Heat pump type main-transformation heat-exchanging device with SF6 (sulfur hexafluoride) as heat-exchanging medium and heat-exchanging method

A heat exchange medium, heat pump technology, used in lighting and heating equipment, transformer/inductor cooling, fluid circulation arrangements, etc. , to achieve the effect of reducing electrical insulation performance and physical and chemical properties, ensuring safe operation, and small size of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

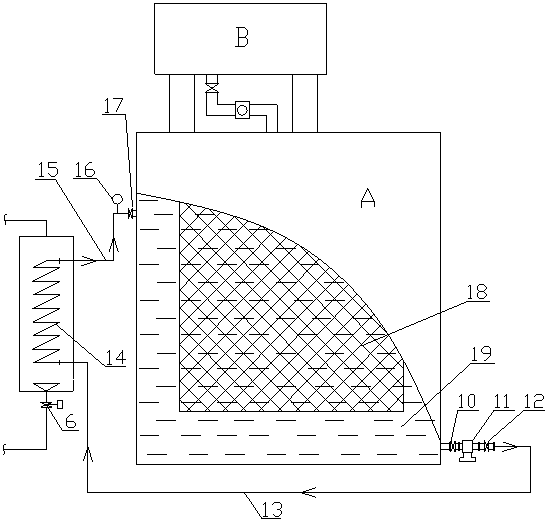

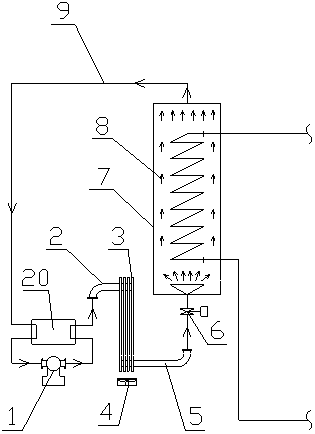

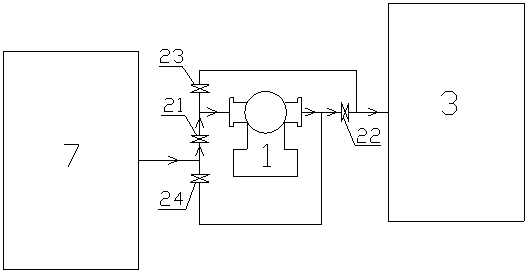

[0029] like Figure 1~7 shown, a SF 6 Heat pump type main heat transfer device as heat transfer medium, including SF6 A heat pump compressor 1, a cooler 3 and an evaporator 7, one port of the cooler 3 is connected to the SF of the evaporator 7 through a two-way throttling valve 6 6 The medium flow path 8 is connected to one port, and the SF of the evaporator 7 6 The other port of the medium flow path 8 and the other port of the cooler 3 pass through the four-way valve 20 and the SF 6 The two ports of the heat pump compressor 1 are connected, and the two ports of the transformer oil flow path 14 of the evaporator 7 are respectively connected with the oil inlet on the upper part of the main transformer body A and the oil outlet on the lower part. The main transformer oil inlet valve 17 is installed at the oil inlet, and the main transformer oil outlet valve 10 is installed at the oil outlet of the main transformer body A, and the transformer oil 19 in the main transformer body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com