Fracturing pulse sand filling system with ultrahigh flow conductivity and method for operating fracturing pulse sand filling system

A technology of diversion capacity and pulse, which is applied in the field of oil and gas field development and research, can solve the problems of increasing equipment and machine maintenance, repair costs, inability to realize proppant slug injection, pressure suppression of sand mixing vehicles, etc., and achieve reliable measurement and control systems , avoid damage and hysteresis effect, improve the effect of relative life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

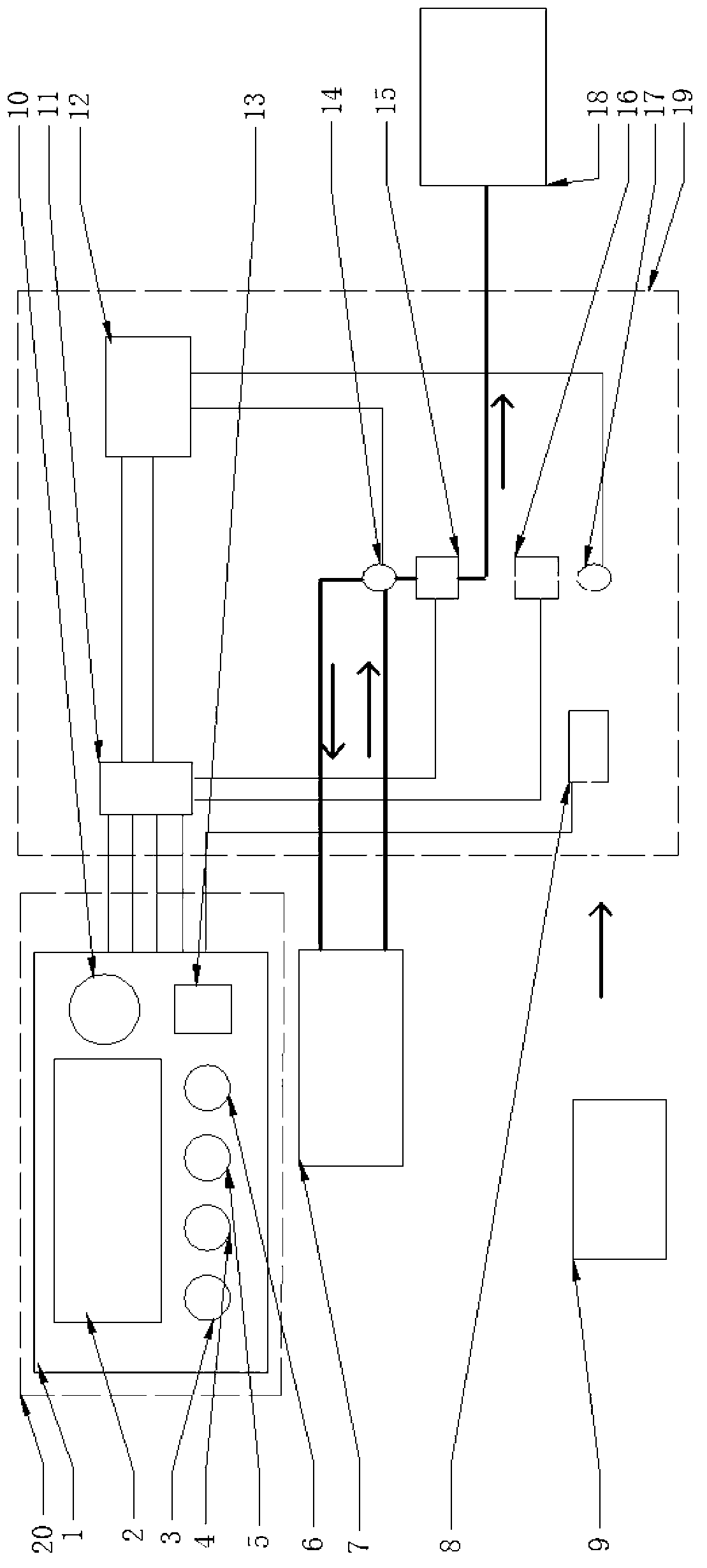

[0038] A fracturing pulse sanding system for achieving ultra-high conductivity, comprising an external control unit 20, an internal controlled unit 19, an external fracturing pump unit 18, a sand mixing vehicle 7 and a liquid storage tank 9; the sand mixing The vehicle 7 is filled with sand mixing fluid for fracturing, the liquid storage tank 9 is filled with base fluid for fracturing, and the external control unit 20 realizes the sand mixing in the sand mixing vehicle 7 through the internal controlled unit 19 The liquid and base fluid in the liquid storage tank 9 are alternately pumped into the external fracturing pump unit 18, and finally the external fracturing pump unit 18 realizes the alternate pumping of sand mixing fluid and base fluid to the middle of underground mining fractures.

[0039] The sand ratio in the sand mixing liquid is 50%.

[0040] The external control unit 20 includes a control panel 1, a display 2 installed on the control panel, a No. 1 electromagnetic...

Embodiment 2

[0046] A fracturing pulse sanding system that achieves ultra-high conductivity as described in Embodiment 1, the difference is that the No. 1 three-way electric ball valve 14 and the No. 2 three-way electric ball valve 17 are in the open or closed state Completely opposite: when the No. 1 three-way electric ball valve 14 is opened, the No. 2 three-way electric ball valve 17 is closed; when the No. 1 three-way electric ball valve 14 is closed, the No. 2 three-way electric ball valve 17 is opened. The selection parameters of the three-way electric ball valve are as follows: with AC220V as the power, the nominal diameter of the three-way electric ball valve: 101.6mm, the nominal pressure: 4MPa, the medium temperature: 20-40°C, the sealing method of the valve body is hard seal, Among them, the material of the valve body is WCB, the material of the ball is 2Cr13 (nitrided), the material of the seat sealing ring is reinforced polyvinyl chloride (PPL), the applicable temperature is -3...

Embodiment 3

[0048] A working method of the fracturing pulse sand adding system as described in embodiment 1, comprising the following steps:

[0049] (1) Press the start button 13 to start the fracturing pulse sand addition system;

[0050] (2) At the initial stage of fracturing, set the upper limit values of the No. 1 and No. 2 electromagnetic flow meters respectively through the control button 3 of the No. 1 electromagnetic flow meter and the control button 4 of the No. 2 electromagnetic flow meter, and select the automatic mode Work, when the flow exceeds the upper limit, the system sends out an alarm, and feeds back to the PLC controller 11 according to the flow data, and the PLC controller 11 sends instructions to the No. 1 electric three-way ball valve 14 and the No. 2 electric three-way ball valve 17, and the valve Turn it down to an appropriate value. If the system has not cleared the alarm, the system will automatically switch to manual mode, and the control button 5 of the thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal diameter | aaaaa | aaaaa |

| Nominal pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com