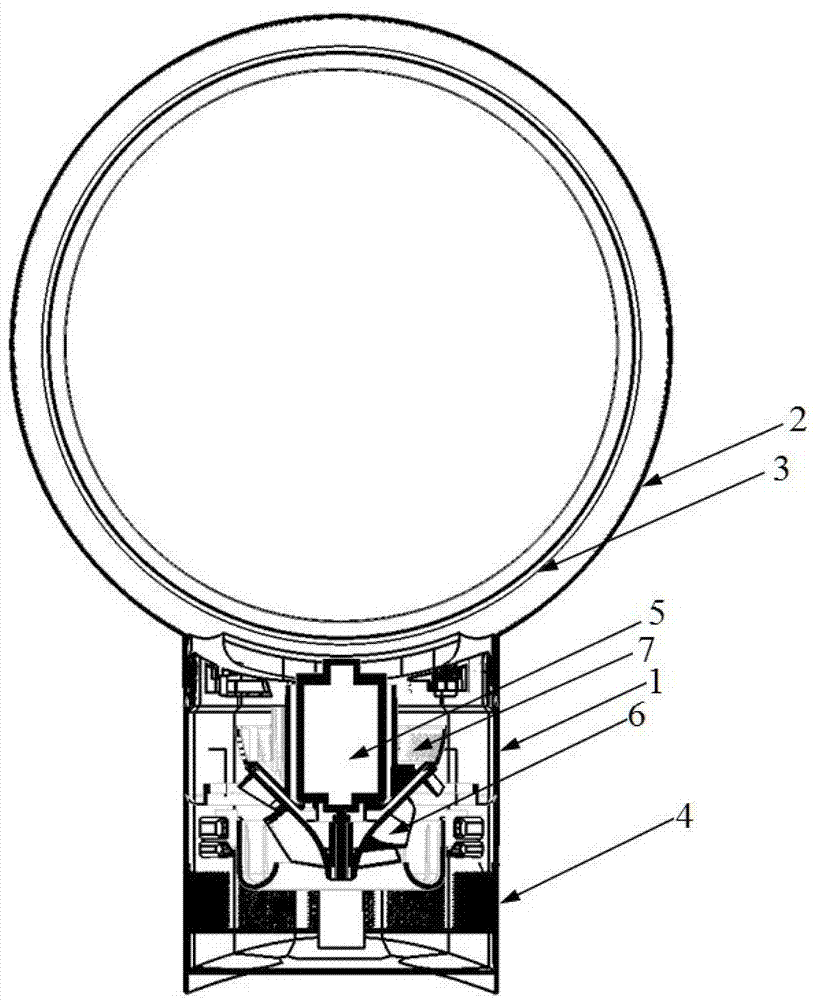

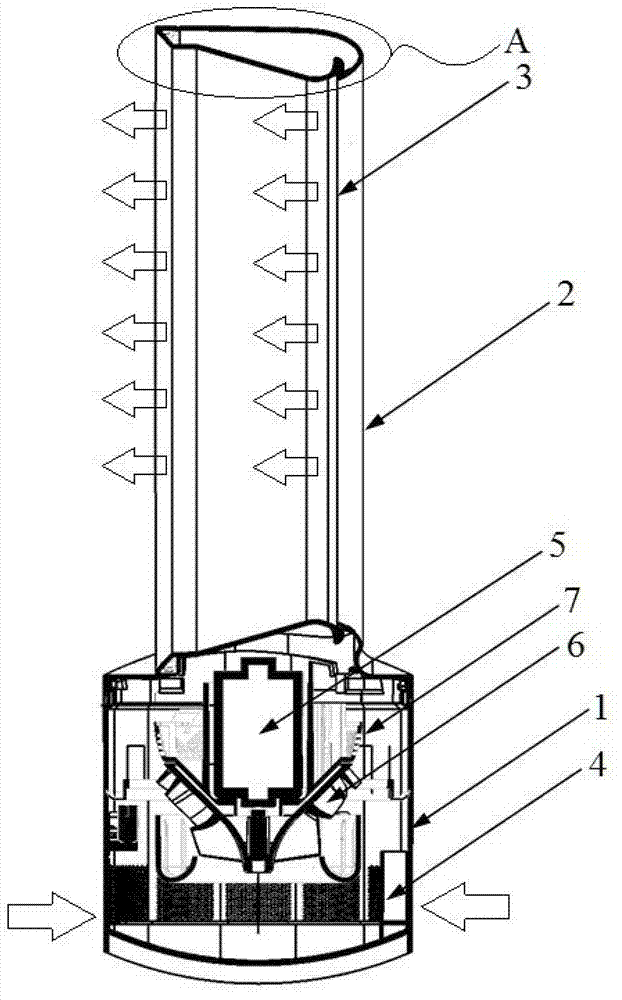

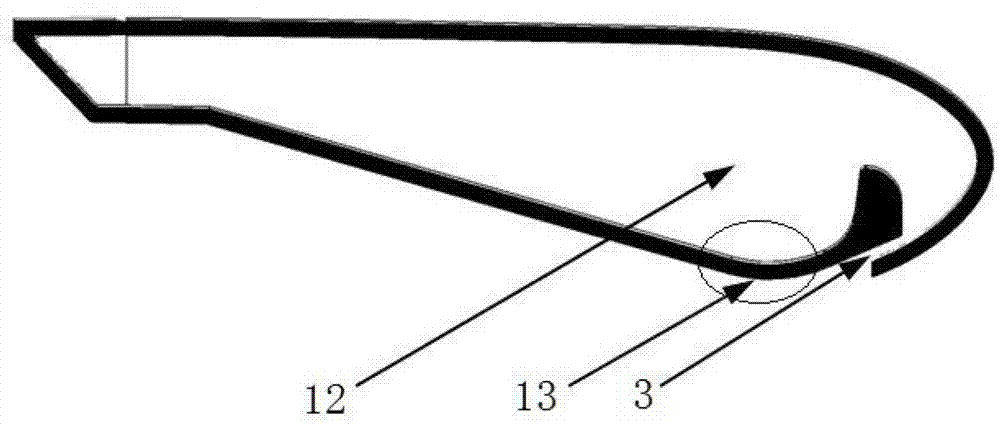

Bladeless fan turbine device with splitter blades

The invention discloses a bladeless fan turbine device with splitter blades. The bladeless fan turbine device with the splitter blades comprises a motor, a motor fixing device, a splitter blade turbine and an outer ring wall. A motor rotating shaft penetrates through the motor fixing device and is connected with the inner side of the inner ring wall of the splitter blade turbine. The inner side of the outer ring wall is sleeved on the splitter blade turbine. The splitter blade turbine comprises the inner ring wall, long blades and splitter blades, wherein the long blades are arranged in the peripheral direction of the inner ring wall, the splitter blades are located between every two adjacent long blades respectively and are distributed on the inner ring wall in the peripheral direction, the outlet diameters of the splitter blades equal those of the long blades, and the inlet diameters of the splitter blades differ from those of the long blades. The bladeless fan turbine device with the splitter blades is located in a bladeless fan base. Pressurizing ability and pressurizing efficiency of the bladeless fan turbine device with the splitter blades are effectively improved, service life of the bladeless fan turbine device with the splitter blades is prolonged, and therefore air-out amount of a bladeless fan is increased, operation stability is improved, noises of the bladeless fan are reduced, overall performance of the bladeless fan is improved, and the bladeless fan has the advantages of saving energy and protecting the environment.

Owner:ZHEJIANG SCI-TECH UNIV

Thermal management module for square battery, and preparation method thereof, and battery pack

ActiveCN108199112AImprove thermal conductivityGuaranteed temperature uniformitySecondary cellsFiberComputer module

The invention relates to a thermal management module for a square battery, and a preparation method thereof, and a battery pack. The thermal management module comprises a thermal management material molding body, which is prepared from a thermal management material through a molding method, wherein the thermal management material contains, by mass, 55-90% of a phase change material, 4-20% of a thermal conduction filler, 4-20% of a flame retardant, and 2-10% of chopped fiber. According to the present invention, by adding the chopped fiber, the thermal management module can provide the effectiveenhancing effect, and can greatly increase the phase change material content in the thermal management material so as to improve the heat storage capacity of the thermal management module and stablyregulate and control the temperature.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

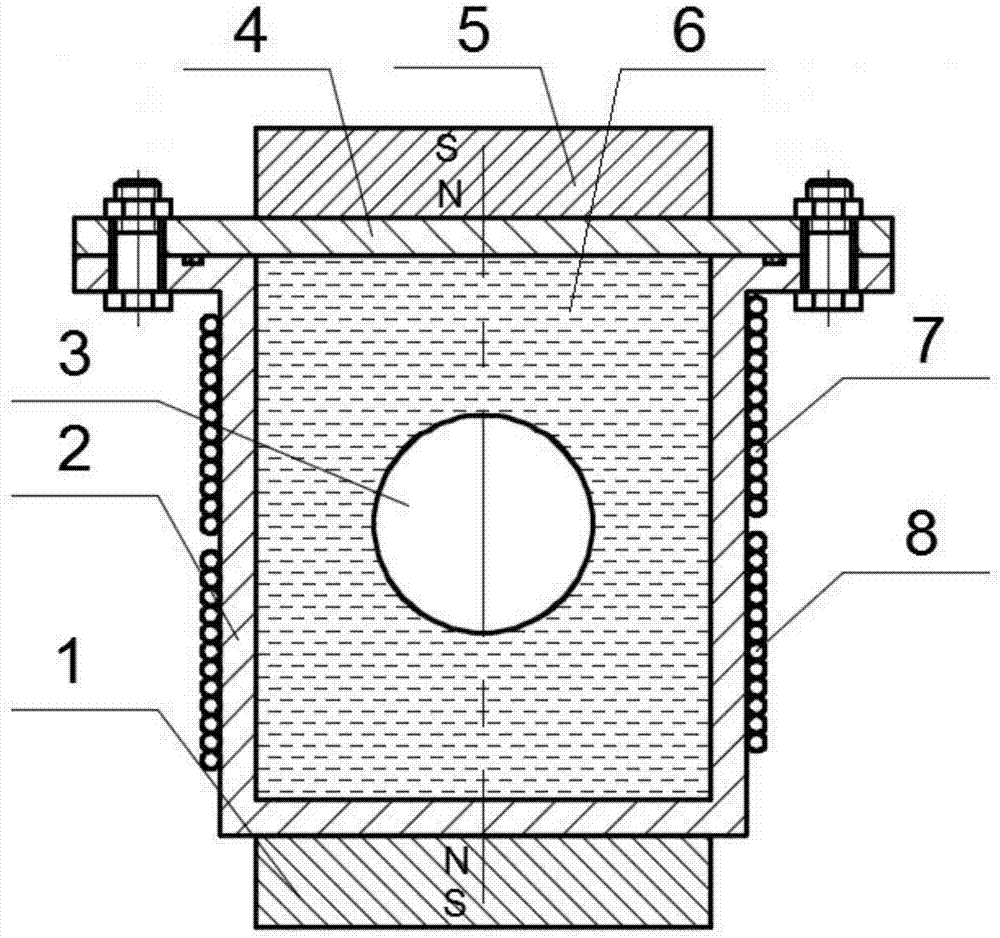

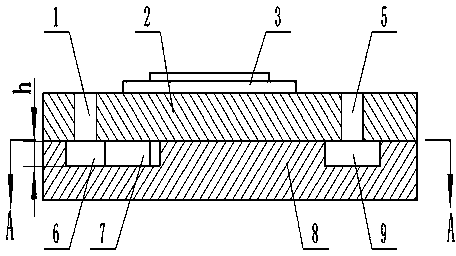

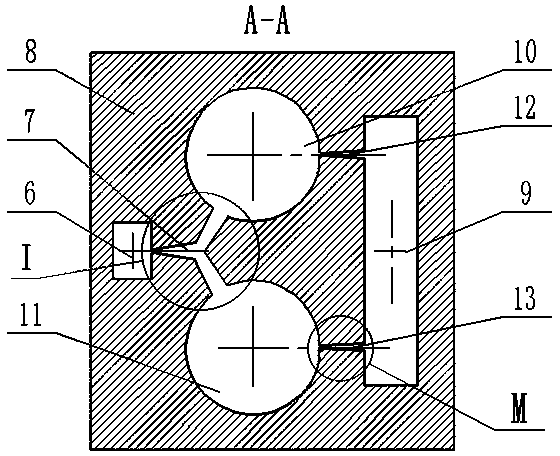

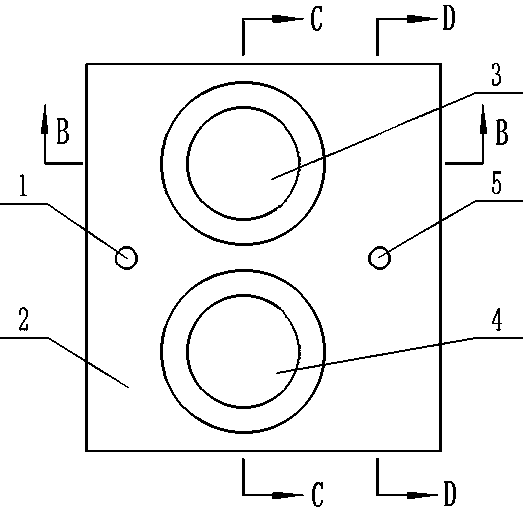

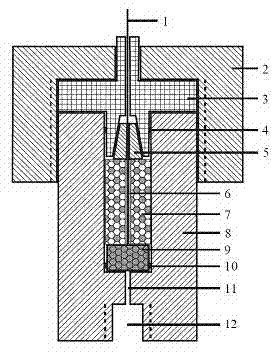

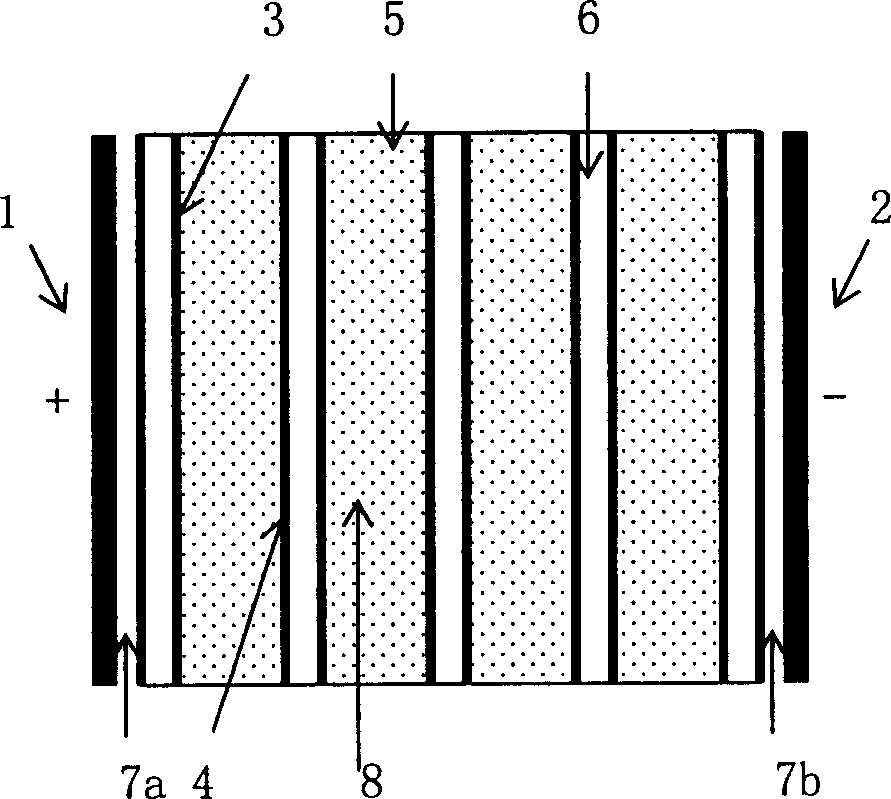

Magnetic fluid acceleration sensor based on first-order buoyancy principle

InactiveCN104849495ASolve mobility problemsSolve the problem that injection is difficult or even impossible to fillAcceleration measurementMagnetic liquidsAcceleration Unit

A magnetic fluid acceleration sensor based on a first-order buoyancy principle belongs to the field of mechanical engineering measurement. The problem that the existing magnetic fluid acceleration sensor cannot be applied in engineering practice due to a variety of structure problems is solved successfully. The device comprises a first permanent magnet (1), a shell (2), a mass block (3), an end cover (4), a second permanent magnet (5), magnetic liquid (6), an upper coil (7), and a lower coil (8). When acceleration is produced outside, the nonmagnetic mass block moves in a cavity, the volume distribution of the magnetic liquid (6) in the shell (2) changes, a signal is output, and first-order buoyancy formed by the first permanent magnet (1) and the second permanent magnet (5) inside the magnetic liquid (6) causes frequency difference between the mass block (3) and the shell (2). Thus, the sensitivity of the sensor is improved.

Owner:BEIJING JIAOTONG UNIV

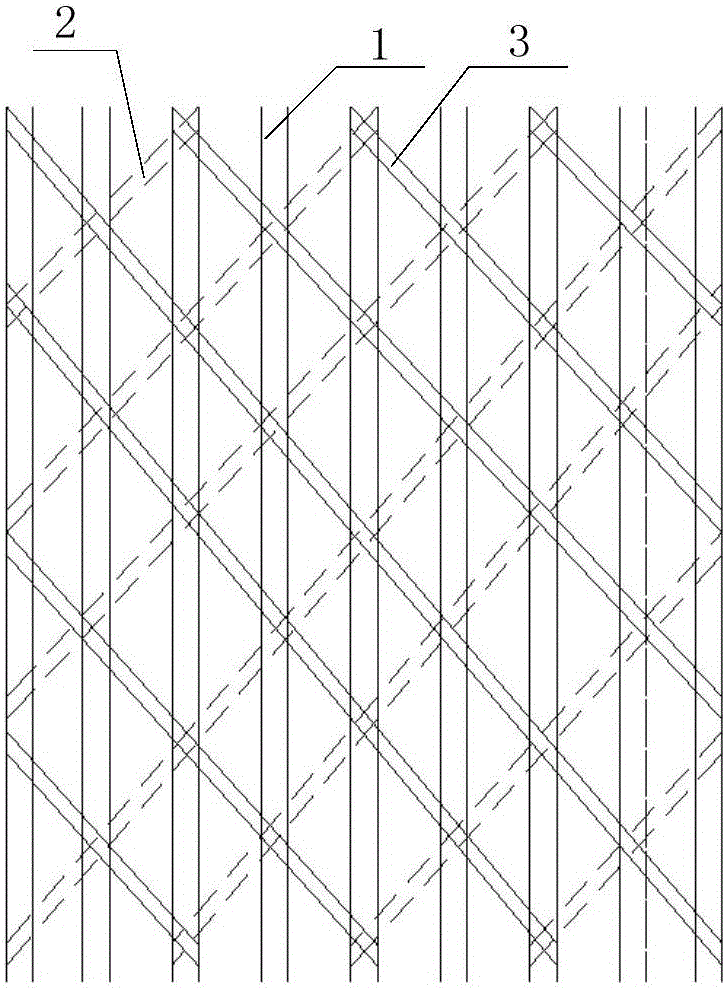

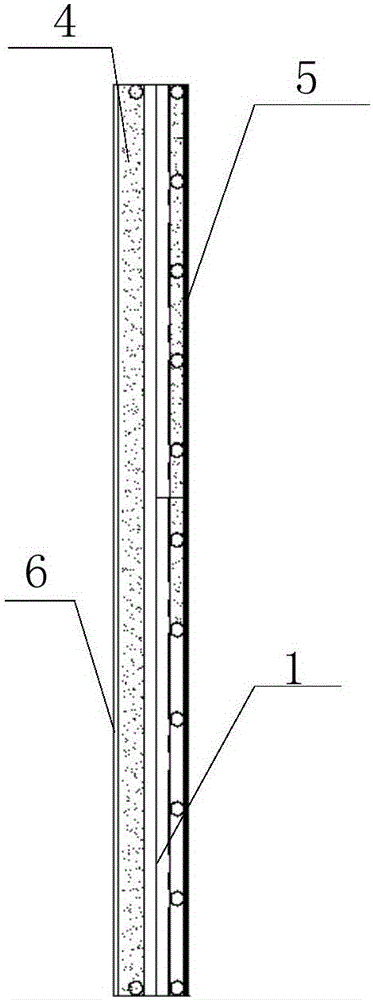

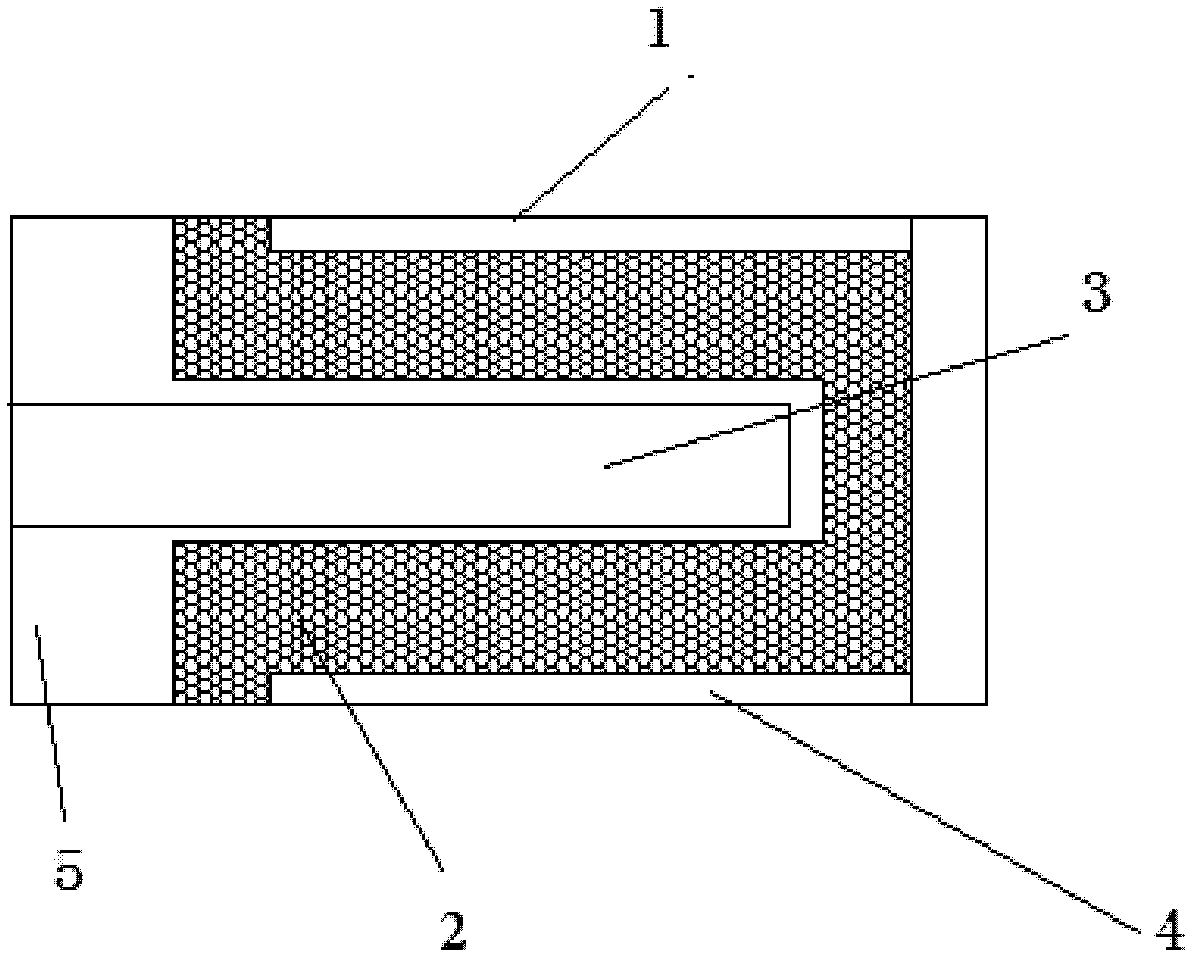

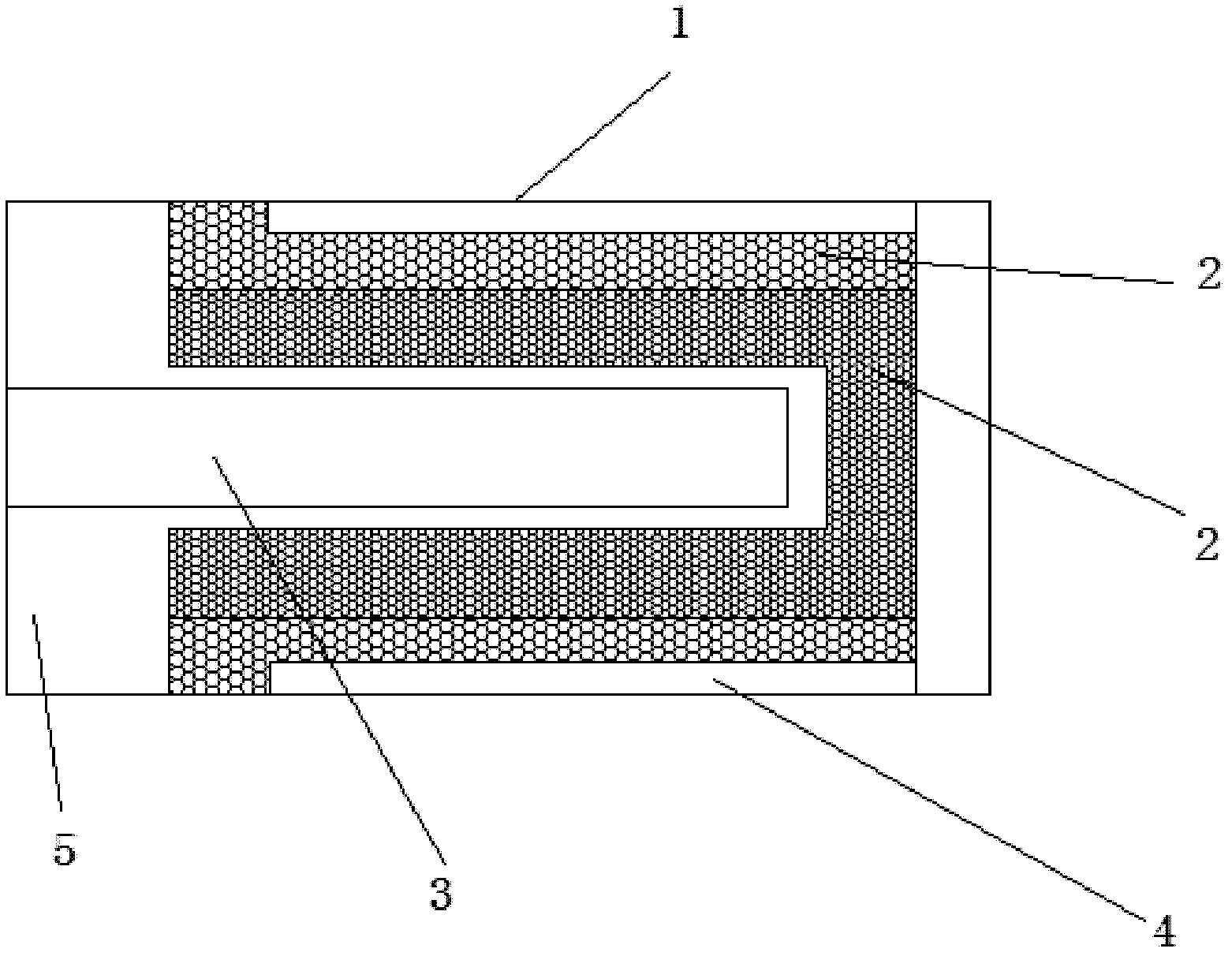

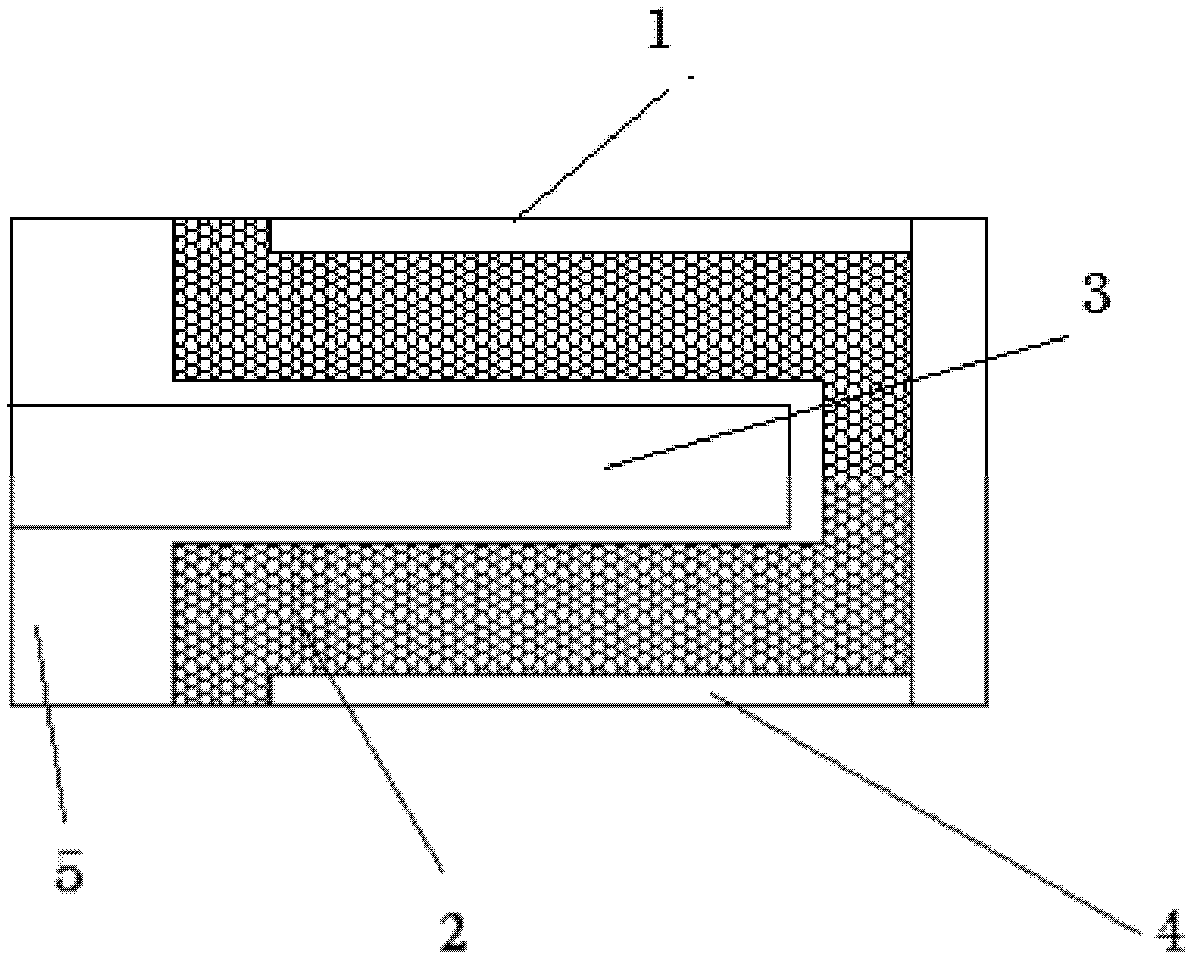

Wall based on raw bamboo framework

The invention discloses a wall based on a raw bamboo framework. The wall based on the raw bamboo framework comprises the raw bamboo framework and a fibred cement board; the raw bamboo framework has a cuboid structure and comprises a plurality of upright columns, a first group of diagonal rods and a second group of diagonal rods; the upright columns are parallel to one another; the first group of diagonal rods are positioned on front side surfaces of the various upright columns; the second group of diagonal rods are positioned on rear side surfaces of the various upright columns; the various diagonal rods in the first group are parallel to one another; the various diagonal rods in the second group are also parallel to one another; the diagonal rods in the first group are intersected with the diagonal rods in the second group, and are connected with the upright columns; the diagonal rods in the second group are connected with the upright columns and side surfaces of the fibered cement board; and a gypsum-based thermal-insulation material wraps the raw bamboo framework. The wall based on the raw bamboo framework is high in strength and long in service life.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Integrated preparation technology of loop heat pipe evaporator

The invention relates to an integrated preparation technology of a loop heat pipe evaporator, which is realized through the following steps: selecting an evaporation cavity, removing an oxidation film on the inner surface of the evaporation cavity; adding mixed powder of porous wick sintered body powder and a pore creating material, inserting a cylindrical liquid storage cavity mold into the mixed powder, determining the insertion depth as per the size of the liquid storage cavity, compacting the mixed powder between the evaporator and the liquid storage cavity mold, putting the evaporation cavity into a sintering furnace for sintering, drilling a plurality of steam passages along the inner wall of the evaporation cavity by means of a bit after sintering and cooling, and taking out the liquid storage cavity mold, so as to obtain an integrated loop heat pipe evaporator. The porous wicks are directly sintered in the evaporation cavity in an enclosed manner, as a result, not only are theporous wicks tightly combined with the wall of the evaporation cavity to avoid problems of heat leakage or steam counterflow, but also the sintered porous wicks can be used directly to avoid problemsof the porous wick breakage brought by secondary machining and the requirement for high accuracy. Lower strength is allowed to realize high porosity factor, thereby facilitating enhancement of the suction force of the porous wicks.

Owner:SHANDONG UNIV

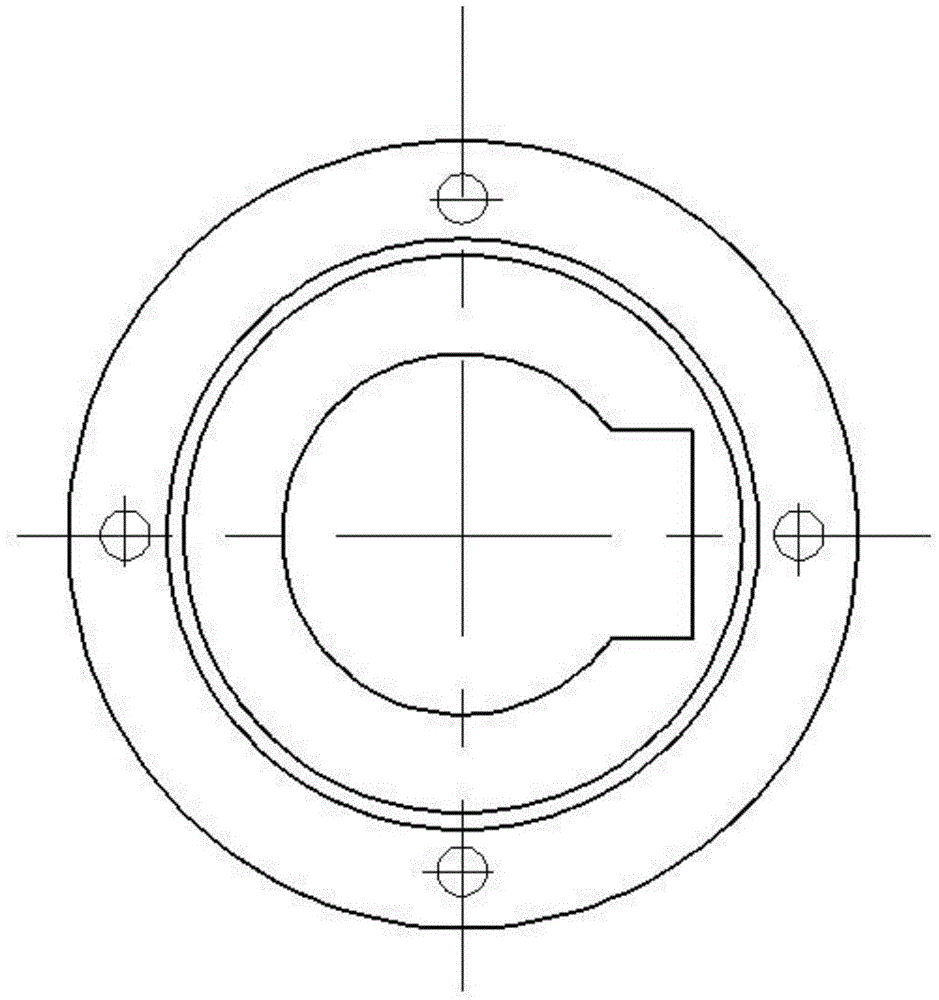

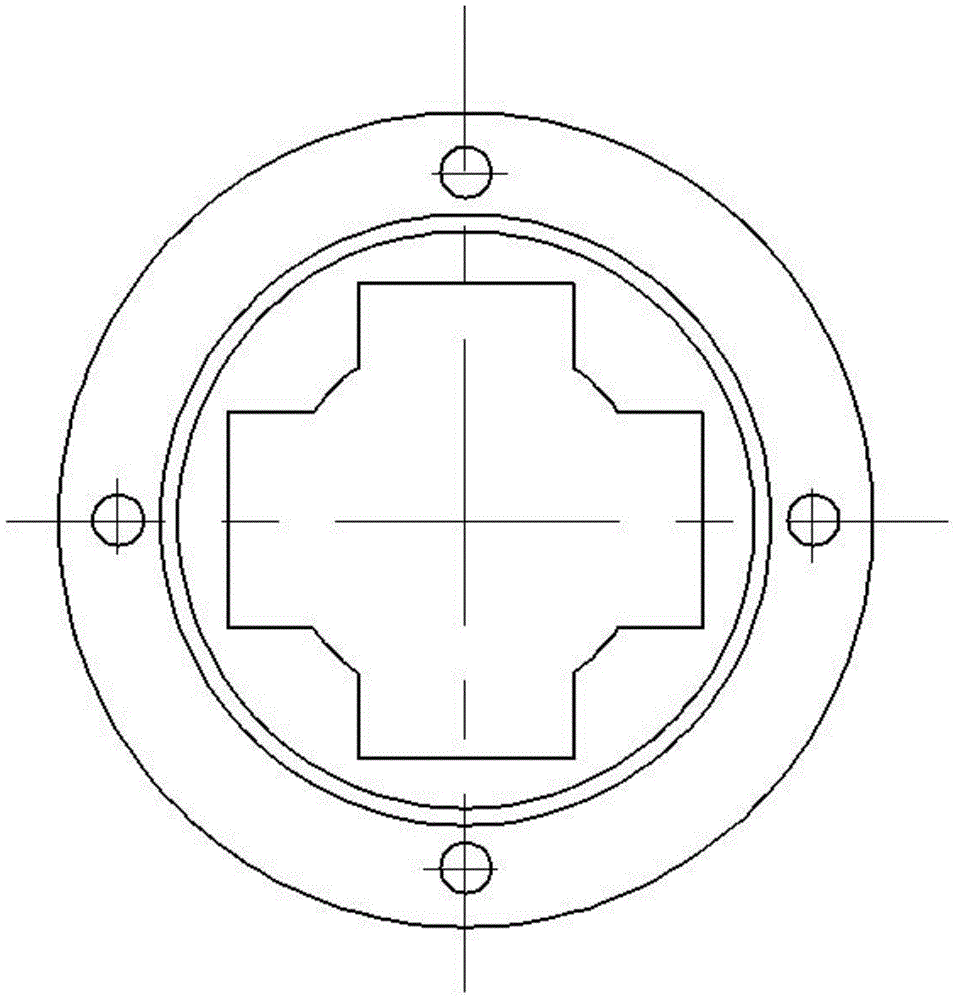

Double-cavity valveless piezoelectric pump of tee joint structure

InactiveCN103644102AImprove efficiencyImprove anti-electromagnetic interference performancePositive displacement pump componentsFlexible member pumpsCushioningEngineering

The invention discloses a double-cavity valveless piezoelectric pump of a tee joint structure. An inlet cushioning cavity, an outlet cushioning cavity, an inlet flow pipe, two outlet flow pipes and the lower half parts of two pump cavities are arranged on a pump body. The inlet flow pipe is formed by a convergence taper pipe and two flow division taper pipes which are symmetrically arranged relative to the center line of the convergence taper pipe in a communicated mode. The convergence taper pipe of the inlet flow pipe is communicated with the inlet cushioning cavity, one ends of the two flow division taper pipes are communicated with the big end of the convergence taper pipe, and the other ends of the two flow division taper pipes are respectively communicated with one of the two pump cavities. One ends of the two outlet flow pipes are respectively communicated with one of the two pump cavities, and the other ends of the two outlet flow pipes are both communicated with the outlet cushioning cavity. The inlet cushioning cavity is communicated with a pump inlet, and the outlet cushioning cavity is communicated with a pump outlet. Two piezoelectric vibrators 3 are loaded with alternating voltage signals of the same phase respectively, the flowing discharge capacity of fluid in the forward direction is enhanced, the phenomena of separation of boundary layers and wall-attached flow due to flowing at a large taper angle and with high frequency are avoided, energy loss is lowered, and the efficiency of the valveless piezoelectric pump is improved.

Owner:JIANGSU UNIV

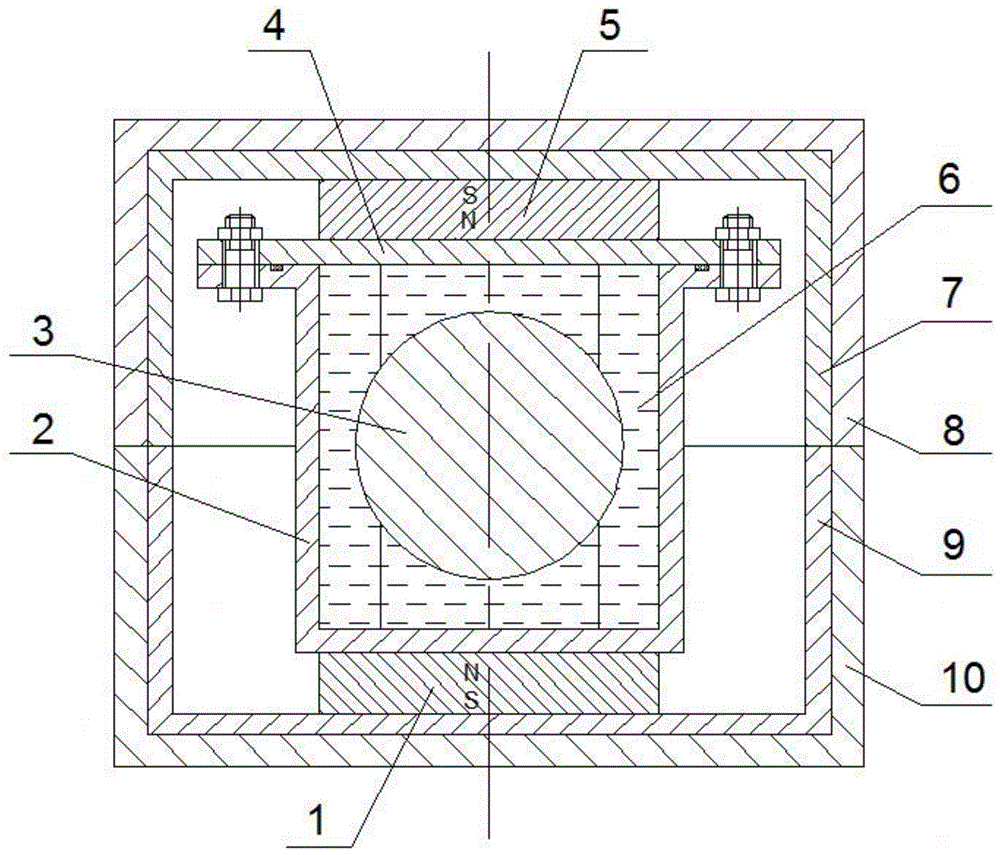

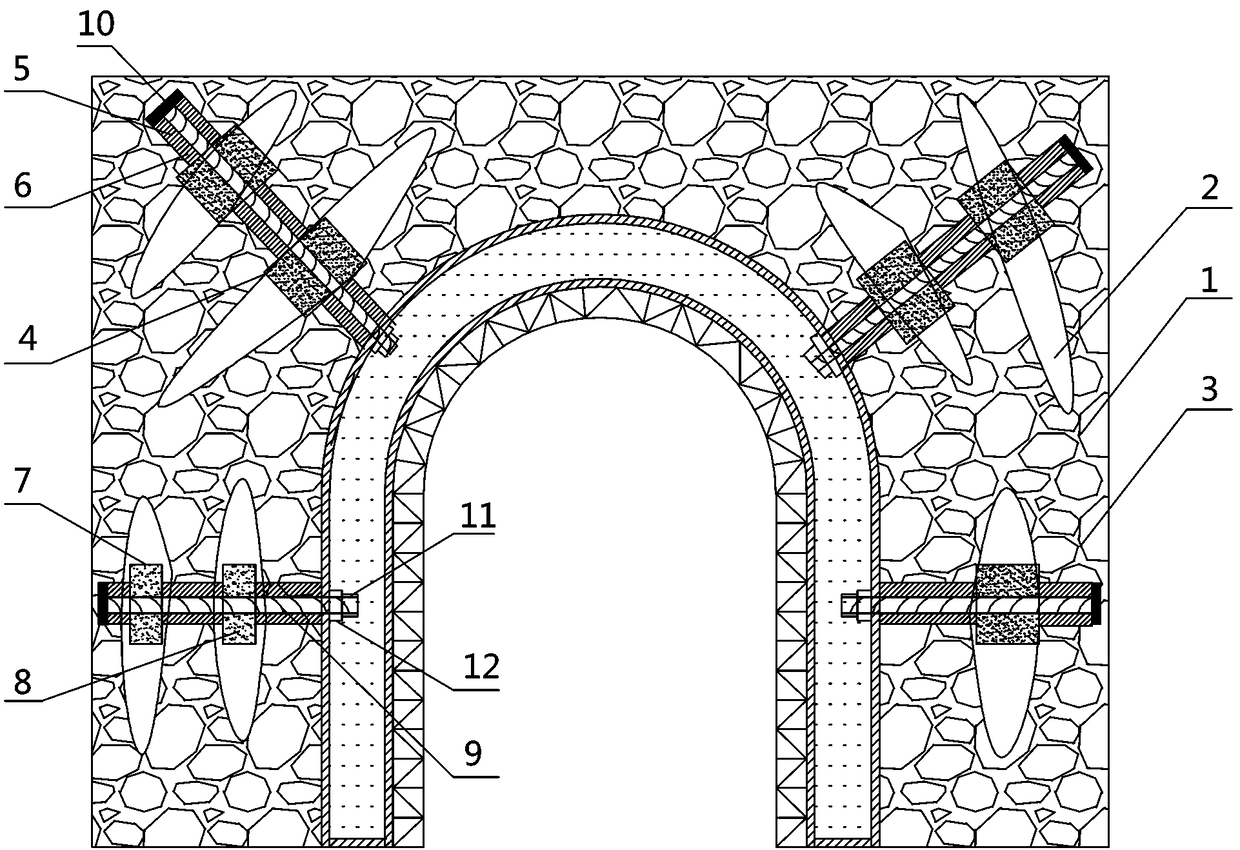

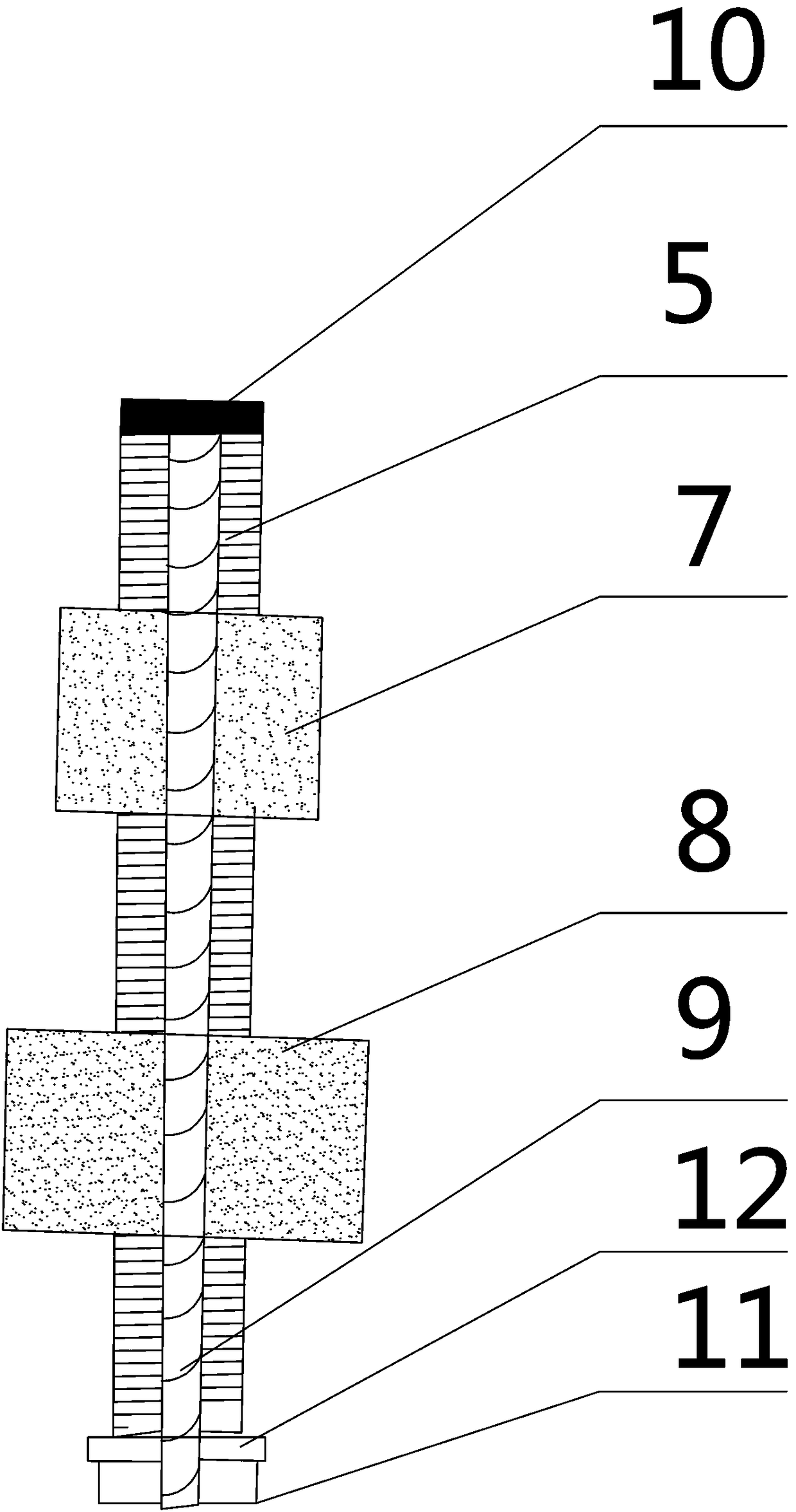

First-order buoyancy principle based magnetic liquid damping shock absorber with magnetic shielding covers

InactiveCN104948627ASuspension stabilityAvoid liquidityVibration dampersMagnetic springsStructural ProblemAbsorbed energy

The invention relates to a first-order buoyancy principle based magnetic liquid damping shock absorber with magnetic shielding covers, belongs to the field of mechanical engineering vibration, and successfully solves the problem that the existing magnetic liquid damping shock absorbers cannot be applied in engineering practice due to various structural problems. The absorber comprises a first permanent magnet (1), a housing (2), a mass (3), an end cap (4), a second permanent magnet (5), magnetic fluid (6), an upper magnetic inner sleeve (7), an upper magnetic shielding outer sleeve (8), a lower magnetic inner sleeve (9) and a lower magnetic shielding outer sleeve (10). When the external vibration occurs, a non-magnetic ball moves in a chamber, the magnetic fluid flows in a recess of the housing (2) to absorb energy, first-order buoyancy formed within the magnetic fluid by the first permanent magnet (1) and the second permanent magnet (5) allows frequency difference to be formed between the mass (3) and the housing (2), so that the maximum vibration damping efficiency is achieved, and the upper and lower magnetic shielding covers effectively prevent magnetic flux leakage of the permanent magnets.

Owner:BEIJING JIAOTONG UNIV

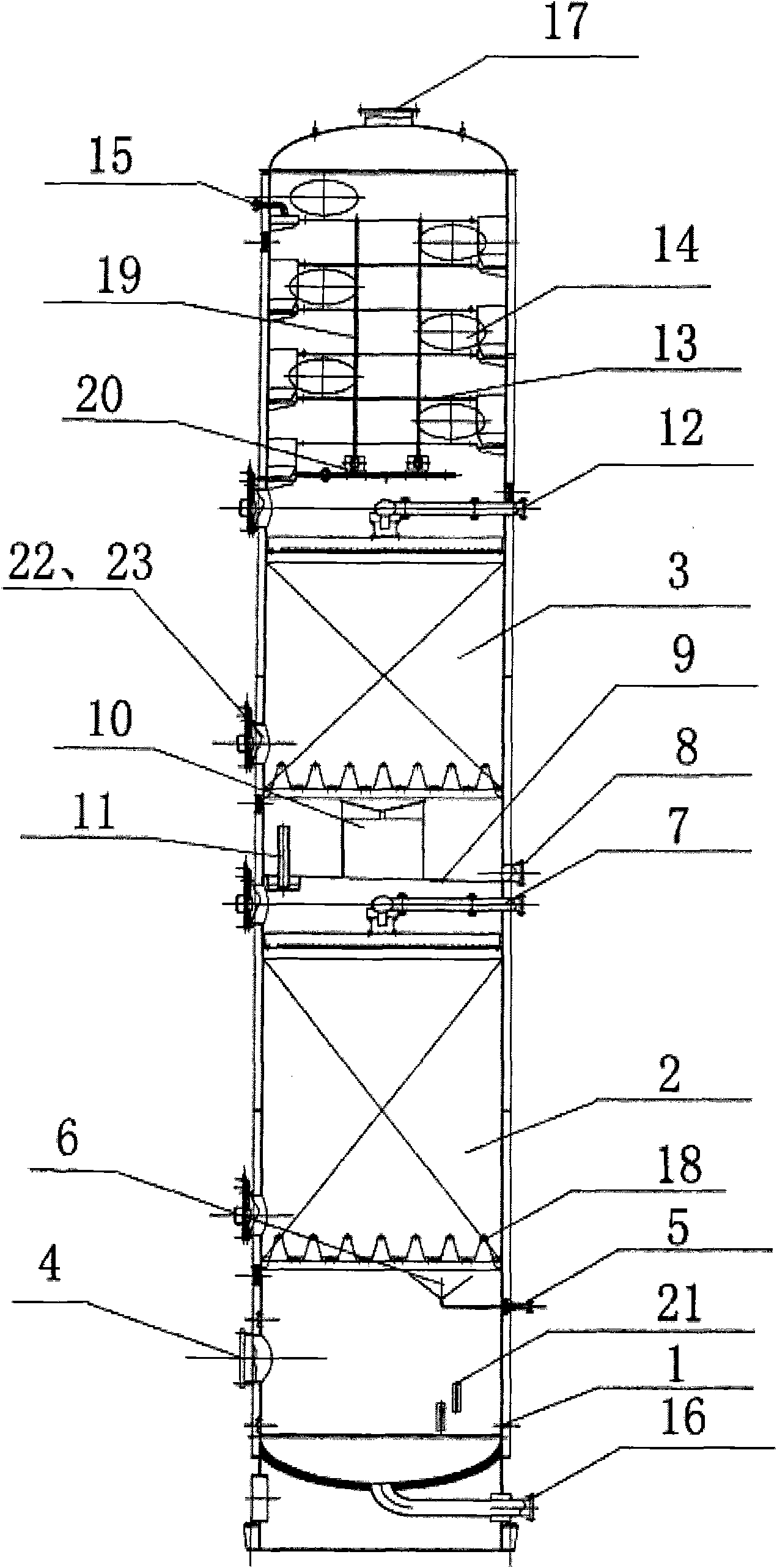

Formaldehyde absorption tower

InactiveCN101670230AAddressing Absorption EfficiencyRedistributionOrganic chemistryDispersed particle separationHigh concentrationHigh absorption

The invention discloses a formaldehyde absorption tower. The absorption tower comprises a tower kettle, wherein the lower part of the tower kettle is provided with a mixed gas inlet and a finished product formaldehyde outlet, the upper part of the tower kettle is provided with a water inlet and a exhaust gas outlet, two layers of packing are arranged in the tower kettle, and formaldehyde solutioncirculating pipes are arranged between packing layers. During the displacement process that mixed gas moves from bottom to top and water flows from top to bottom, formaldehyde in the mixed gas is dissolved in water to form formaldehyde solution, wherein the formaldehyde solution is circulated between two layers of packing so as to gradually increase the concentration of formaldehyde. A sprinkler used for wetting the inner wall of the tower kettle is arranged below the packing layers so as to prevent the wall-cling phenomenon of the formaldehyde absorption solution. The formaldehyde absorptiontower can be used to prepare high concentration formaldehyde and has higher absorption efficiency; in addition, the absorption tower can solve the problem of formaldehyde polymerization in the production process of high concentration formaldehyde.

Owner:江阴市华燕石化机械装备有限公司

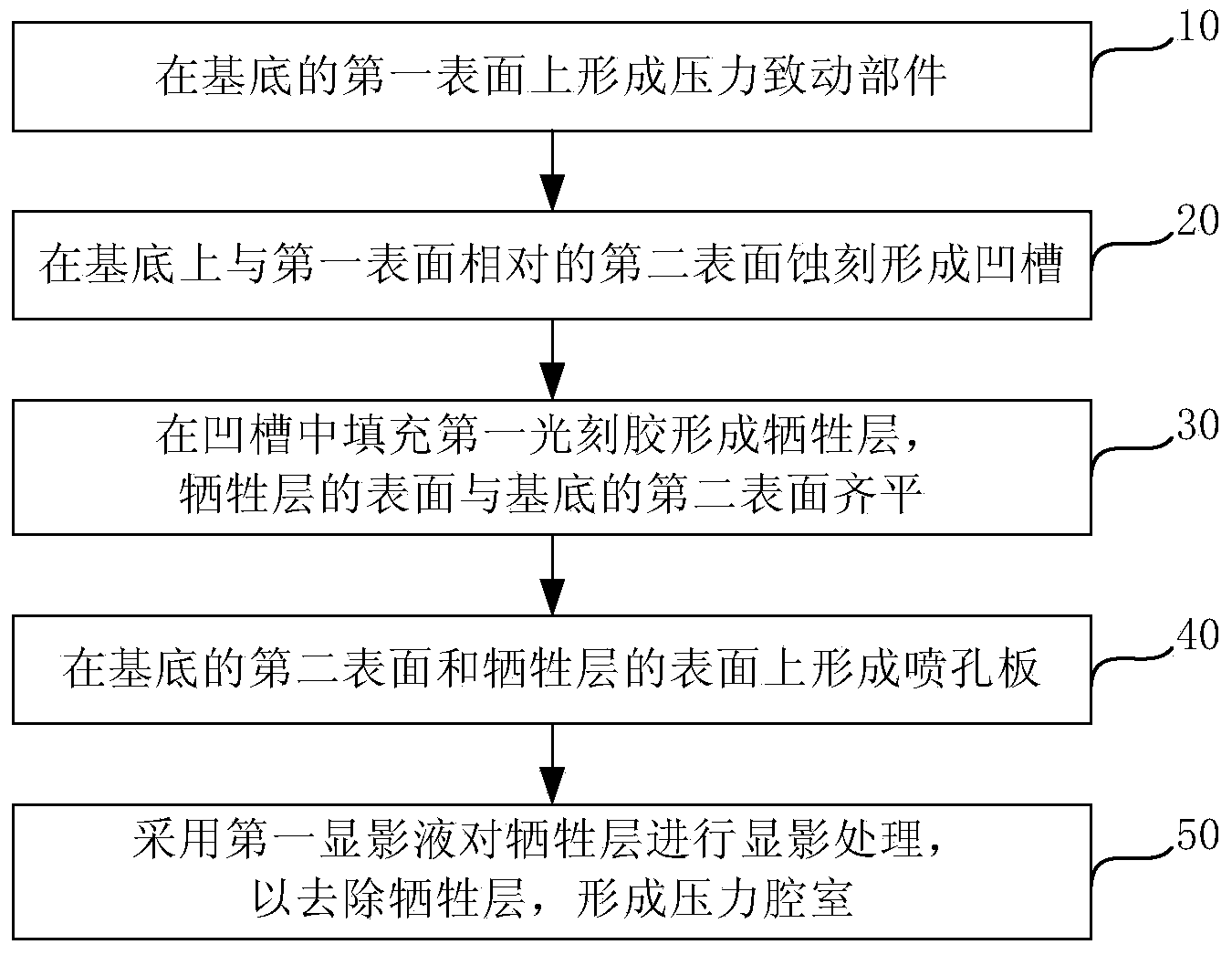

Liquid ejection head manufacturing method, liquid ejection head and printing device

The invention provides a liquid ejection head manufacturing method, a liquid ejection head and a printing device. The method comprises the steps that a pressure actuating part is formed on a first surface of a substrate; a groove is etched on a second surface opposite to the first surface on the substrate; the groove is filled with a first photoresist to form a sacrificial layer; the surface of the sacrificial layer is flush with the second surface of the substrate; orifice plates are formed on the second surface of the substrate and the surface of the sacrificial layer; and a first developer is used to develop the sacrificial layer to remove the sacrificial layer and form a pressure chamber. According to the liquid ejection head manufacturing method, the liquid ejection head and the printing device, which are provided by the invention, the problems that the manufacturing process of the existing liquid ejection head is complex, and the use of an adhesive easily reduces the printing quality are solved.

Owner:DALIAN UNIV OF TECH +1

External pressure-balance type Ag/AgCl reference electrode and preparation method thereof

ActiveCN104764783AEasy to control the lengthAvoid the problem that the working temperature is difficult to exceed 300°CMaterial electrochemical variablesElectrode insertionPressure balance

The invention discloses an external pressure-balance type Ag / AgCl reference electrode and a preparation method thereof. A porous ceramic pillar is located at the bottom of a cavity of a pressure cavity body and connected with the inner wall of the lower part of the cavity of the pressure cavity body by a first O-shaped sealing ring, the upper end face of the pressure cavity body is in close contact with a compression ring by an external nut, the lower end of the compression ring is provided with a taper hole, a circular-truncated-cone-shaped sealing element is arranged in the taper hole, an Ag / AgCl wire electrode is inserted in an internal reference substance in the pressure cavity body until extending to the upper end face of the porous ceramic pillar, and an electrode lead is led out through an axial through hole in the circular-truncated-cone-shaped sealing element located in the taper hole at the lower end of the compression ring and an axial through hole in the compression ring. According to the invention, a problem that various existing Ag / AgCl reference electrodes are inapplicable to high-temperature and high-pressure hydrothermal systems at a temperature and pressure range of 400-700 DEG C and 40-100 MPa can be solved, and a problem that samples are polluted and streaming potentials and use occasions are limited can be solved.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

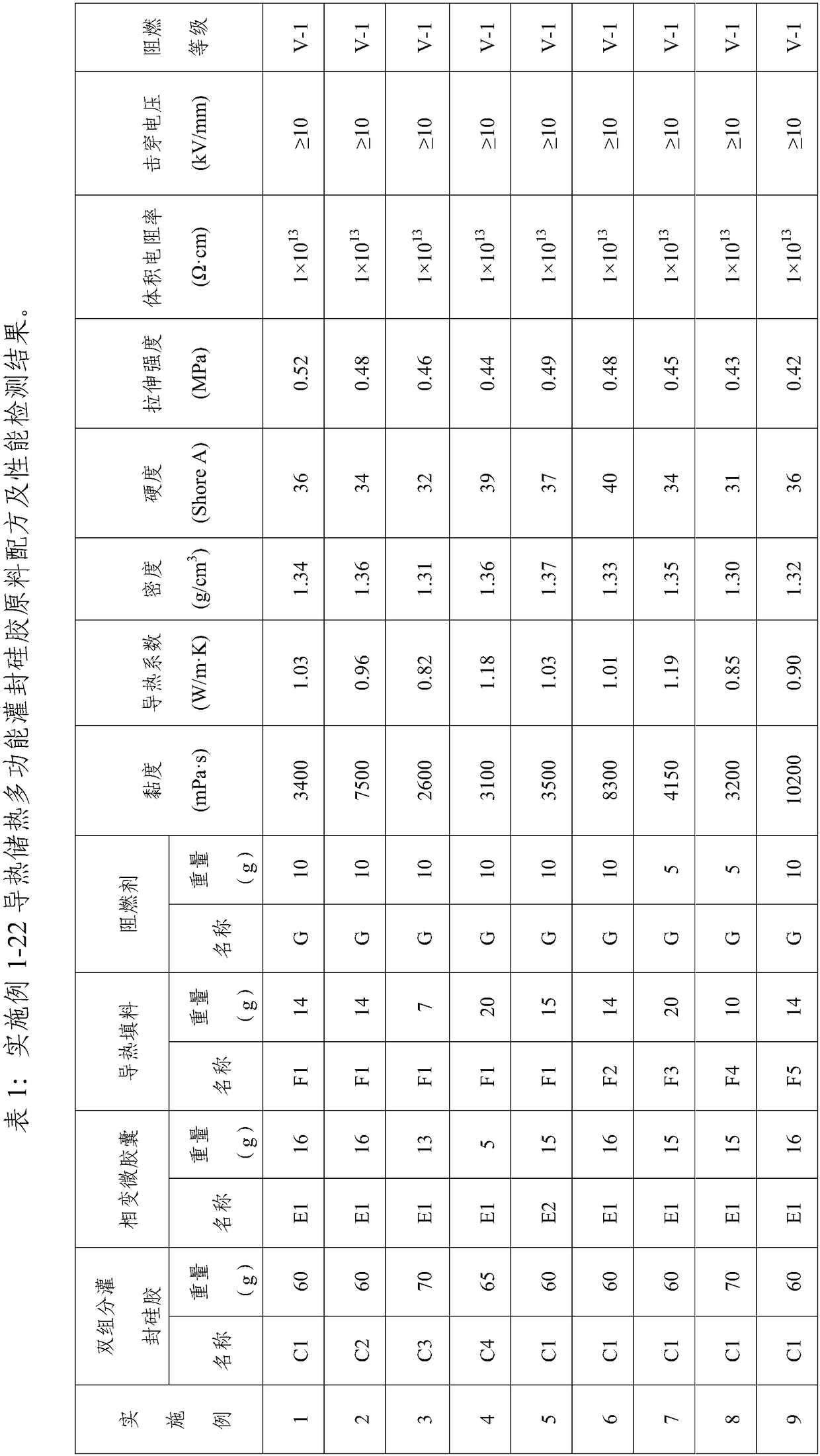

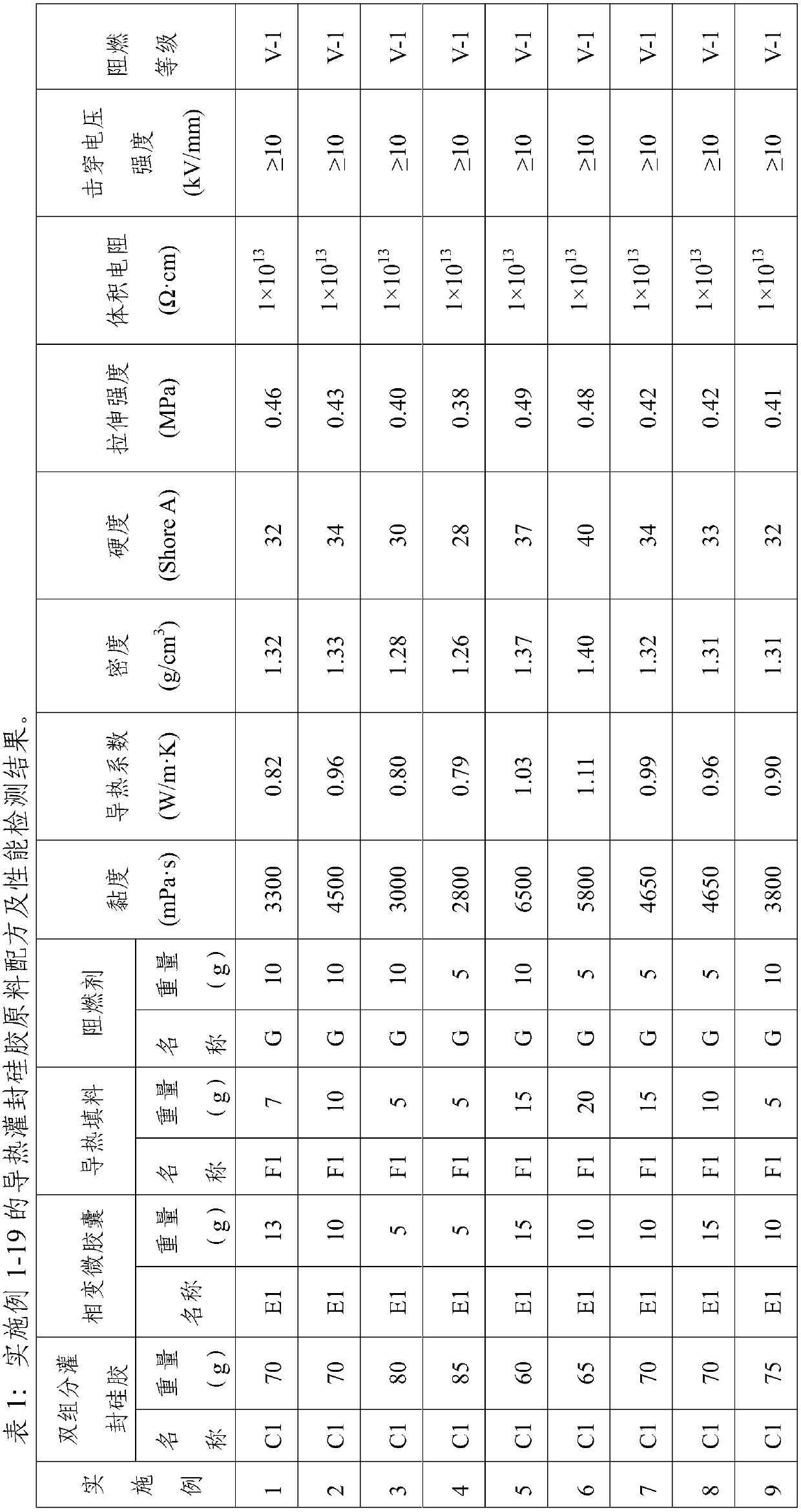

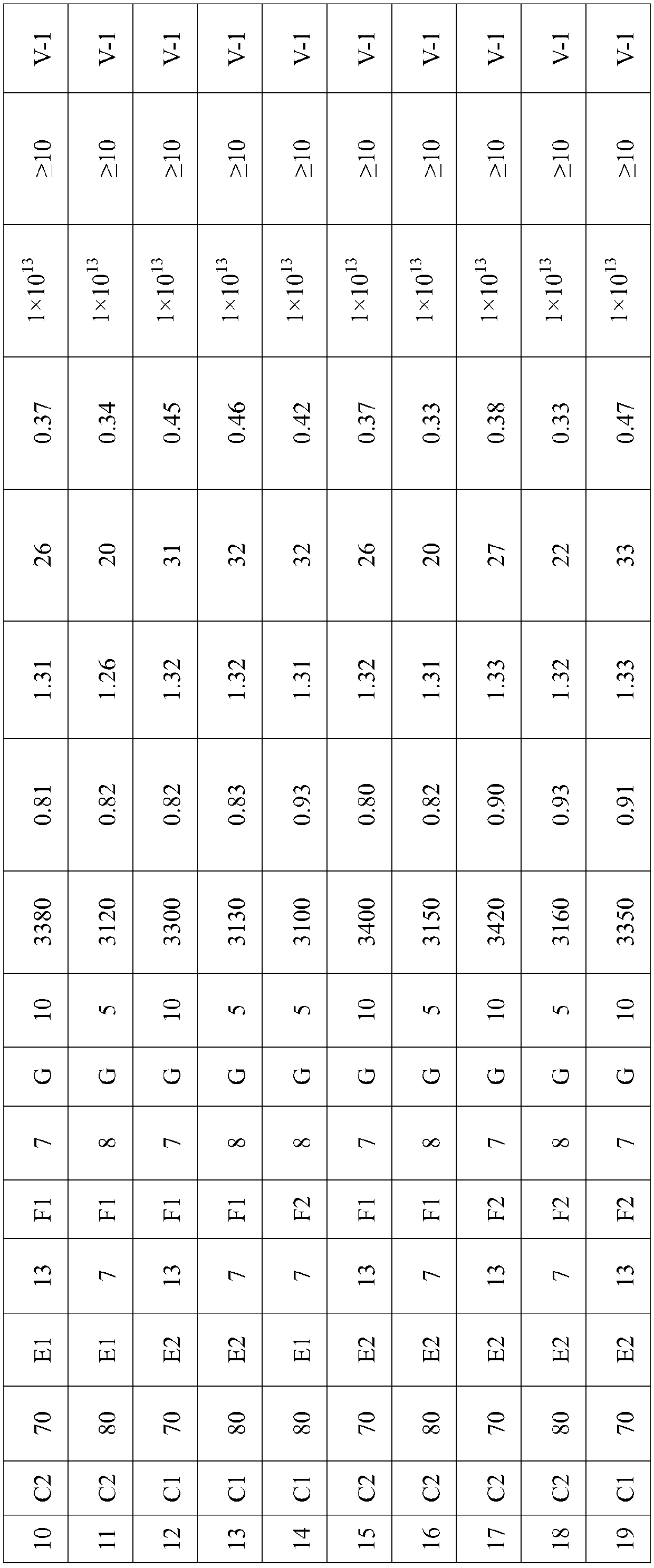

Heat conduction and storage multifunctional pouring silica gel and preparation method thereof

ActiveCN108084957AReduce viscosityImprove mechanical propertiesNon-macromolecular adhesive additivesSecondary cellsTemperature controlSilica gel

The invention relates to heat conduction and storage multifunctional pouring silica gel and a preparation method thereof. The heat conduction and storage multifunctional pouring silica gel consists ofthe following components in percentage by mass: 40-89% of double-component pouring silica gel, 5-20% of phase-change microcapsules, 5-20% of heat conduction packing after surface treatment, and 1-20%of a flame retardant, wherein the heat conduction packing consists of small particle size heat conduction packing and large particle size heat conduction packing through mixing. The preparation method comprises the following steps: performing surface treatment on the heat conduction packing; preparing the heat conduction and storage composite packing; preparing the double-component pouring silicagel; preparing components A1 and B1 of the heat conduction and storage multifunctional pouring silica gel; preparing the heat conduction and storage multifunctional pouring silica gel. Due to surfacetreatment on heat conduction packing of different particle sizes, the dispersibility of the packing in a silica gel substrate is improved, the heat conduction properties of the heat conduction and storage multifunctional pouring silica gel are improved, and due to addition of the phase-change microcapsules, the heat conduction and storage multifunctional pouring silica gel has heat storage temperature control properties.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Phase-change microcapsule-based heat conducting potting silica gel comprising flame retardant and preparation method thereof

ActiveCN107815287AGood dispersionIncrease the amount addedNon-macromolecular adhesive additivesMacromolecular adhesive additivesTemperature controlDispersity

The invention relates to a phase-changing microcapsule-based heat conducting potting silica gel comprising flame retardant and a preparation method thereof. The heat conducting potting silica gel is prepared from 40 to 89 percent of dual-component potting silica gel, 5 to 20 percent of phase-changing microcapsule, 5 to 20 percent of surface treated heat conducting filler, and 1 to 20 percent of flame retardant. The preparation method comprises the following steps: treating the surface of the heat conducting filler; preparing heat conducting composite filler; preparing a component A and a component B in the dual-component potting silica gel; preparing a component A1 and a component B1 in the heat conducting potting silica gel; and preparing the heat conducting potting silica gel. Accordingto the preparation method, the surface of the heat conducting filler is treated in the preparation process, so that the dispersity of the heat conducting filler in a silica gel matrix is improved, theheat conduction performance of the heat conducting potting silica gel is improved, and by adding the phase changing microcapsule, the heat conducting potting silica gel has heat storage temperature control performance. The heat conducting potting silica gel has good heat conduction performance and heat storage temperature control performance.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

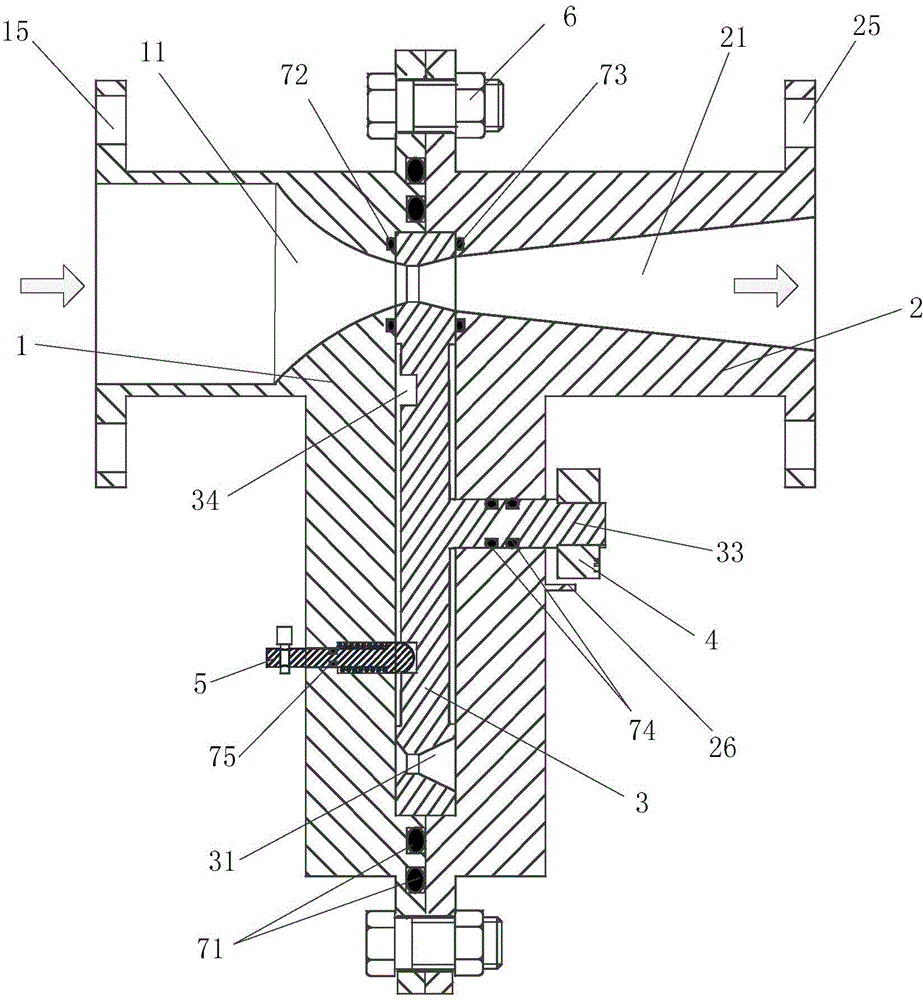

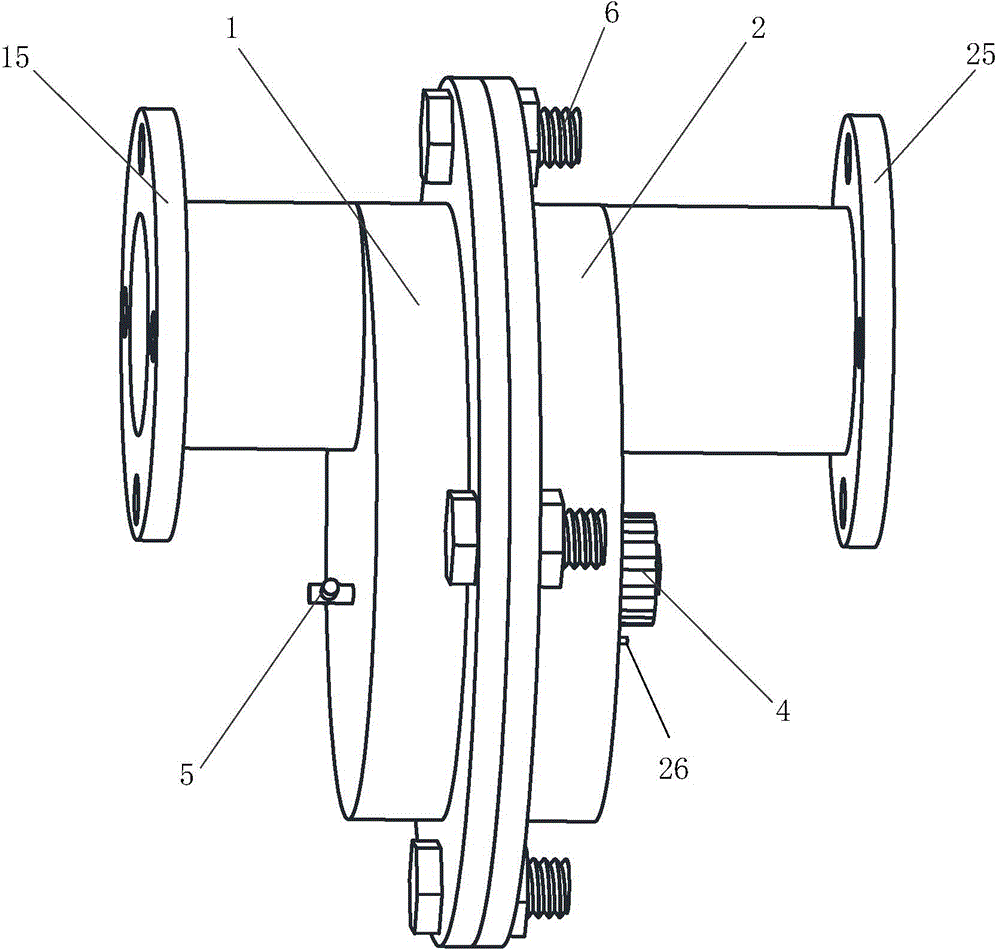

Critical flow venturi nozzle with throat rotating wheel and with adjustable throat area

InactiveCN104535121AEasy to adjustExpand the adjustment rangeVolume/mass flow by differential pressureSpray nozzleEngineering

A critical flow venturi nozzle with a throat rotating wheel and with the adjustable throat area comprises an upstream contraction section, a downstream expansion section and the throat rotating wheel which is arranged between the upstream contraction section and the downstream expansion section in a wrapped mode. The throat rotating wheel is provided with throat holes of different diameters, and a contraction flow channel of the upstream contraction section, an expansion flow channel of the downstream expansion section and the throat holes in the throat rotating wheel form the critical flow venturi nozzle. The throat rotating wheel rotates through an adjusting hand wheel, so that different throat holes are selected to be matched with the contraction flow channel and the expansion flow channel, and accordingly the throat area of the critical flow venturi nozzle is changed. The position of a throat can be determined precisely under the combined effect of the adjusting hand wheel and a spring positioning pin, and therefore the throat area can be determined. The critical flow venturi nozzle can achieve on-line adjusting of critical flow conveniently without cutting off flow, and has the advantages of being wide in flow adjusting range, good in fluid flowing performance, high in flow control precision, simple in structure, reliable in performance, applicable to high-temperature and high-pressure fluid, and the like.

Owner:XI AN JIAOTONG UNIV

Inorganic phase-change energy storing particles, floor heating mortar and preparation method thereof

The invention provides inorganic phase-change energy storing particles, floor heating mortar and a preparation method thereof. The inorganic phase-change energy storing particles comprise the following components in percentage by mass: 20-50% of inorganic phase-change material, 10-25% of water, 0.1-1.5% of phosphorylated starch gum, 0.1-1.5% of water-absorbent resin, 10-35% of gypsum, and 15-35% of cement. The inorganic phase-change energy storing particles are prepared by the steps of preparing phosphorylated starch gum, preparing materials, mixing, pelletizing, coating, and covering with films. The floor heating mortar comprises 15-35% of cement, 10-25% of sand, 20-50% of inorganic phase-change energy storing particles, and 20-30% of water. The floor heating mortar is prepared by preparing materials, and mixing. According to the inorganic phase-change energy storing particles, the floor heating mortar and the preparation method thereof, the raw materials are wide in source; the chemical stability is high; the phase change temperature is low; leakage is avoided; the energy storing particles are good in energy storing effect, and high in stability; the floor heating mortar is highin strength, and the indoor temperature can be effectively conditioned, and the energy saving effect is good; and various buildings such as a house, a school and a hospital widely apply.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Device and method for strengthening different fracture zones of deep rock mass with expansion agent head-enlarging effect

The invention discloses a device and method for strengthening different fracture zones of deep rock mass with the expansion agent head-enlarging effect. The device comprises the deep rock mass, the deep rock mass is internally provided with different fracture rock mass zones and intact rock mass zones; anchor rods are anchored in the fracture rock mass zones and the intact rock mass zones, expansion cement slurry with different contents of expansion agents is poured in the fractured rock mass zones at different depths or layers at which the anchor rods are located to form anchoring bodies at different depths, and then the anchor rods are anchored in the deep rock mass; and cushions are arranged on the anchor rods and located on the edges of the fractured rock mass zones. The device and method have the advantages of greatly shortening the length of anchoring segments, reducing the diameter of drilling holes, greatly increasing the anti-pulling force, saving the construction cost and theconstruction period and the like. The device for strengthening the different fracture zones of the deep rock mass with the expansion agent head-enlarging effect is mainly used in bridge and tunnel engineering, ports and piers, slope engineering, mine construction, national defense engineering and the like, and has a wide range of engineering practical significance and application prospects.

Owner:CHINA THREE GORGES UNIV

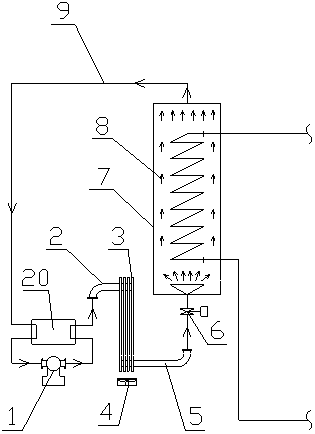

Heat pump type main-transformation heat-exchanging device with SF6 (sulfur hexafluoride) as heat-exchanging medium and heat-exchanging method

ActiveCN103779049AImprove insulation performanceExcellent arc extinguishingMechanical apparatusTransformers/inductances coolingFour-way valveSulfur hexafluoride

The invention relates to a heat-pump-type main-transformation heat-exchanging device with SF6 (sulfur hexafluoride) as a heat-exchanging medium and a heat-exchanging method. The heat pump type main-transformation heat-exchanging device comprises an SF6 heat pump compressor, a cooler and an evaporator, wherein one port of the cooler is connected with one port of the SF6 medium flow passage of the evaporator through a bidirectional throttle valve; the other port of the SF6 medium flow passage of the evaporator and the other port of the cooler are connected with two ports of the SF6 heat pump compressor through a four-way valve; two ports of transformer oil flow passage of the evaporator are connected with an oil inlet and an oil outlet of the main-transformation body; transformer oil in the main-transformation body is conveyed into the oil inlet from the oil outlet through an oil pump; and the transformer oil exchanges heat with the SF6 heat-exchanging medium inside the SF6 medium flow passage directly through the side wall of the transformer oil flow passage of the evaporator. The heat pump type main-transformation heat-exchanging device has huge advantages of safety, reliability, high heat-exchanging efficiency, small equipment volume, low oil consumption, small maintenance, economical overall operation and the like, and is a revolutionary innovation of a main-transformation heat-exchanging way.

Owner:STATE GRID CORP OF CHINA +5

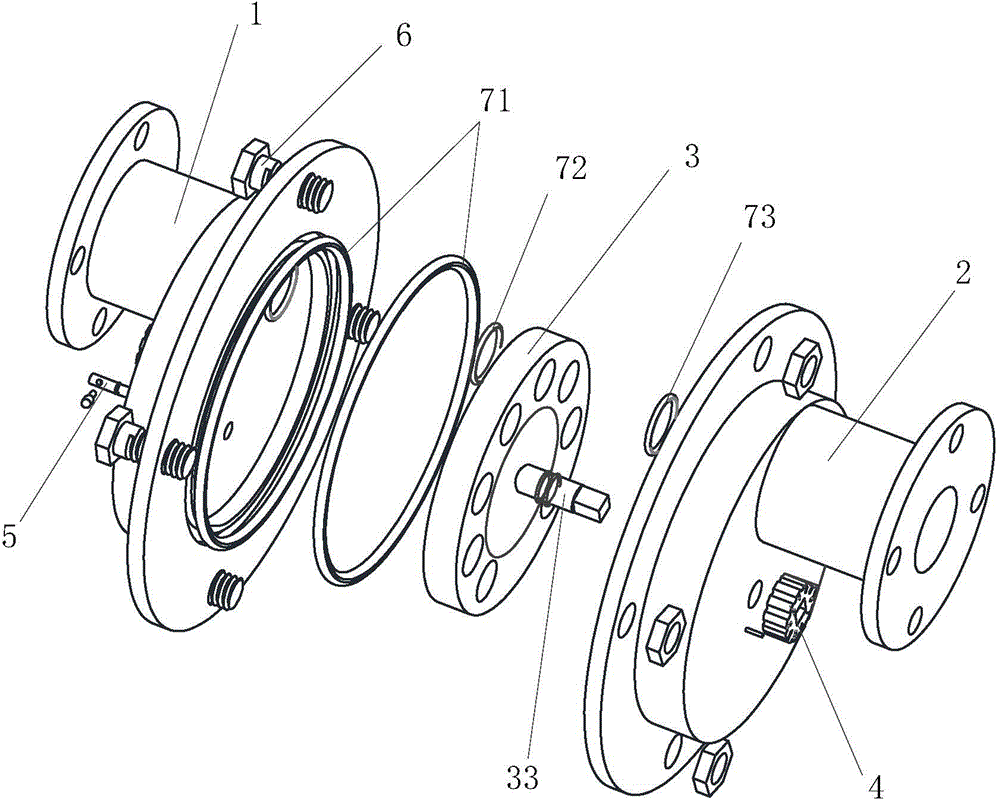

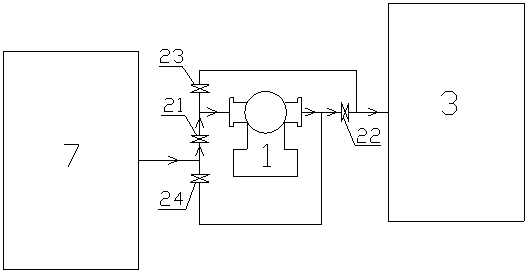

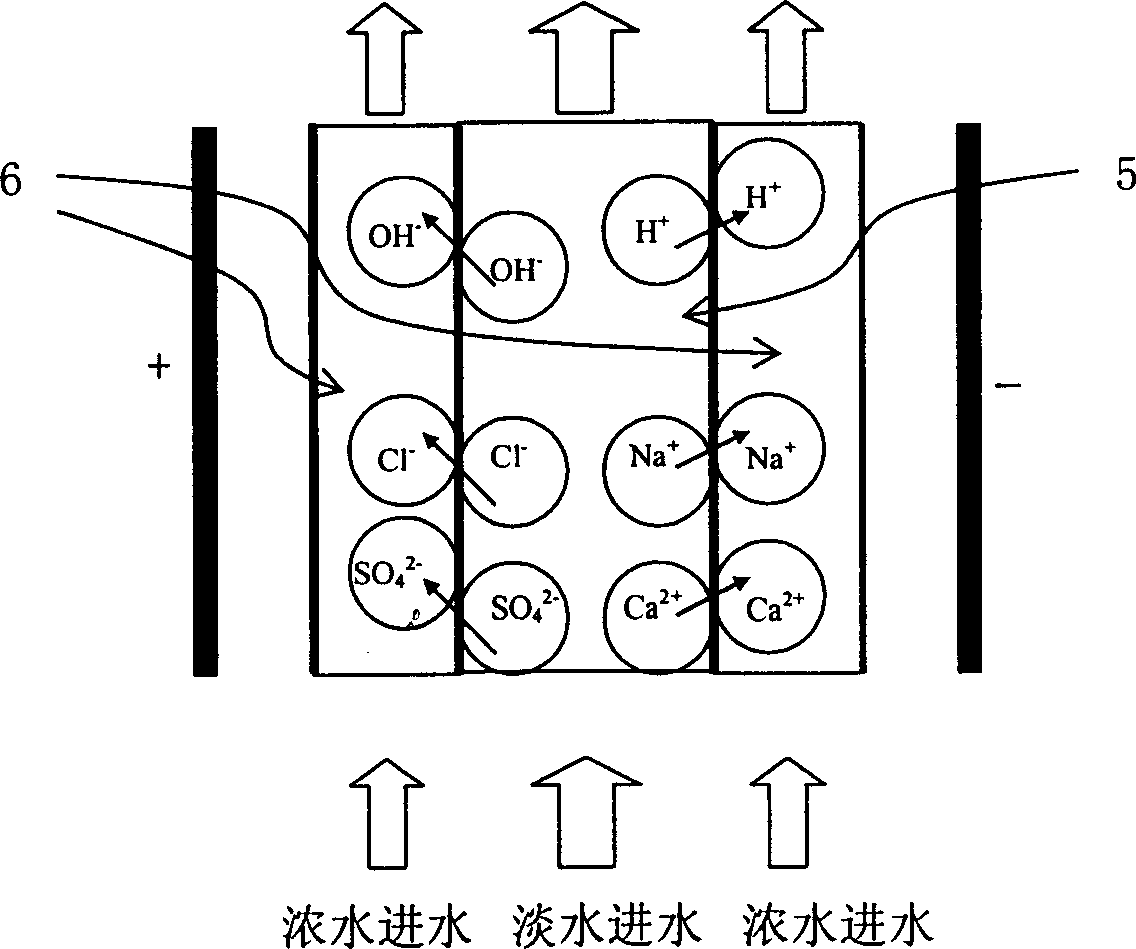

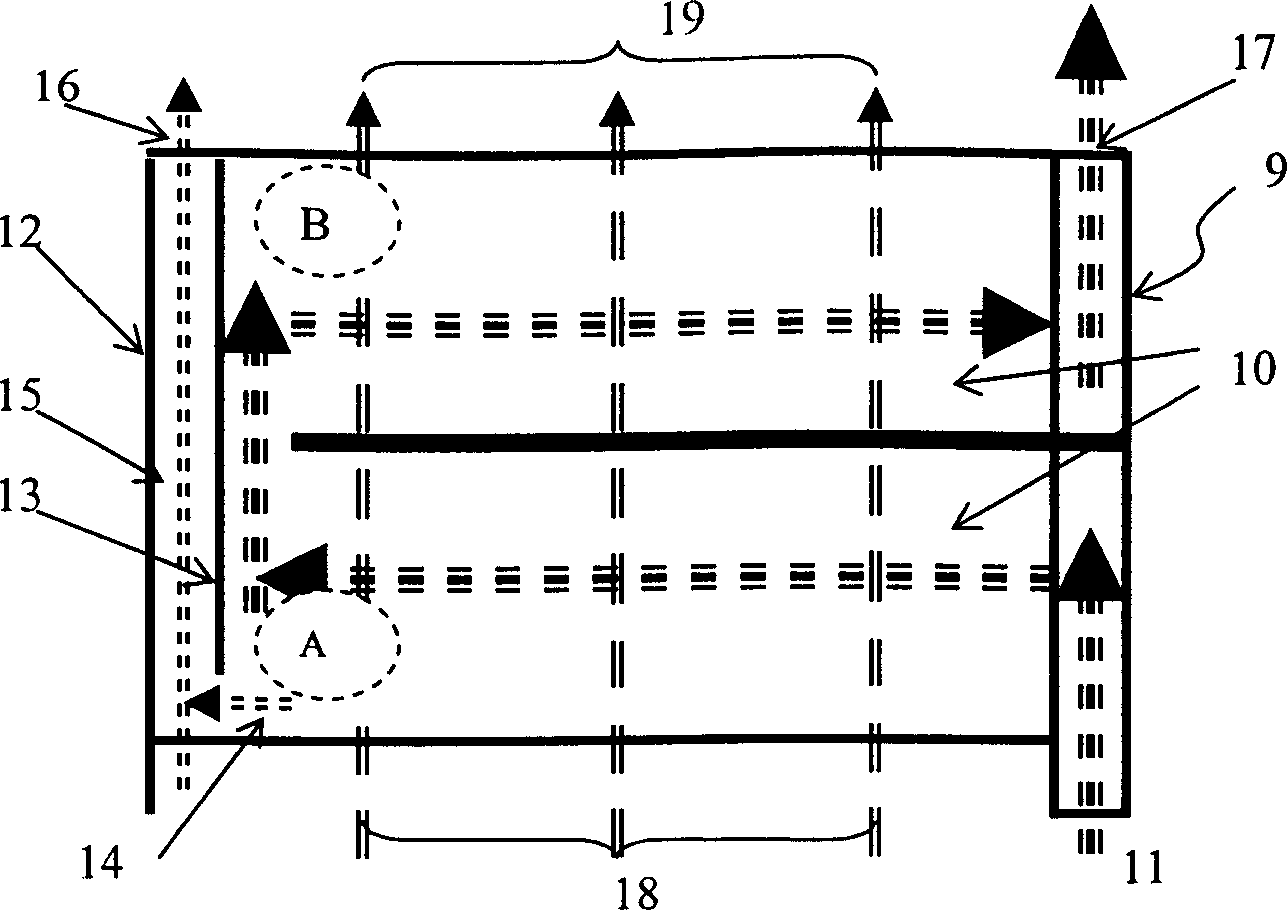

Continuous electrodeionization device

InactiveCN1864823ASimplify the assembly processShorten assembly cycleDispersed particle separationElectrodialysisElectricityWater flow

The invention discloses a plate-and-frame electric deionizing unit. One side of working zone of freah water room is equipped with a fresh water room opening (21) connected to it; said opening is used as filling port for filling or changing ion material, and is sealed by sealing baffle; the two relative sides in heavy concentration water room working zone paralleling to fresh water flowing direction are provided with water inlet (25) and outlet (26) for heavy concentration room respectively; said inlet and outlet extend along direction parallelling to fresh water flowing direction. It is convenient for said device to fill and change resin on the pot, and adjust the resin filling ratio; the sealing problem caused by resin particle is avoided; and the water flow direction of fresh water and heavy concentration water is in cross flow.

Owner:四川龙瑞源环境科技股份有限公司

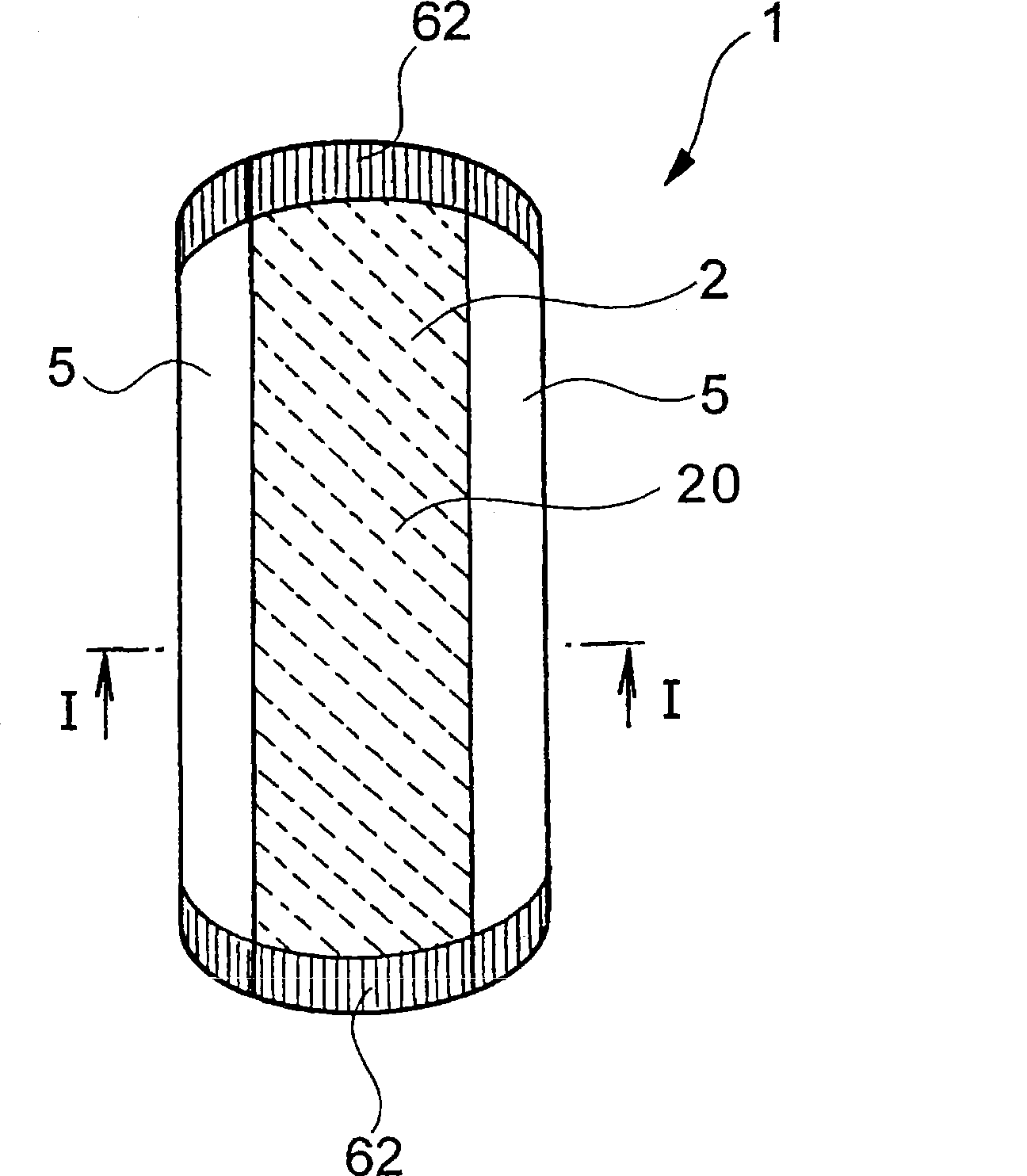

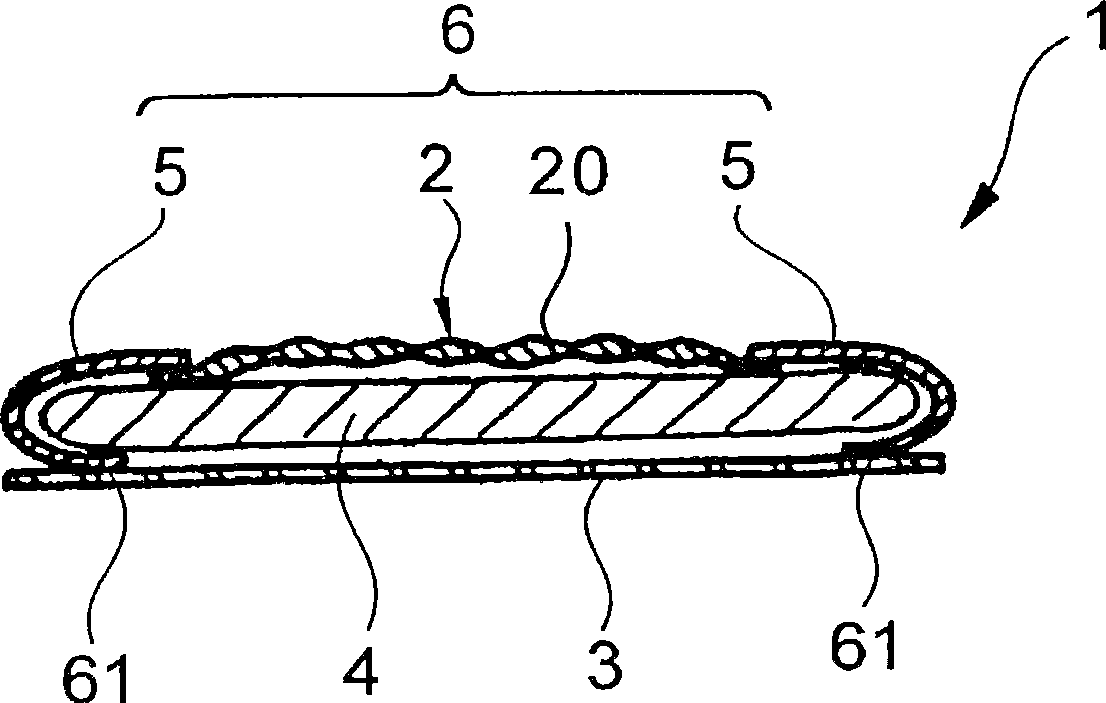

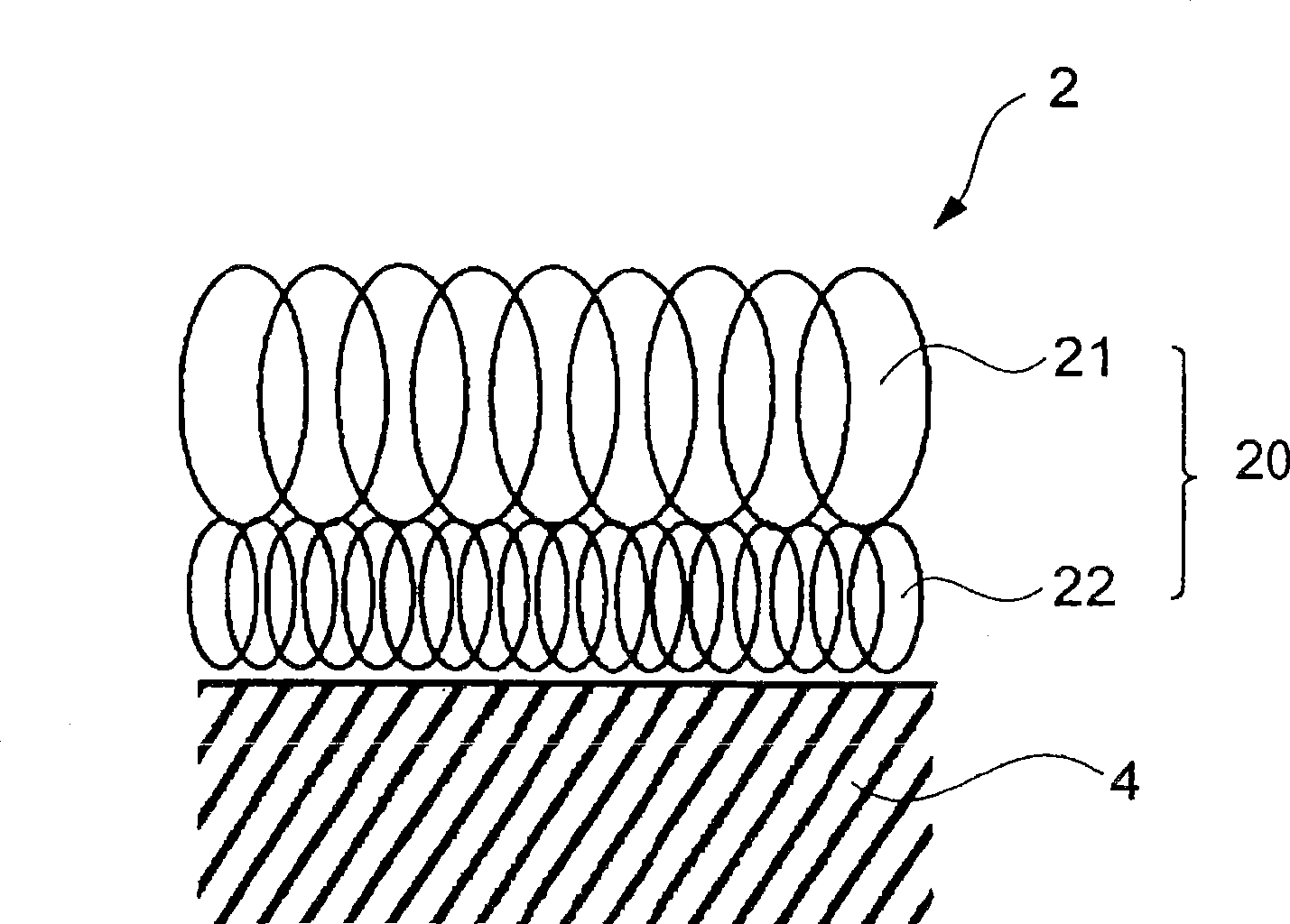

Surface sheet of absorptive article

The top sheet of the absorbent article of the present invention is composed of a laminated nonwoven fabric (20) having an upper layer (21) disposed on the skin side and a lower layer (22) disposed on the absorber (4) side, and before liquid permeation, The hydrophilic degree of the lower layer (22) is higher than the hydrophilic degree of the upper layer (21) or approximately equal to the hydrophilic degree of the upper layer (21); after the liquid penetrates, the upper layer (21) The degree of hydrophilicity is higher than that of the lower layer (22).

Owner:KAO CORP

Cemented filling close to back processing technology for goaf at barren rock filling background

The invention provides a cemented filling close to back processing technology for a goaf at the barren rock filling background and belongs to the technical field of mining engineering. The cemented filling close to back processing technology for the goaf at the barren rock filling background is characterized in that iron tailings and cementation powder are used as filling slurry, and the filling slurry is delivered to underground through an existing filling tube; liquid sodium aluminate accelerator which is, by mass, 7% of the cementation powder are added into a stirring bucket which is arranged on the plane of the goaf, the slurry is delivered to an overflowing pool which is built on the front edge of the goaf through a tube, the slurry takes advantages of the situation when plug flow is formed and slides into the goaf, the slurry entering the goaf loses liquidity in a short time and coagulates, and therefore bottom pavement is achieved; low-cement-sand ratio slurry is used for filling the close to back, and filling is finished, wherein the cement-sand ratio of the low-cement-sand ratio slurry is 1:10-1:12. The cemented filling close to back processing technology for the goaf at the barren rock filling background achieves rapid coagulation of the slurry, reduces the flow resistance of the tubes, the phenomenon that the slurry flows out under the condition that no sealing wall is arranged is avoided, the filling close to back effect is good, strength is high, and technology implementation cost is low.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com