Inorganic phase-change energy storing particles, floor heating mortar and preparation method thereof

A technology of inorganic phase change and inorganic phase change materials, which is applied in the field of floor heating mortar and its preparation, and inorganic phase change energy storage particles, can solve the problems of building material performance change, wall damage, phase separation, etc. The effect of preventing loss, avoiding flow and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for preparing inorganic phase change energy storage particles and floor heating mortar, comprising the following steps:

[0046] 1. Preparation of phosphated starch glue:

[0047] A, the mass percent composition of this esterified starch glue comprises: 1.3% sodium dihydrogen phosphate, 9.0% starch, 79.3% water (comprising 7% in the first step of the preparation process and 72.3% in the third step ); 10.4% mass percent concentration is 20% NaOH aqueous solution (including 1‰ in the first step of the preparation process and 10.3% in the third step)

[0048] b. Preparation process:

[0049] The first step: esterification synthesis: add water to sodium dihydrogen phosphate, stir to dissolve, adjust the pH value to 5.5 with NaOH aqueous solution with a concentration of 20% by mass percentage, add starch, fully stir and disperse to make starch slurry, at 65 Heating and reacting at ℃ for 20 minutes to obtain esterified starch mixed slurry;

[0050] The second step...

Embodiment 2~8

[0064] It is mainly aimed at changing the dosage of sodium sulfate decahydrate, gypsum and cement in the preparation process of inorganic phase change energy storage particles, while the dosage of water-absorbing resin, phosphated starch glue and water remains unchanged.

[0065] 1. Preparation of phosphated starch glue:

[0066] A, the mass percentage composition of this phosphated starch glue is consistent with embodiment 1;

[0067] B, preparation procedure: the preparation procedure of this phosphated starch glue is consistent with embodiment 1;

[0068] 2. Preparation of inorganic phase change energy storage particles:

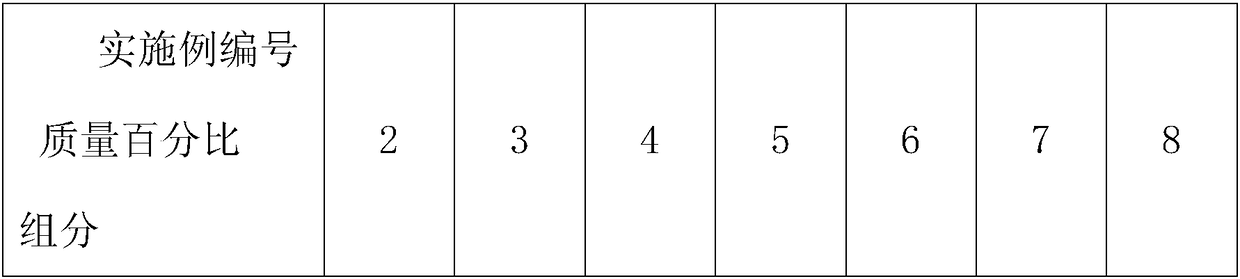

[0069] A, the component and the mass percentage example of batching in each embodiment are shown in Table 1;

[0070] b. Mixing, granulation and coating:

[0071]Mix sodium sulfate decahydrate with water, stir to dissolve part of sodium sulfate decahydrate, add phosphated starch glue, stir and disperse evenly, add water-absorbing resin after dispersion...

Embodiment 9~14

[0081] It is mainly aimed at changing the amount of water, water-absorbing resin, phosphated starch glue, gypsum and cement in the preparation process of inorganic phase change energy storage particles, while the amount of sodium sulfate decahydrate is fixed.

[0082] 1. Preparation of phosphated starch glue:

[0083] A, the mass percentage composition of this phosphated starch glue is consistent with embodiment 1;

[0084] B, preparation procedure: this phosphated starch glue preparation procedure is consistent with embodiment 1;

[0085] 2. Preparation of inorganic phase change energy storage particles:

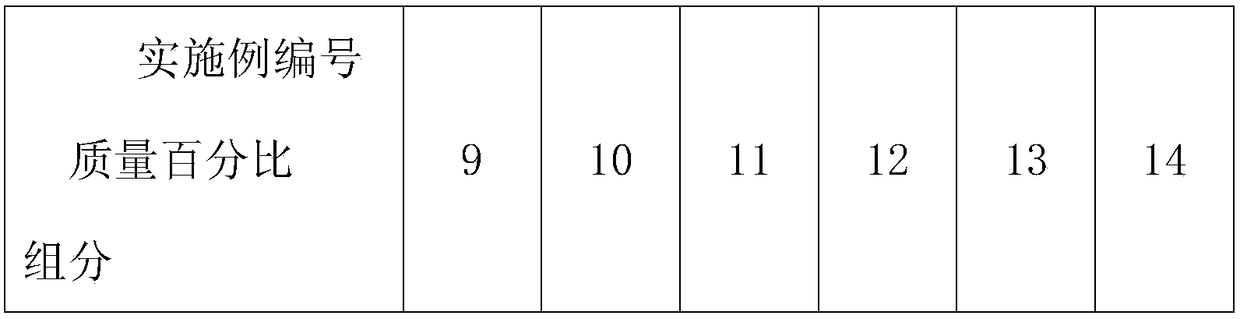

[0086] A, the component and the mass percent example of batching in each embodiment are shown in Table 2;

[0087] B, mixing, granulation and coating: consistent with embodiment 1;

[0088] Table 2: Component and mass percentage of batching in each embodiment:

[0089]

[0090]

[0091] c. Envelope:

[0092] Its coating process is consistent with embodiment 1;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com