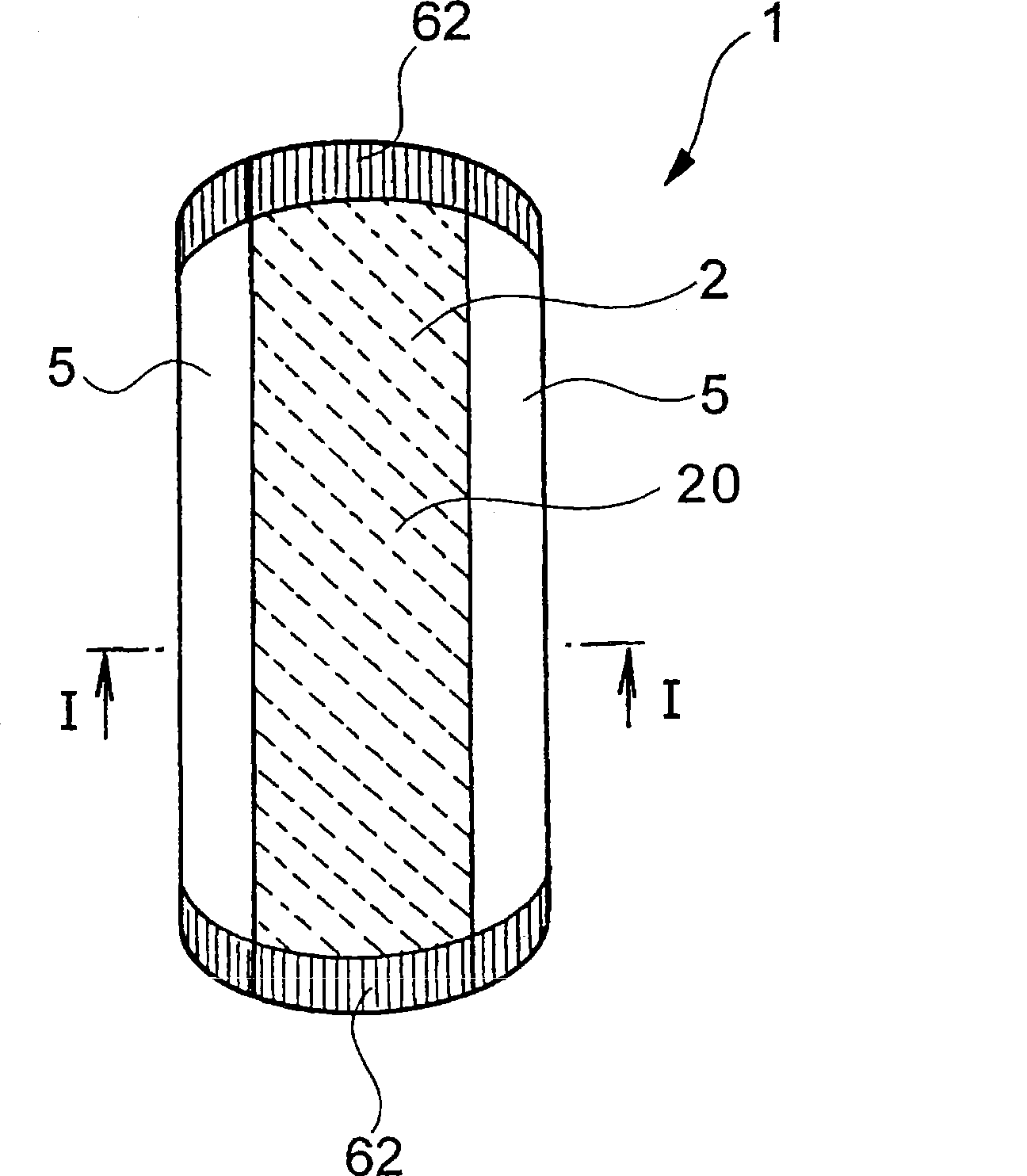

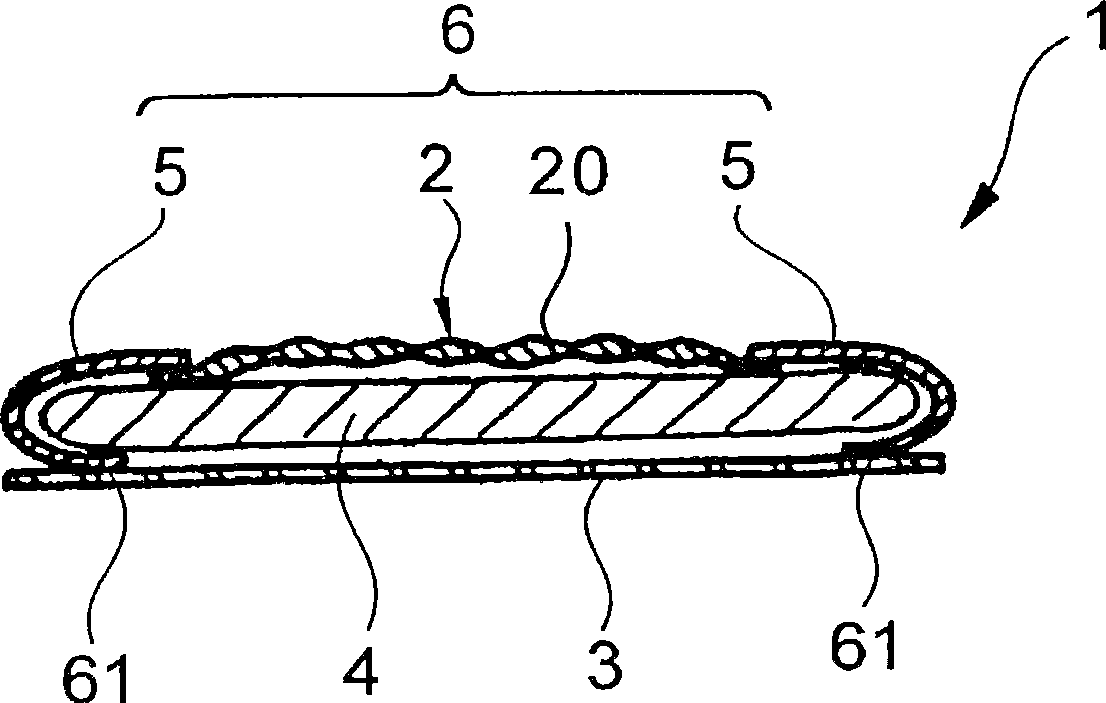

Surface sheet of absorptive article

An absorbent and surface sheet technology, applied in the field of surface sheets, can solve the problems of inability to move liquid, difficult liquid inhalation, flow to the surface of the surface sheet, etc., and achieve the effect of preventing surface flow and wet back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] (Preparation of samples for measurement)

[0053] Cut the surface sheet to a size of 150mm × 70mm, and stack it on 10 pieces of paper adjusted to the same size as the surface sheet (based on the mass per unit area of 30g / m 2 Paper formed from pulp, crepe ratio (crepe ratio) is 5 to 10%) and loaded on a horizontal plane, on which Figure 5 Acrylic plate with cylinder shown. Then, place a weight on the acrylic plate and apply 10 g / cm to the surface sheet 2 load. The size of the acrylic resin plate is 200 mm long × 100 mm wide × 8 mm thick, the height of the cylinder from the upper surface of the acrylic resin plate is 50 mm, and the inner diameter of the cylinder is 22 mm from the upper end of the cylinder to the large diameter part of 40 mm. The inner diameter is reduced within a range of 5 mm below the diameter portion, and further, the small diameter portion (height 5 mm) of the lower end of the cylinder is 10 mm below it. A coaxial hole with an inner diameter of...

Embodiment 1

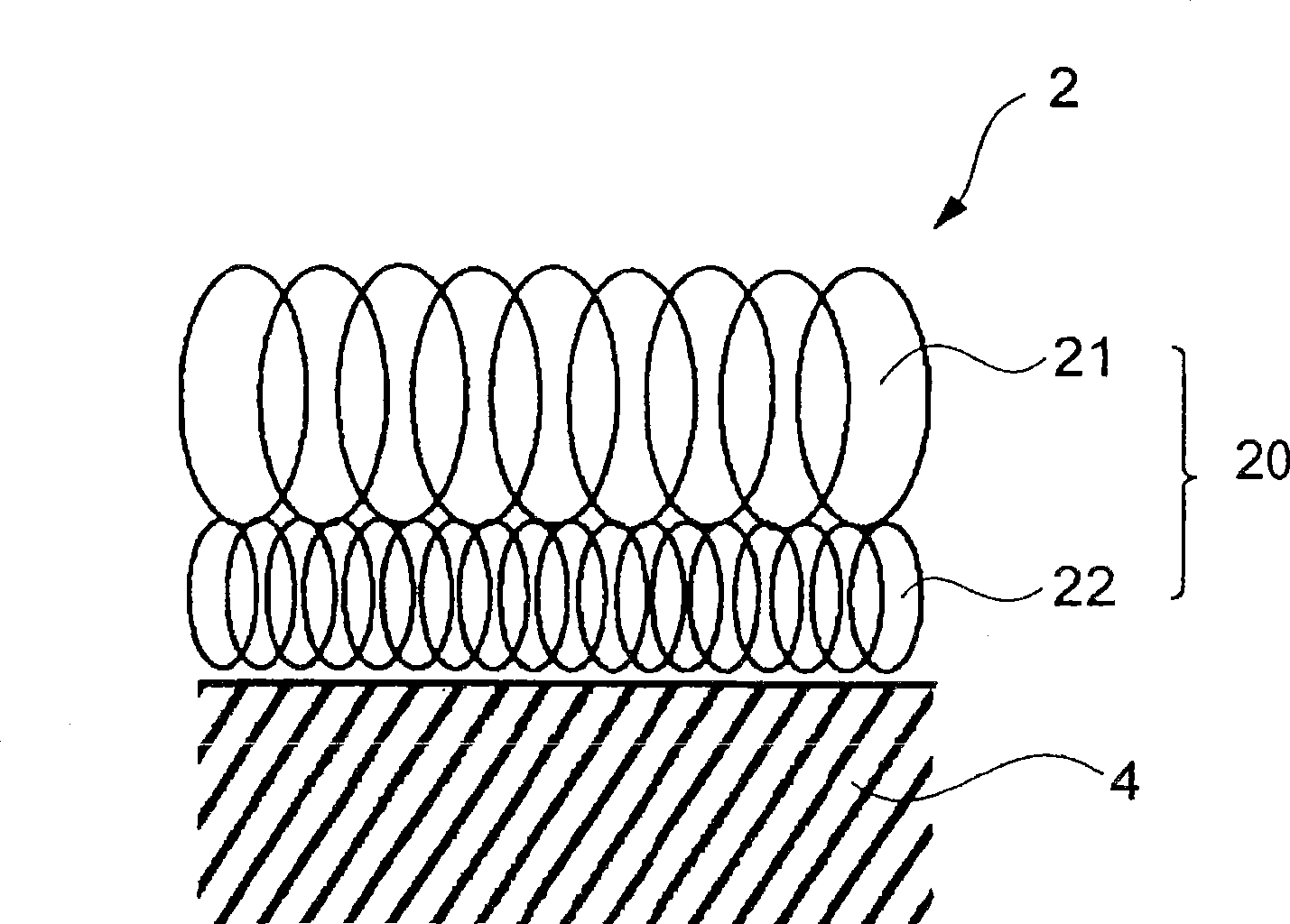

[0111] Embodiment 1: By carding machine, fiber A is carded and manufactured with a mass per unit area of 12g / m 2 fiber web, and then the fiber D is carded by a carding machine to produce a mass per unit area of 13g / m 2 After superimposing the two fiber webs, the mass per unit area is 25g / m2 through hot air at 136°C (hot air method). 2 of non-woven fabrics.

Embodiment 2

[0112] Embodiment 2: By carding machine, fiber B is carded and manufactured with a mass per unit area of 12g / m 2 fiber web, and then the fiber C is carded by a carding machine to produce a mass per unit area of 13g / m 2 After superimposing the two fiber webs, the mass per unit area is 25g / m2 through hot air at 136°C (hot air method). 2 of non-woven fabrics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com