Hydrogen storing apparatus of metal hydrides and manufacturing method thereof

A hydride and hydrogen storage technology, applied in the field of transportation and compression, hydrogen storage, can solve the problems of excessive accumulation, poor thermal conductivity of metal hydride powder, slow hydrogen absorption and desorption speed, etc., to prevent flow and local accumulation, long-term operation Safe and reliable, the effect of improving heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

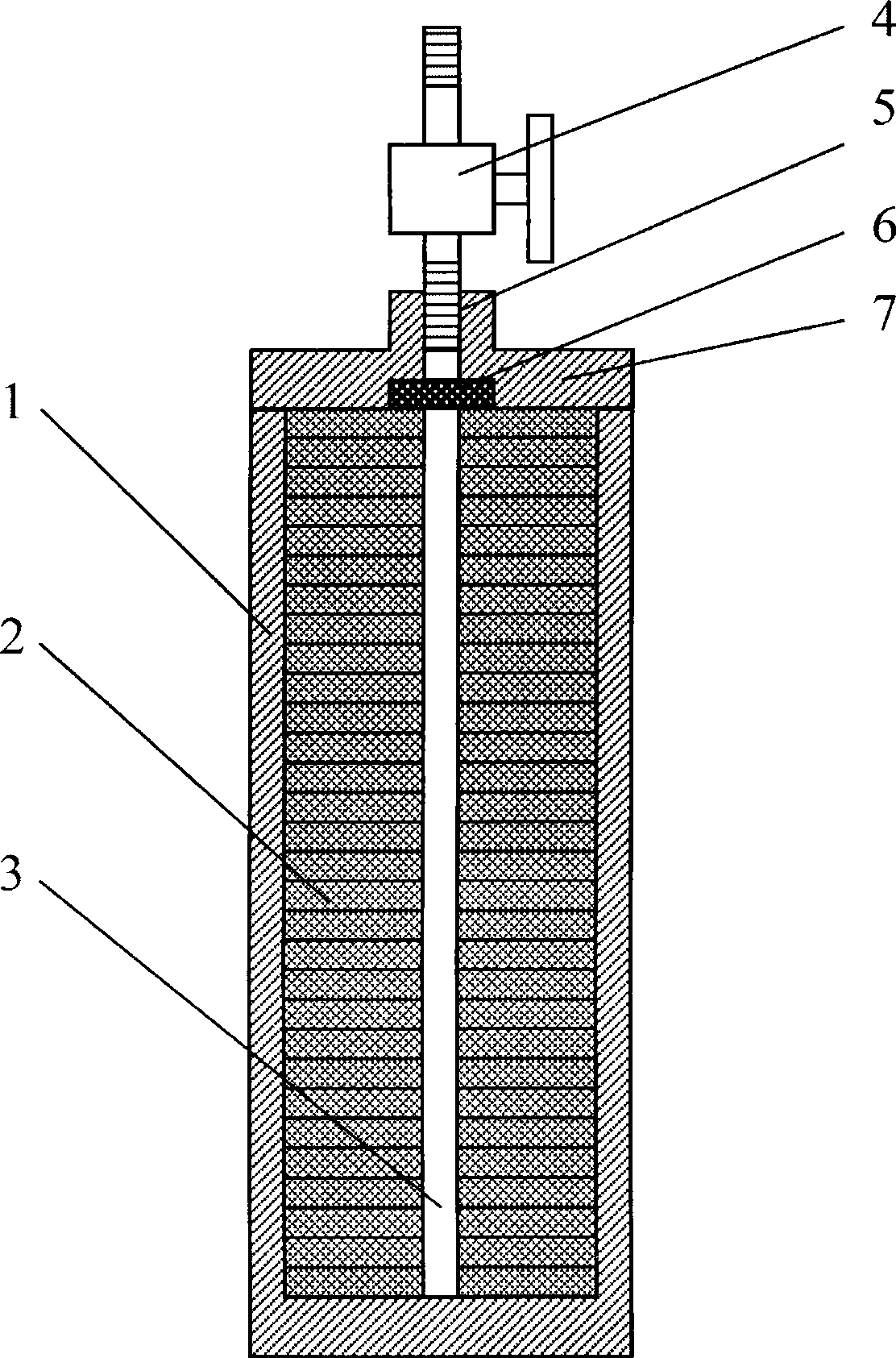

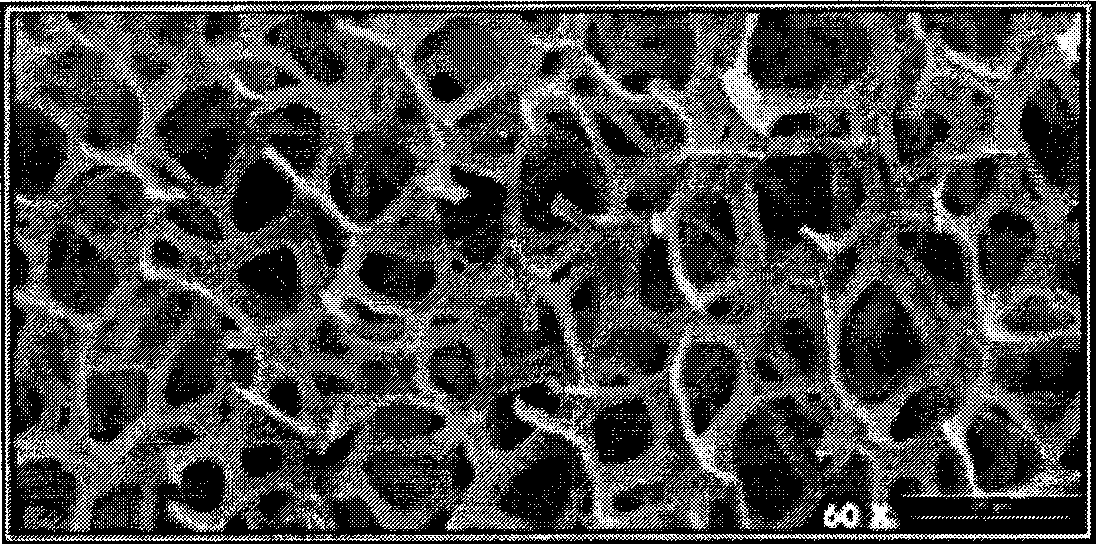

Embodiment 1

[0029] The non-hydrogen-absorbing foamed metal substrate in the metal hydride hydrogen storage device adopts a foamed aluminum substrate with a porosity of 91% and a thickness of 15 mm. The cylindrical shell of the hydrogen storage device is made of aluminum alloy with an inner diameter of 80 mm; the hydrogen storage alloy is a rare earth hydrogen storage alloy Mm 0.8 Ca 0.2 Ni 5 , where Mm is a mixed rare earth metal. Mm 0.8 Ca 0.2 Ni 5 The alloy is crushed to form a powder with a particle size not greater than 0.2 mm; then Mm 0.8 Ca 0.2 Ni 5 Mix the alloy powder with a 3% PVA aqueous solution (the amount added is one-tenth of the weight of the hydrogen storage alloy powder) to form a paste, then smear it into the pores of the foamed aluminum substrate, and heat it at 30 ° C. Completely dry to form a hydrogen storage material sheet; then cut the dried hydrogen storage material sheet into a disc with an outer diameter of 80 mm, and make a circular hole with a diameter ...

Embodiment 2

[0032] The non-hydrogen-absorbing foamed metal substrate in the metal hydride hydrogen storage device adopts a foamed copper substrate with a porosity of 95% and a thickness of 10 mm. The shell of the hydrogen storage device is made of stainless steel with an inner diameter of 63 mm; the hydrogen storage alloy is titanium-based TiFe 0.85 mn 0.15 alloy. TiFe 0.85 mn 0.15 The alloy is crushed to form a powder with a particle size of no more than 0.2 mm, and then mixed with a CMC aqueous solution with a mass concentration of 1.5% (the amount added is one tenth of the weight of the alloy powder) to make a paste, and then smeared and filled into the foamed copper substrate In the pores, and completely dried at 50 ℃ to form a hydrogen storage material sheet; then the dried hydrogen storage material sheet is cut into many discs with an outer diameter of 63 mm, and a hole diameter of 6 mm is made in the center of the disc. Round holes; then stack the hydrogen storage material shee...

Embodiment 3

[0034] The non-hydrogen-absorbing foamed metal substrate in the metal hydride hydrogen storage device adopts a foamed nickel substrate with a porosity of 98% and a thickness of 2 mm. The shell of the hydrogen storage device is made of stainless steel, with an inner diameter of 50 mm; the hydrogen storage alloy is titanium vanadium BCC alloy Ti 0.16 Cr 0.22 V 0.52 Fe 0.05 Zr 0.05 . Ti first 0.16 Cr 0.22 V 0.52 Fe 0.05 Zr 0.05 The alloy is crushed to form a powder with a particle size of no more than 0.15 mm, and then mixed with a PVA aqueous solution with a mass concentration of 3% (the amount added is one tenth of the weight of the alloy powder) to make a paste, and then smeared and filled into the foamed nickel substrate The pores of the hydrogen storage material are completely dried at 60°C to form a hydrogen storage material sheet; then the dried hydrogen storage material sheet is cut into many discs with an outer diameter of 50 mm, and a hole diameter of 3 mm is m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com