Bladeless fan turbine device with splitter blades

A technology of splitting blades and bladeless fans, which is applied to the components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., which can solve the complex flow conditions of bladeless fans and reduce the overall cost of bladeless fans Performance, turbocharger performance degradation and other issues, to achieve the effect of improving operational stability, reducing overall noise, and increasing pressure ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

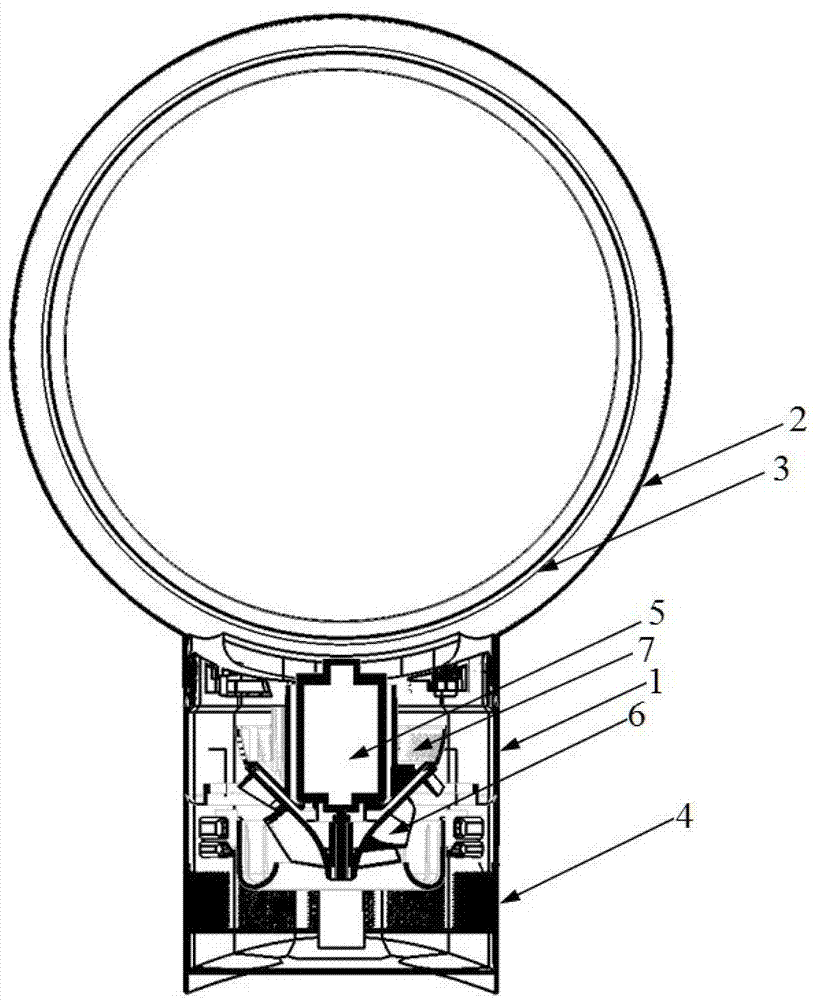

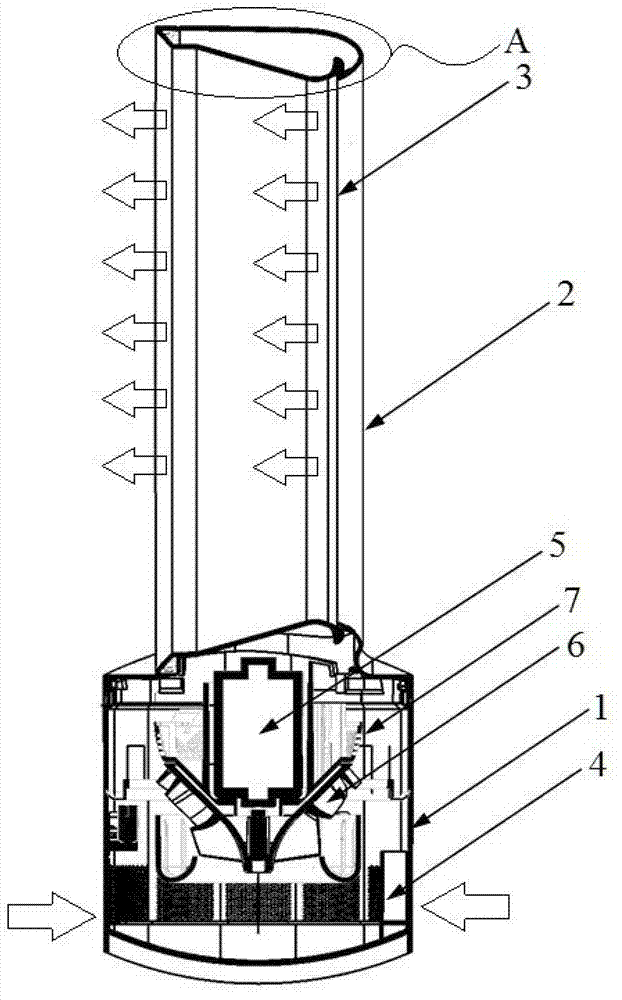

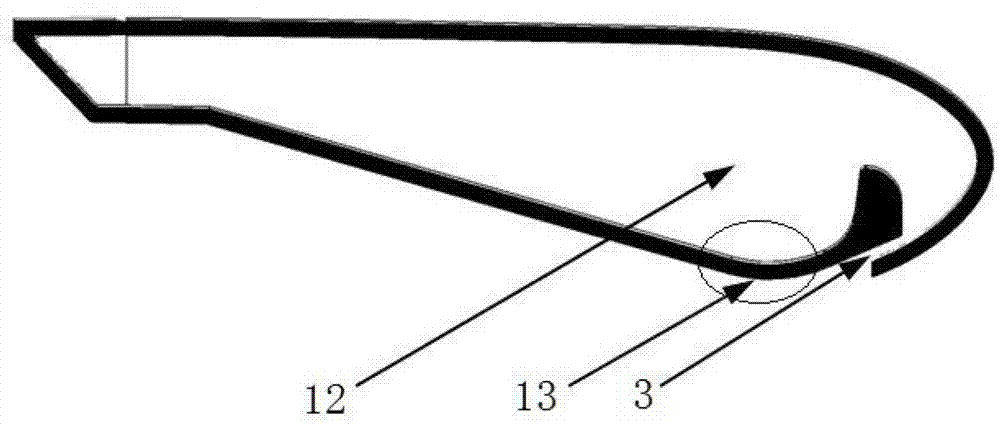

[0049] Such as figure 2 , Figure 9 As shown, the inlet end of the splitter vane turbine 6 is facing downward, and the outlet end is upward, and the airflow enters from the air inlet 4 horizontally. After the supercharging effect of the splitter vane turbine 6, the airflow enters the air outlet ring 2 vertically upwards, and then flows from the air outlet ring The air outlet 3 on the 2 flows out along the Coanda surface.

Embodiment 2

[0051] Such as Figure 10 , Figure 11 As shown, another kind of splitter vane turbine 6 is proposed in this embodiment, and this splitter vane turbine 6 adopts the blade layout form of intersecting distribution of long, medium and short blade intervals; the splitter vane turbine 6 includes an inner ring wall 8, long blades 9. The middle vane 21 and the short vane 11. The middle vane 21 is the splitter vane 10 in the above-mentioned embodiment. In order to further highlight the ability of the splitter vane 10 to improve the performance of the overall device, the splitter vane can be added on the basis of the above-mentioned embodiment, namely In the present embodiment, short blades 11 are added to the flow channels of middle blades 21 and long blades 9, where the outlet radii of long blades 9, middle blades 21 and short blades 11 are all the same, and the inlet radii from large to small are as follows: short Blade 11, middle blade 21, long blade 9, the ratio of the inlet radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com