Liquid ejection head manufacturing method, liquid ejection head and printing device

A technology of a liquid ejection head and a manufacturing method, which is applied in the manufacture of liquid ejection heads, liquid ejection heads, and printing equipment, and can solve problems such as complex manufacturing processes and lower printing quality, and solve complex manufacturing processes, increase yield, and The effect of improving printing accuracy and printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

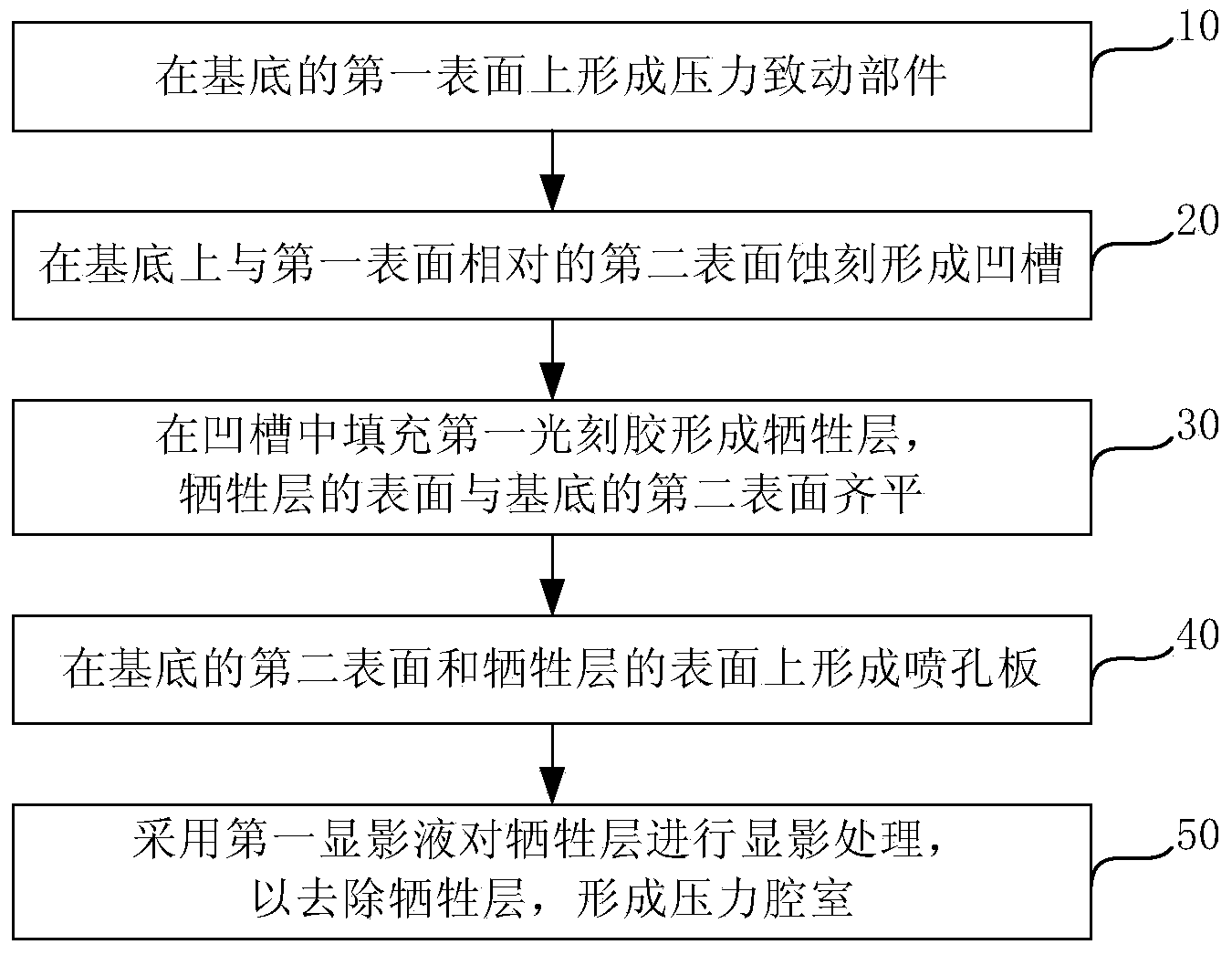

[0033] figure 1 A flow chart of a method for manufacturing a liquid ejection head provided by an embodiment of the present invention. Such as figure 1 As shown, the manufacturing method of the liquid jet head may include the following steps:

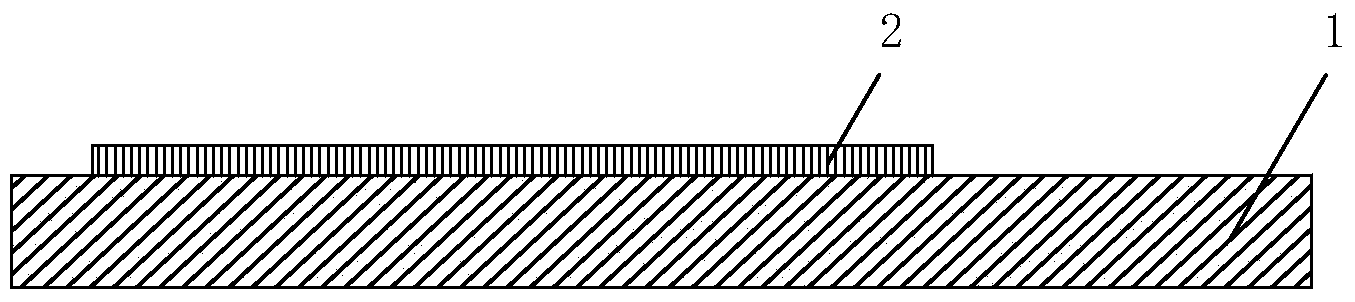

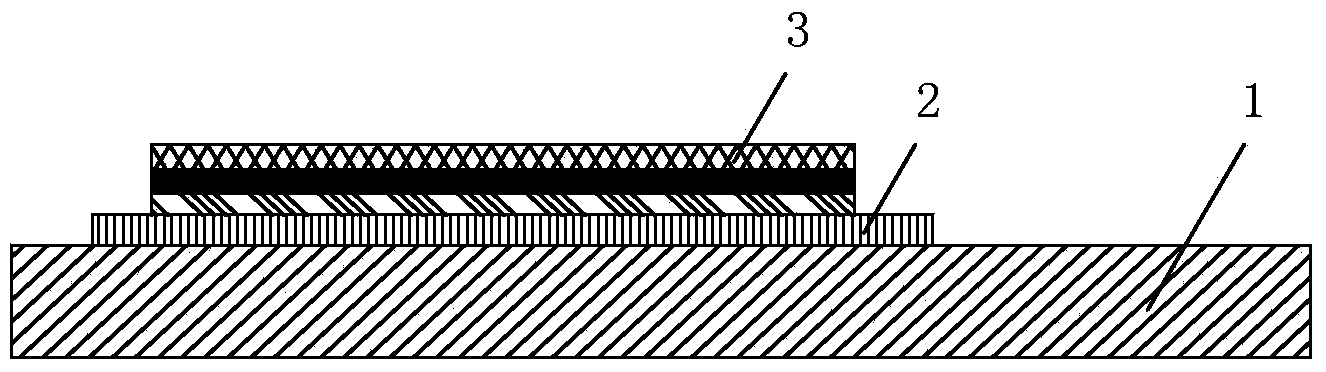

[0034] Step 10, forming a pressure actuated component on the first surface of the substrate.

[0035] The pressure actuation component can be a piezoelectric element or a thin film resistor commonly used in the prior art. If a piezoelectric element is used, the piezoelectric element is formed on the first surface of the substrate, and a voltage is applied through the piezoelectric element to deform the piezoelectric element, thereby applying pressure to the surrounding ink, so that the ink is ejected from the nozzle hole. On the printing medium; if a thin-film resistor is used, a thin-film resistor layer is formed on the first surface of the substrate, and a pulse voltage signal is applied to the thin-film resistor, and the thin-film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com