Phase-change microcapsule-based heat conducting potting silica gel comprising flame retardant and preparation method thereof

A phase change microcapsule, thermal conductivity potting technology, applied in chemical instruments and methods, adhesives, adhesive additives, etc., can solve the problems of poor thermal conductivity, poor compatibility, penetration and migration, etc., and achieve thermal conductivity and heat storage. Good temperature control performance, ensure temperature uniformity, and increase the effect of uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

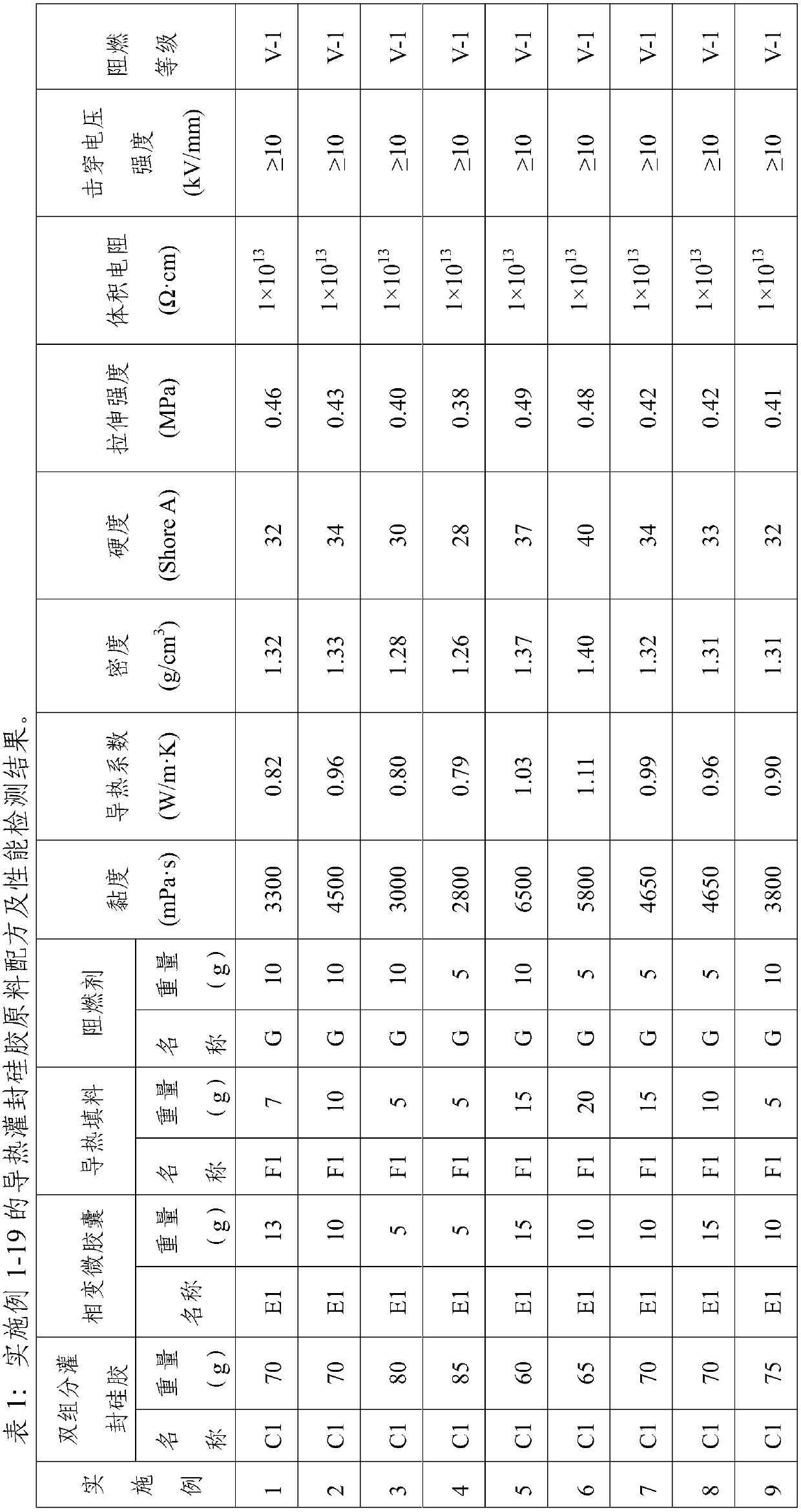

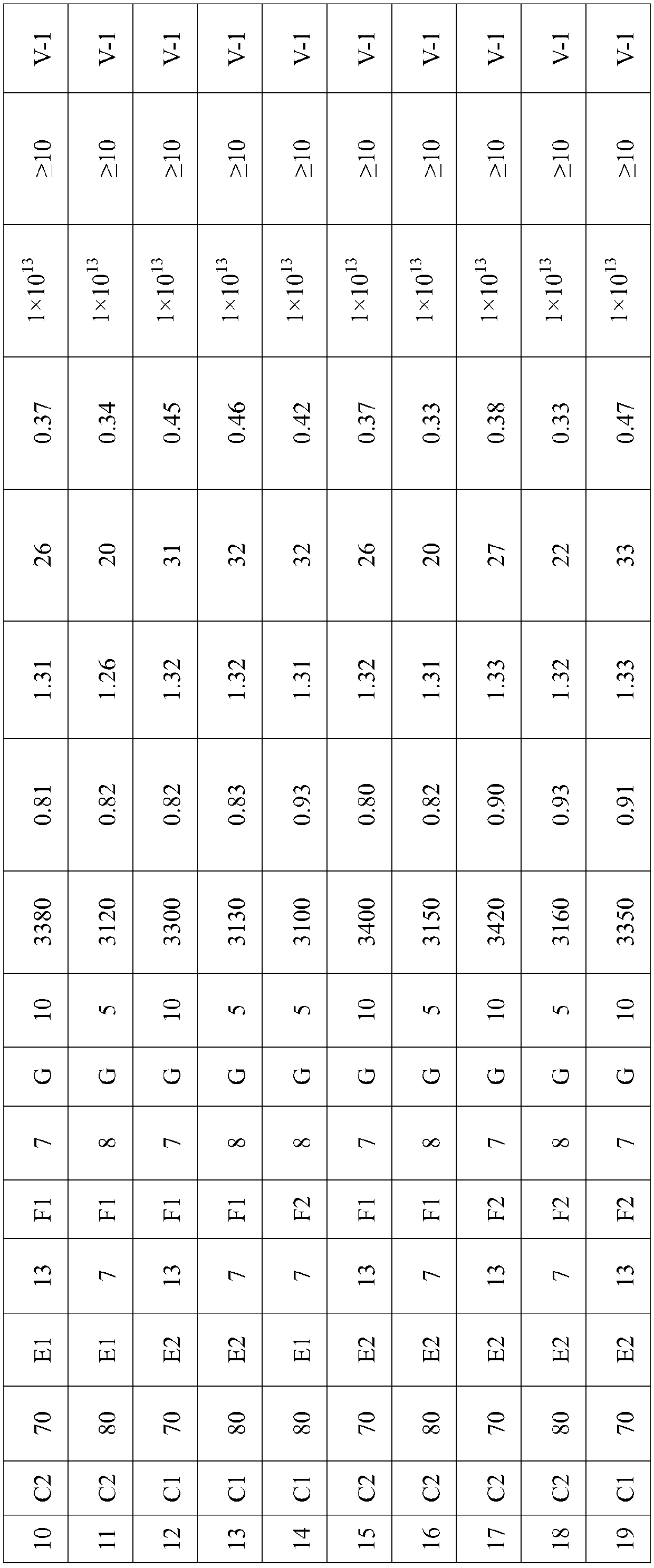

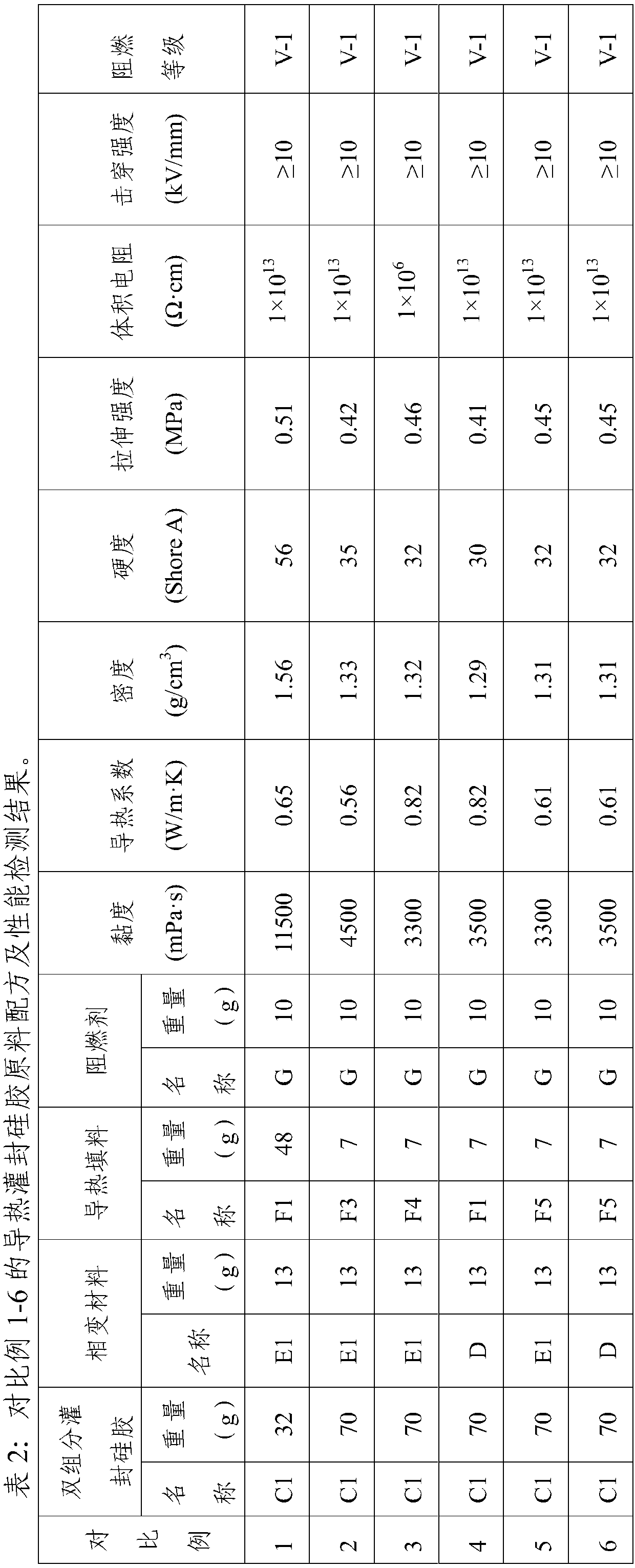

Examples

preparation example Construction

[0034] The phase-change microcapsules described in the present invention can be commercially available phase-change microcapsules, for example, paraffin alkane can be used as the core material, urea-formaldehyde resin is used as the shell, and a thermally conductive filler is also contained. The thermally conductive filler is coated with paraffin wax in the urea-formaldehyde resin. The low-temperature heat-controlled phase-change microcapsules are added in the alkane process, and the heat-conducting filler is added in an amount of 5% to 30% of the paraffin alkane mass percentage. The specific preparation method of the low-temperature thermally controlled phase change microcapsules, for example, may include: the first step, paraffin alkane preheating; the second step, urea-formaldehyde resin prepolymer synthesis; the third step, styrene maleic anhydride resin solution , water and inorganic salt polymerization; the fourth step, the materials are mixed to obtain the mixture; the f...

Embodiment 1

[0052] ① Weigh 7g of thermally conductive filler nano-alumina powder and 0.07g of silane coupling agent n-octyltriethoxysilane, prepare n-octyltriethoxysilane and water at a mass ratio of 1:3 to make a solution, add Proper amount of ethanol was mixed evenly and allowed to stand for 20 minutes. Slowly add the hydrolyzed silane coupling agent solution into the thermally conductive filler, stir well until it is uniformly dispersed, and heat and stir the mixed solution in a water bath at 65°C, so that the hydrolyzed silane coupling agent can perform surface treatment on the thermally conductive filler , to obtain a surface-treated thermally conductive filler mixture. Centrifuge the surface-treated thermally conductive filler mixture at a centrifugal speed of 1500r / min for 6 minutes for solid-liquid separation and separate the thermally conductive filler solid matter, and place the thermally conductive filler solid material in a 75°C drying oven for vacuum drying treatment After 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com