Integrated preparation technology of loop heat pipe evaporator

A technology of loop heat pipe and preparation process, which is applied in the direction of indirect heat exchangers, lighting and heating equipment, etc., and can solve the problems of evaporating chamber and capillary wick assembly and capillary wick preparation complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

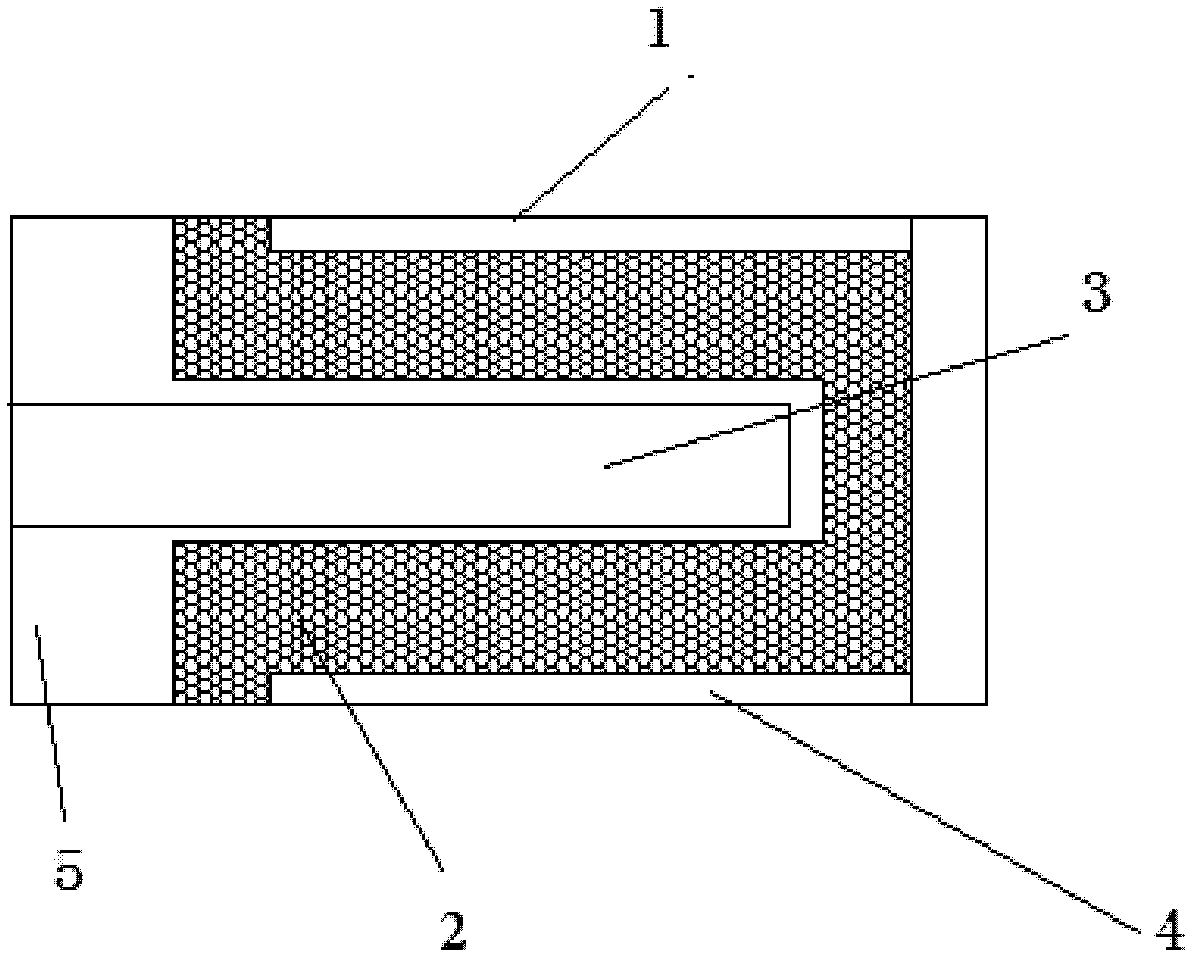

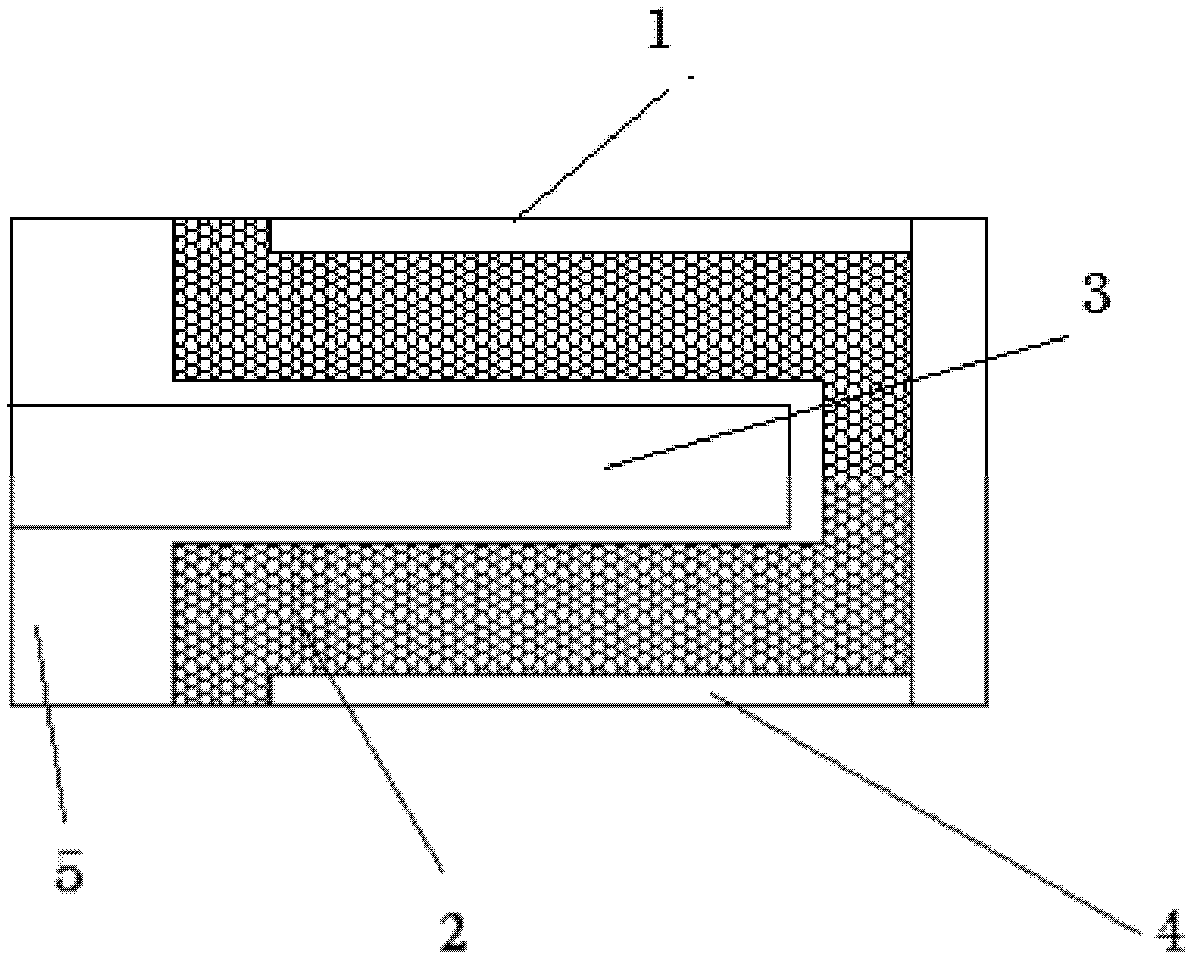

[0022] like figure 1 As shown, the loop heat pipe evaporator includes an evaporation chamber 1, a capillary wick 2, a liquid storage chamber 3 is formed in the middle of the capillary wick 2, the liquid storage chamber 3 communicates with the evaporation chamber 5, and there is an There are multiple steam channels 4, and the capillary core 2 is a single-pore capillary core layer.

[0023] The integrated preparation process of the loop heat pipe evaporator, the steps are as follows:

[0024] (1) Select a copper evaporation chamber (with an inner diameter of 2 cm and a length of 5 cm), and add a mixed powder of nickel powder capillary core sintered matrix powder and pore-forming agent to it; before loading the powder, the evaporation chamber is cleaned with dilute sulfuric acid surface;

[0025] (2) Insert a cylindrical graphite liquid storage chamber mold in the middle of the powder, the insertion depth is about 4 / 5 of the height of the evaporation chamber, compact the powder...

Embodiment 2

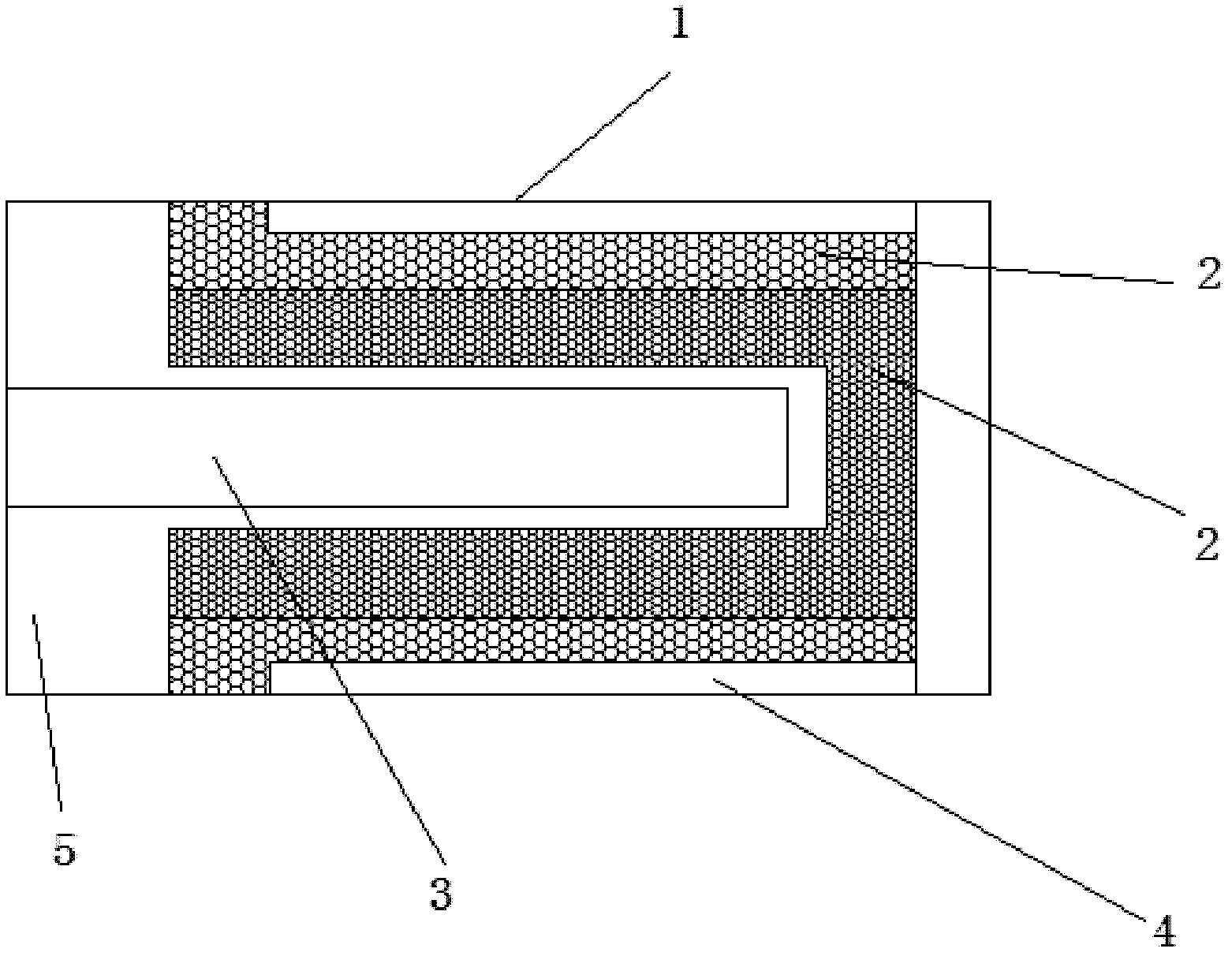

[0028] like figure 2 As shown, the loop heat pipe evaporator includes an evaporation chamber 1, a capillary wick 2, a liquid storage chamber 3 is formed in the middle of the capillary wick 2, the liquid storage chamber 3 communicates with the evaporation chamber 5, and there is an A plurality of steam channels 4, the capillary core 2 is a composite porous capillary core layer.

[0029] (1) Select a copper evaporation chamber (with an inner diameter of 2 cm and a length of 5 cm). Before loading powder, the inner surface of the evaporation chamber is cleaned with dilute sulfuric acid; Make a cylinder) into the center of the evaporation chamber, fill the first ratio of nickel powder and pore-forming agent mixed powder between the cylinder and the evaporation chamber; then fill the cylinder with the second ratio The mixed powder of nickel powder and pore-forming agent is inserted in the middle of a graphite rod with an inner diameter of 6 mm, and the insertion depth is 4 cm.

...

Embodiment 3

[0033] like figure 1 As shown, the loop heat pipe evaporator includes an evaporation chamber 1, a capillary wick 2, a liquid storage chamber 3 is formed in the middle of the capillary wick 2, the liquid storage chamber 3 communicates with the evaporation chamber 5, and there is an There are multiple steam channels 4, and the capillary core 2 is a single-pore capillary core layer.

[0034] The integrated preparation process of the loop heat pipe evaporator, the steps are as follows:

[0035] (1) Select an aluminum evaporation chamber (with an inner diameter of 2 cm and a length of 5 cm), and add the mixed powder of ceramic powder capillary core sintered matrix powder and pore-forming agent to it; before loading the powder, clean the inside of the evaporation chamber with dilute sulfuric acid surface;

[0036] (2) Insert a cylindrical graphite liquid storage chamber mold in the middle of the powder, the insertion depth is about 4 / 5 of the height of the evaporation chamber, com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com