Thermal management module for square battery, and preparation method thereof, and battery pack

A prismatic battery, heat management technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of poor shape stability and cycle stability of components, no pre-heating function, reduced service life, etc., to achieve good thermal conductivity and Temperature control function, ensure temperature uniformity, and improve overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0080] In a second aspect, the present invention provides a method for preparing a thermal management module for a prismatic battery according to the first aspect, which includes the following steps:

[0081] (1) paving the thermal management material in the inner cavity of the mold;

[0082] (2) Clamp the mold and place it in an oven for preheating; preferably, when no oil absorbing agent is added to the thermal management material, preheat to a temperature higher than the melting point of the phase change material by 10°C, preferably higher than the melting point of the phase change material Melting point of 10 to 20 ° C. When an oil absorbing agent is added to the thermal management material, it is preheated to 10° C. higher than the melting point of the oil absorbing agent, preferably 10 to 20° C. higher than the melting point of the oil absorbing agent.

[0083] (3) Compression molding;

[0084] (4) After cooling down, the mold is disassembled, the prefabricated block i...

example 1

[0094] (1) Spread a layer of heat management material in the inner cavity of the mold; wherein the components of the heat management material are as shown in Table 1;

[0095] (2) Place the mold in an oven to preheat after closing the mold;

[0096] (3) Compression forming;

[0097] (4) After cooling down, the mold is disassembled, and the prefabricated block is taken out to obtain a thermal management module for a square battery;

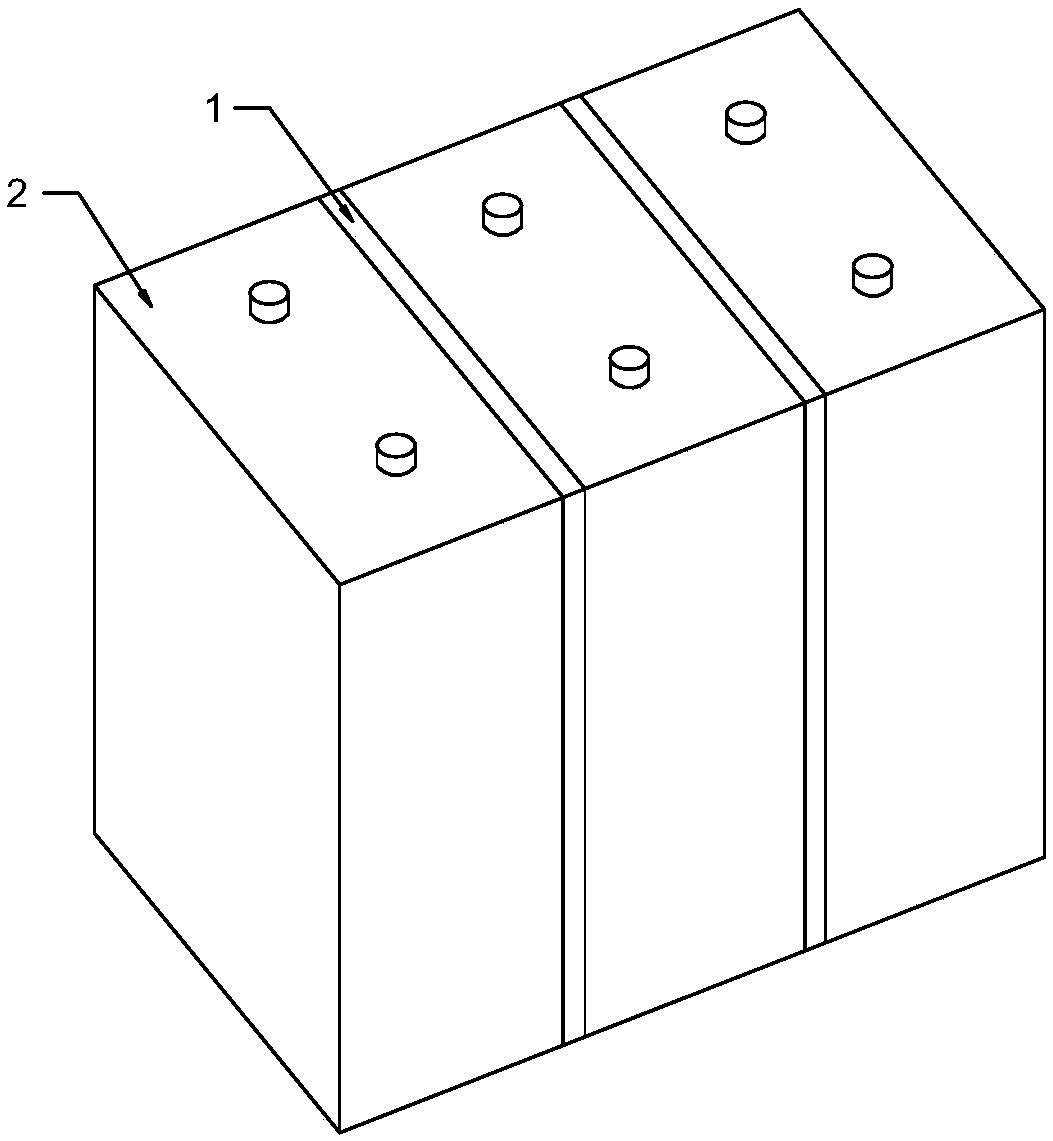

[0098] (5) According to figure 1 Assemble the prismatic battery and the thermal management module to obtain a battery pack.

[0099] Examples 2 to 30

[0100] Examples 2 to 30 were performed in the same manner as Example 1 except for the contents shown in Table 1 below. The enthalpy value, phase transition temperature and thermal conductivity of the thermal management material were detected, and the detection results are shown in Table 1.

[0101]

[0102]

[0103] In Table 1: A1 represents alkane type paraffin wax with a melting point of ...

example 31

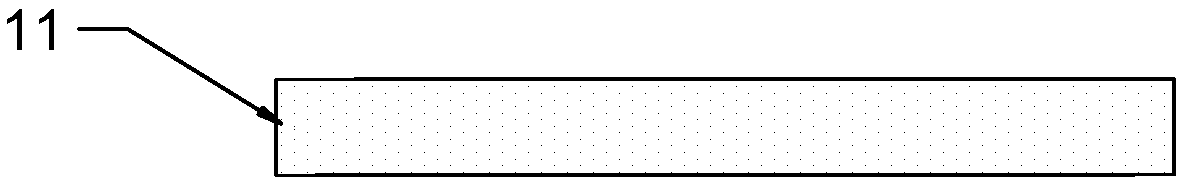

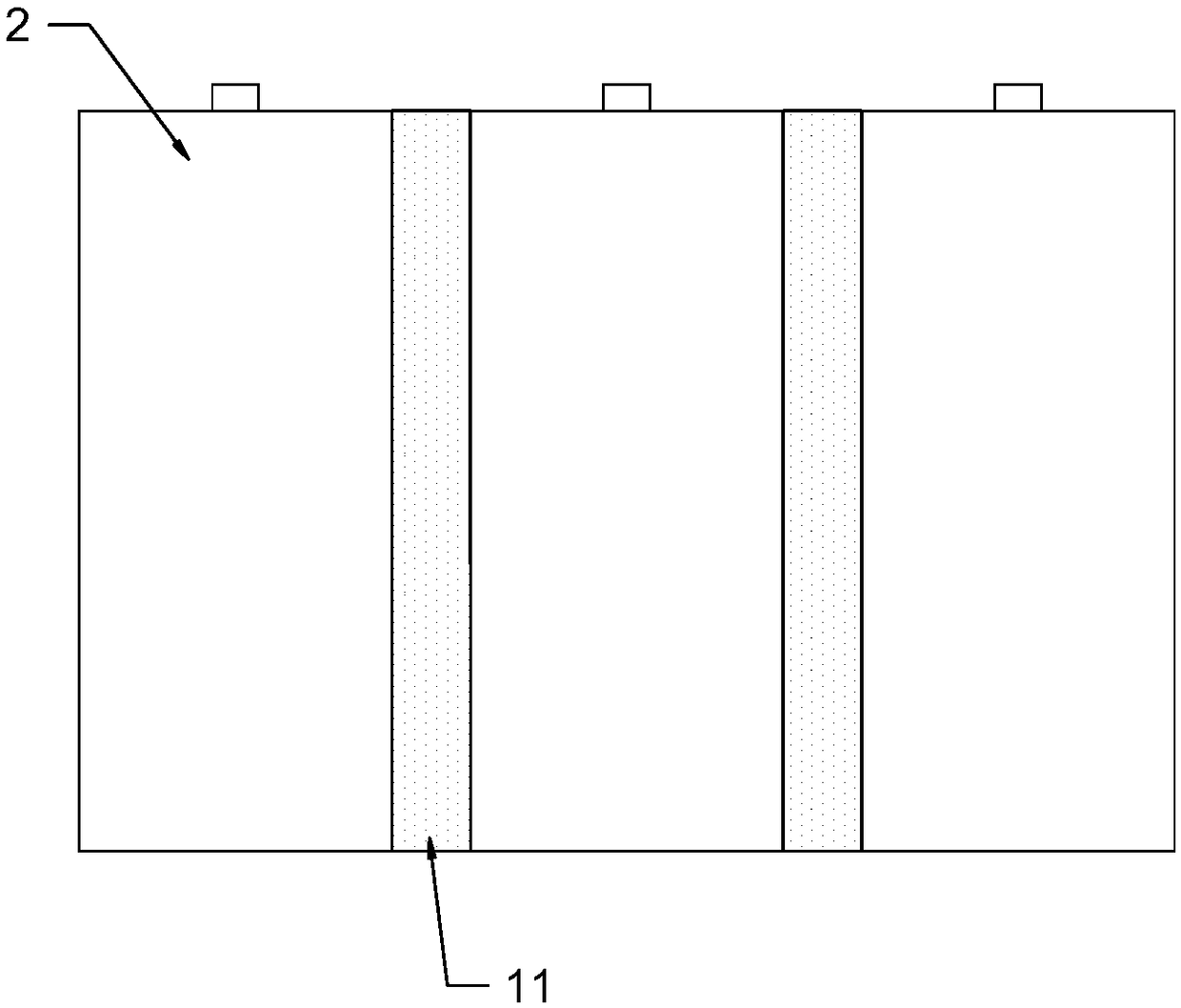

[0106] Example 31 is basically the same as Example 1, the only difference is that in step (1), a layer of expanded graphite powder is evenly spread on the bottom of the mold cavity; then, the powder of the thermal management material is evenly spread; finally, Spread a layer of expanded graphite powder uniformly again. Thereby, graphite sealing layers 12 are formed on the upper surface and the lower surface of the thermal management material molded body 11 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com