Patents

Literature

88results about How to "Prevent heat leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

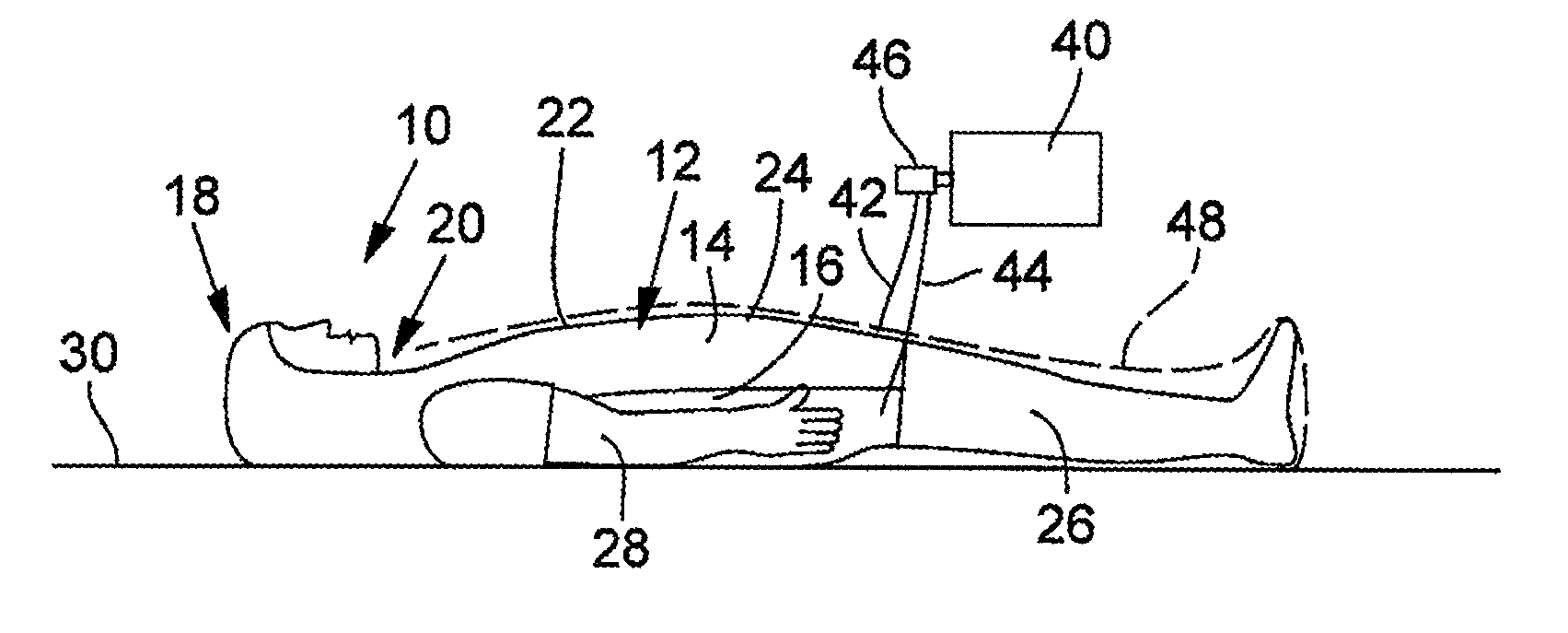

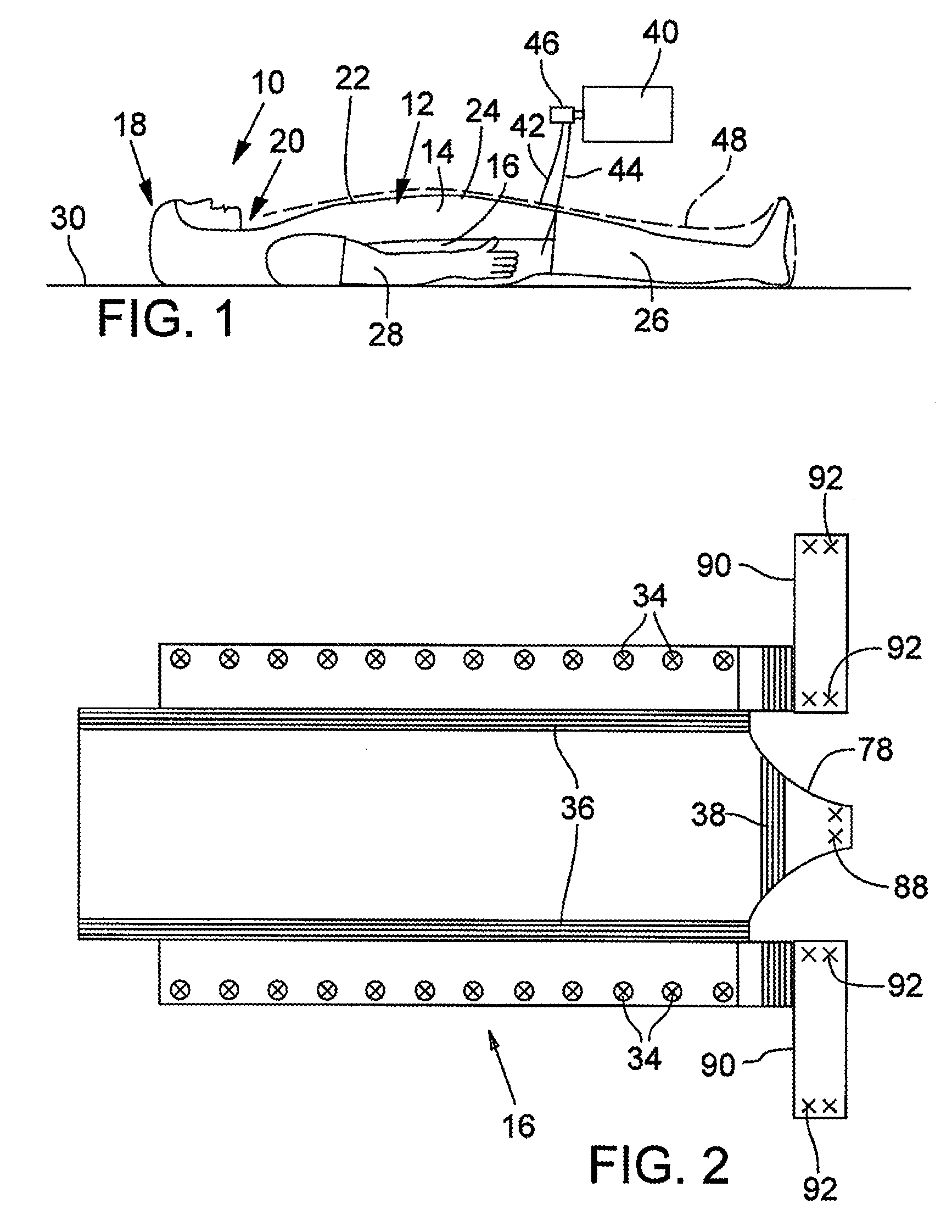

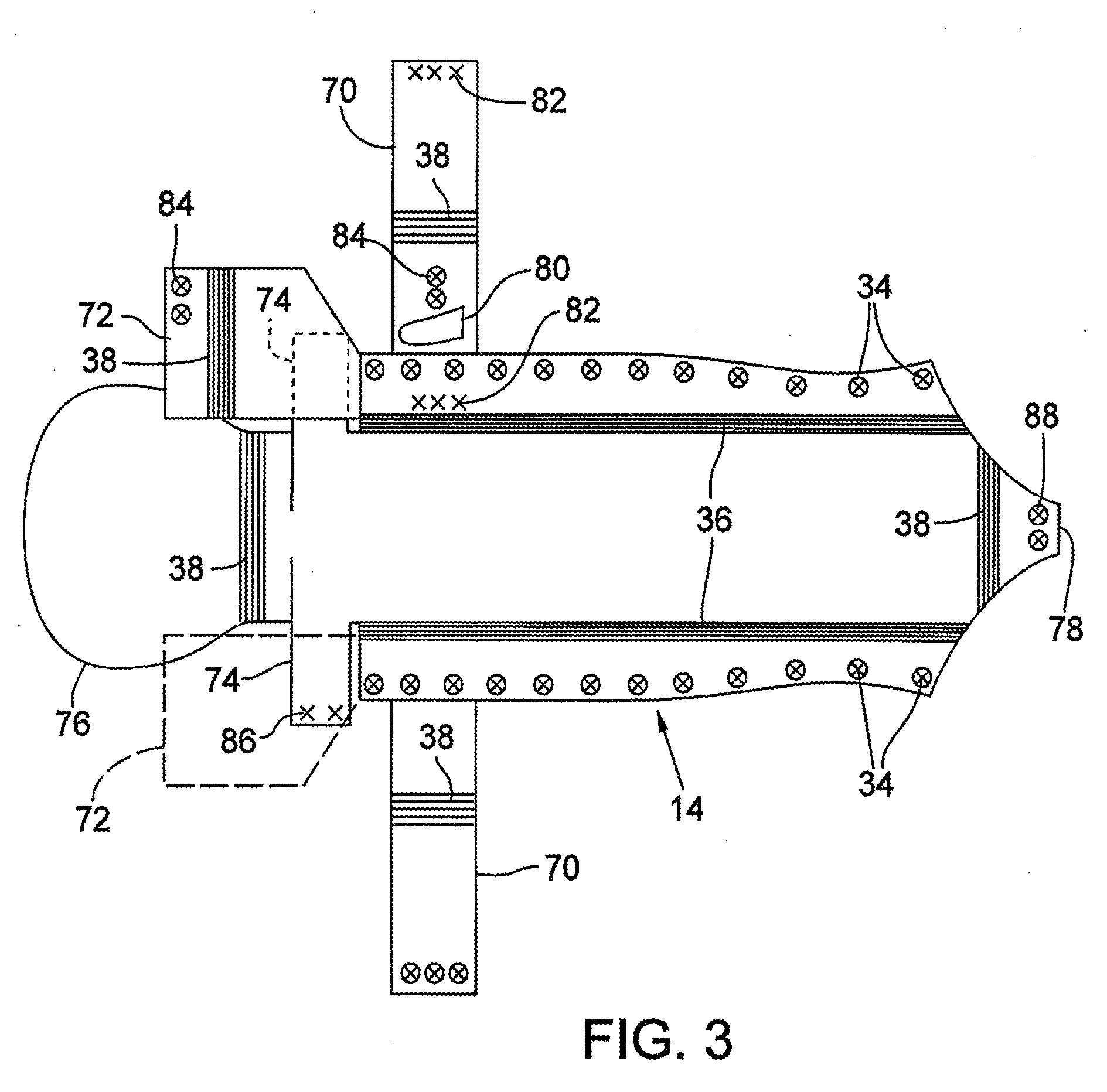

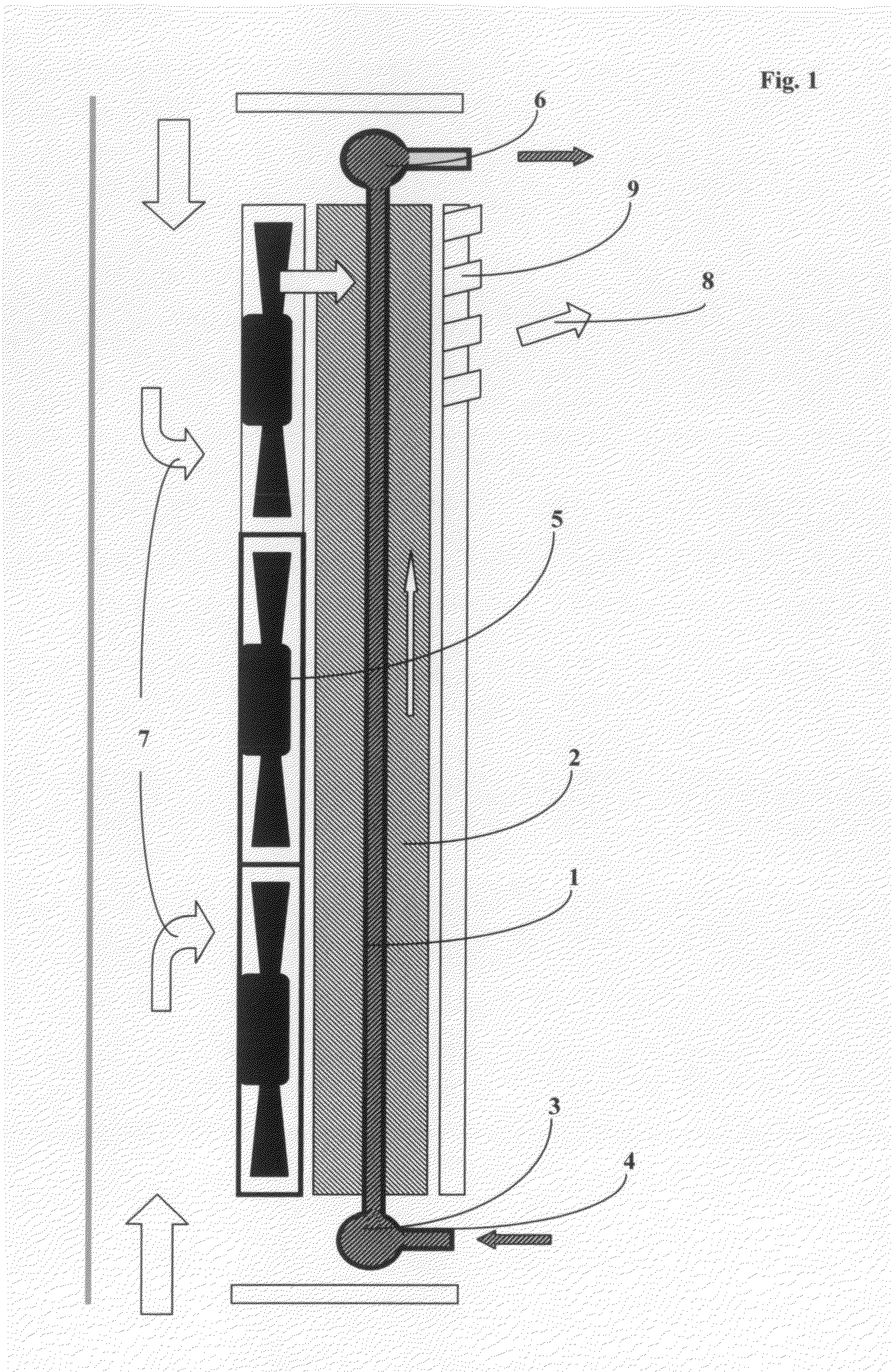

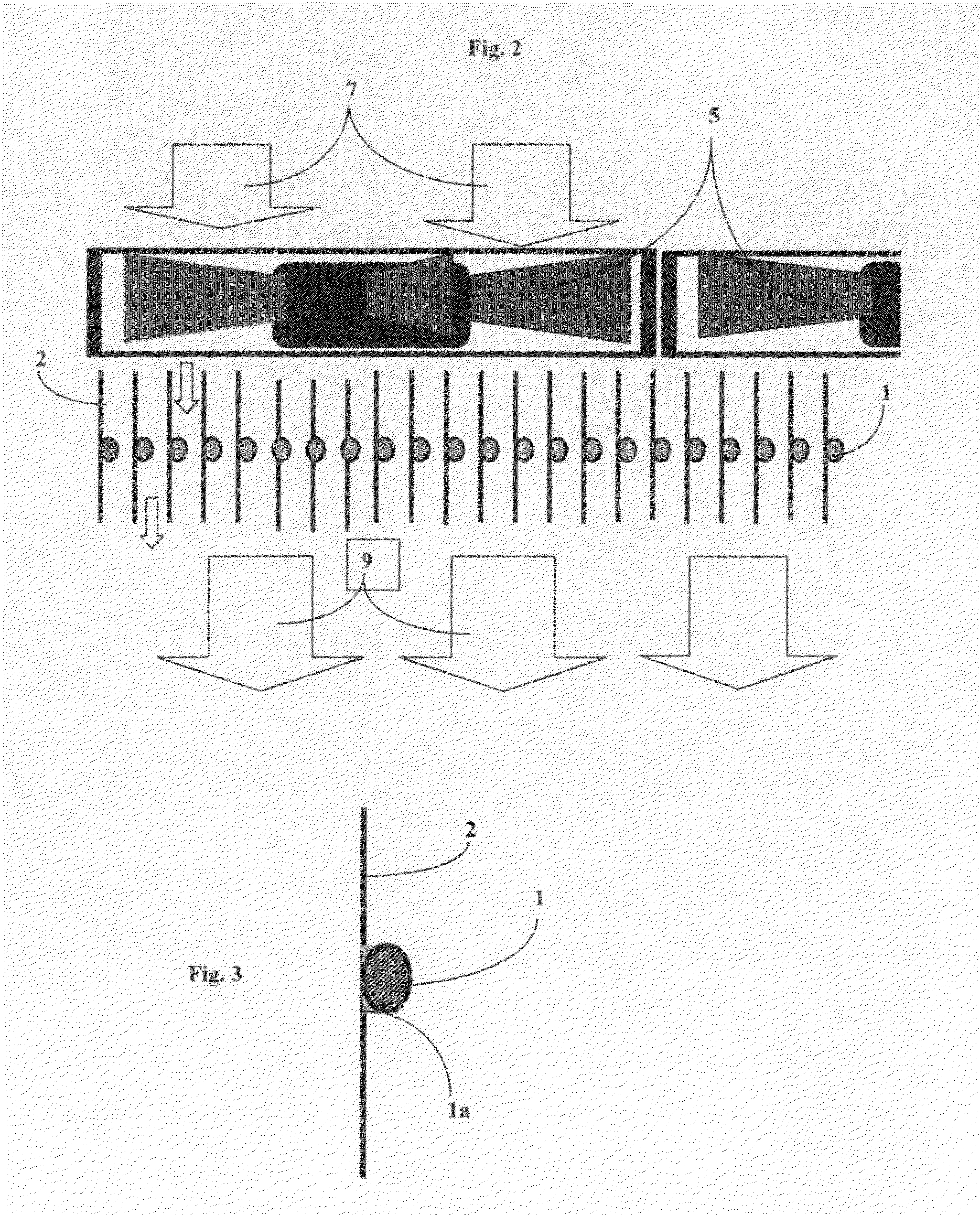

Heating system to alleviate hypothermia

ActiveUS20070049997A1Aggressive treatmentFacilitates patient insertionTherapeutic coolingTherapeutic heatingCold exposureBody area

A medical, electrically powered thermal cover for fitting predominantly the trunk and head of a person experiencing or potentially experiencing traumatic or cold-exposure hypothermia. The thermal cover encases all of the torso and neck, and portions of other body areas. Heating may be distinctly non-uniform, being applied to the body surface only in special regions where the body's capacity for heat uptake may be relatively high. In sum, the system may monitor deep body core temperature, direct heat to the body core where it may be most needed, and controls therapy over time to restore normothermia.

Owner:GRI ALLESET INC

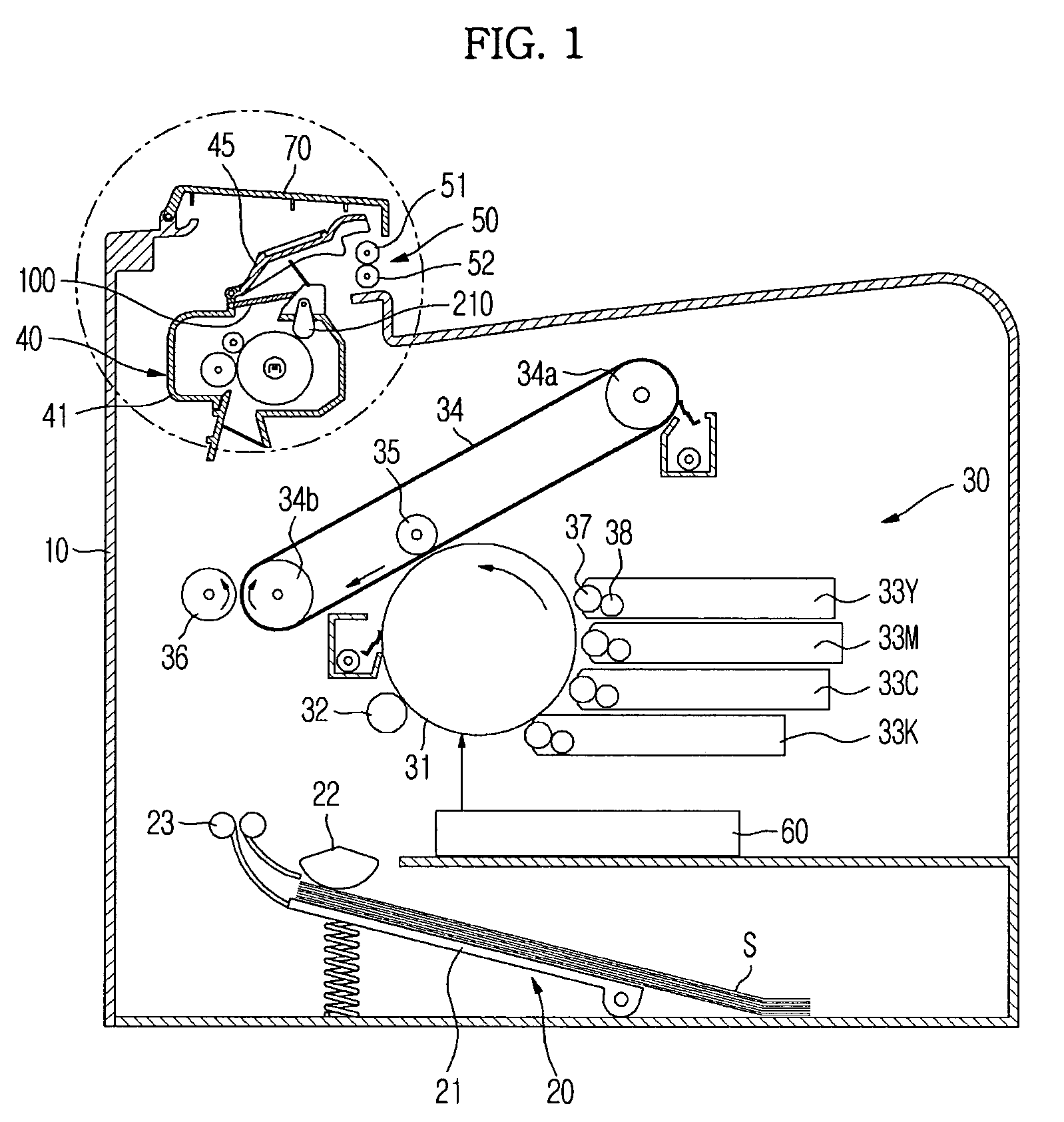

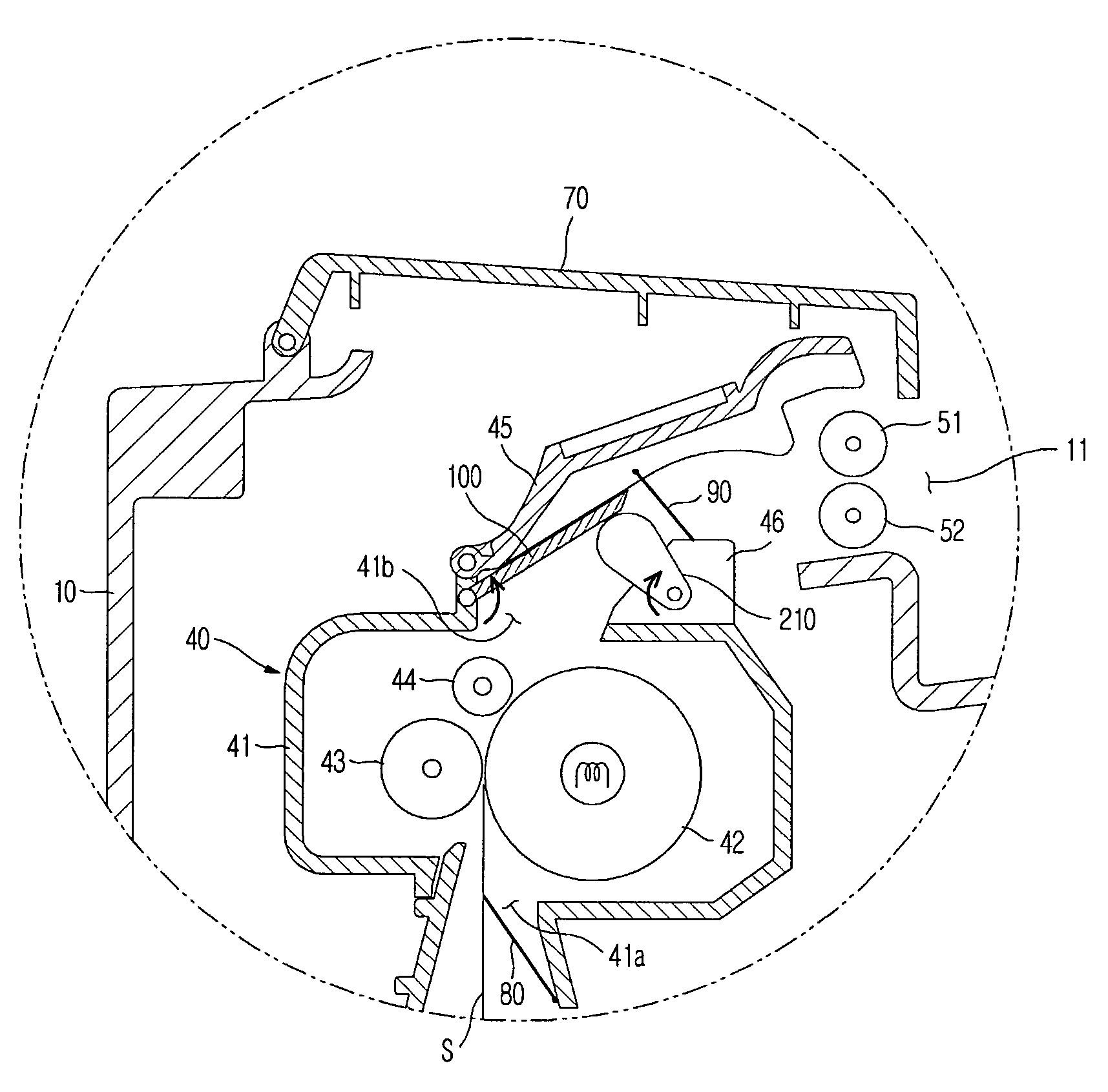

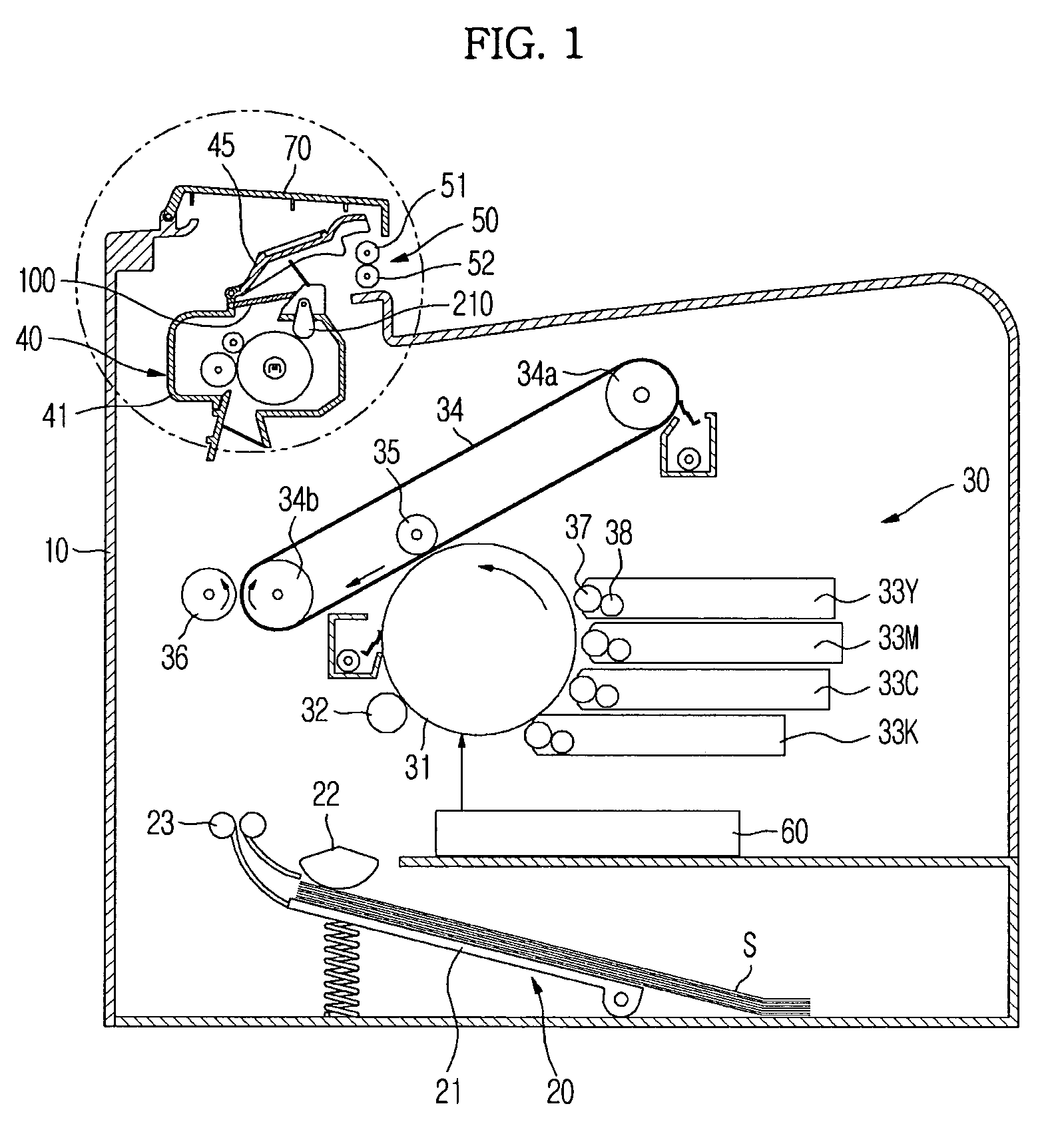

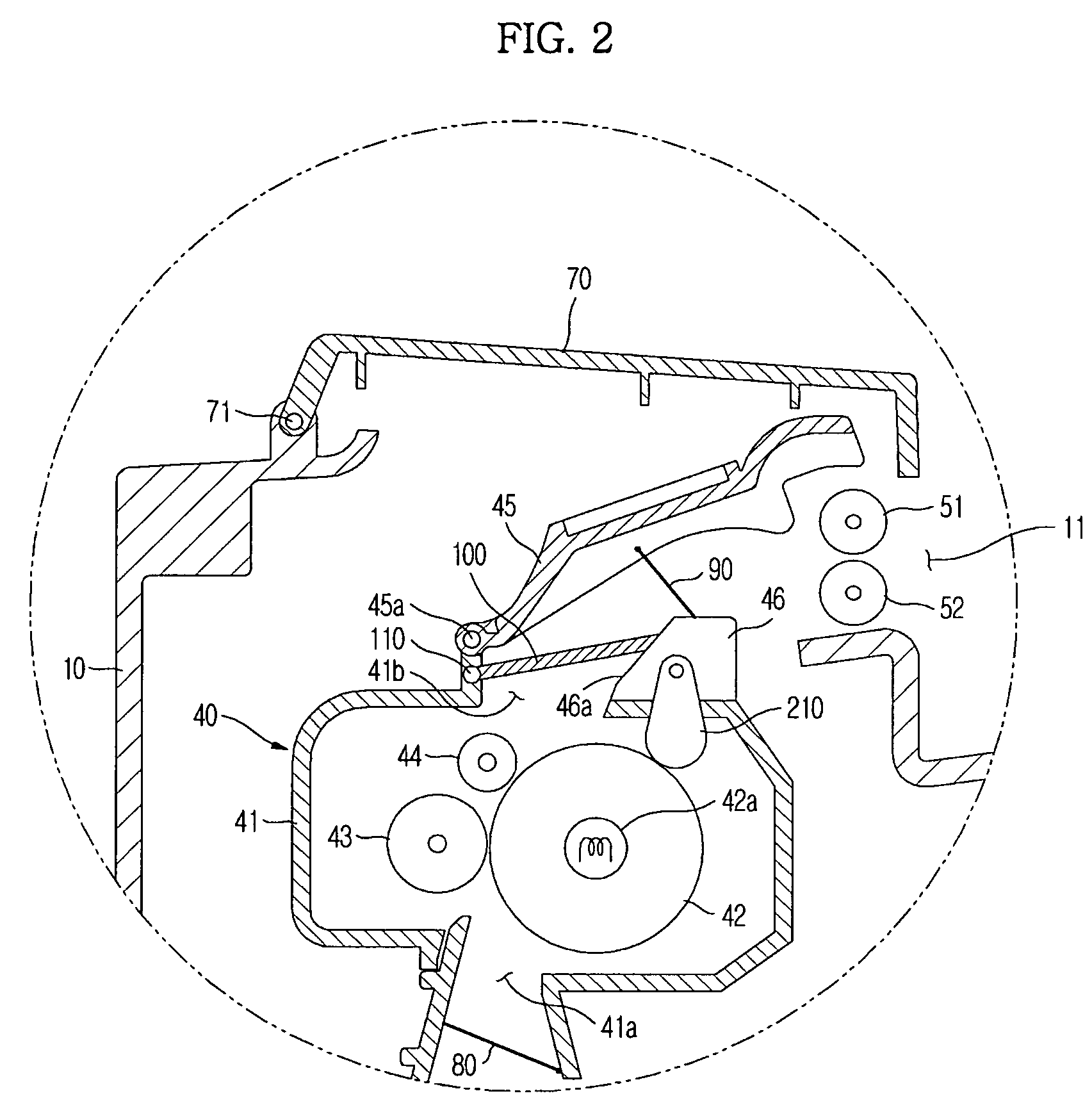

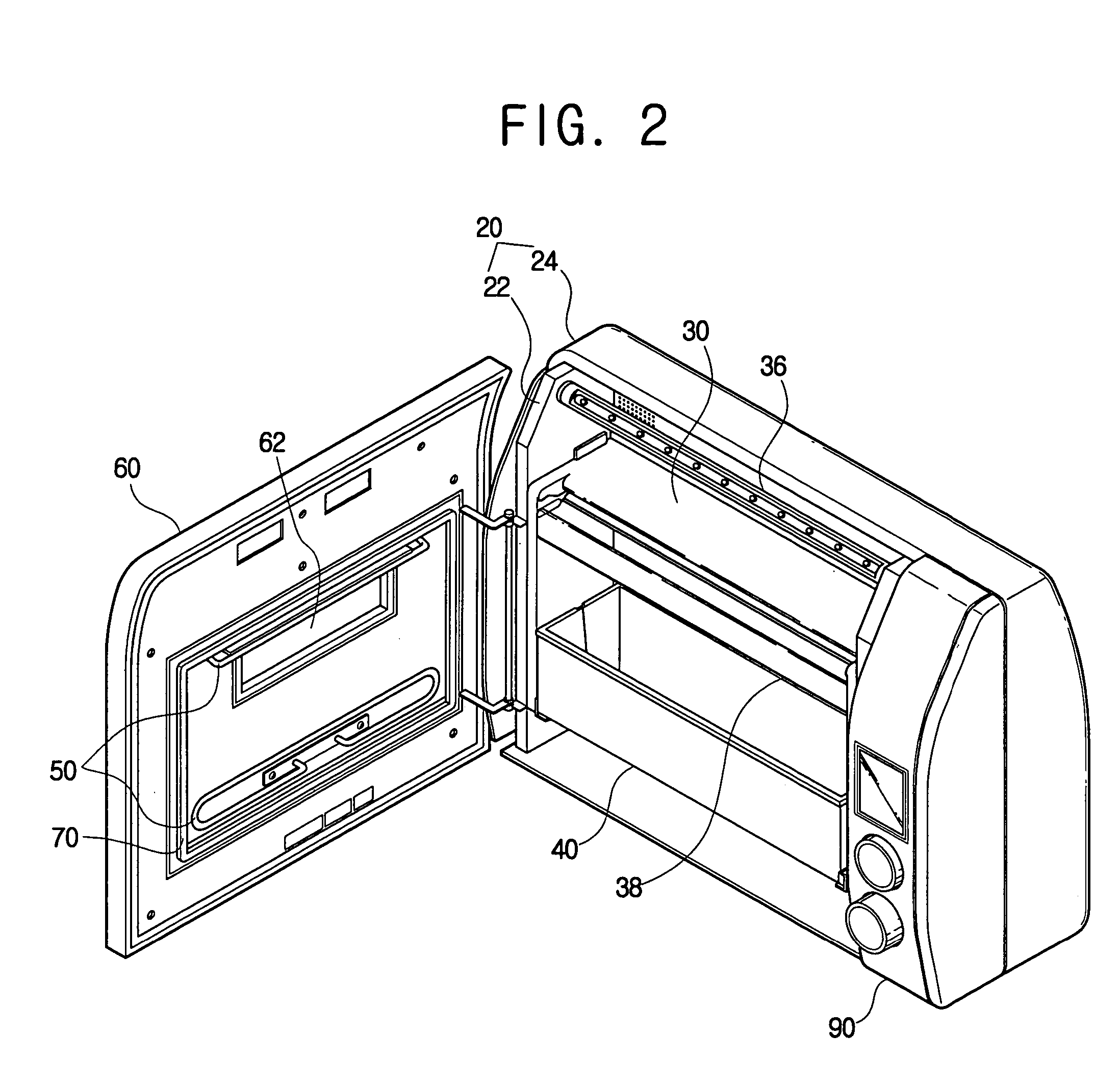

Image forming apparatus with opening/closing member

InactiveUS20090052924A1Minimize temperature risePrevent heat dissipationElectrographic process apparatusImage formationEngineering

An image forming apparatus capable of minimizing a temperature rise of a cover by substantially preventing heat emission from a fusing device to an outside is disclosed. The image forming apparatus includes a main body, a fusing device mounted in the main body, the fusing device having an outlet to discharge paper, an opening / closing member opening and closing the outlet of the fusing device, a cam member moving the opening / closing member between a first position in which the opening / closing member closes the outlet to prevent heat in the fusing device from being emitted through the outlet and a second position in which the opening / closing member opens the outlet to permit the paper to pass through the outlet, a driving part rotating the cam member, and a control unit controlling the driving part to determine a rotational position of the cam member.

Owner:SAMSUNG ELECTRONICS CO LTD

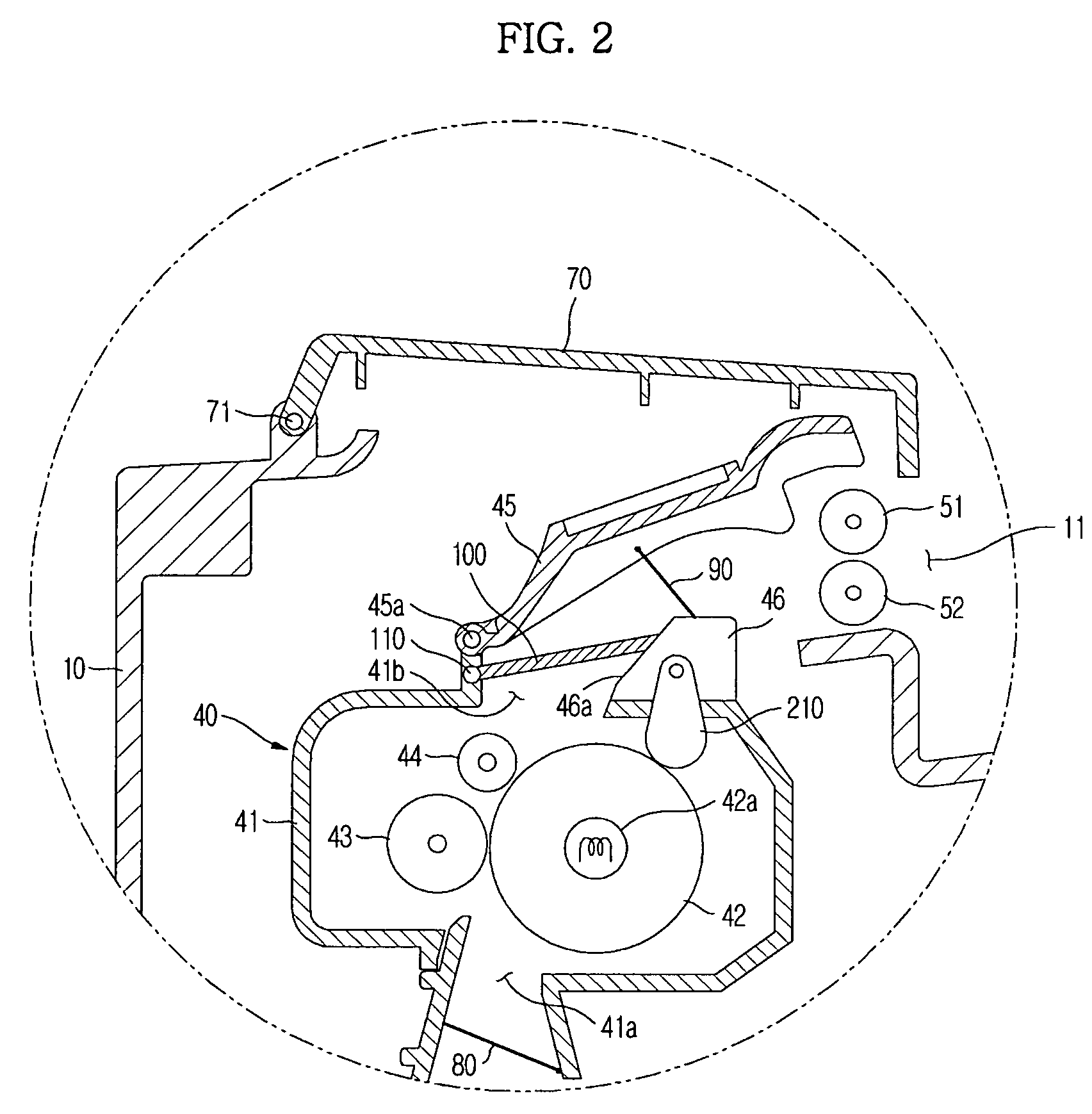

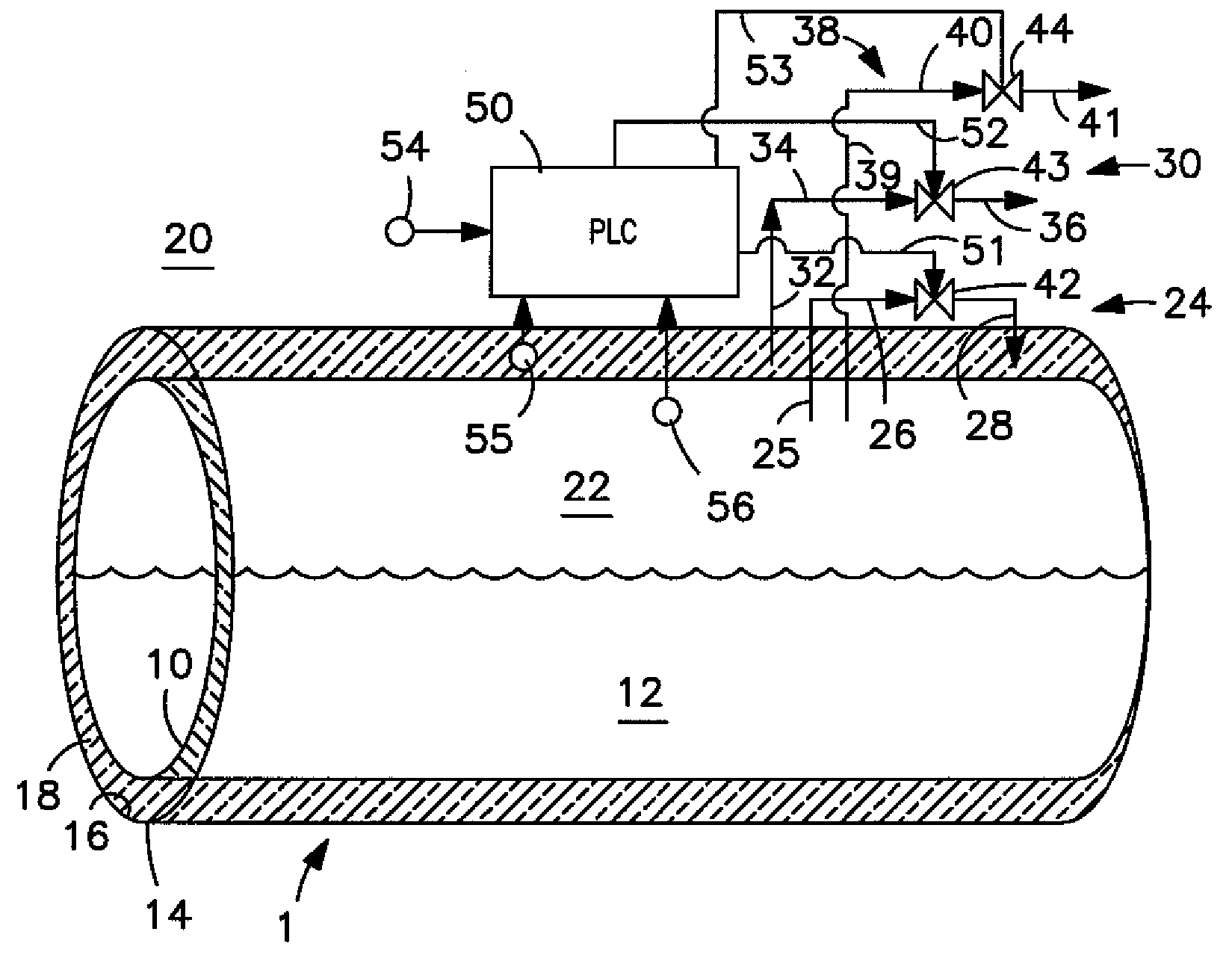

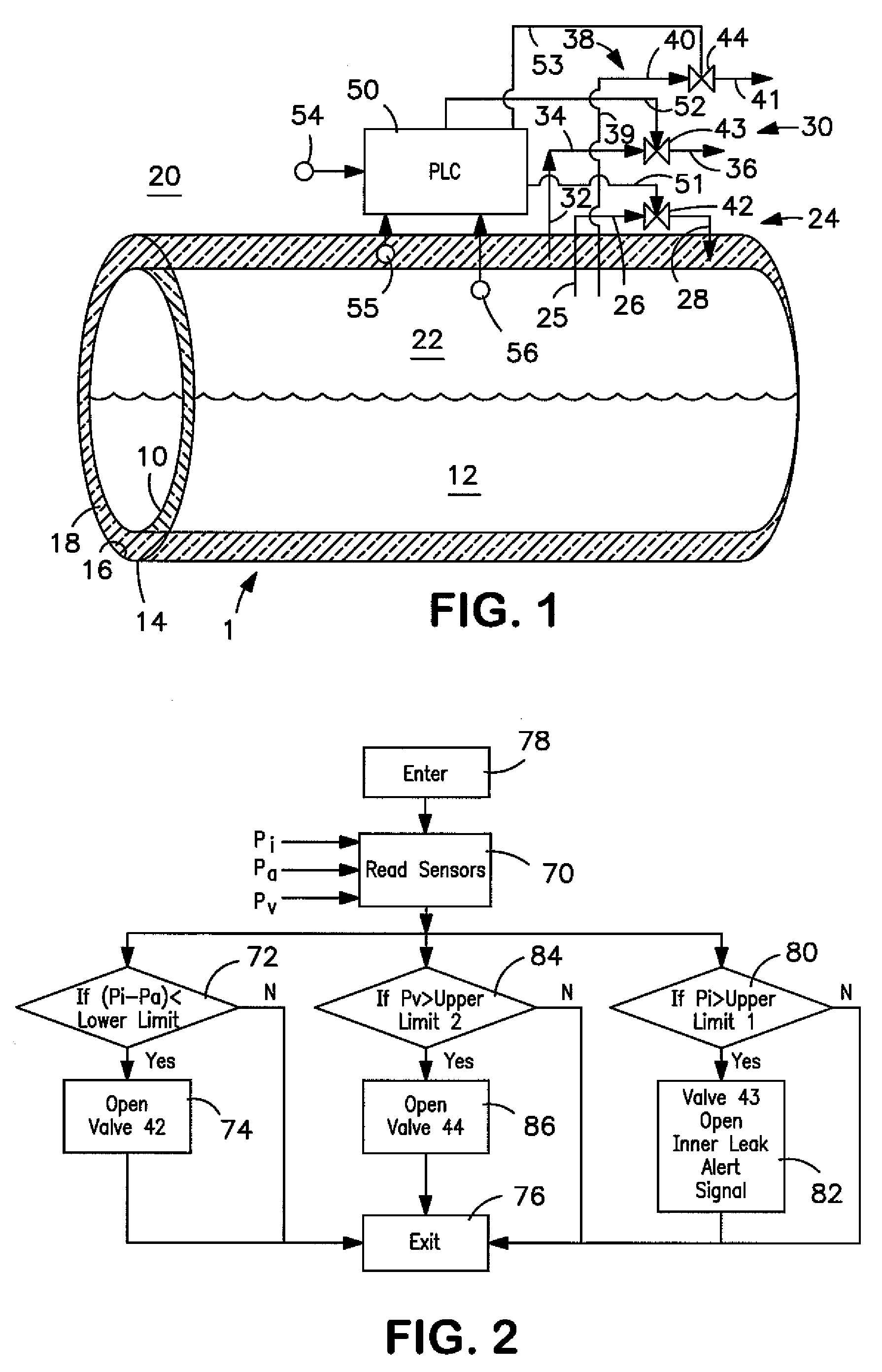

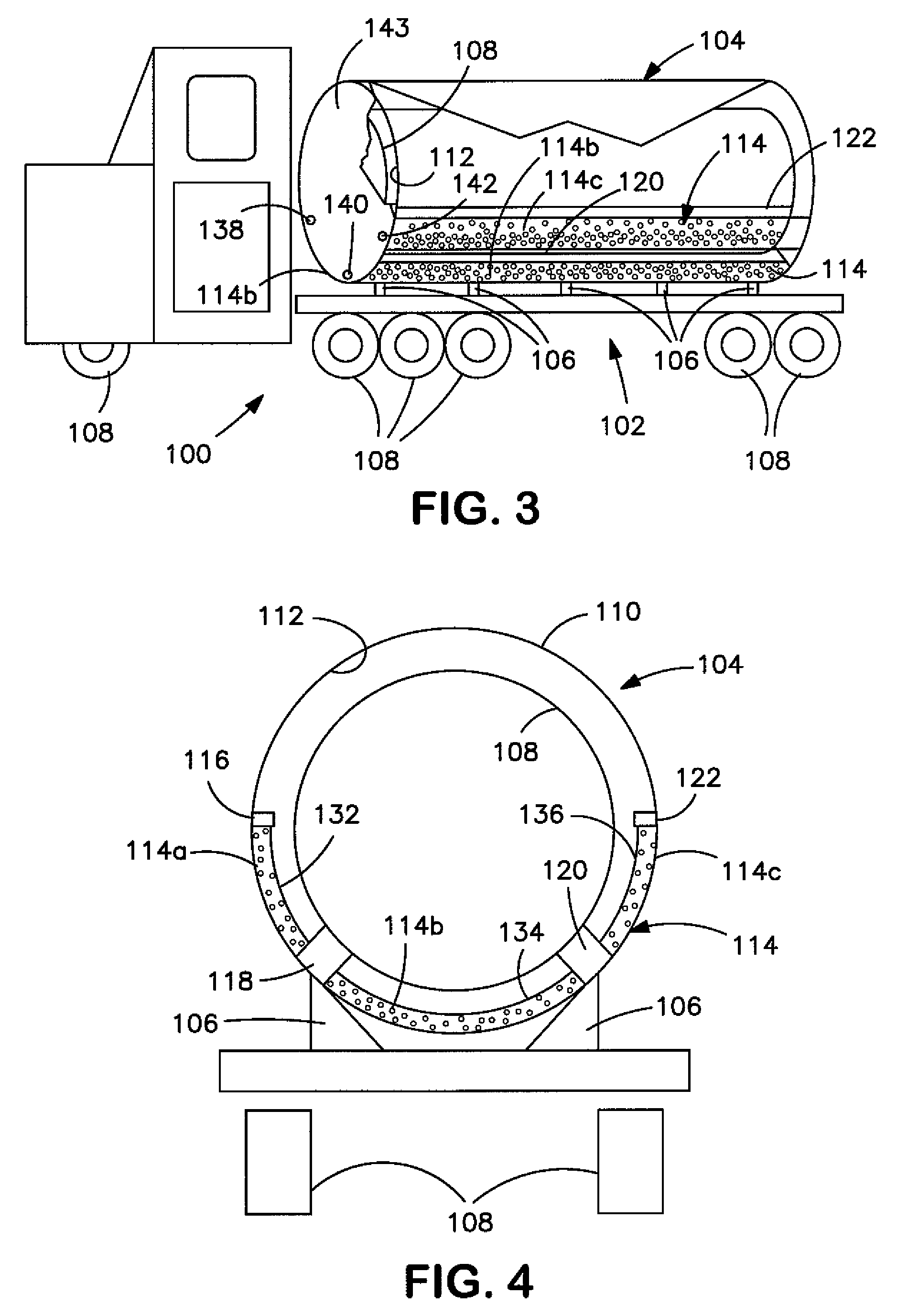

Cryogenic liquid tank and method

InactiveUS20080307798A1Prevent heat leakageVessel mounting detailsVessel geometry/arrangement/sizeProgrammable logic controllerLiquid tank

A tank and method for containing a cryogenic liquid in which a purge gas is introduced into an insulation space defined between an outer vessel and an inner vessel to contain insulation material. The inner vessel is used to contain the cryogenic liquid. The purge gas can be cryogenic vapor evolved from the liquid and routed into the insulation space. Control of the purge gas within the insulation space can be provided by a programmable logic controller in which purge gas is vented from the insulation space should the pressure be indicative of a leak within the inner vessel and purge gas is introduced into the insulation space should the pressure be below the ambient to maintain a positive purge gas pressure. An adsorbent bed can also be located within the insulation space to adsorb any moisture.

Owner:PRAXAIR TECH INC

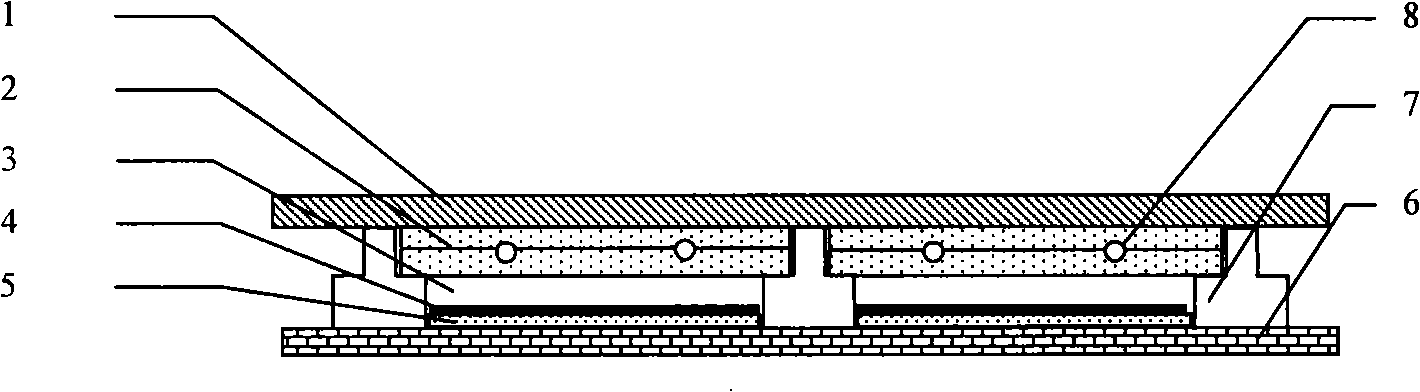

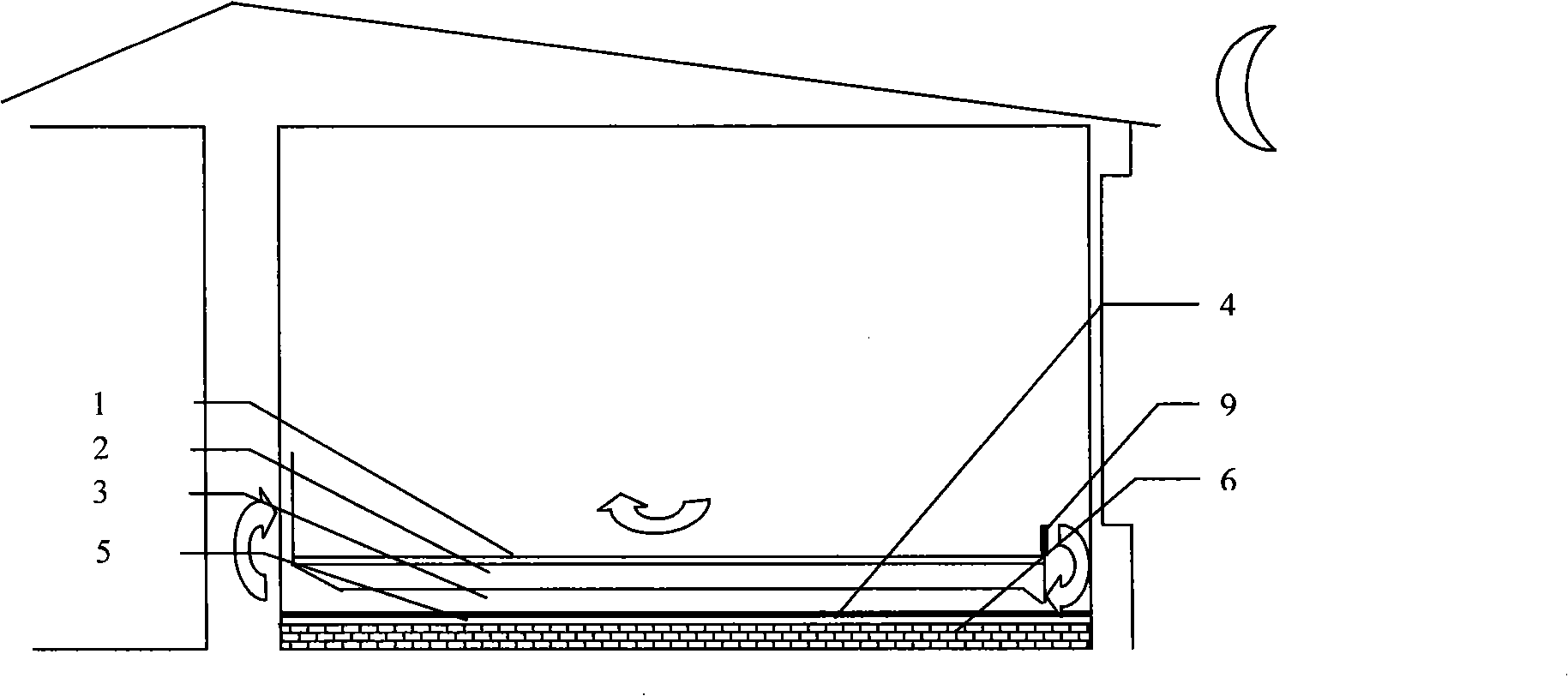

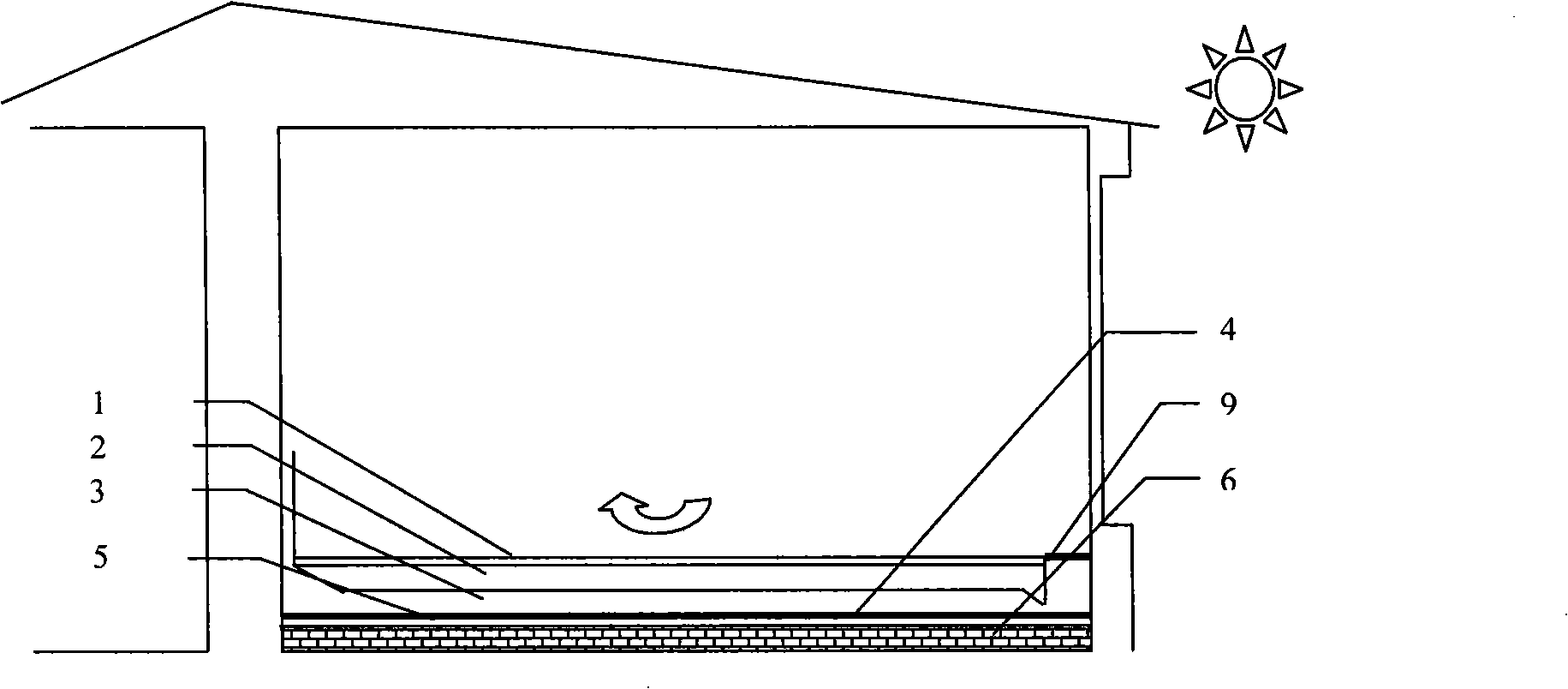

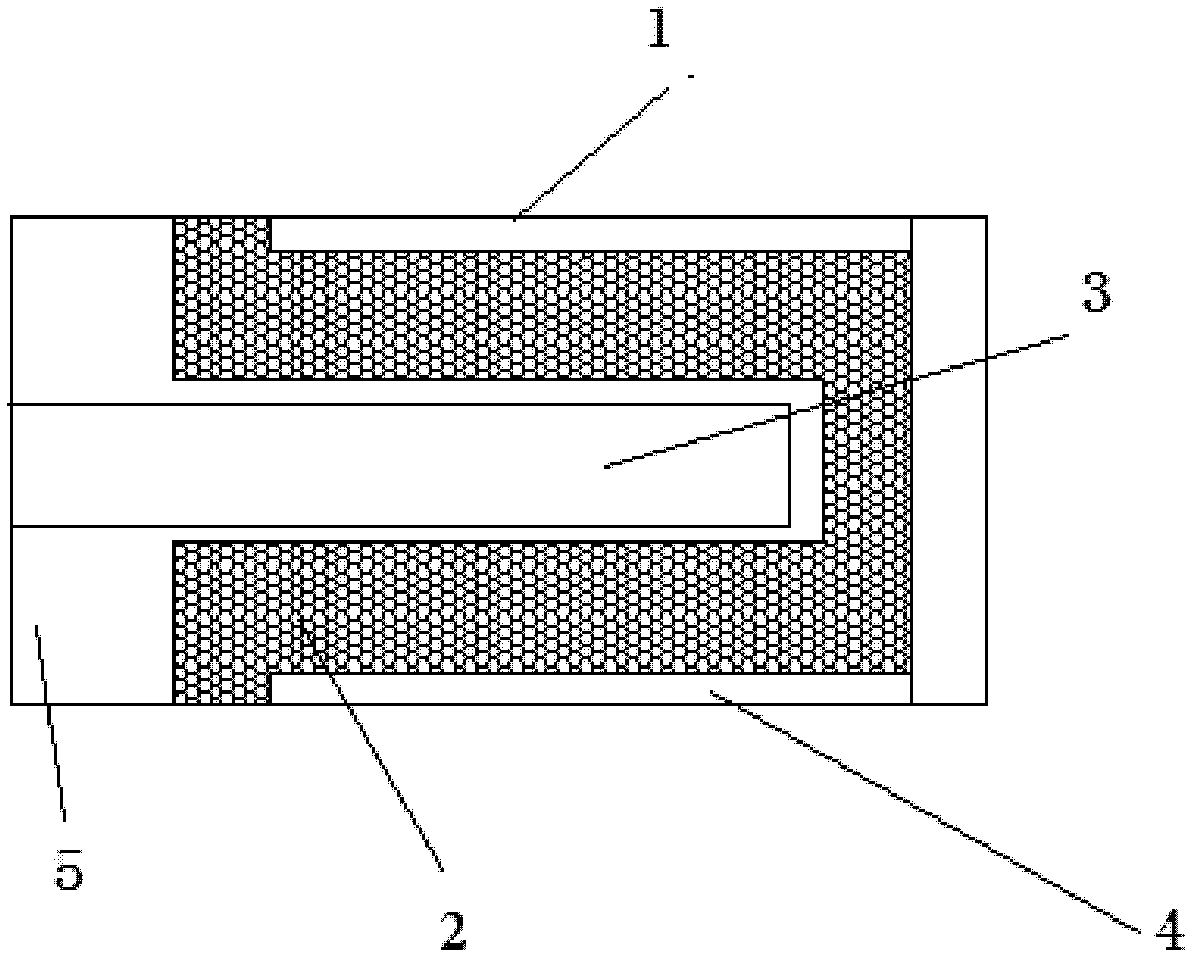

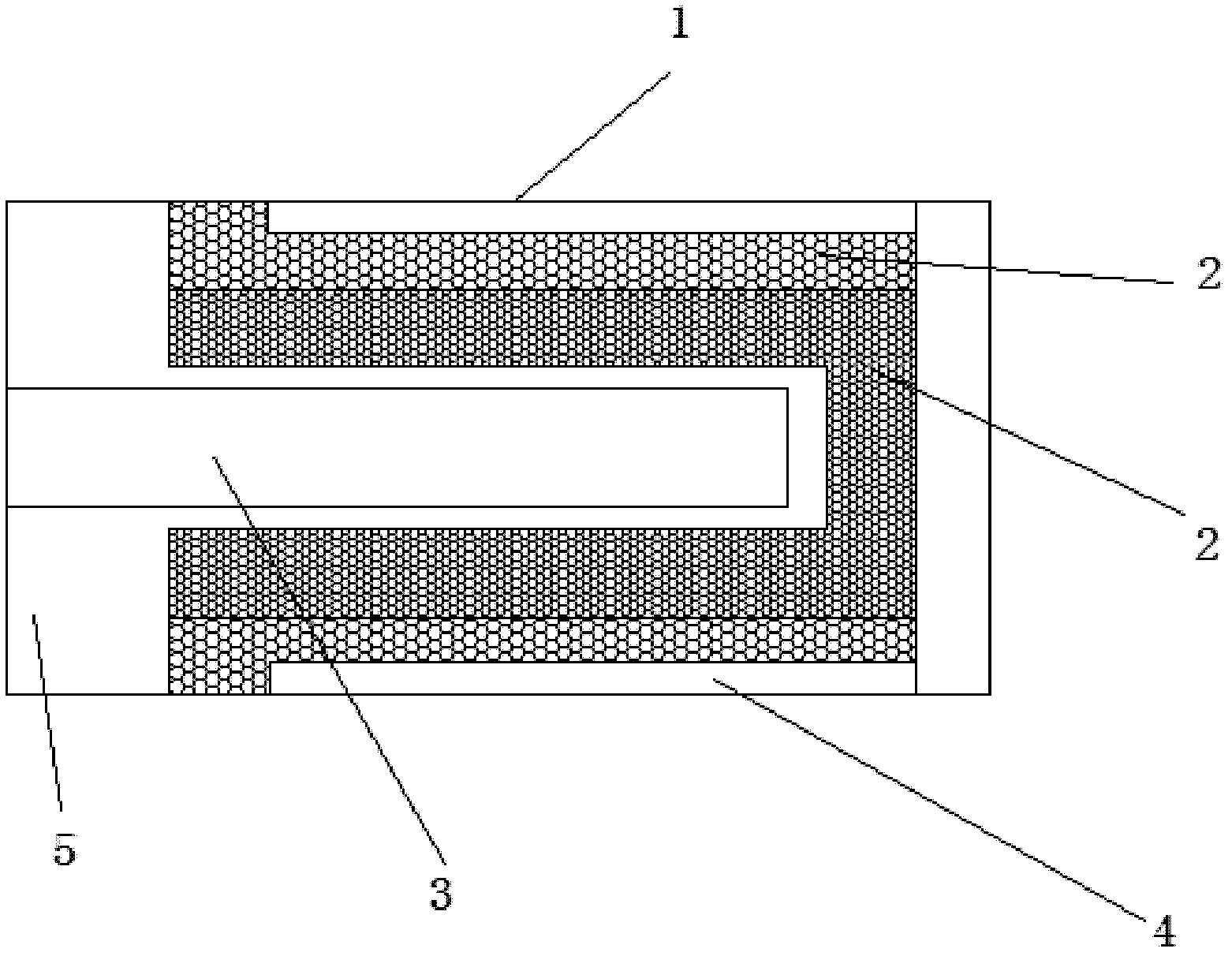

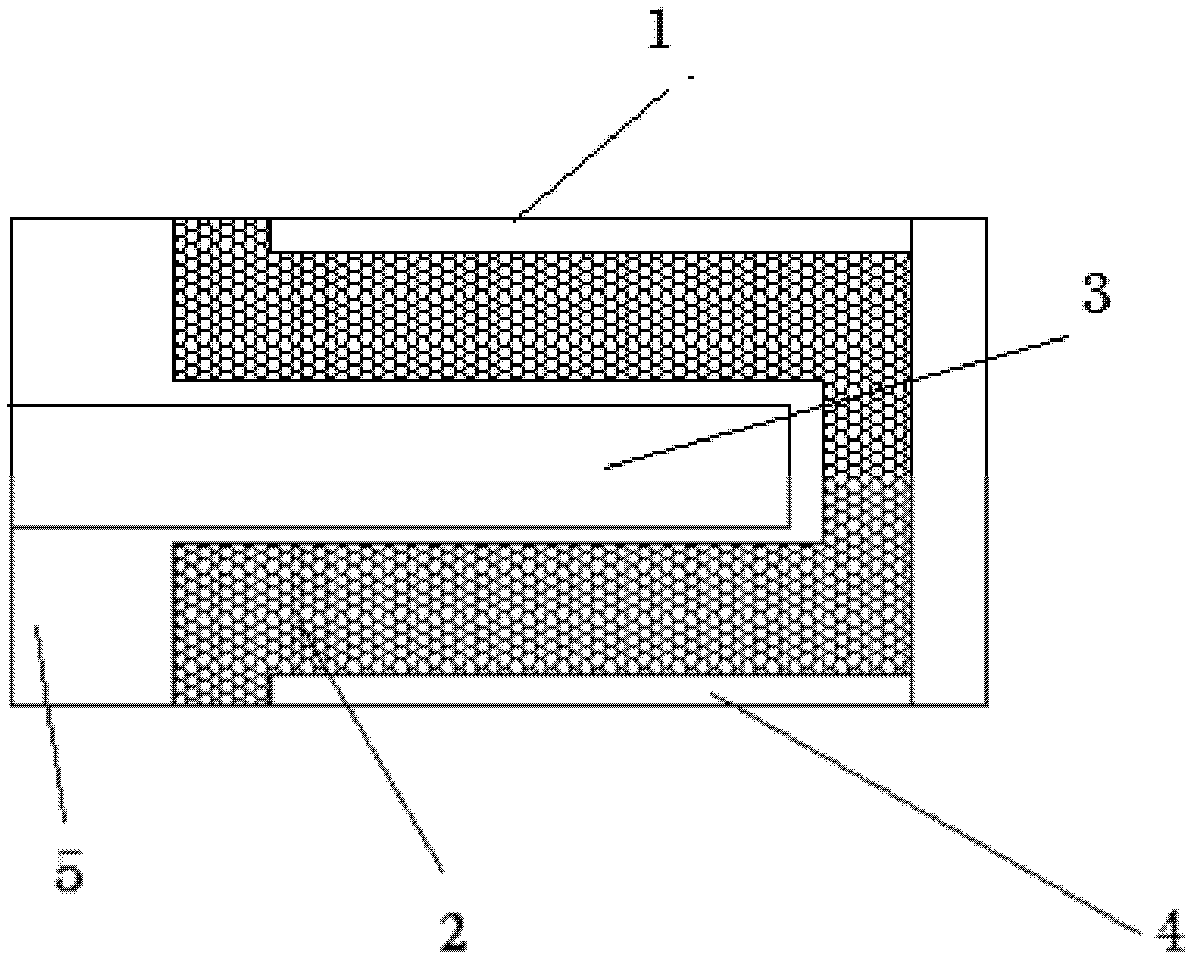

Dry-type phase-change thermal storage floor heating terminal device

InactiveCN101280935AHigh heating comfortSave spaceLighting and heating apparatusElectric heating systemRadiation protectionPhase-change material

The invention provides a phase-changing heat accumulation floor heating terminal device pertaining to building heating technique field. The invention employs phase-changing material as heat storage medium for heating. The device, from above to below, includes a floor decoration layer, a phase-changing material layer, an air duct, a radiation protection film, a thermal insulation layer and a floor base layer in turn; keels are arranged between the floor decoration layer and the floor base layer, at least a heat supply waterpipe or a electrical heating film are buried in the phase-changing material layer between adjacent keels; a wind gap is arranged at both ends of the air duct to communicate with indoor air. The phase-changing material supplies heat for indoor heating by heat conduction upwards and convection current, meanwhile heat supply of the phase-changing material is adjusted by air duct and indoor aeration speed, which further regulates and controls heat supply speed. The invention resolves defects of discommodity of heat supply speed adjustment of phase-changing floor energy storage mode, finity of phase-changing material availability, and the invention effectively decreases thermal transmission damage of floor heating downwards.

Owner:TSINGHUA UNIV

Thermoelectric nanowire array with low heat leakage and manufacturing method thereof

InactiveUS20100162728A1Low thermal conductivityImprove performanceLiquid/solution decomposition chemical coatingMachines using electric/magnetic effectsNanowire arrayThermal dissipation

A thermoelectric nanowire array with a low heat leakage and a manufacturing method thereof are described. Nanowire array units separated from each other are formed on a substrate, and an air wall is formed at a region on the substrate free of the nanowire array units. Or, a polymeric material having a low thermal conductivity is combined with a template material so as to form a composite template structure for nanowires to deposit therein. With the design of the air wall or the composite template structure, the thermal reflow phenomenon of the thermoelectric nanowire array is avoided, thereby greatly improving a thermal dissipation efficiency of the thermoelectric nanowire array.

Owner:IND TECH RES INST

Refrigerating system of low-temperature superconducting magnet

ActiveCN113035486APrevent heat leakagePrevent heat radiationSuperconducting magnets/coilsSustainable buildingsPower applicationSuperconducting Coils

The invention belongs to the technical field of superconducting power application, and discloses a refrigerating system of a low-temperature superconducting magnet. The refrigerating system comprises a cold shield, a lead cooling channel, a cold shield cooling channel, a first liquid helium input opening, a first helium output opening, a helium tank, a liquid helium input pipe and a helium output pipe; the cold shield is arranged outside a low-temperature superconducting coil; the helium tank is arranged between the cold shield and the low-temperature superconducting coil and does not make contact with the cold shield and the low-temperature superconducting coil; the liquid helium input pipe and the helium output pipe are both connected with the helium tank; liquid helium is injected into the helium tank from the first liquid helium input opening through the liquid helium input pipe; helium volatilized from the helium tank is output from the first helium output opening through the helium output pipe; the lead cooling channel is connected between the helium output pipe and a superconducting current lead and is used for guiding cold to cool the superconducting current lead; the cold shield cooling channel is connected between the helium output pipe and the cold shield and is used for conducting cold to cool the cold shield. Therefore, volatilization of liquid helium can be effectively reduced, and the risk of quenching of the low-temperature superconducting magnet is reduced.

Owner:HIWING TECH ACAD OF CASIC

Heat dissipation structure

InactiveUS20140246176A1Avoid heat leakageHeat dissipation performance be enhanceThermal insulationSemiconductor/solid-state device detailsWorking fluidElectrical and Electronics engineering

A heat dissipation structure includes a main body. The main body has a chamber. The chamber has an evaporation section, a condensation section, a first backflow section and a second backflow section. The evaporation section and the condensation section and the first and second backflow sections communicate with each other. A junction between the first and second backflow sections is coated with a heat insulation coating. A working fluid is filled in the chamber. By means of the heat insulation coating, the heat leakage between the evaporation section and the condensation section can be avoided. In this case, the vapor-liquid circulation of the working fluid in the heat dissipation structure can be continuously successfully performed.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

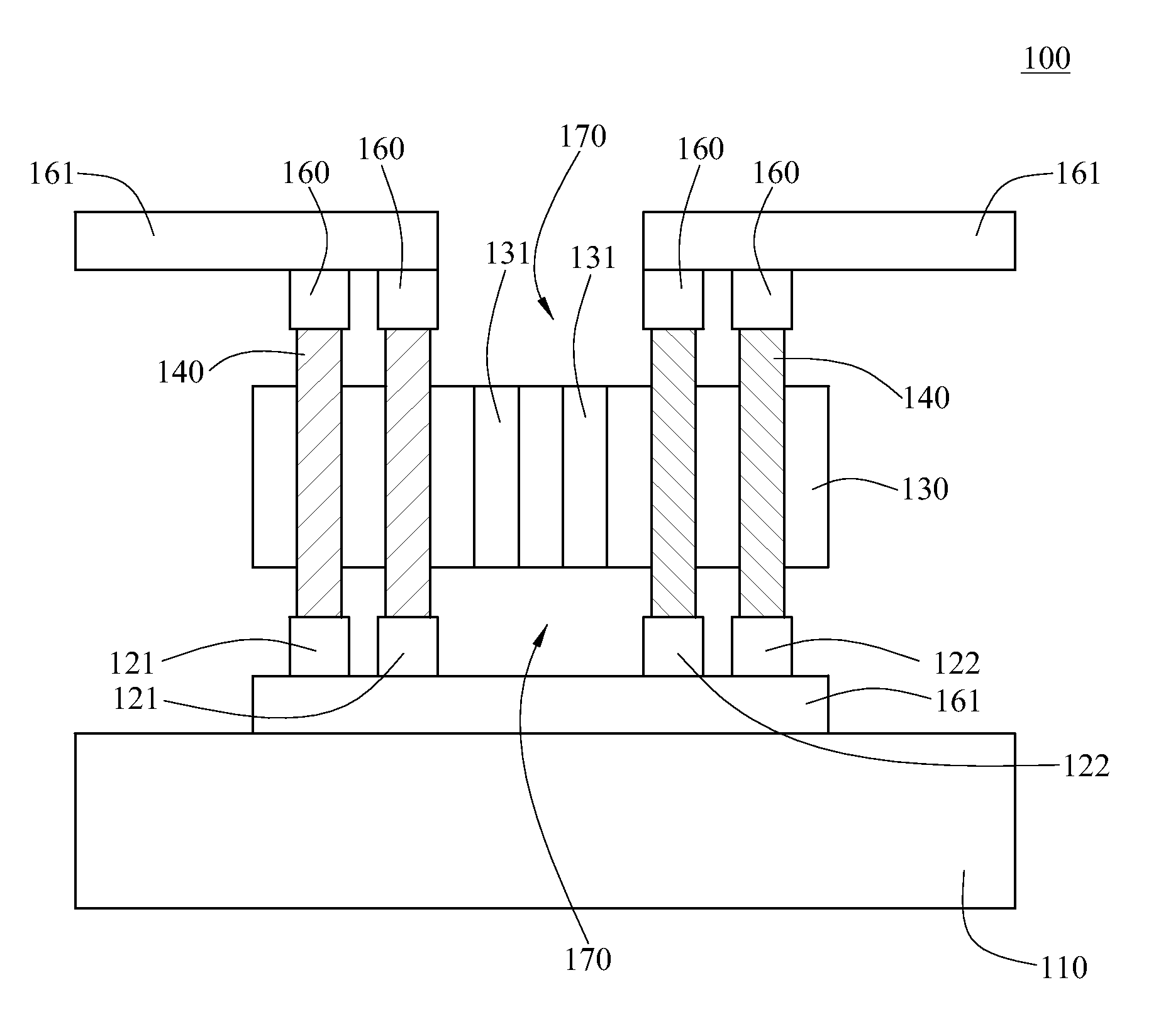

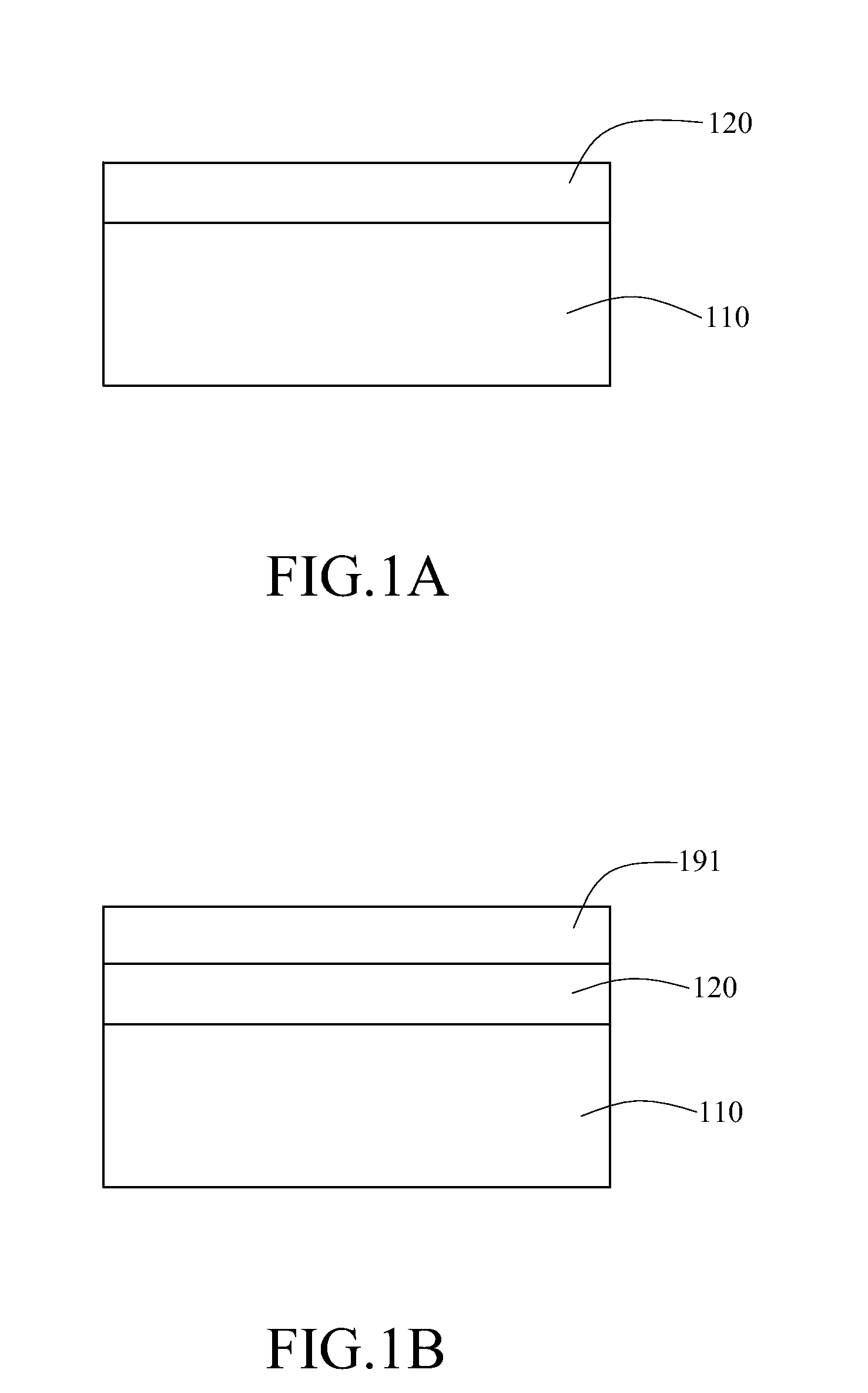

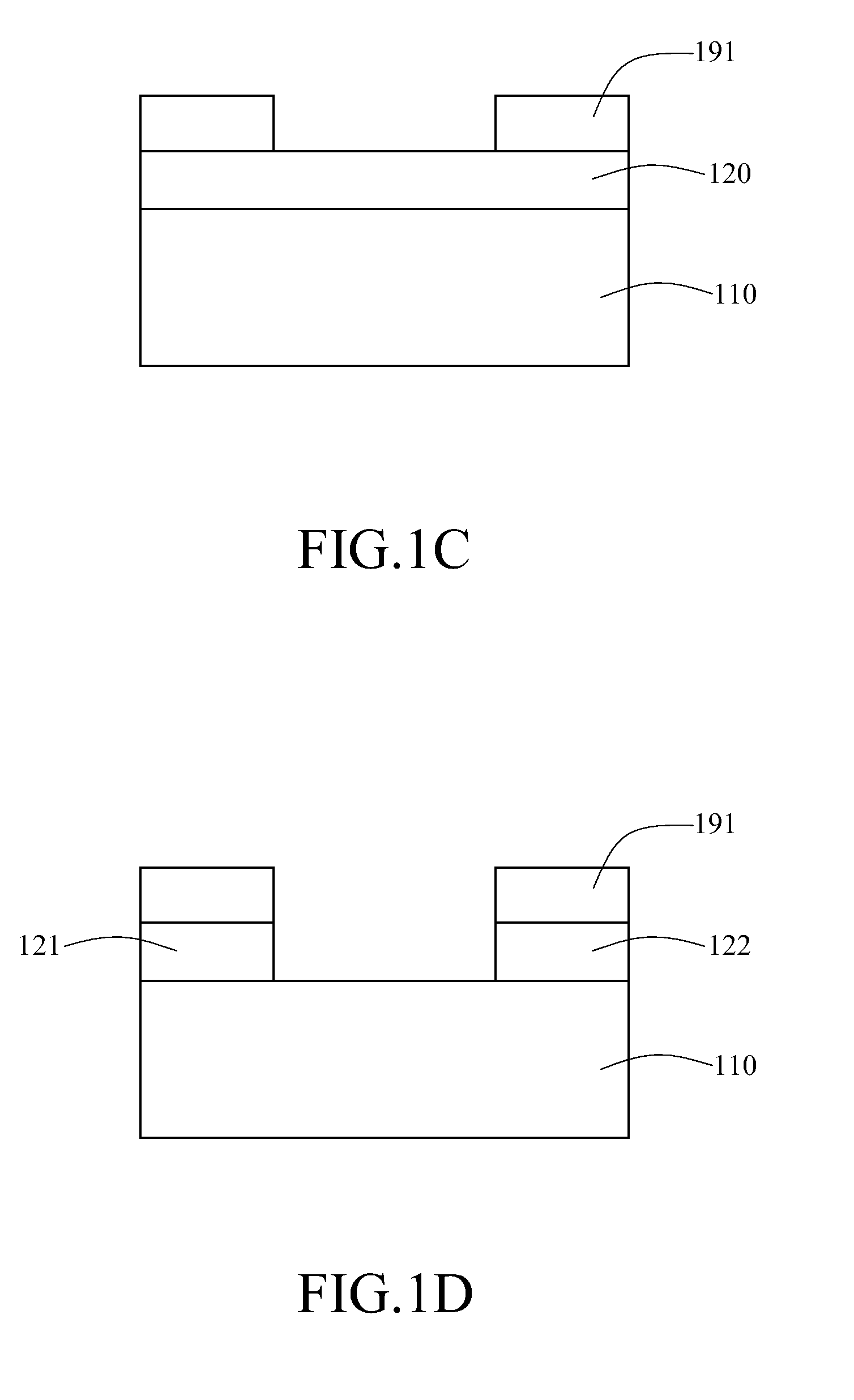

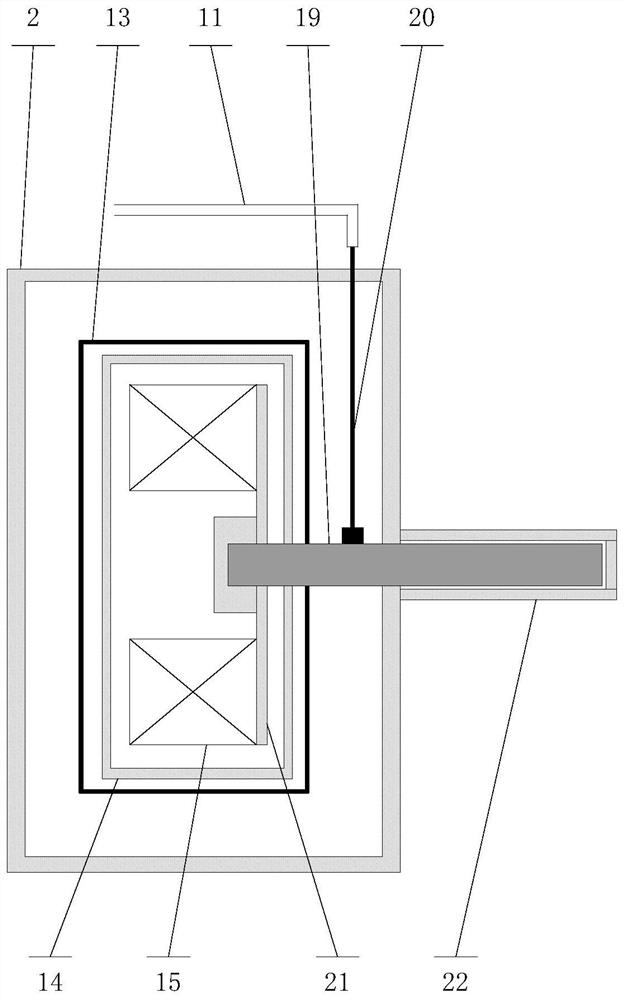

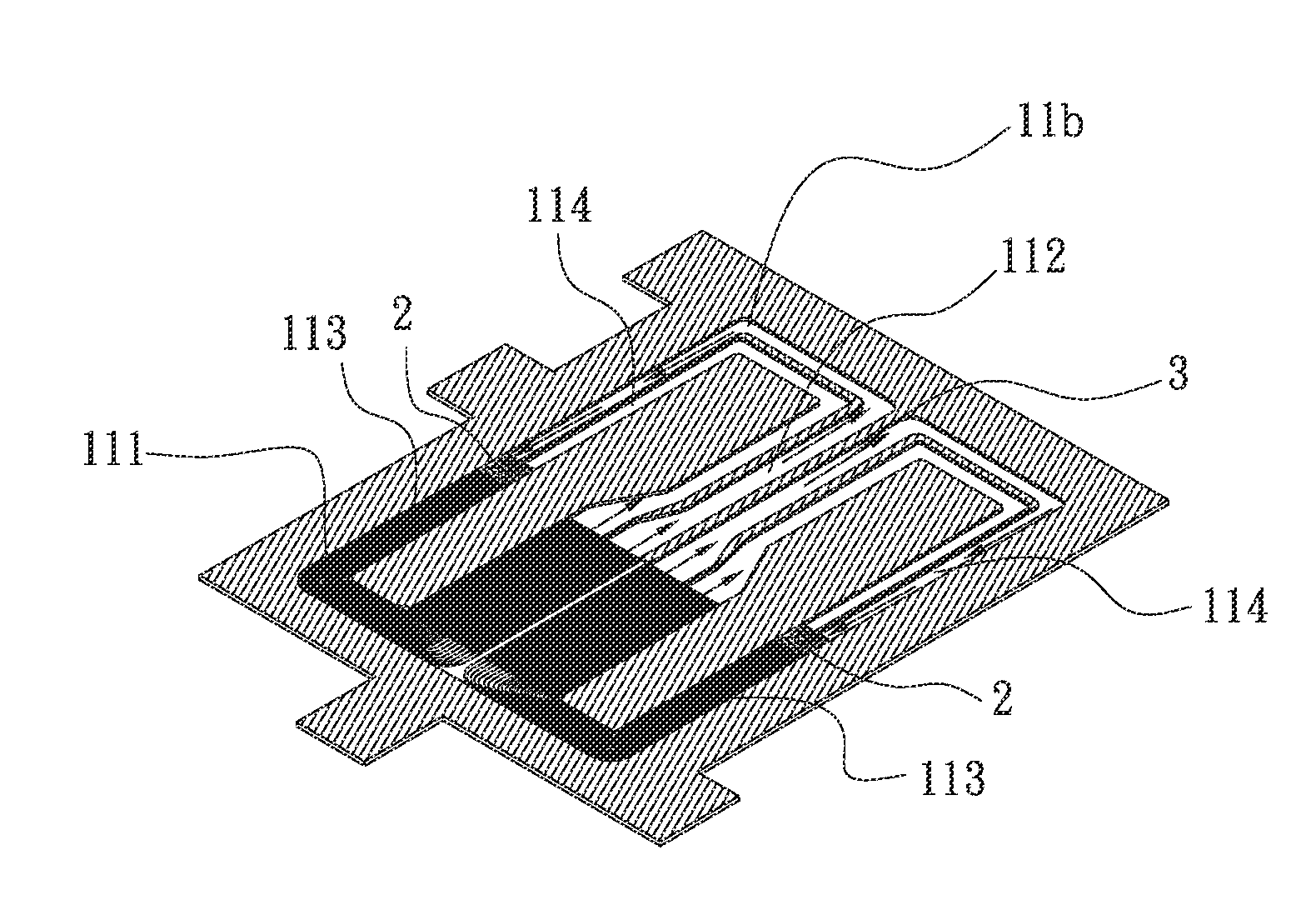

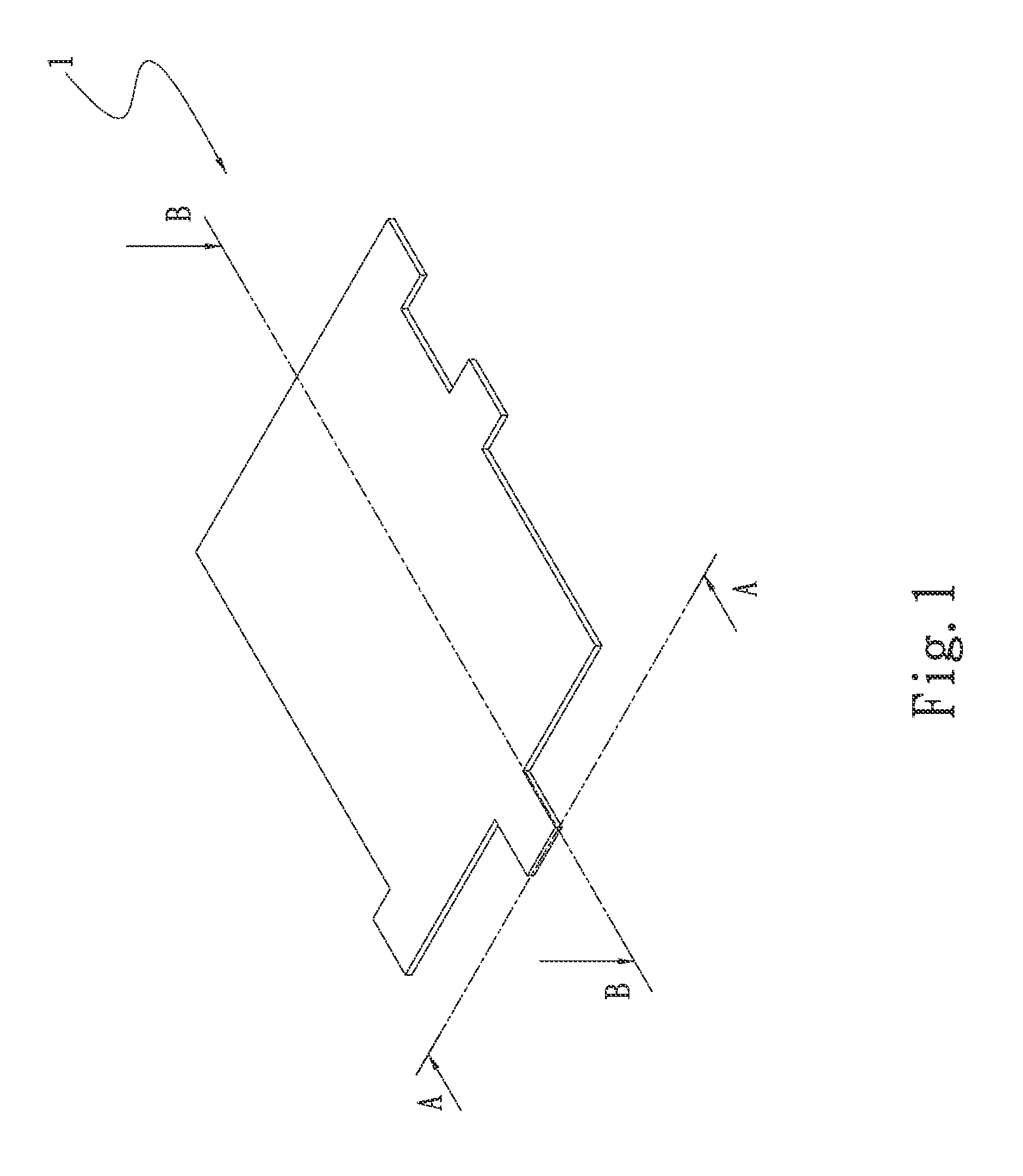

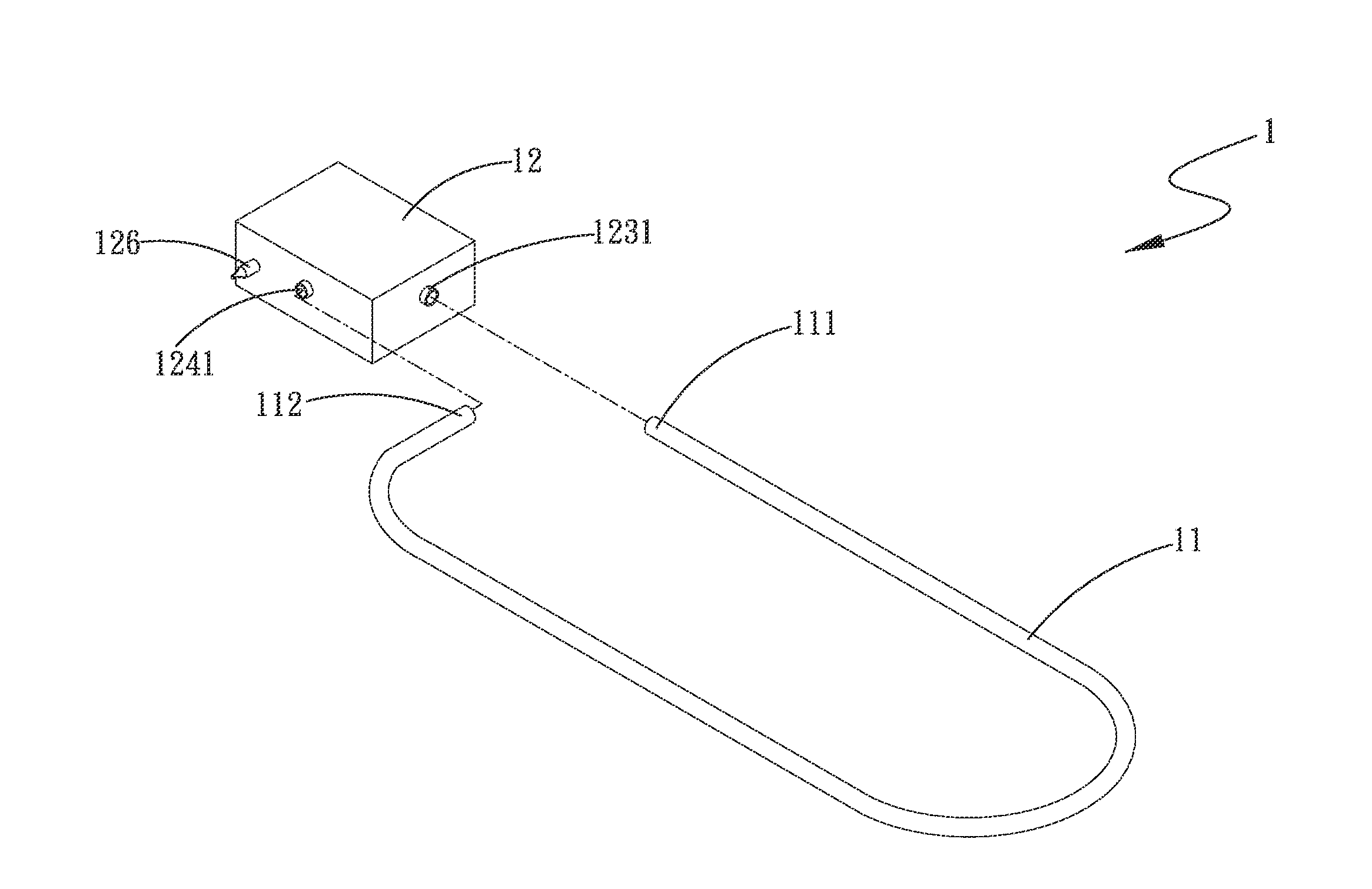

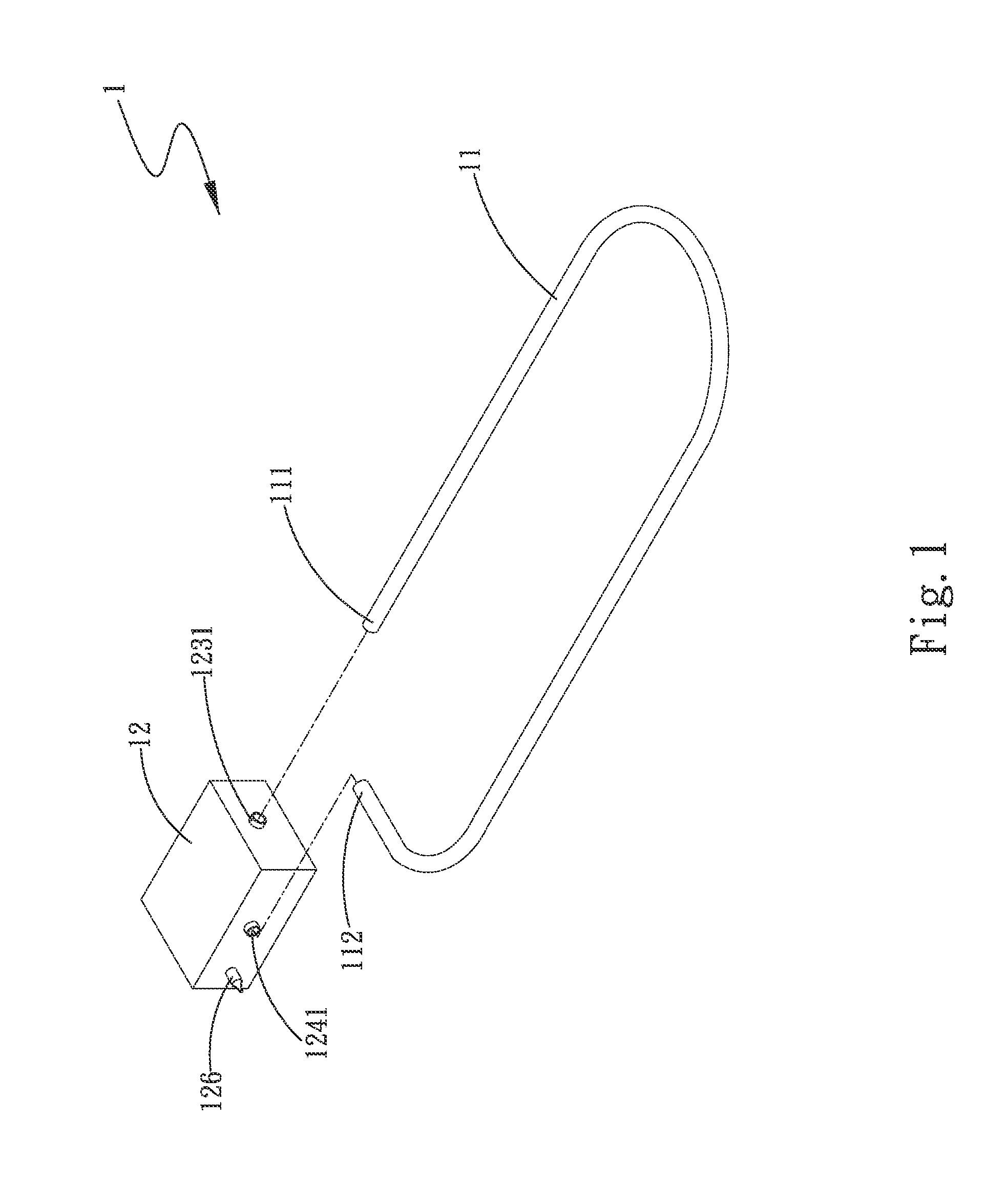

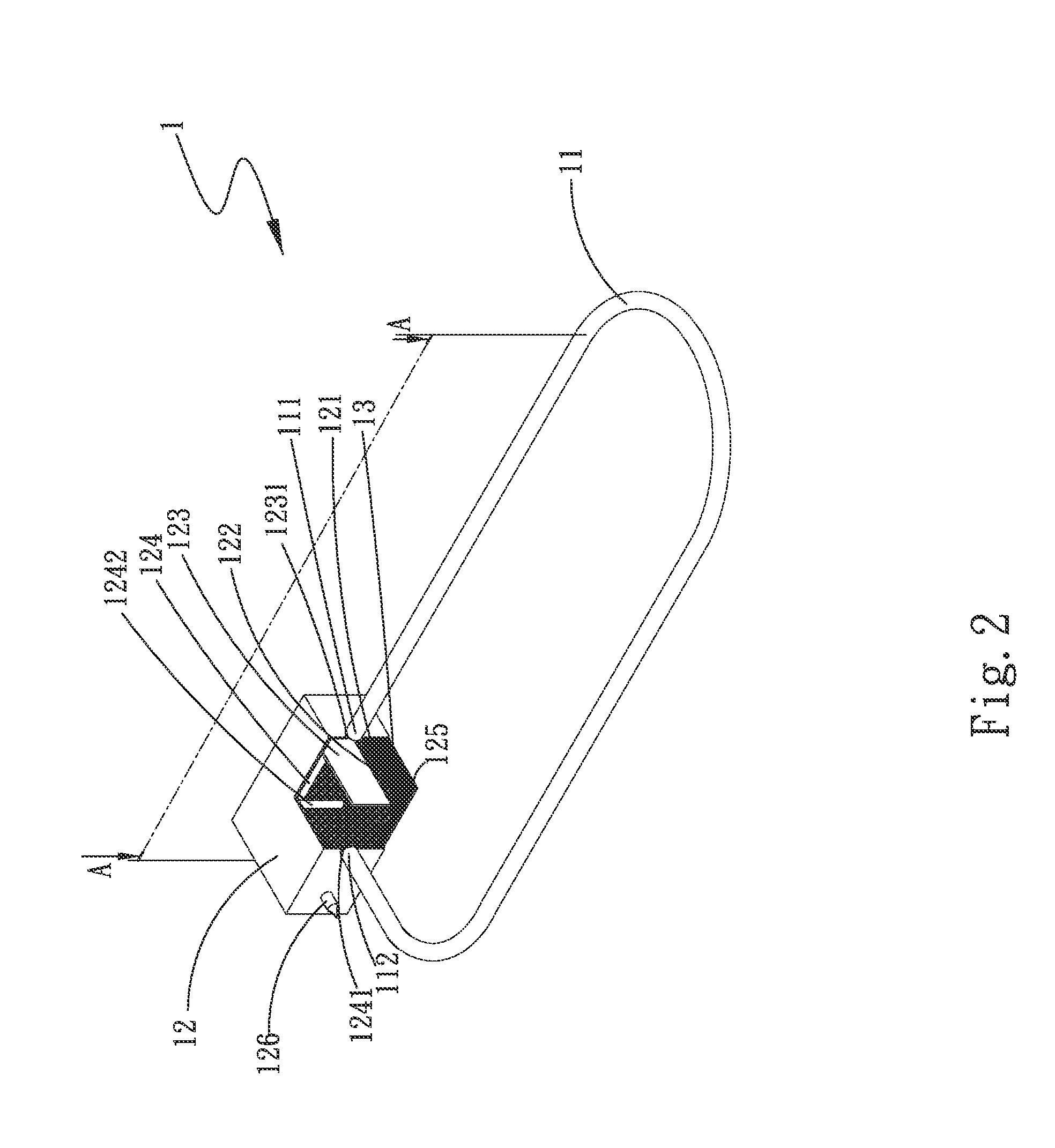

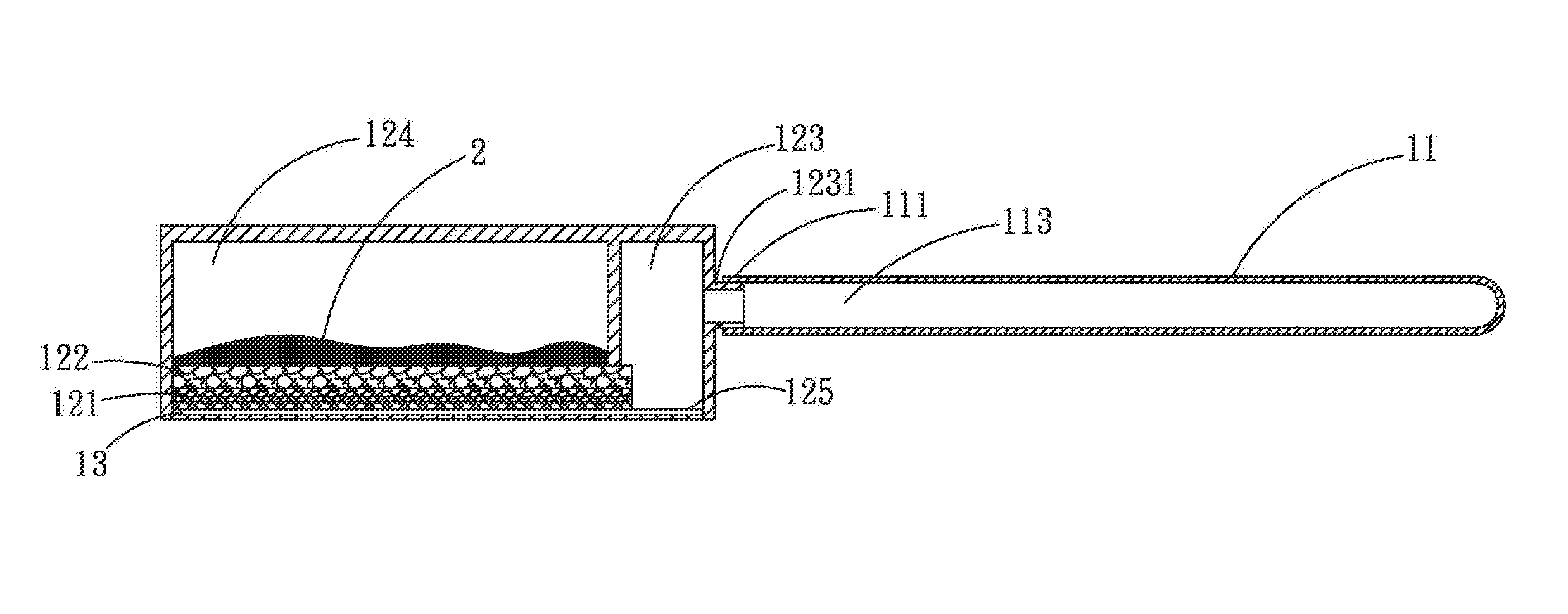

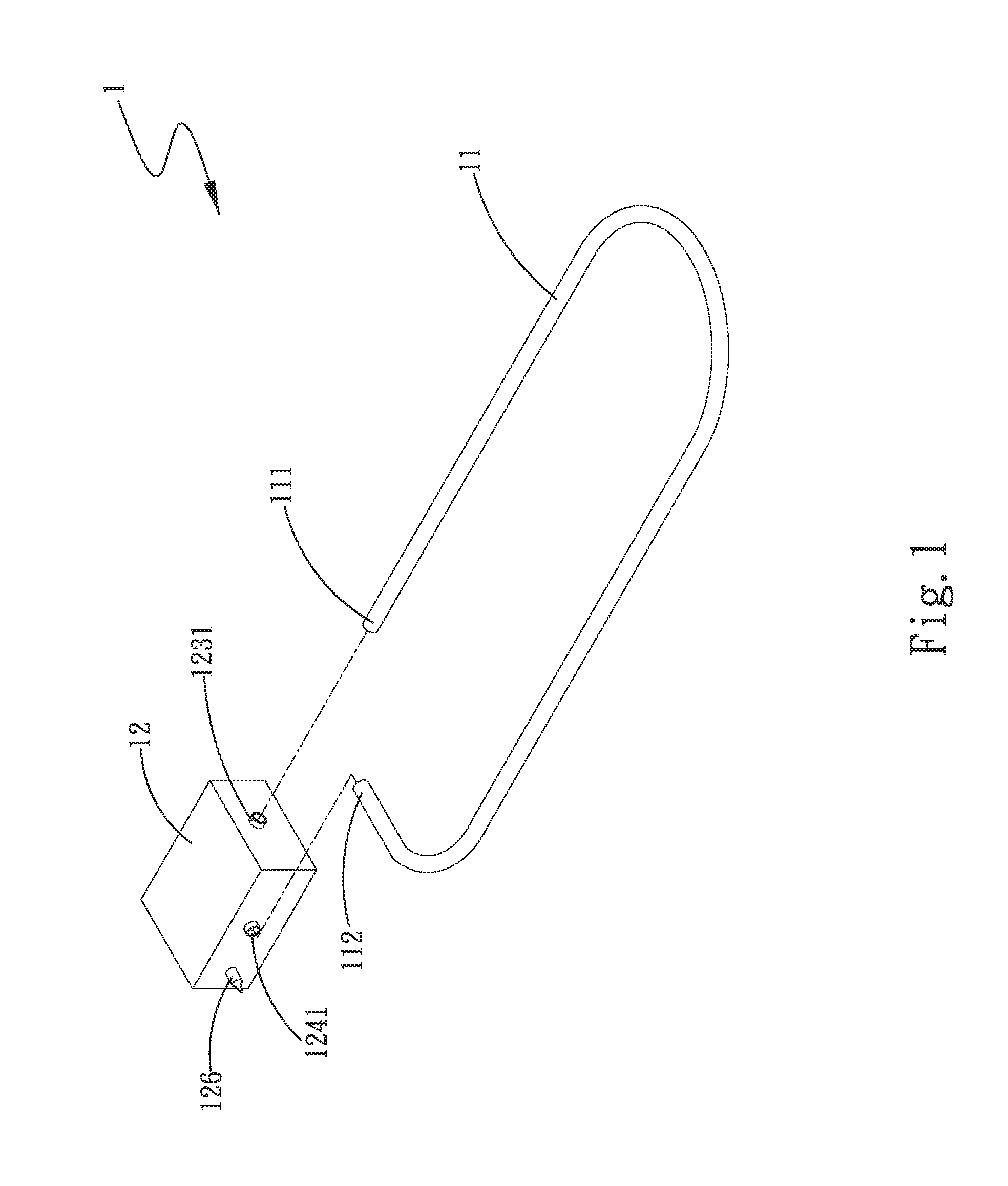

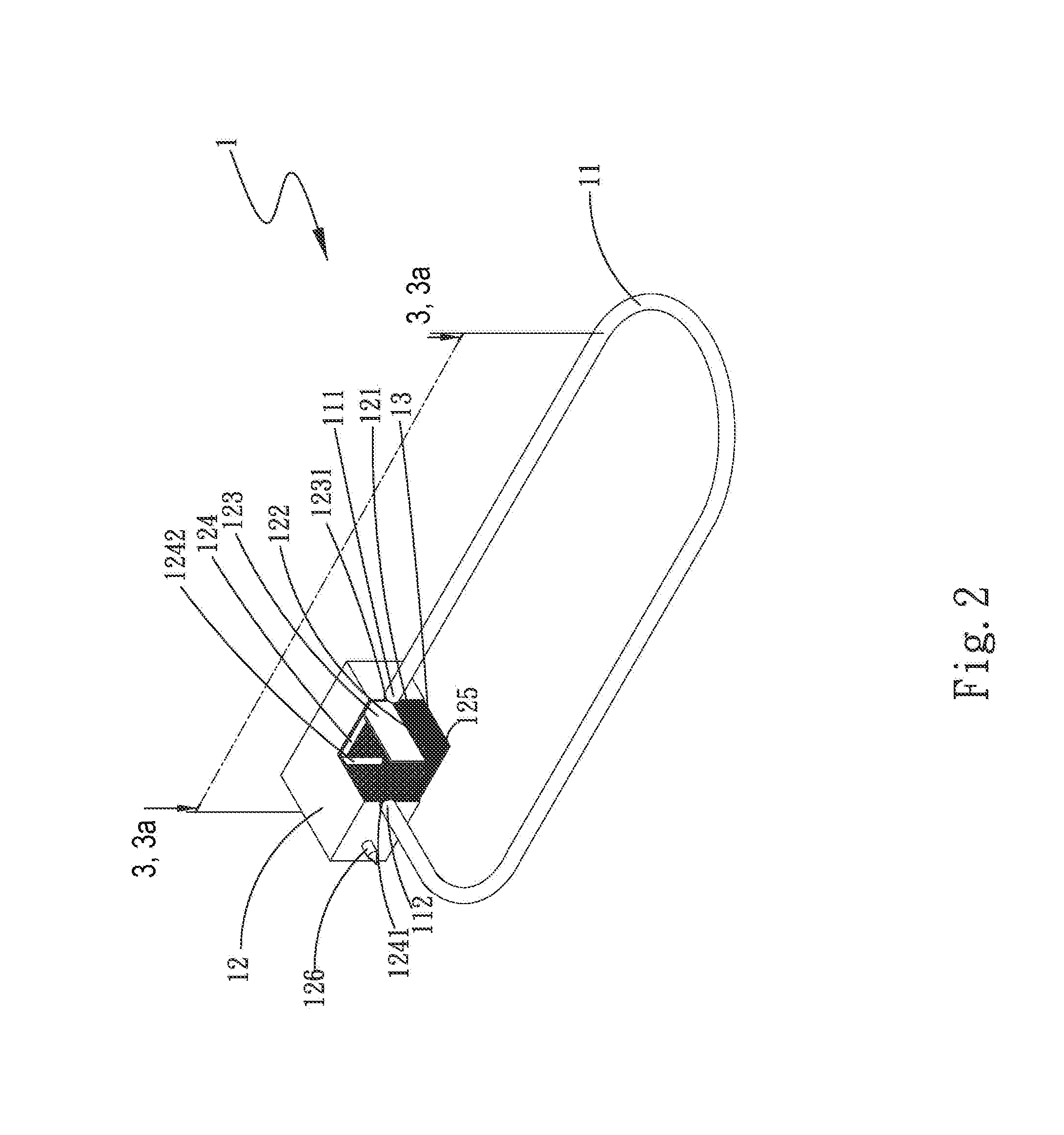

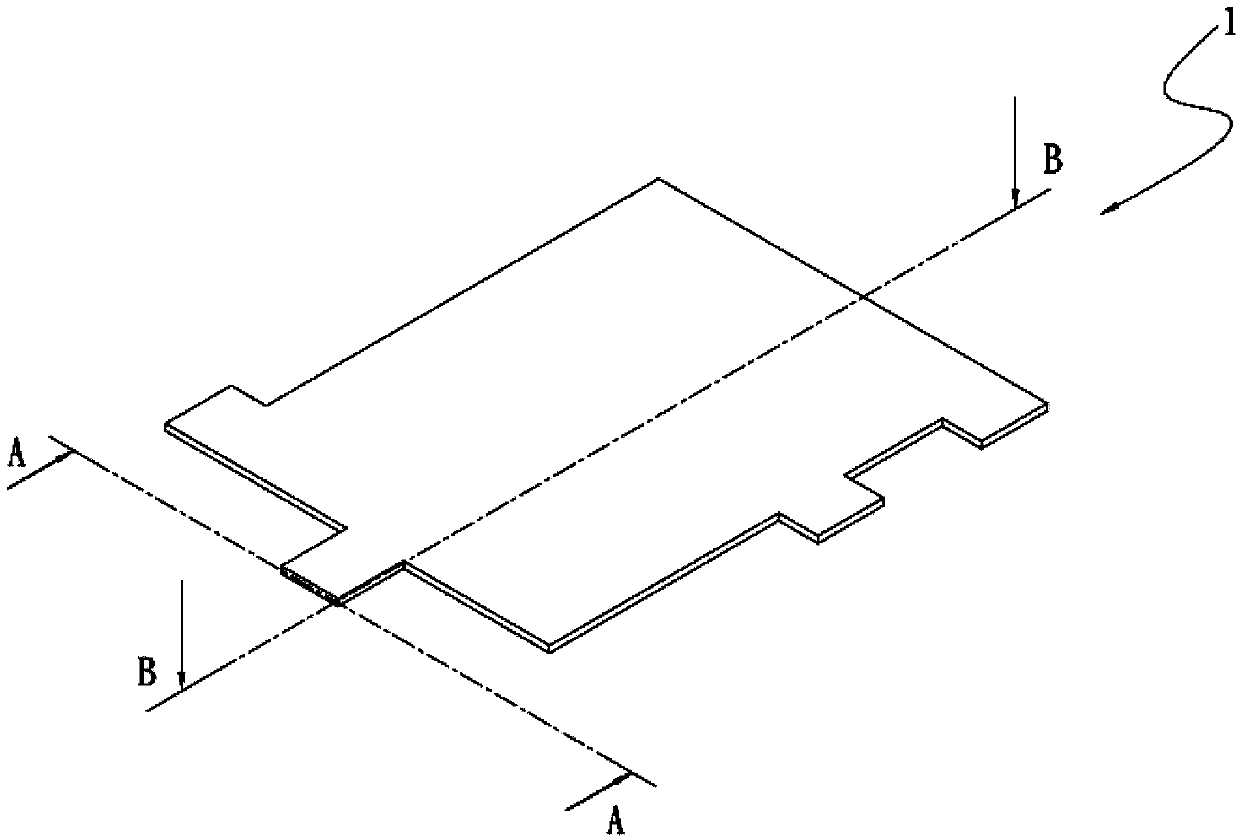

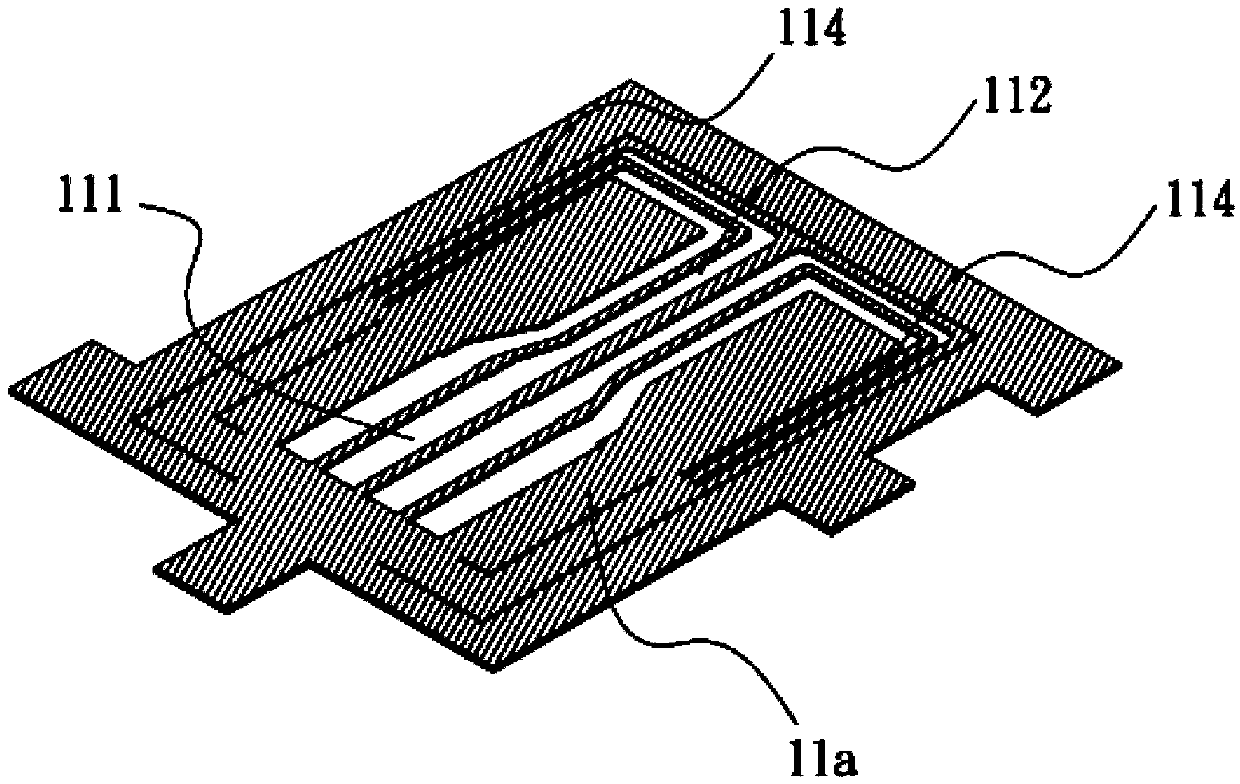

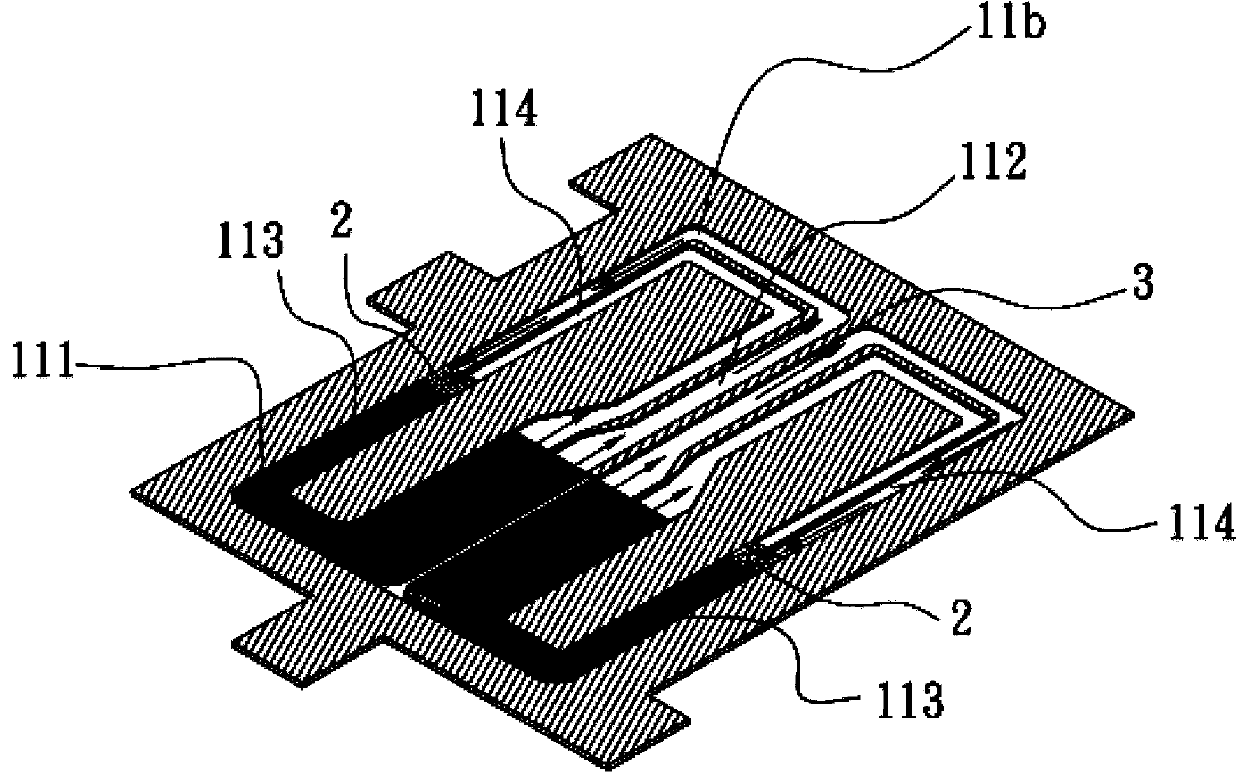

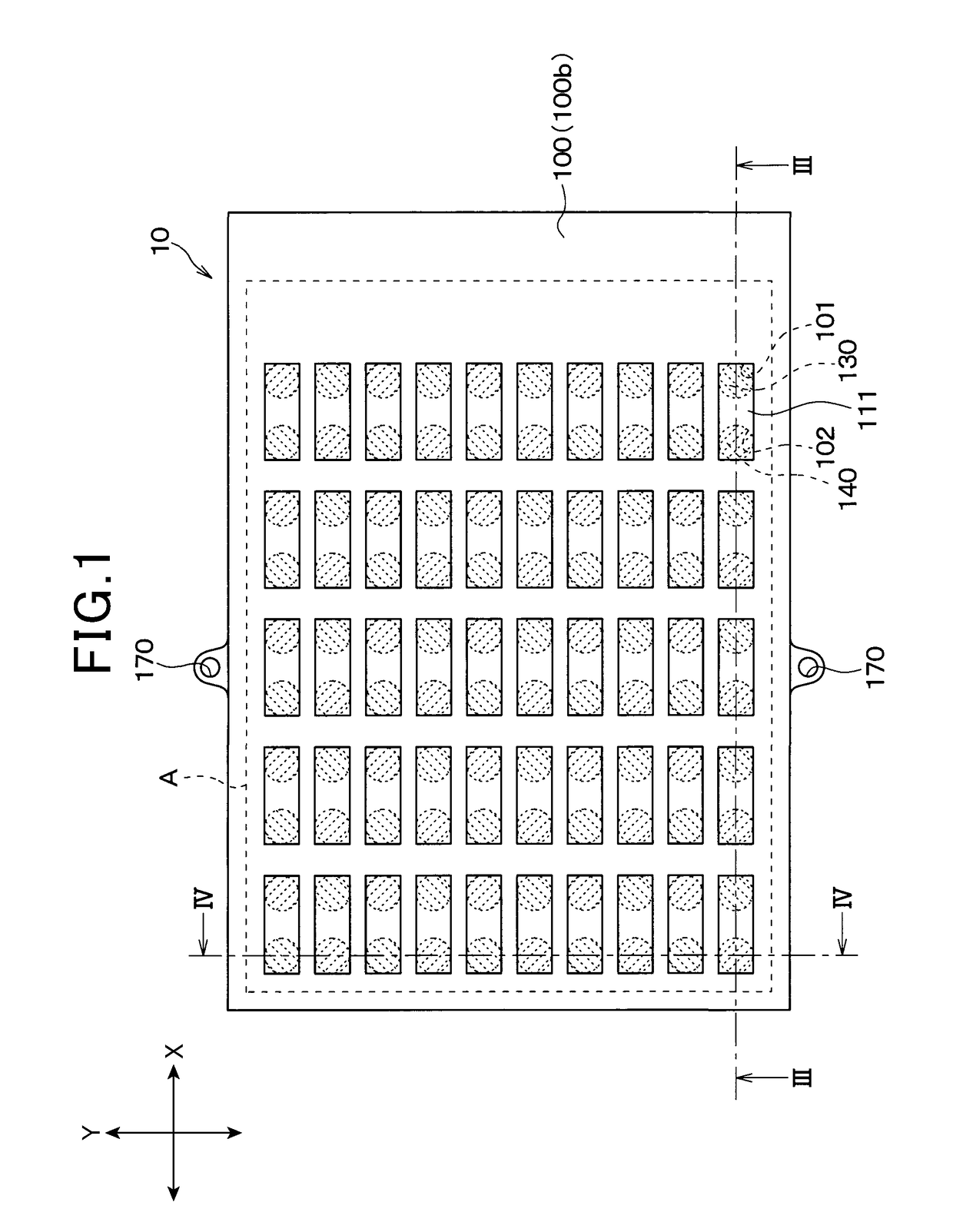

Loop heat pipe structure

ActiveUS20120247736A1Reduce total pressure lossUpgraded overall heat dissipation efficiencySemiconductor/solid-state device detailsSolid-state devicesWorking fluidEngineering

A loop heat pipe structure includes a transport pipe, an evaporator, a first wick layer, a second wick layer, and a plurality of grooves. The transport pipe communicates with the evaporator. The evaporator has a bottom and internally defines a first chamber and a second chamber, and has a working fluid filled therein. The first wick layer is located on the bottom, and the second wick layer is located on and covers the first wick layer. The grooves can be selectively provided on the first wick layer or the bottom. The first and second wick layers are so designed that the situation of very high vapor pressure would not occur in the second chamber, enabling the loop heat pipe structure to have upgraded heat dissipation efficiency.

Owner:ASIA VITAL COMPONENTSSHEN ZHEN

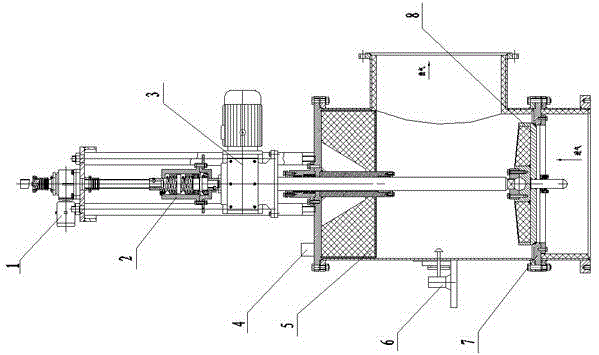

Integrated preparation technology of loop heat pipe evaporator

The invention relates to an integrated preparation technology of a loop heat pipe evaporator, which is realized through the following steps: selecting an evaporation cavity, removing an oxidation film on the inner surface of the evaporation cavity; adding mixed powder of porous wick sintered body powder and a pore creating material, inserting a cylindrical liquid storage cavity mold into the mixed powder, determining the insertion depth as per the size of the liquid storage cavity, compacting the mixed powder between the evaporator and the liquid storage cavity mold, putting the evaporation cavity into a sintering furnace for sintering, drilling a plurality of steam passages along the inner wall of the evaporation cavity by means of a bit after sintering and cooling, and taking out the liquid storage cavity mold, so as to obtain an integrated loop heat pipe evaporator. The porous wicks are directly sintered in the evaporation cavity in an enclosed manner, as a result, not only are theporous wicks tightly combined with the wall of the evaporation cavity to avoid problems of heat leakage or steam counterflow, but also the sintered porous wicks can be used directly to avoid problemsof the porous wick breakage brought by secondary machining and the requirement for high accuracy. Lower strength is allowed to realize high porosity factor, thereby facilitating enhancement of the suction force of the porous wicks.

Owner:SHANDONG UNIV

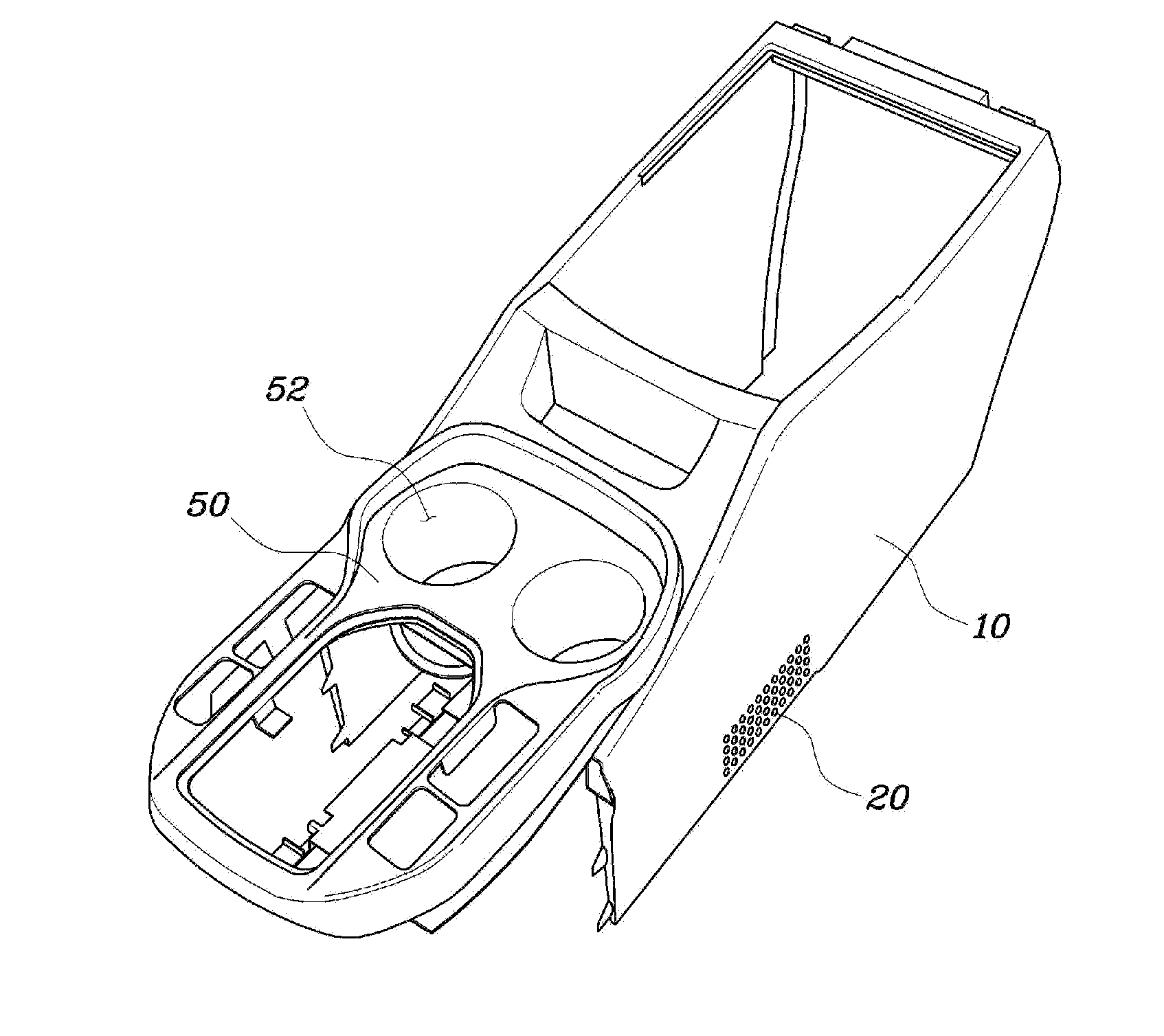

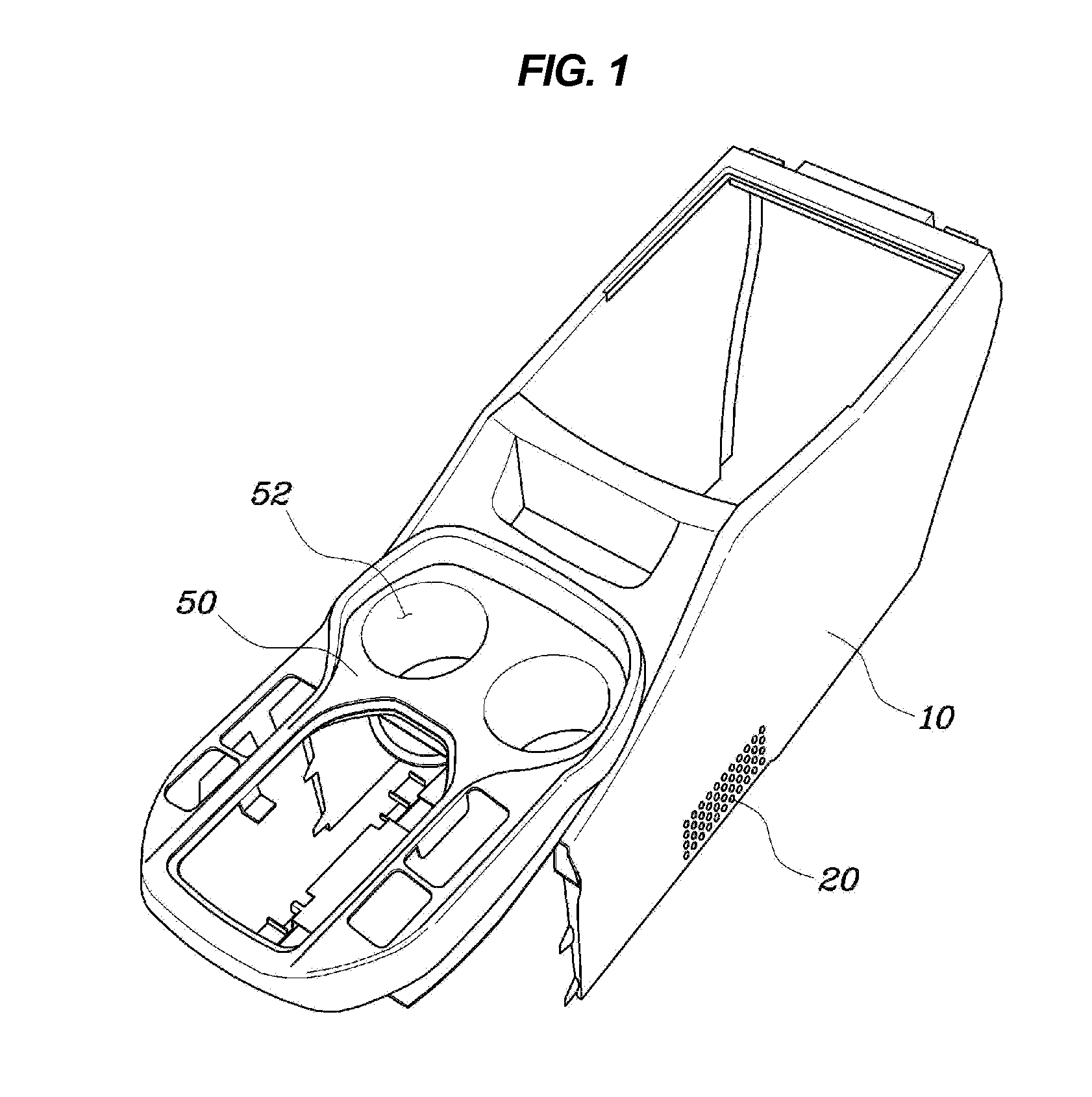

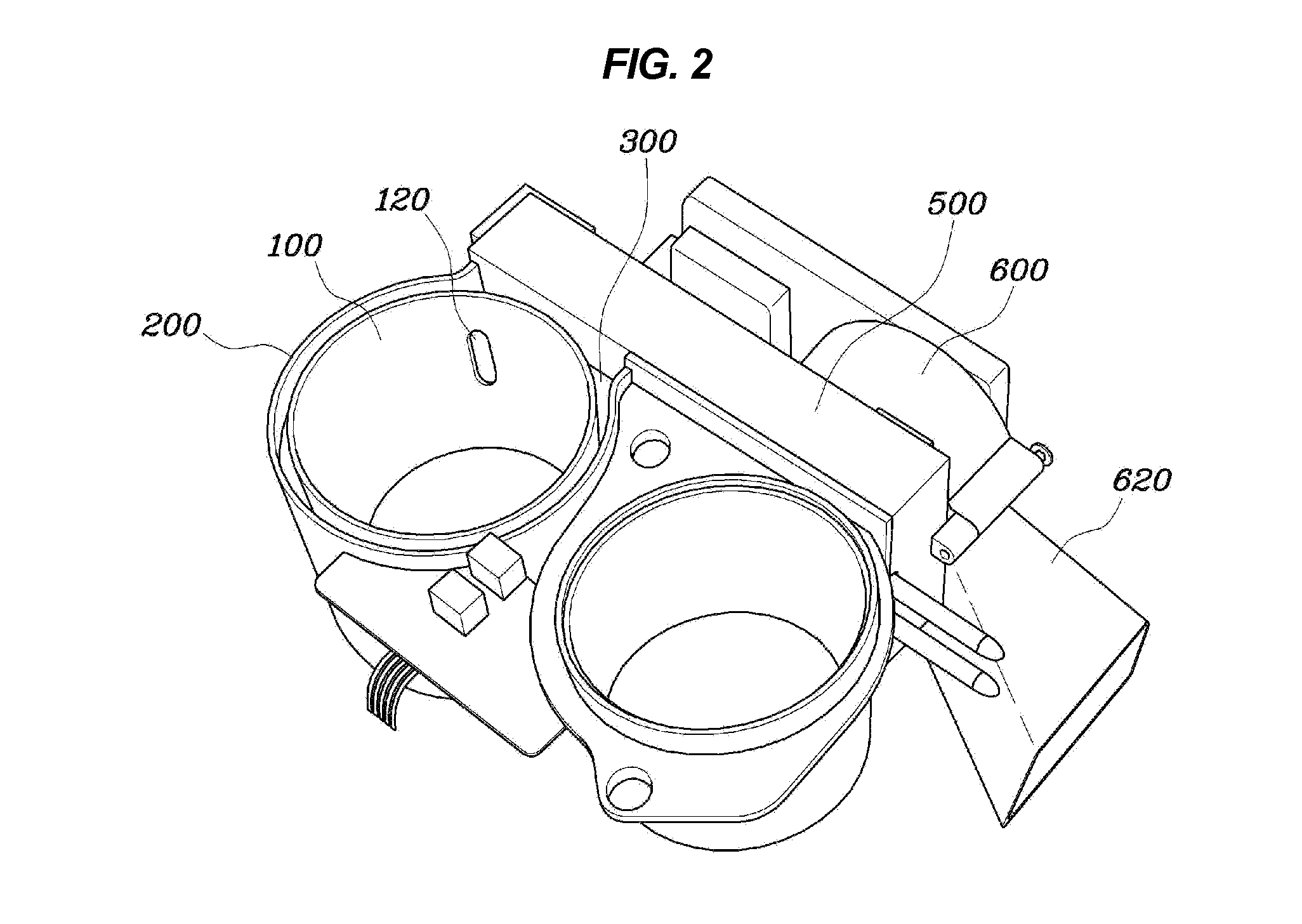

Heating and cooling cup holder

ActiveUS20150107271A1Easy to useImprove performanceVehicle arrangementsPassenger spaceEngineeringHeat spreader

A heating and cooling cup holder may include an inner holder having an air hole, a heat exchanging unit covering the air hole and having an intake port at a first side so that air flowing inside through the intake port exchanges heat through heat transfer fins in the heat exchanging unit and flows into the inner holder through the air hole, a peltier element having a front coupled to a rear of the heat exchanging unit, a heat dissipation module including a heat sink and a heat dissipating fan coupled to the rear of the peltier element, an outer holder surrounding the side of the inner holder and defining a ventilation space together with the inner holder therebetween, and a blower disposed in the ventilation space and having a discharge port connected to the intake port of the heat exchanging unit.

Owner:HYUNDAI MOTOR CO LTD +1

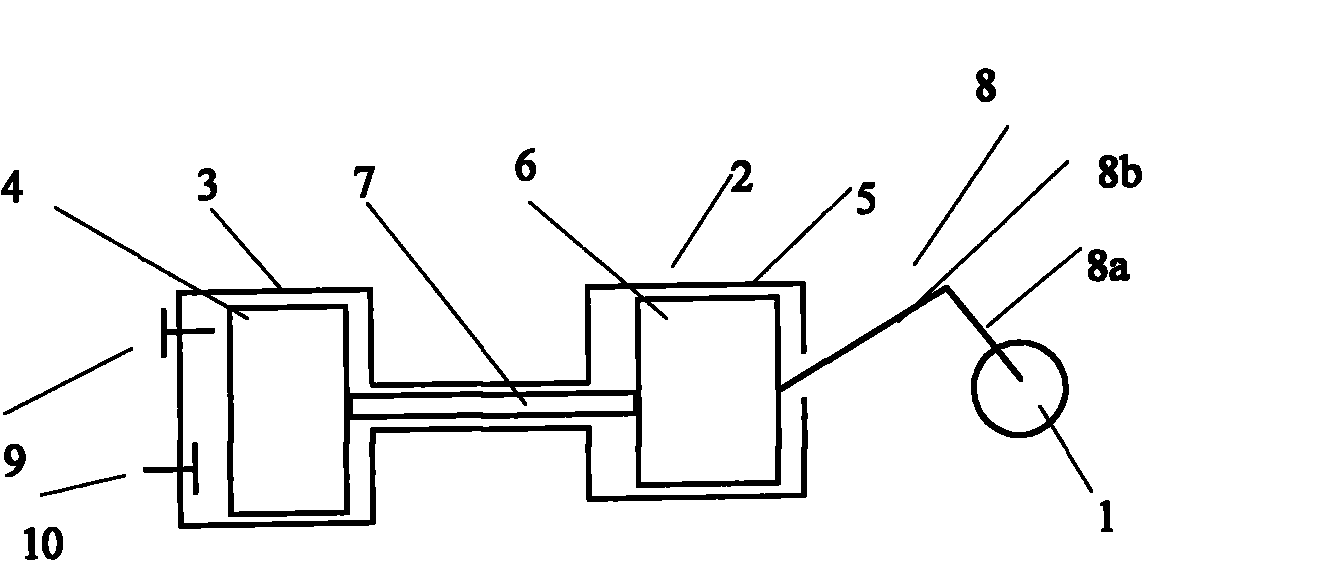

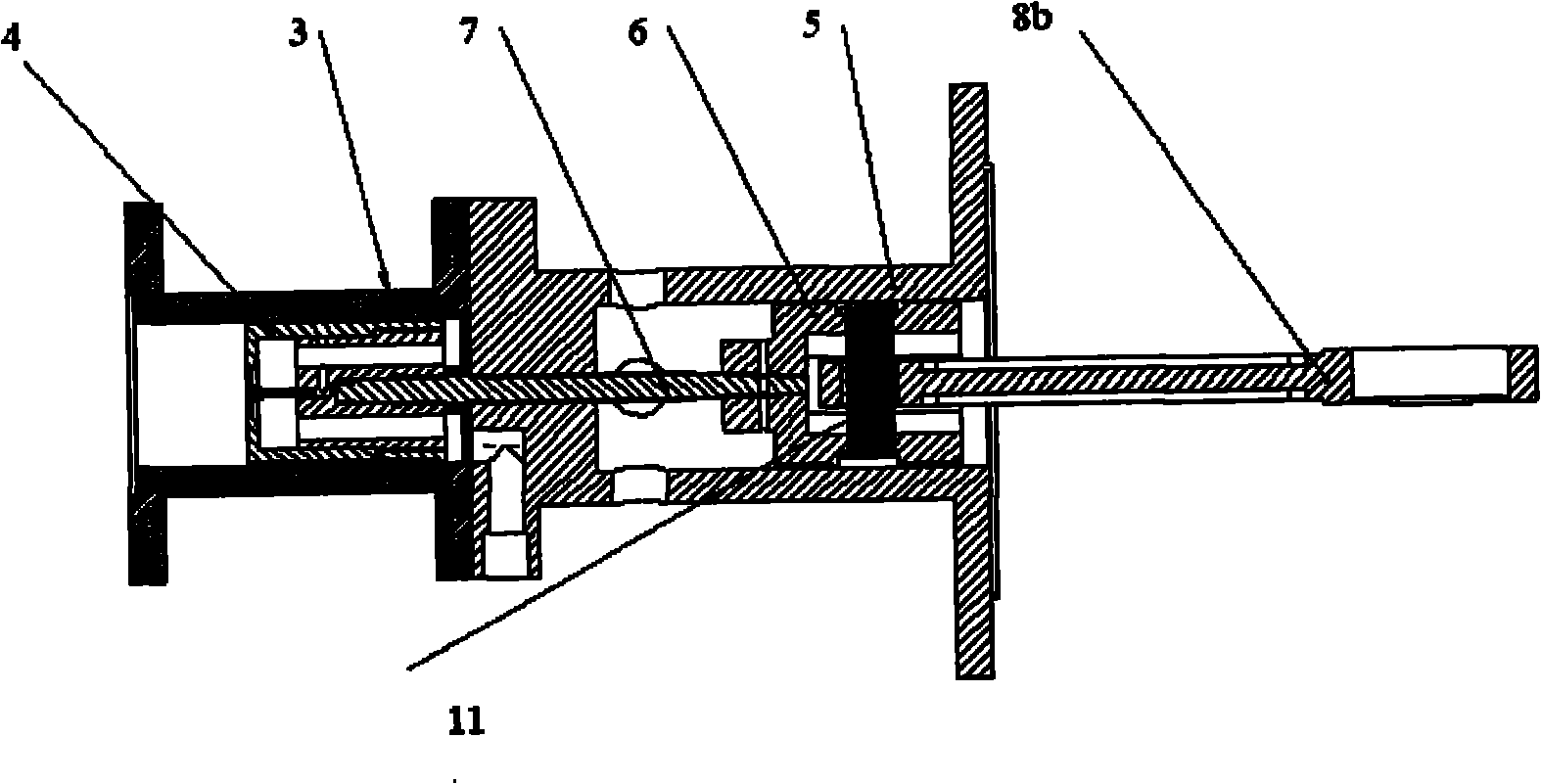

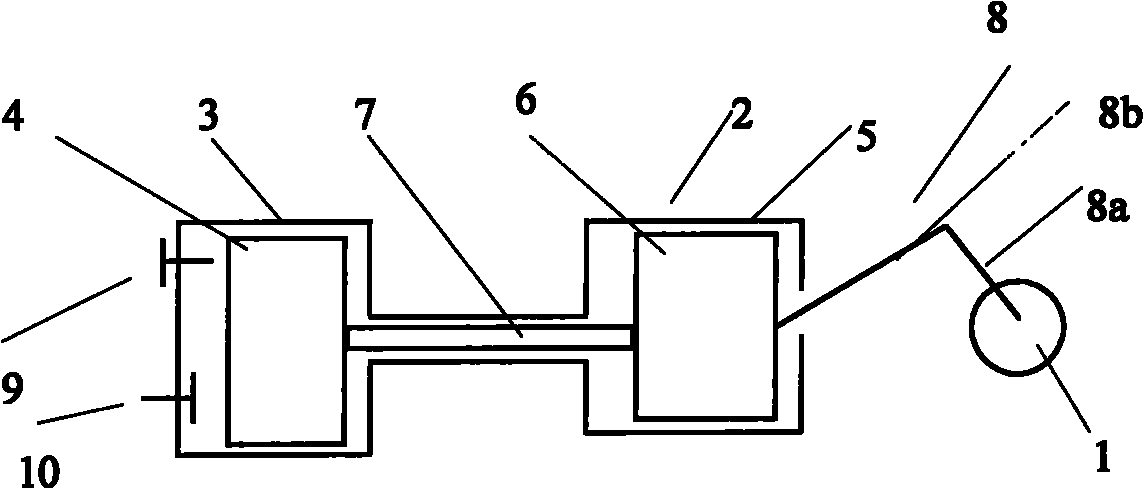

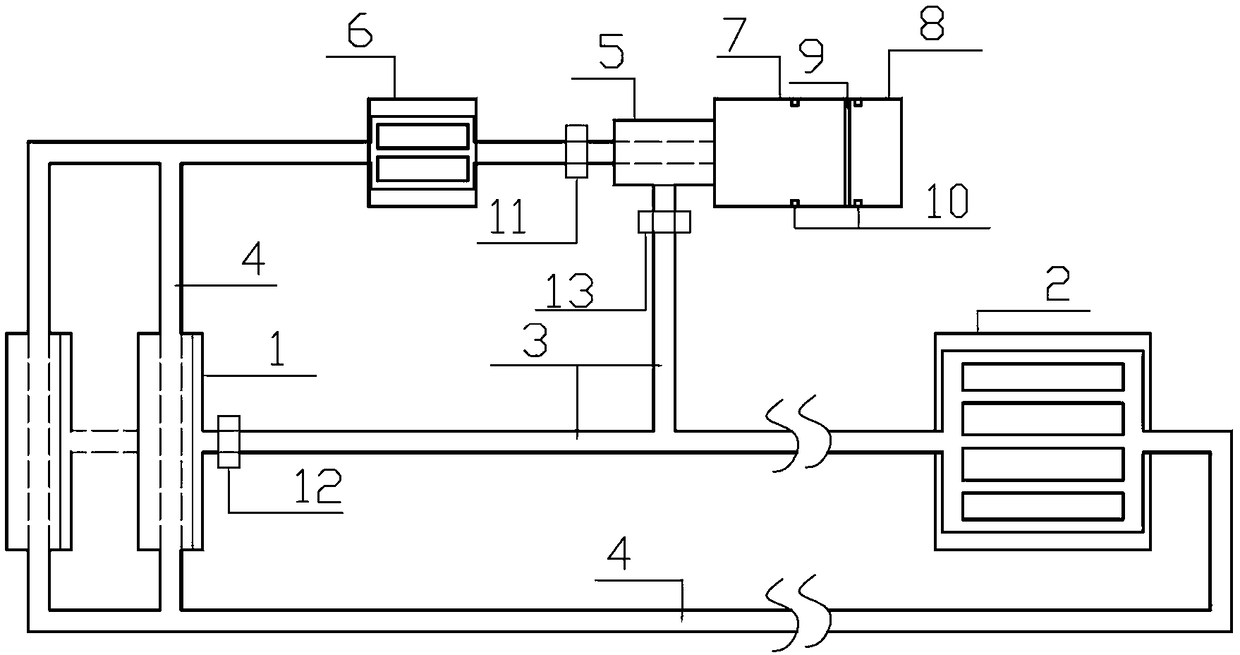

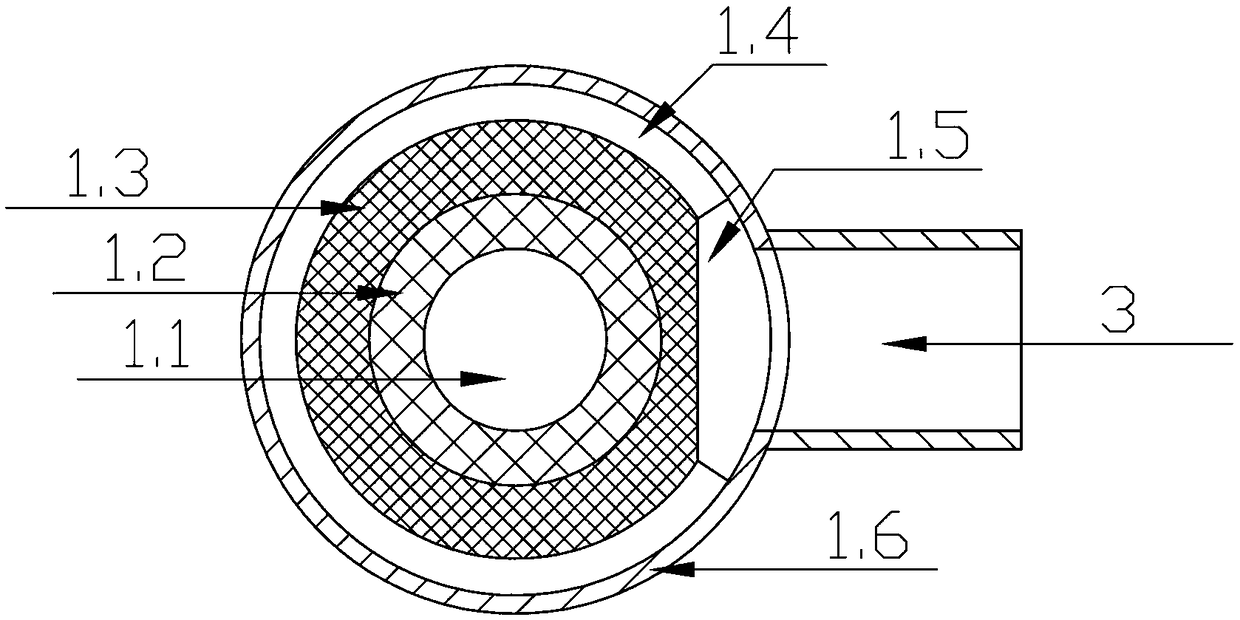

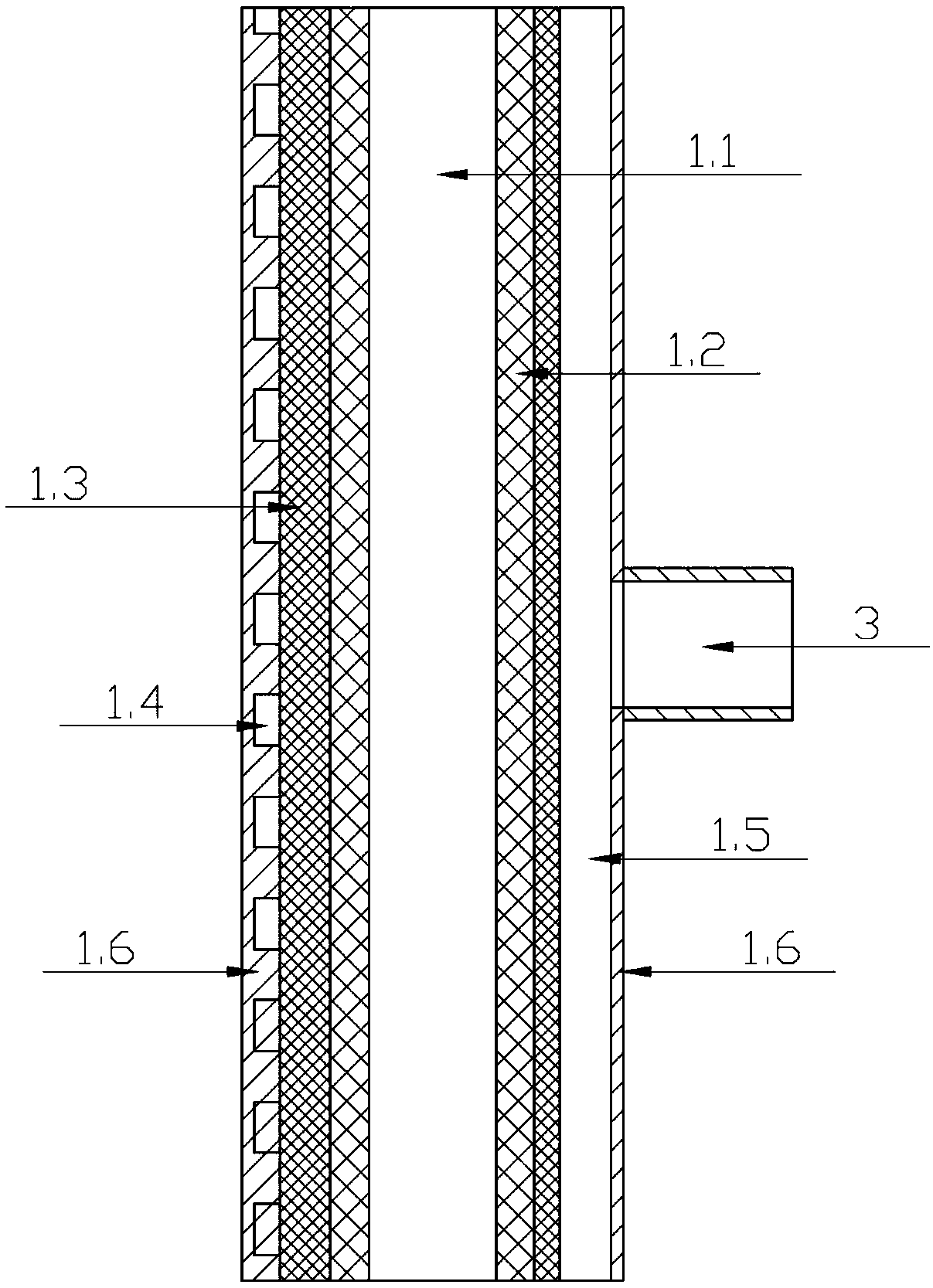

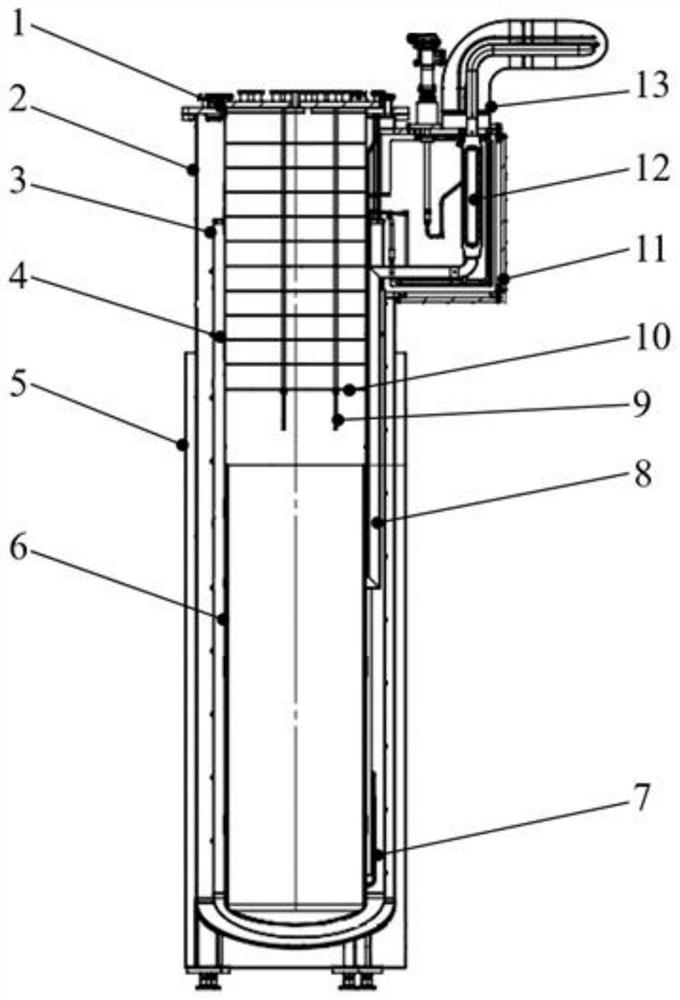

Low-temperature liquid hydrogen pump and use thereof

InactiveCN102042188APrevent heat leakageAvoid structurePumpsPositive-displacement liquid enginesLiquid hydrogenCopper coil

The invention provides a low-temperature liquid hydrogen pump, which comprises an electric motor (1), a drive mechanism (2), a working cylinder (3) and a first piston (4) arranged in the working cylinder (3). The low-temperature liquid hydrogen pump is characterized in that: the electric motor (1) is an iron core-free electric motor, and comprises a stator winding formed by pouring an epoxy material and a copper coil; and the shrinkage of the epoxy material in liquid hydrogen is 0.3 to 0.5 percent, so that the liquid hydrogen pump can be impregnated in the liquid hydrogen for work. In addition, the invention also provides the use of the low-temperature liquid hydrogen pump in the delivery of the liquid hydrogen.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

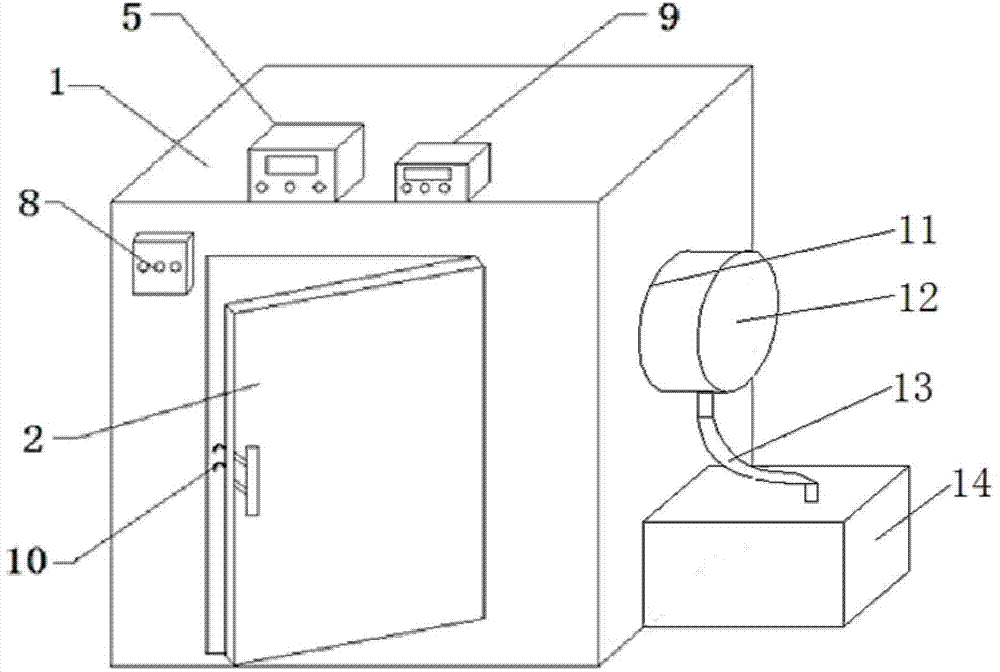

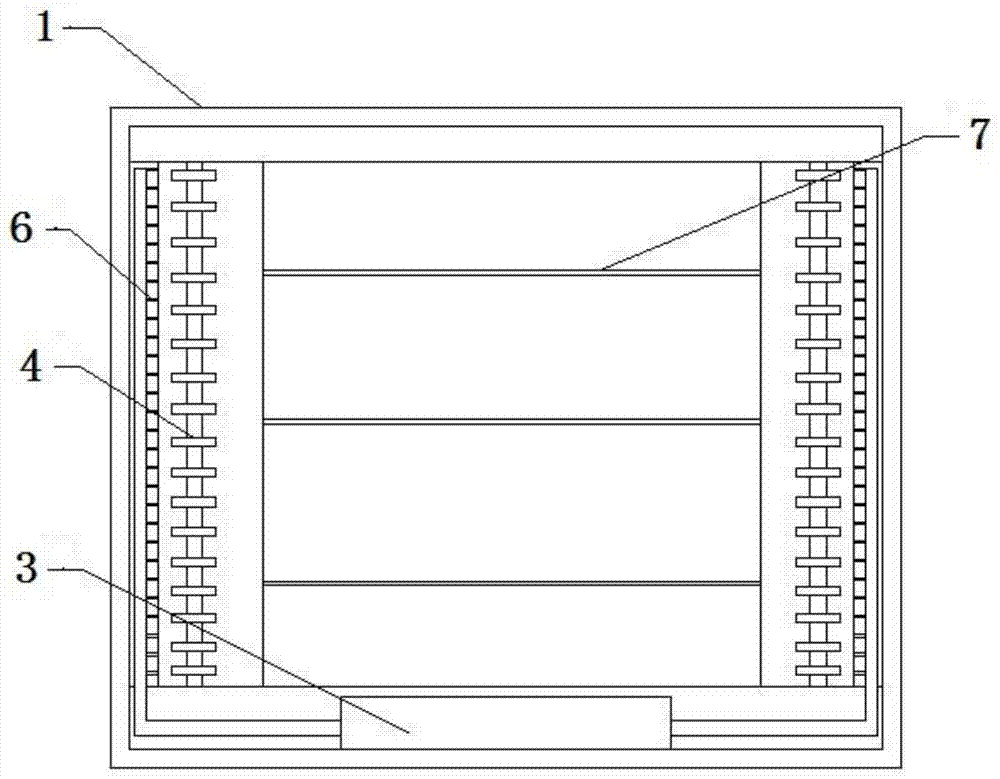

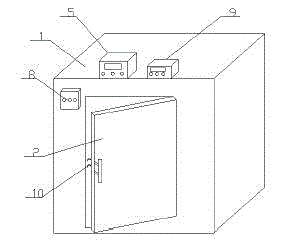

Energy-saving industrial oven

InactiveCN104279841ASave internal spaceEvenly heatedDrying gas arrangementsDrying chambers/containersElectricityTemperature control

The invention discloses an energy-saving industrial oven and relates to the field of machinery. The energy-saving industrial oven comprises a shell, an oven door, a circulating fan, electrical heating elements and a temperature controller; the oven door is movably hinged to the shell, the circulating fan is arranged at the bottom of the shell, the electrical heating elements are electrically connected with the temperature controller and are arranged on inner walls on two sides of the shell, air flow pipelines are further arranged on the inner walls on two sides of the shell, the diameter of each air flow pipeline ranges from 1mm to 2mm, and a two-point lock is arranged on the oven door. By the energy-saving industrial oven, heat can be effectively uniformly transferred to a material to be heated, and the uniform heating of the material is guaranteed; the oven door and the shell are locked in a two-point locking mode, so that the oven door and the shell can be firmer in contact, and heat leakage caused by deformation generated due to higher temperature is avoided.

Owner:ZHENGZHOU HANTONG ELECTRONICS TECH

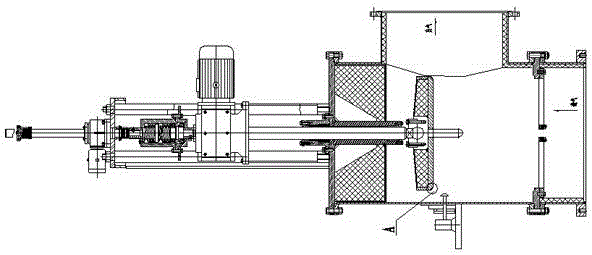

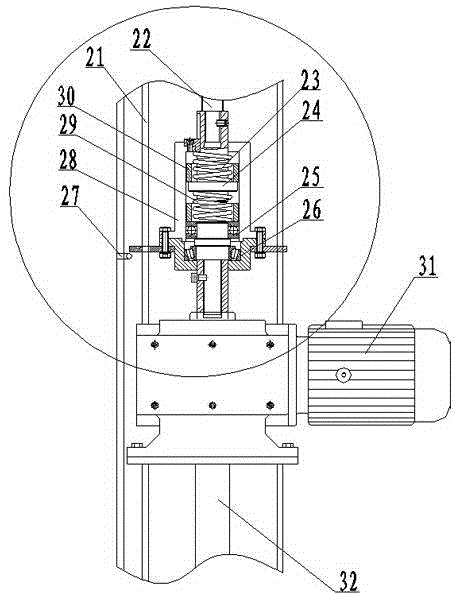

Self-grinding gas pipeline seal seat valve for high temperature and dust environments

ActiveCN104806772AReduce lossKeep warmOperating means/releasing devices for valvesLift valveRotary valveProduct gas

The invention discloses a self-grinding gas pipeline seal seat valve for high temperature and dust environments. The self-grinding gas pipeline seal seat valve comprises a valve casing body, a lifting mechanism, a suspension mechanism, a rotation driving mechanism, a sweeping mechanism, a valve core and a seal ring; the lifting mechanism is connected with a valve rod; the valve rod is connected with the suspension mechanism; the lower part of the suspension mechanism is provided with the rotation driving mechanism; the lower part of the rotation driving mechanism penetrates through the valve casing body through a rotary valve rod and is connected with the valve core; the seal ring is arranged at an air inlet in the lower part of the valve casing body; the sweeping mechanism is arranged at the side wall of the valve casing body; a control mechanism is connected with the lifting mechanism, the rotation driving mechanism and the sweeping mechanism. The problem of the seal stop of a valve body under the high temperature and dust environments is solved, so that the seal valve is prolonged to 11 thousand times of opening and closing from several times after which the seal valve can lose efficacy after being opened and closed originally; moreover, the self-grinding gas pipeline seal seat valve disclosed by the invention has an excellent seal effect; after the self-grinding gas pipeline seal seat valve is closed, zero leakage is realized; the equipment replacing frequency is reduced; production can be smoothly performed; the self-grinding gas pipeline seal seat valve is worthy of being applied and popularized.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

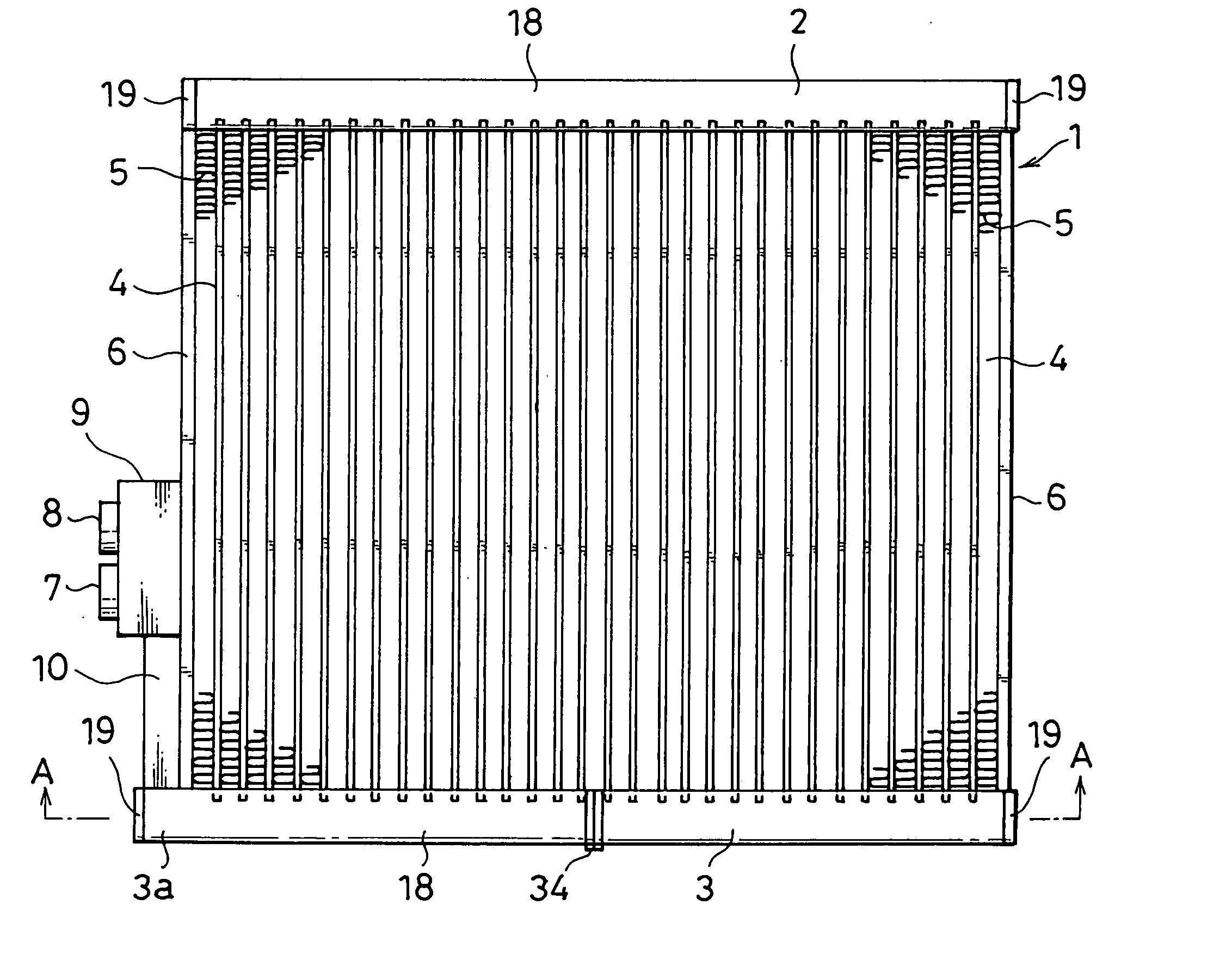

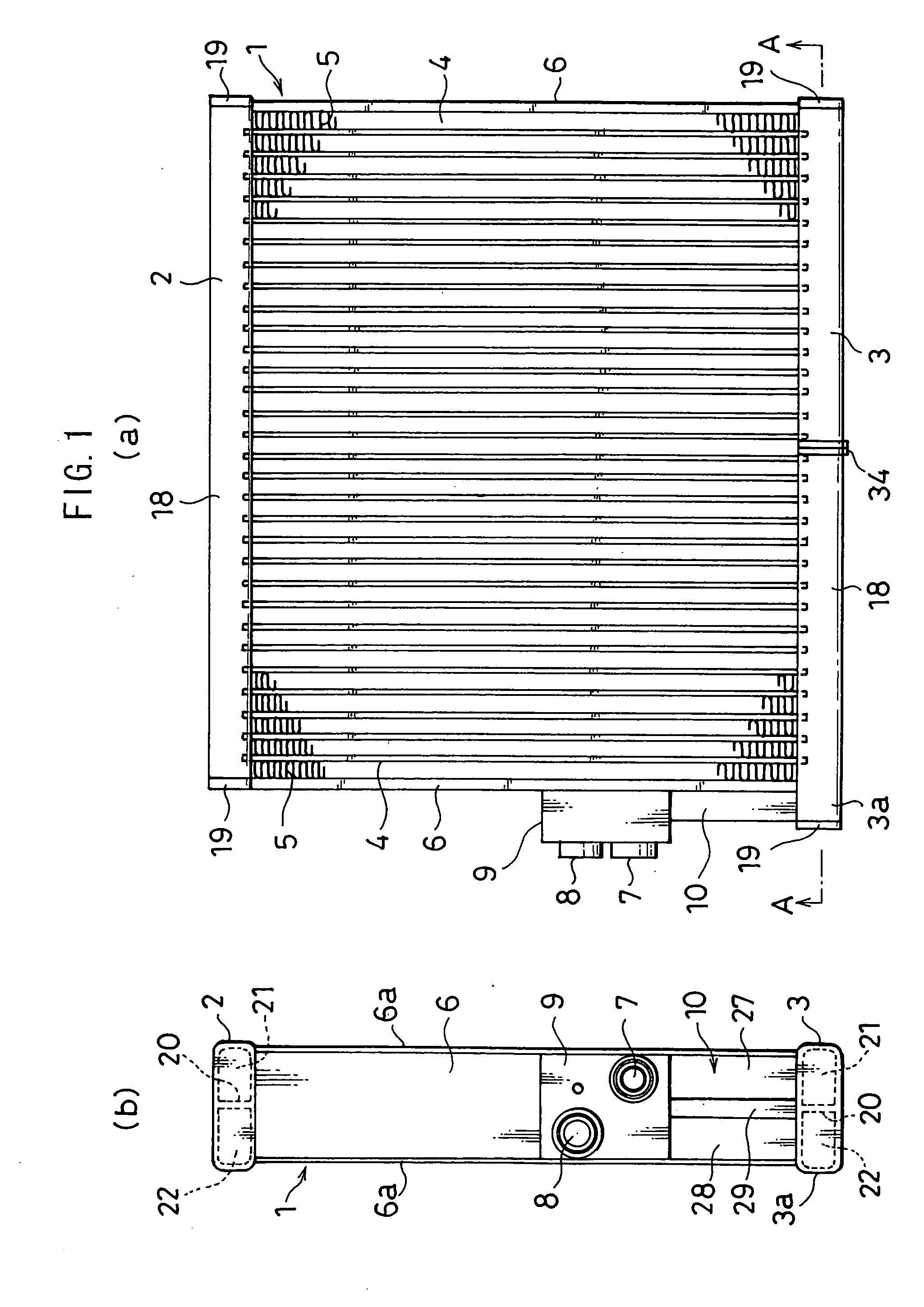

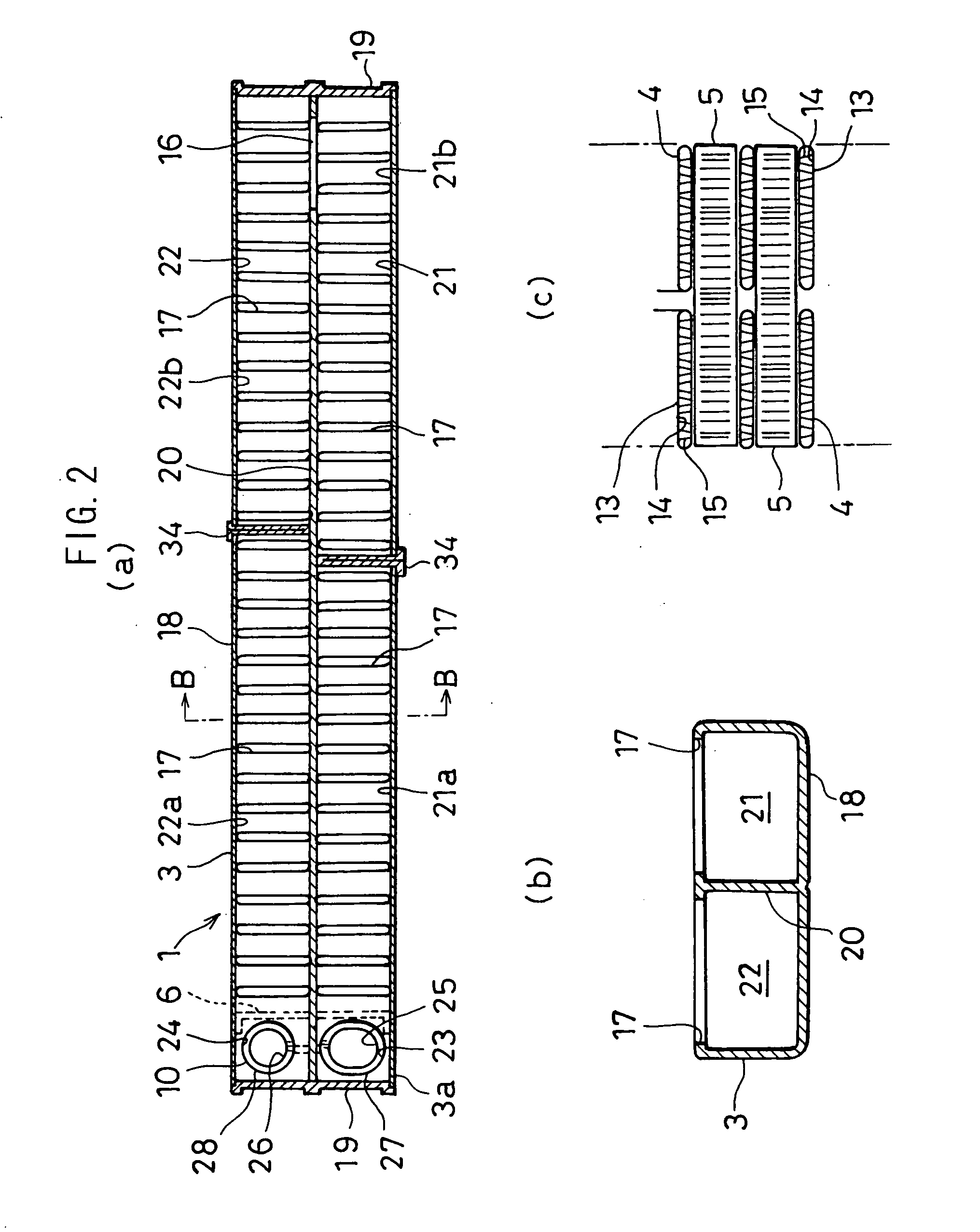

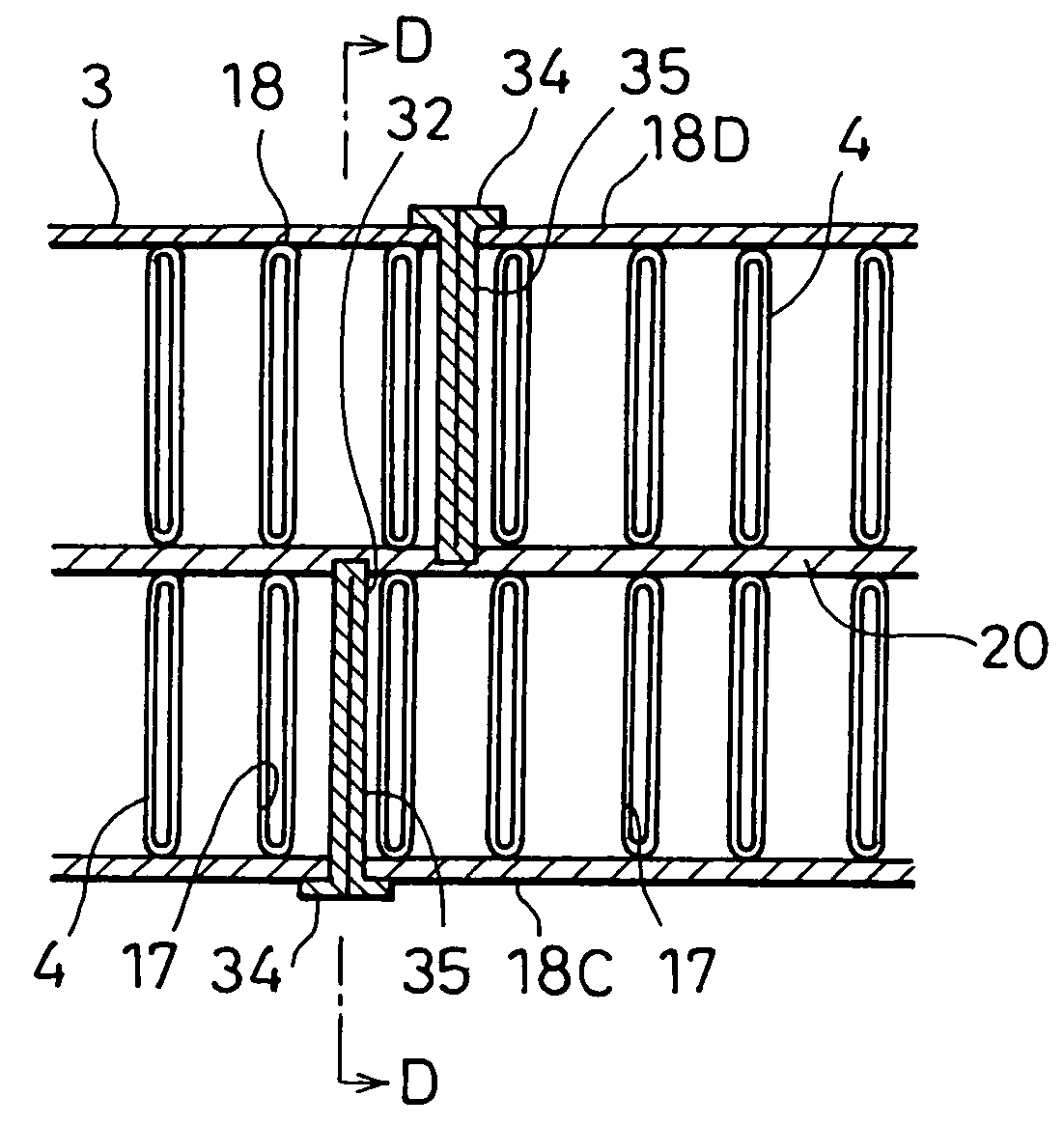

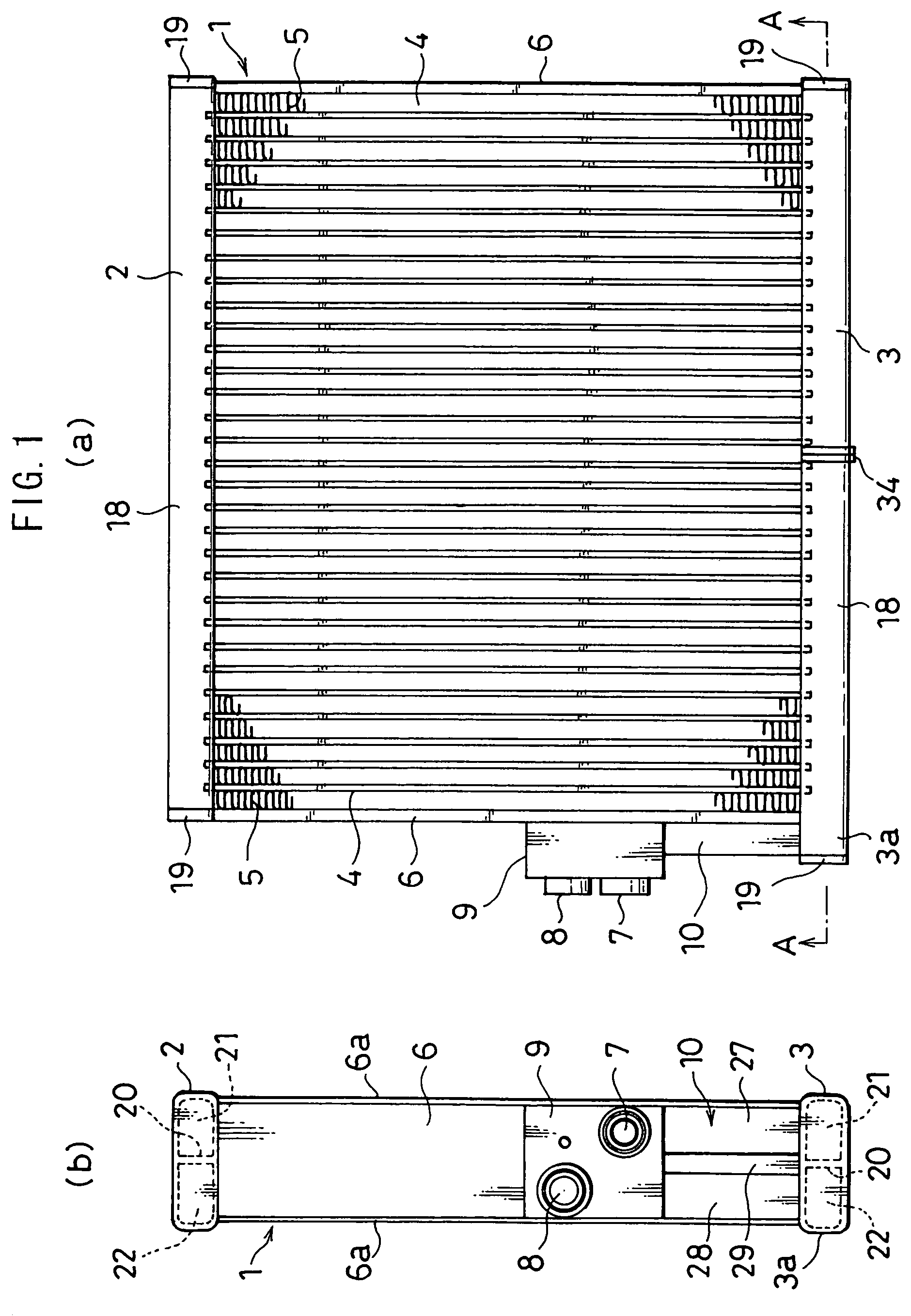

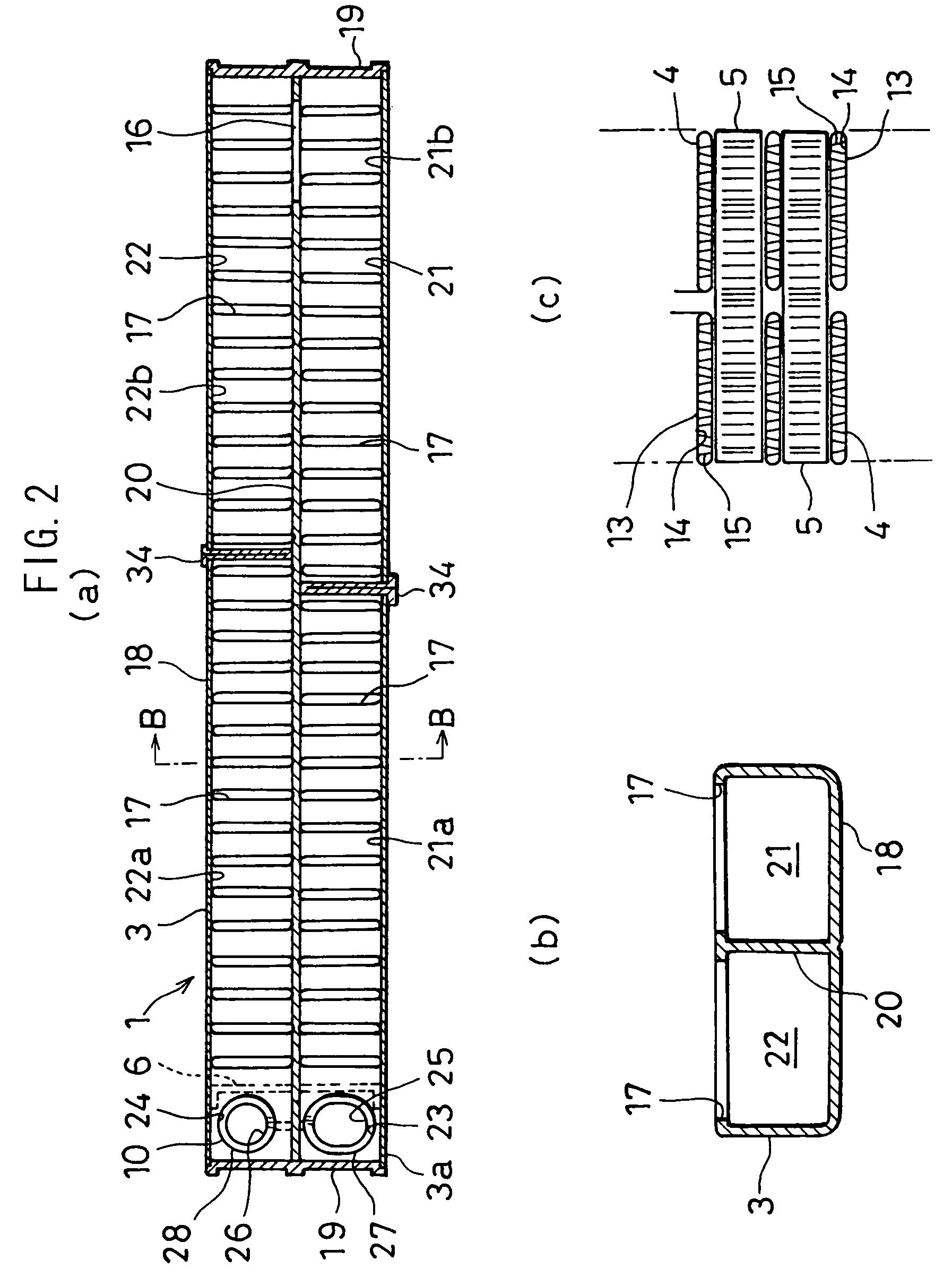

Tank for heat exchanger

InactiveUS20060086489A1High strengthImprove reliabilityStationary conduit assembliesHeat exchanger casingsFuel tankHeat exchanger

In tubular portion of a tank, slits are formed in each side face of chambers or across all side faces of the chambers. For partition plates that are to be inserted from the slits, groove portions in which the partition plates are fitted are formed by cutting portions to which the partition plates butt. The slits are formed in the chambers at positions relatively shifted from each other in a direction in which tubes are layered. This structure guarantees that, in the tank for a heat exchanger, bypass leakage of a heat exchange medium between sub-chambers is prevented from occurring when the partition plates are inserted in the tank from the slits provided on the tank side faces. Further, the tank can maintain required strength even if the slits are formed in it.

Owner:ZEXEL VALEO CLIMATE CONTROL CORP SAITAMA

Tank for heat exchanger

InactiveUS7156165B2Improve reliabilityPrevent heat leakageStationary conduit assembliesHeat exchanger casingsFuel tankHeat exchanger

In tubular portion of a tank, slits are formed in each side face of chambers or across all side faces of the chambers. For partition plates that are to be inserted from the slits, groove portions in which the partition plates are fitted are formed by cutting portions to which the partition plates butt. The slits are formed in the chambers at positions relatively shifted from each other in a direction in which tubes are layered. This structure guarantees that, in the tank for a heat exchanger, bypass leakage of a heat exchange medium between sub-chambers is prevented from occurring when the partition plates are inserted in the tank from the slits provided on the tank side faces. Further, the tank can maintain required strength even if the slits are formed in it.

Owner:ZEXEL VALEO CLIMATE CONTROL CORP SAITAMA

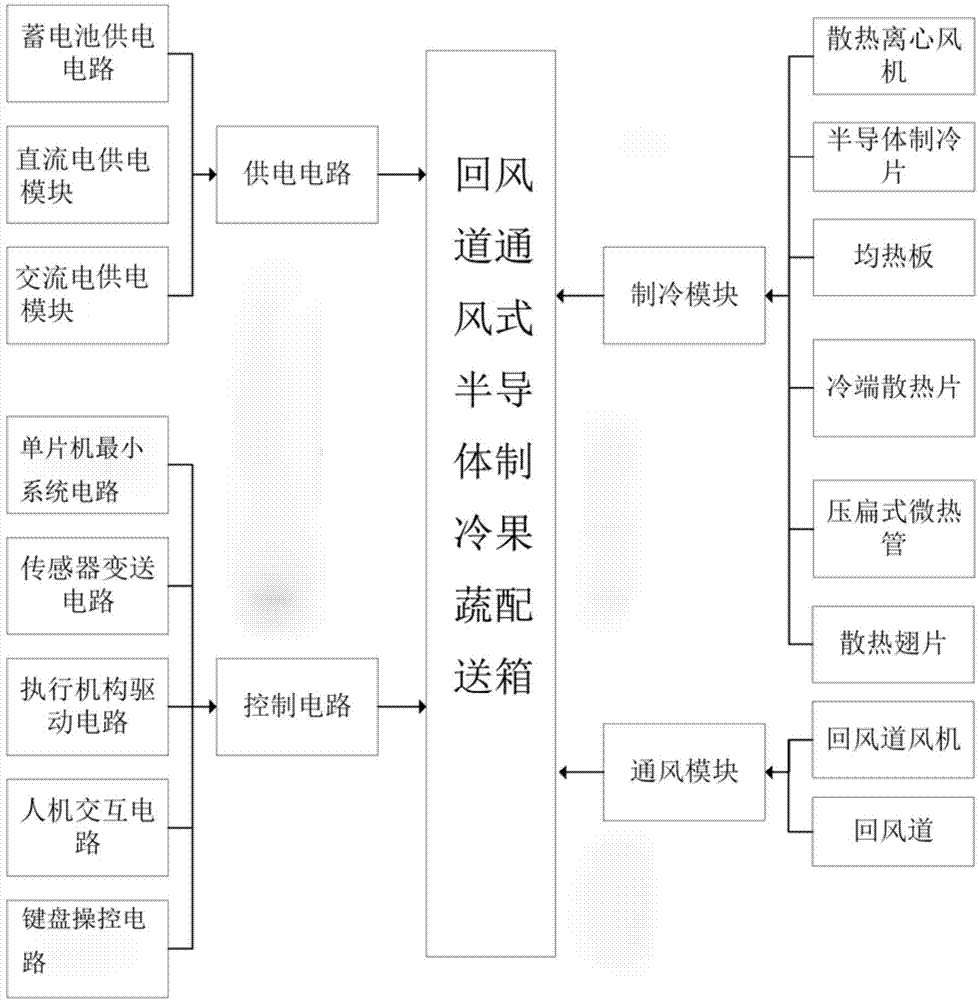

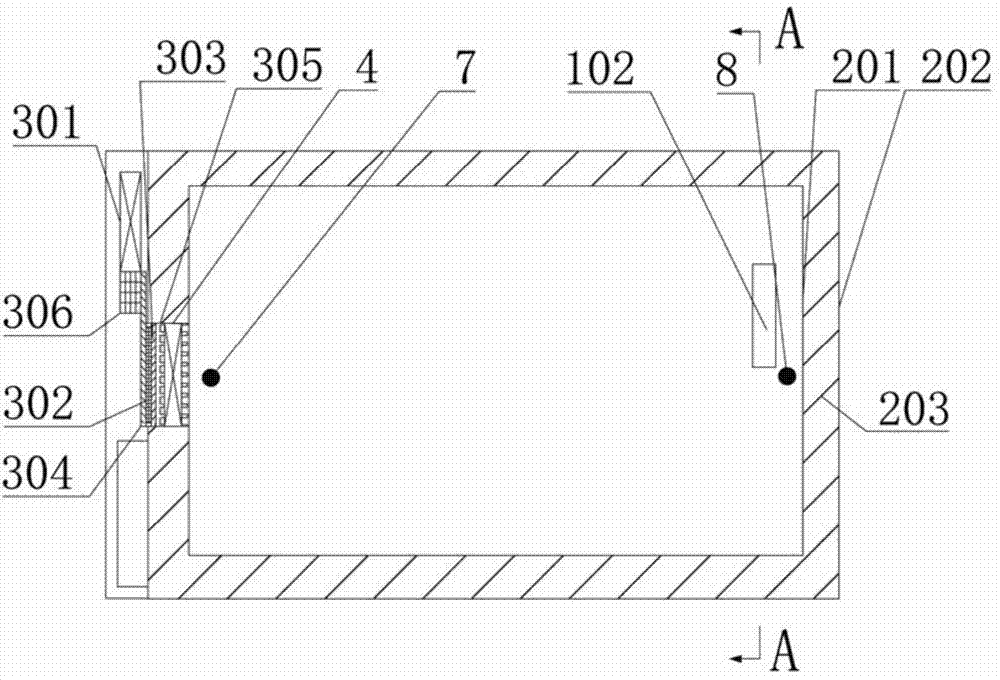

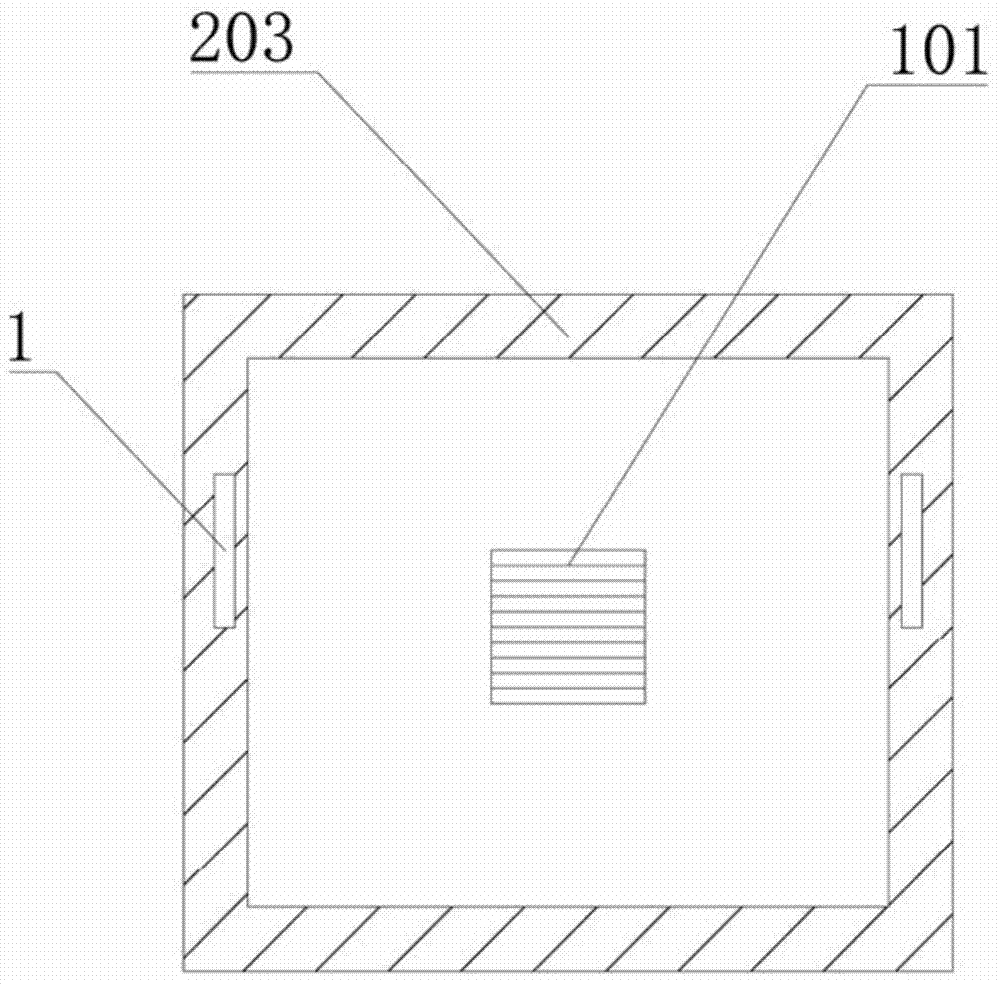

Return airway ventilated type semiconductor refrigerating fruit and vegetable distributing box

ActiveCN104843339AStable temperaturePrevent heat leakageShock-sensitive articlesPackaging fruits/vegetablesCooling effectSemiconductor

The invention discloses a return airway ventilated type semiconductor refrigerating fruit and vegetable distributing box. The return airway ventilated type semiconductor refrigerating fruit and vegetable distributing box comprises inside-and-outside embedded type double-layer box body, a control module, a refrigerating module, a ventilating module and a power supplying module; a return airway which extends from the front portion of the box body to the rear portion of the box body is formed in the interlayer of the inside-and-outside embedded type double-layer box body, the refrigerating module is used for achieving a refrigerating work mode and a heat insulation work mode, the ventilating module is used for achieving a front portion refrigerating and ventilating mode and a rear portion refrigerating and ventilating mode, the power supplying module is used for supplying power for the whole distributing box and suitable for power supplying of different input power types, and it is guaranteed that refrigerating is not interrupted in the conveying process. The defects that an existing distributing box is low in refrigerating efficiency, poor in cooling effect, large in volume mass of a refrigerating unit, unequal in temperature field distribution inside the box and the like are overcome.

Owner:SOUTH CHINA AGRI UNIV

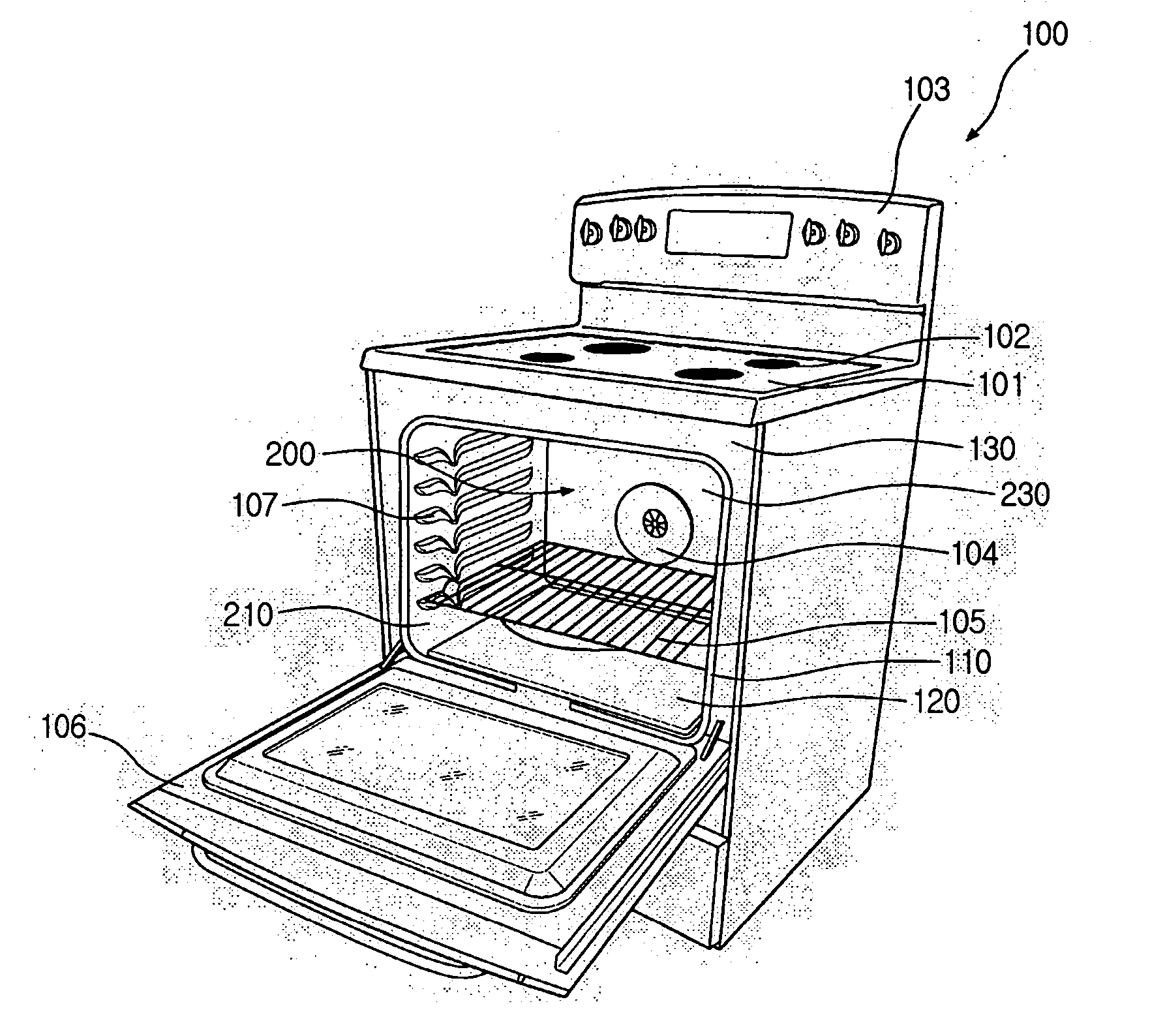

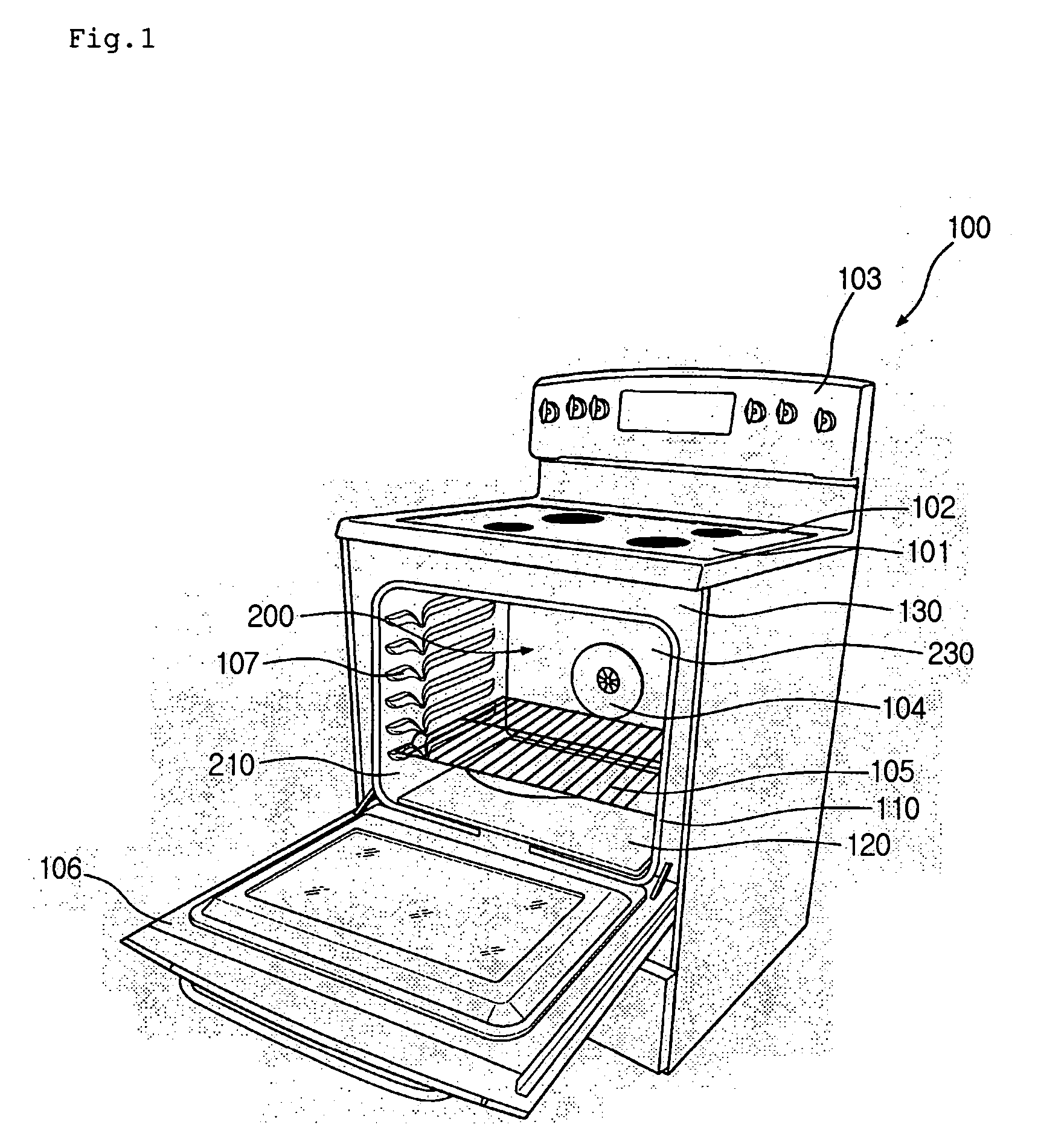

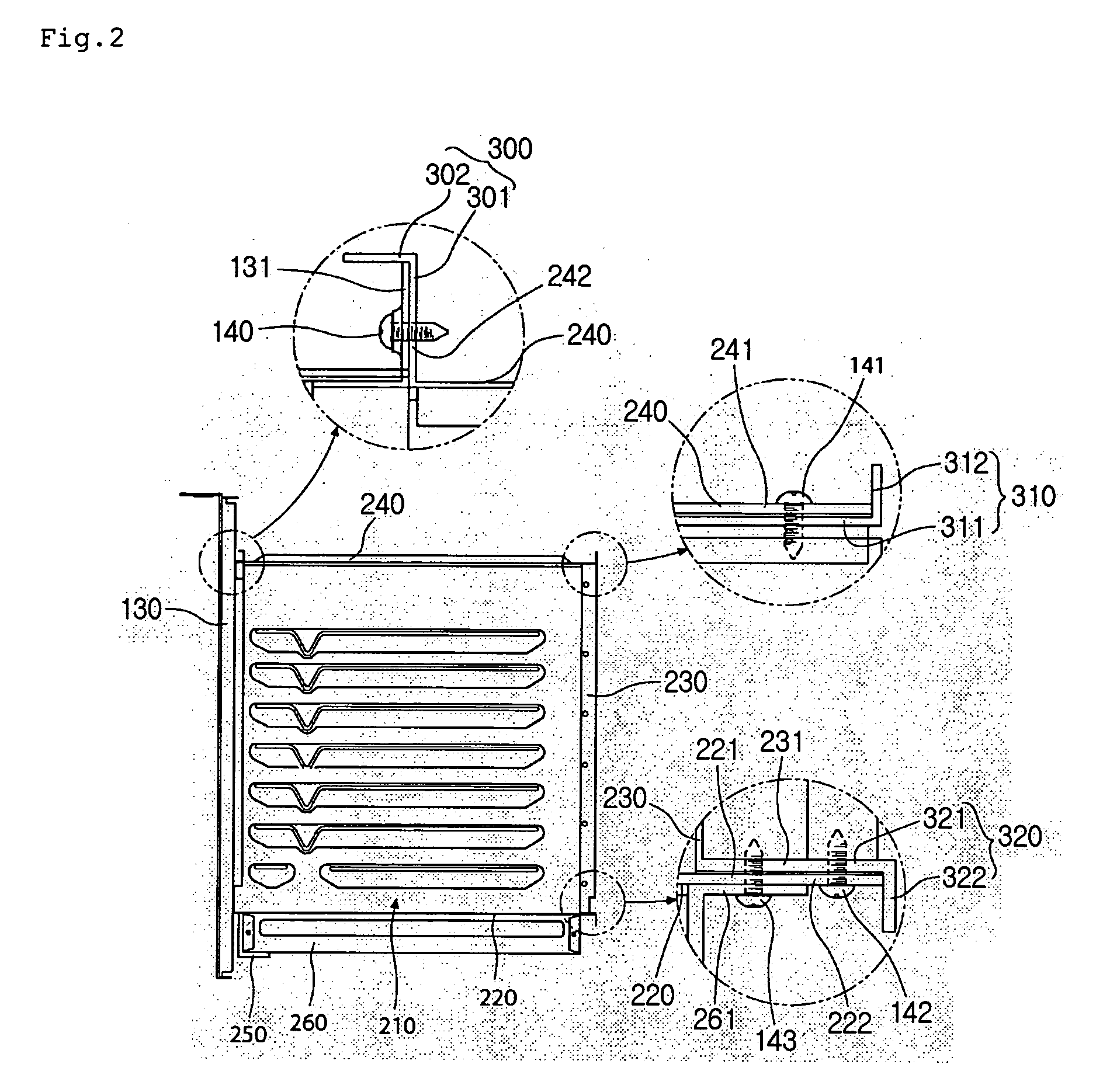

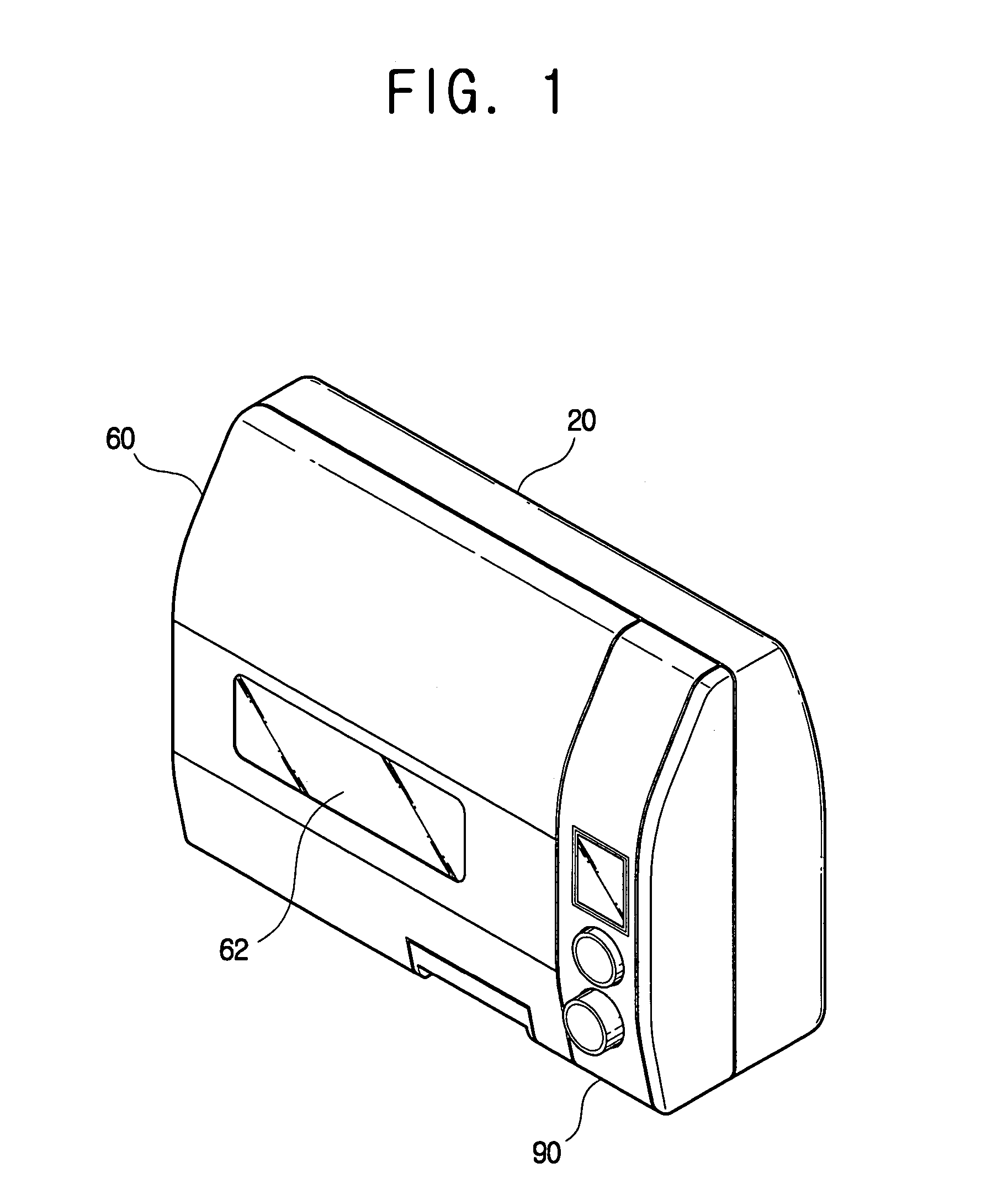

Oven

InactiveUS20060151483A1Prevent heat leakageImprove heating efficiencyStoves/ranges foundationsMicrowave heatingSaggarEngineering

An oven is provided. The oven includes a block sealing a gap between a plate coupling portion and a coupling portion of a counterpart. The oven includes the plate coupling portion for coupling cavity plates to a front plate. The plate coupling portion has a shape formed by bending a front side of the cavity plates to cover the front plate. The oven includes a unit support and a unit fixing portion. The unit support is formed on cavity plates to support a chamber unit, and the unit fixing portion fixes the chamber unit to the cavity plates.

Owner:LG ELECTRONICS INC

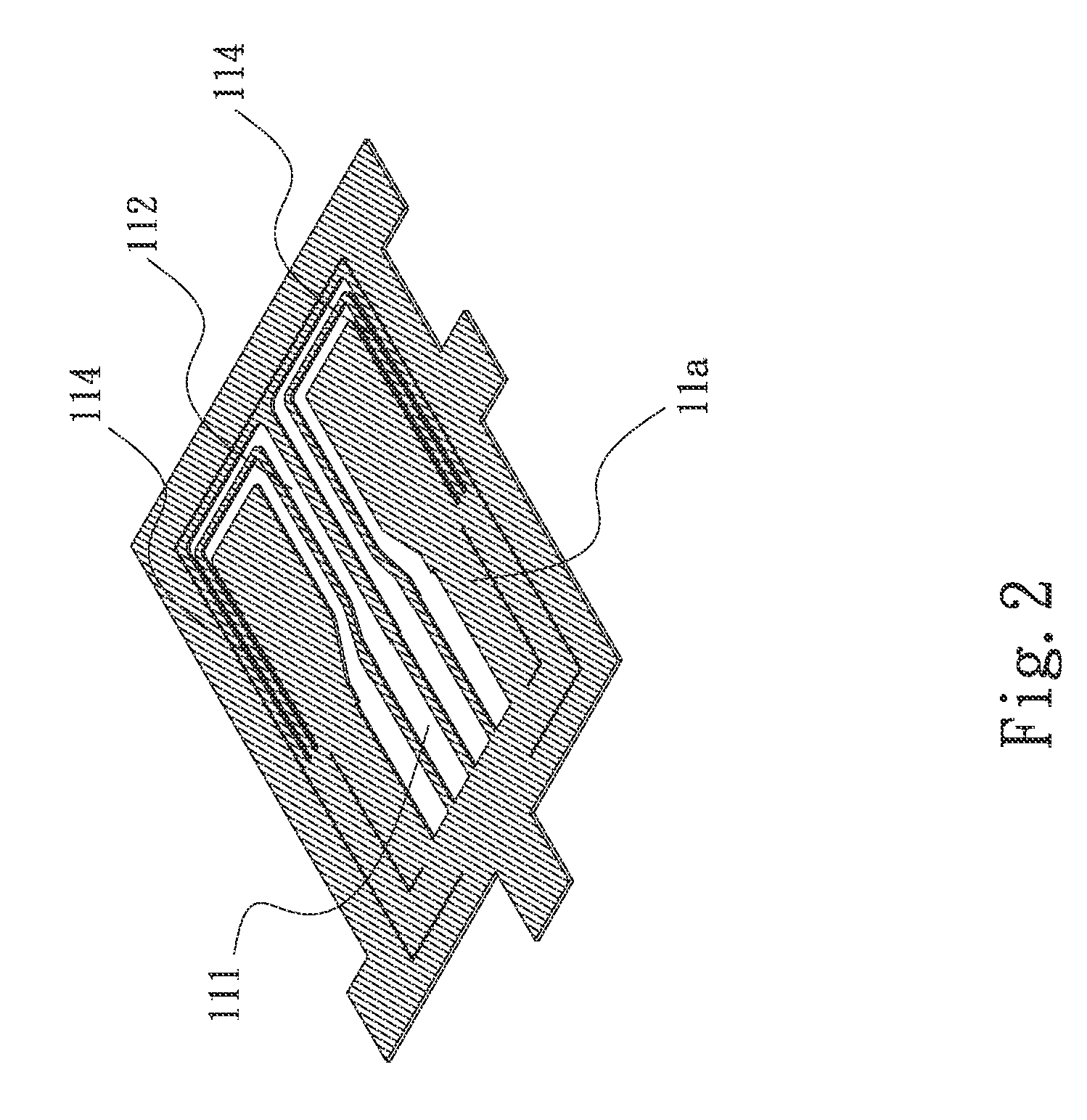

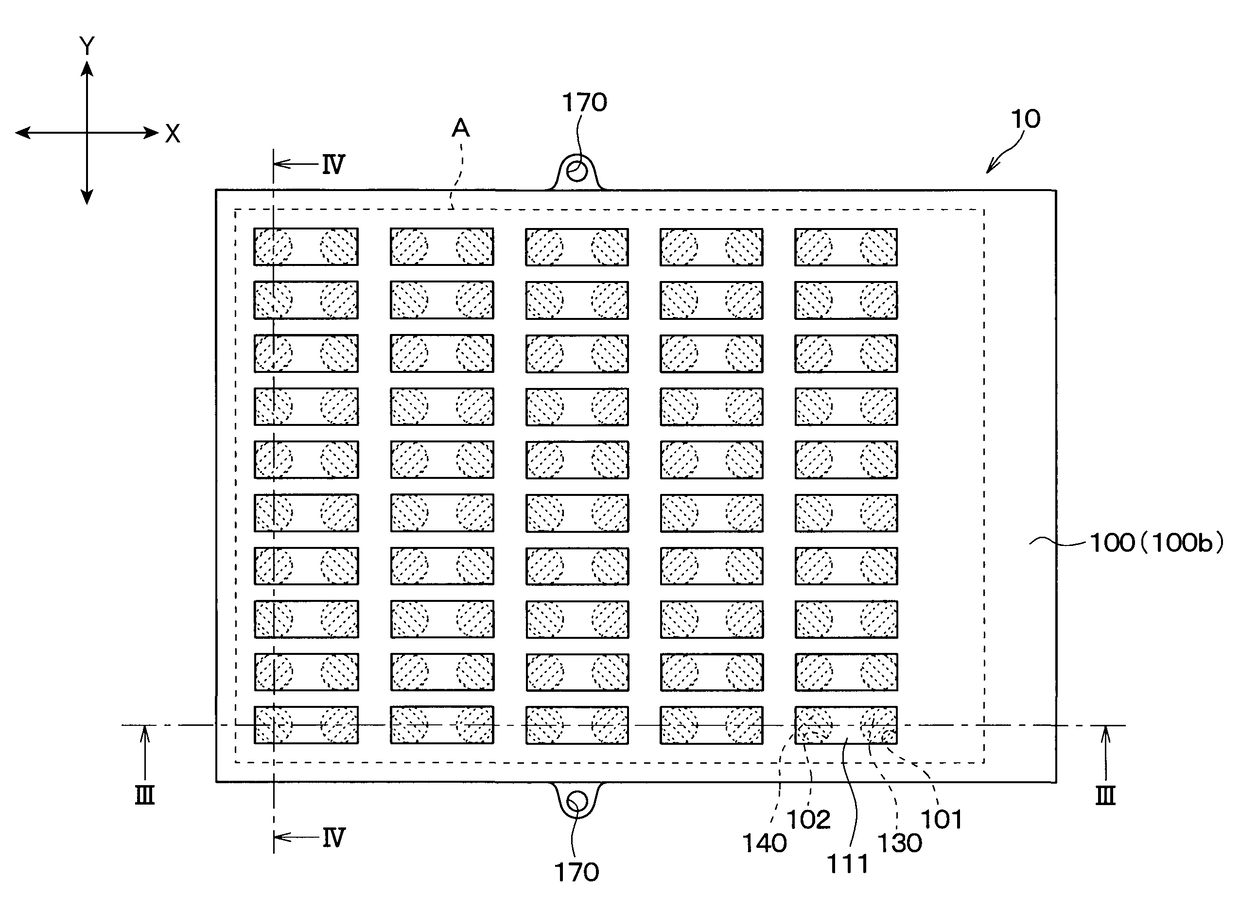

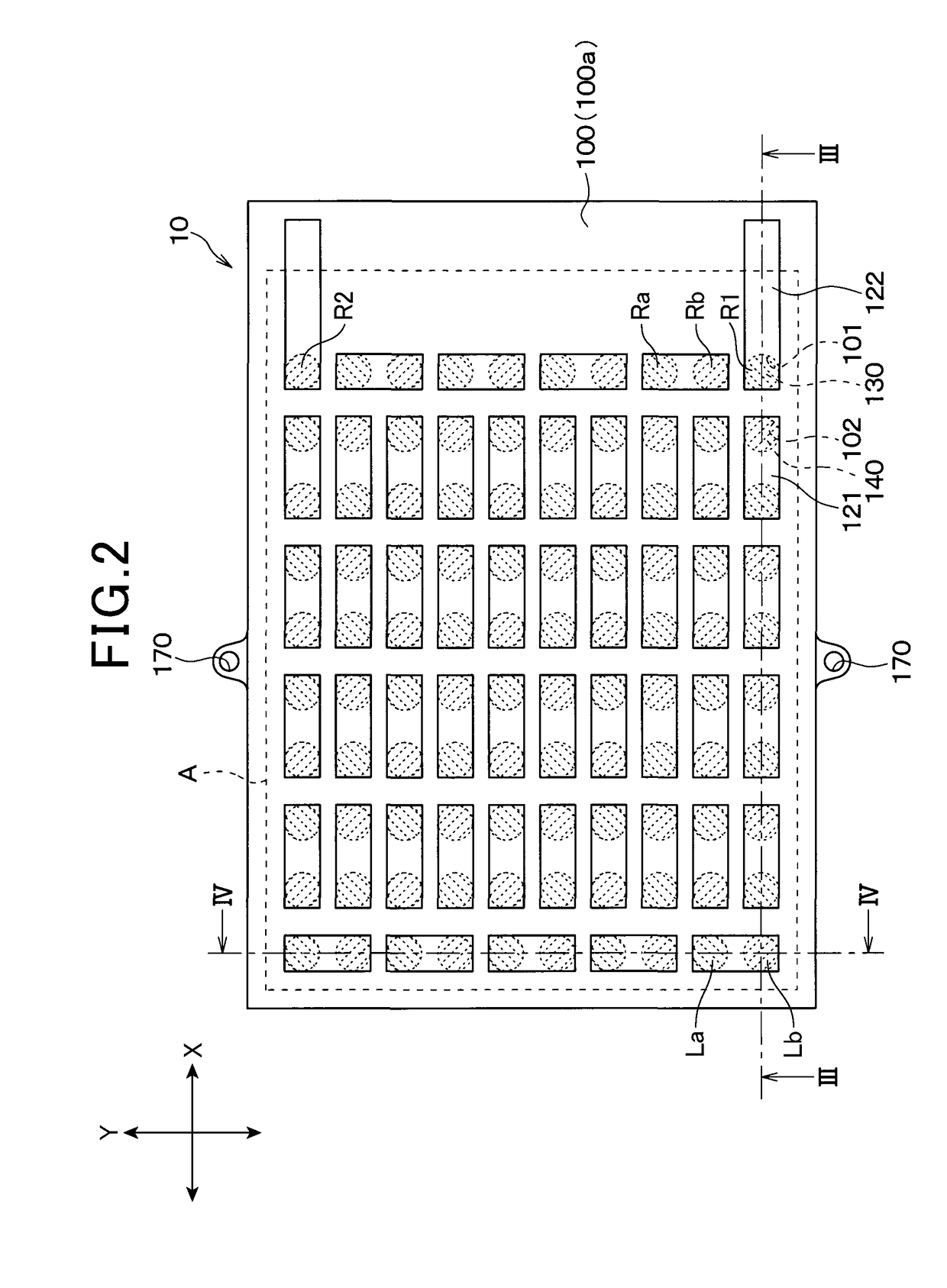

Dual chamber loop heat pipe structure with multiple wick layers

ActiveUS9504185B2Improve cooling effectPrevent heat leakageSemiconductor/solid-state device detailsSolid-state devicesWorking fluidEngineering

A loop heat pipe structure includes a transport pipe, an evaporator, a first wick layer, a second wick layer, and a plurality of grooves. The transport pipe communicates with the evaporator. The evaporator has a bottom and internally defines a first chamber and a second chamber, and has a working fluid filled therein. The first wick layer is located on the bottom, and the second wick layer is located on and covers the first wick layer. The grooves can be selectively provided on the first wick layer or the bottom. The first and second wick layers are so designed that the situation of very high vapor pressure would not occur in the second chamber, enabling the loop heat pipe structure to have upgraded heat dissipation efficiency.

Owner:ASIA VITAL COMPONENTSSHEN ZHEN

Radiating structure

ActiveCN103968692AAchieve thinningGood heat transfer performanceIndirect heat exchangersEvaporationBackflow

The invention discloses a radiating structure which comprises a body. The body is provided with a chamber, the chamber is provided with an evaporation zone, a condensation zone, a first backflow zone and a second backflow zone, the evaporation zone is communicated with the condensation zone, the first backflow zone and the second backflow zone, a heat-insulation plating covers an intersection of the first backflow zone and the second backflow zone, and the chamber is filled with working liquid. The radiating structure has the advantages that heat leakage in a space between the evaporation zone and the condensation zone can be prevented owing to the heat-insulation plating, and accordingly vapor and liquid in the radiating structure can keep smoothly circulating.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

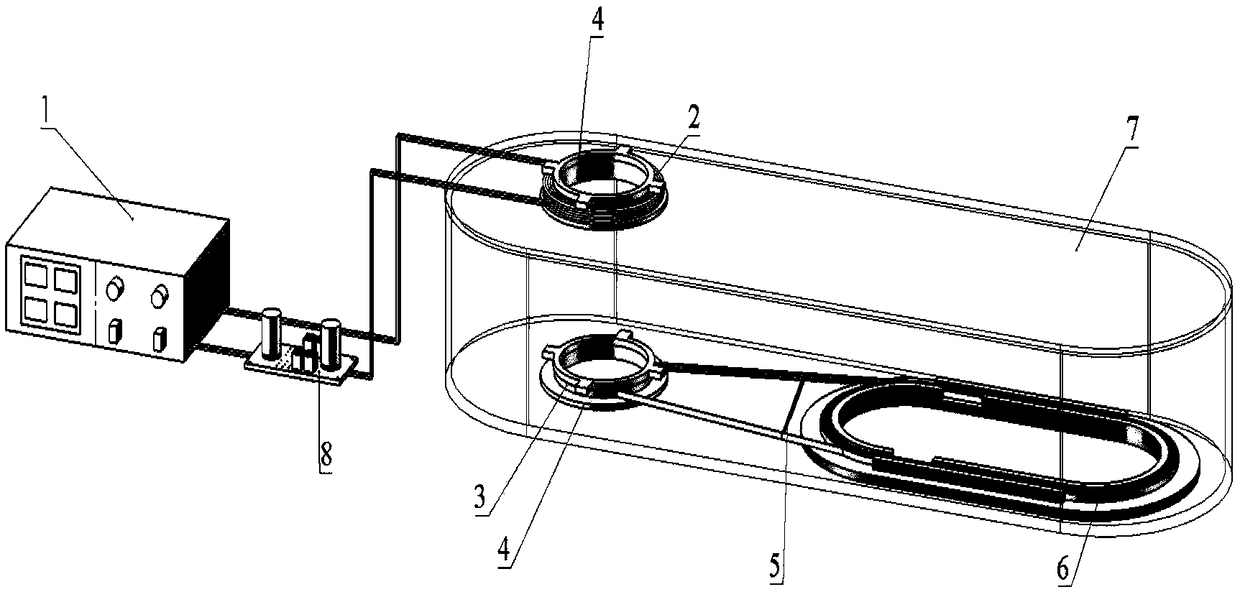

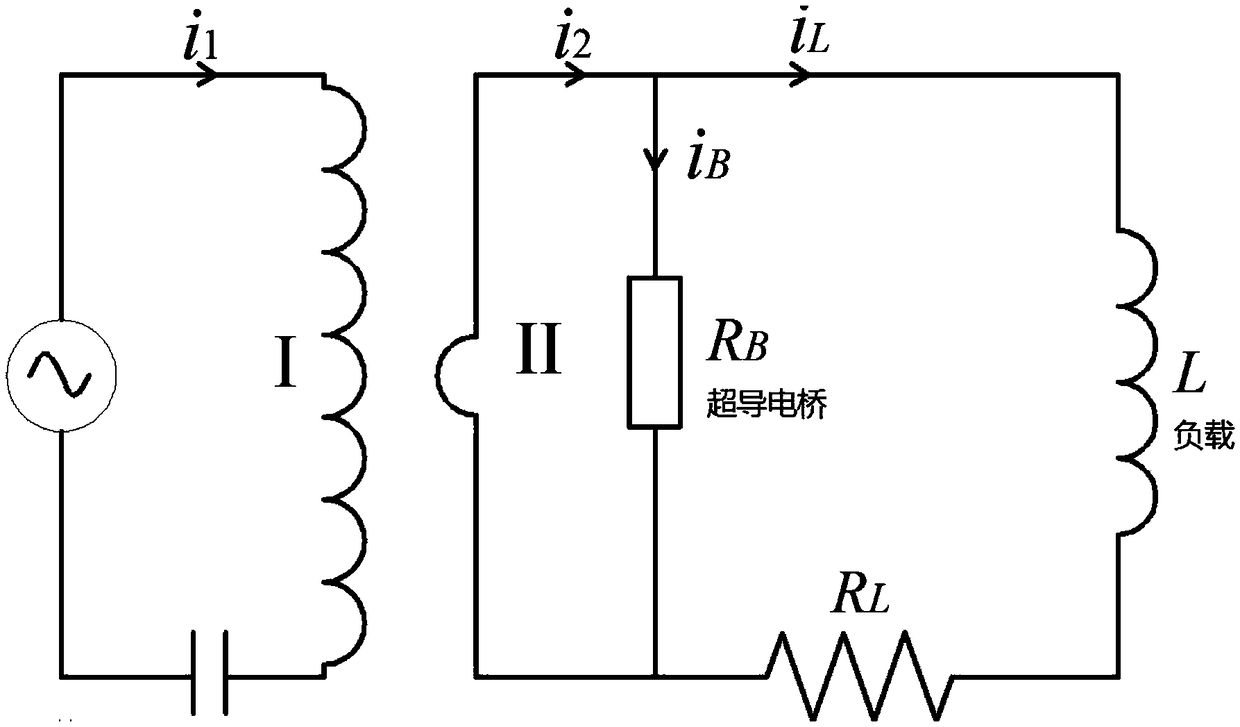

A superconduct magnet contactless power supply device

InactiveCN109217492APrevent heat leakageReduce wall thickness requirementsCircuit arrangementsCapacitanceLitz wire

A superconduct magnet contactless power supply device is provided. An output terminal of an alternating current power supply is serially connected with a compensation capacitor and then connected withone end of a primary winding. the other output of AC power supply is connected to the other end of primary winding, the primary winding wound by Leeds wire is arranged on the top surface of cryogenicvessel, the two ends of secondary winding wound by superconducting wire are connected with superconducting magnet load through superconducting bridge respectively, and the turns ratio of primary winding to secondary winding is greater than 1; The primary winding and the secondary winding are respectively wound on a disk-shaped coil skeleton, and the secondary winding and the coil skeleton, the superconducting bridge and the superconducting magnet load are all packaged in a cryogenic vessel. The invention solves the problems of large heat leakage of the lead wire, low efficiency of the low-temperature system, easy to induce quenching and the like existing in the contact power supply mode of the external driving power supply, and has the advantages of simple structure, high transmission efficiency, large working air gap and the like.

Owner:SOUTHWEST JIAOTONG UNIV

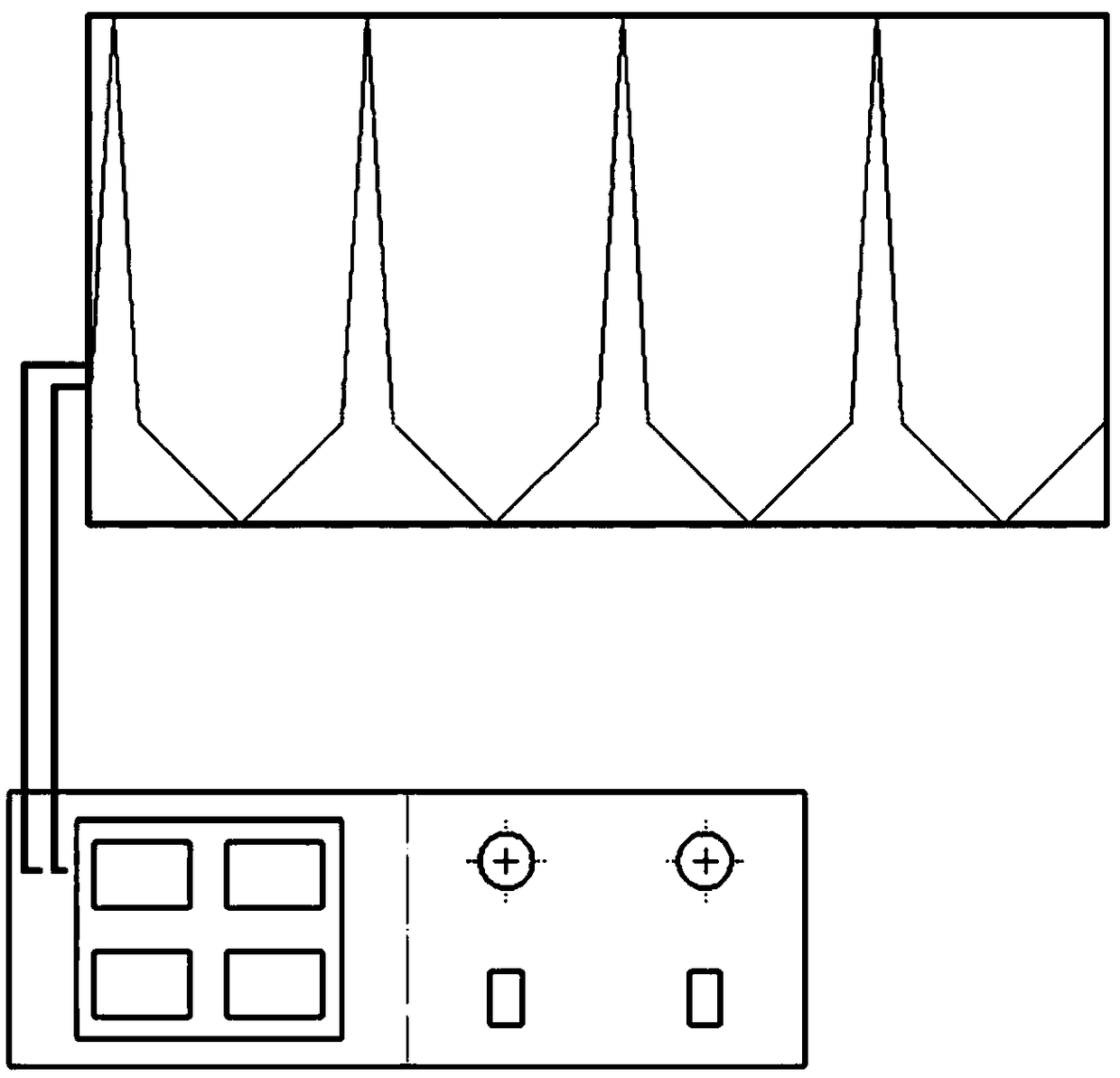

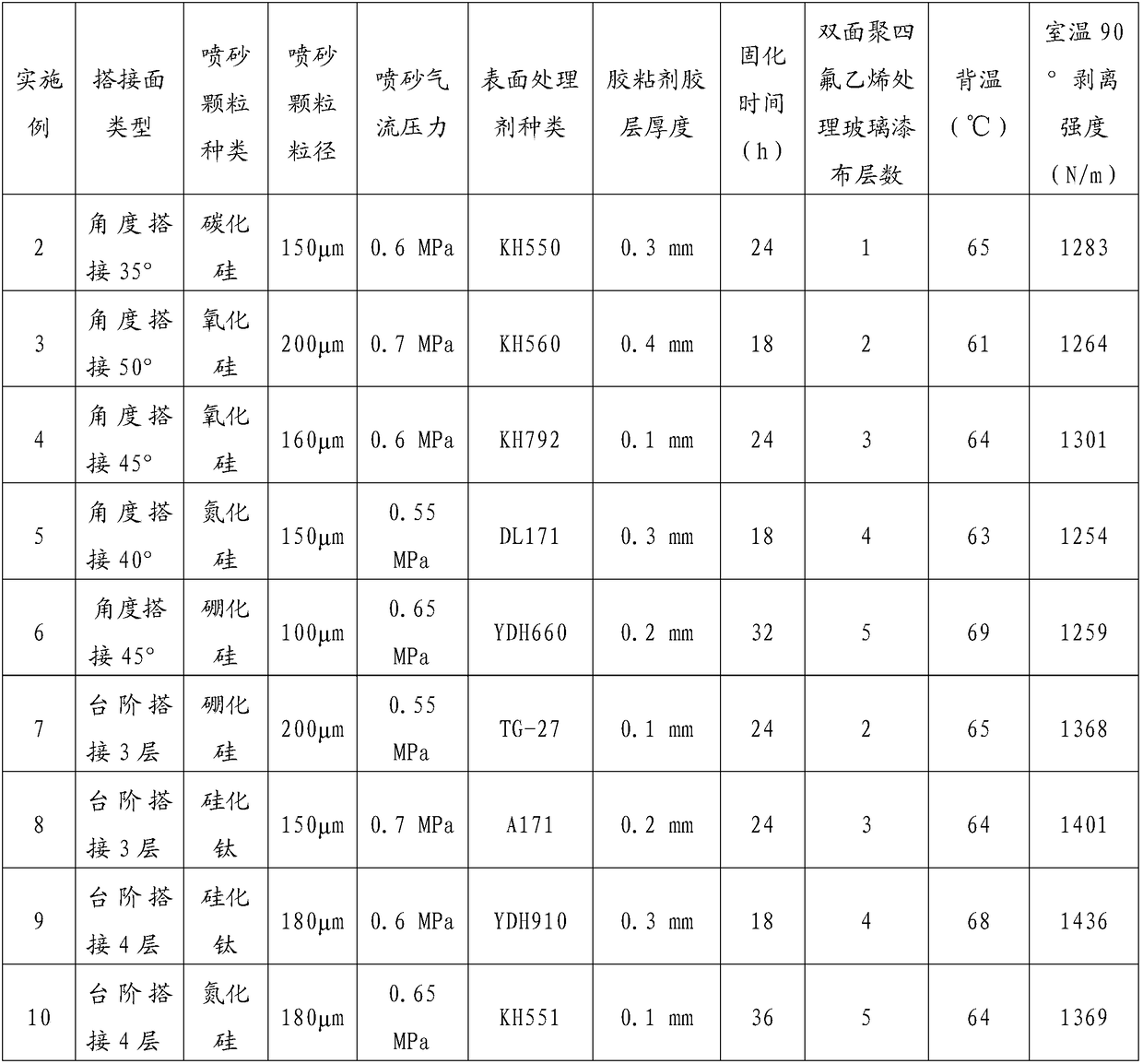

Repairing method of inner heat insulating layer

ActiveCN108115953APromote repairReduce the difficulty of repairCosmonautic thermal protectionFuselage insulationInsulation layerEngineering

The invention provides a repairing method of an inner heat insulating layer. By trimming the damaged portion of the inner heat insulating layer, machining the to-be-repaired contact face of the innerheat insulating layer, machining the inner heat insulating layer for repairing and filling, performing surface treatment, using a gap heat insulation material to perform gap filling, adhering a sealing heat insulation pad to the joint position of the to-be-repaired surface, and adhering two-side polytetrafluoroethylene to treat varnished glass cloth and the like to achieve repairing of the inner heat insulation layer. According to the repairing method of the inner heat insulating layer, repairing is convenient, repairing can be performed just trimming the inner heat insulation layer at the damaged position, it is not needed to disassemble and replace a whole heat insulating module, and therefore influences by devices in equipment are avoided, and the repairing difficulty and the repairingworkload are reduced.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

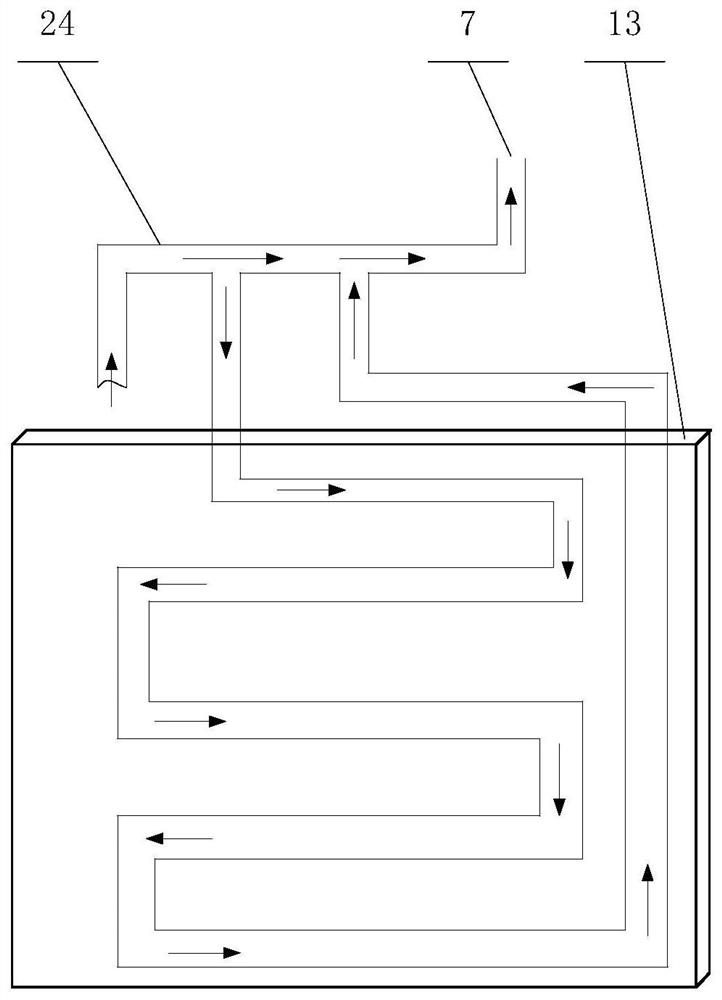

Capillary pump loop heat pipe with outer space working capacity and working method

ActiveCN109458864AAbility to workCapable of working in outer spaceIndirect heat exchangersEvaporationEngineering

The invention discloses a capillary pump loop heat pipe with an outer space working capability and a working method. The heat pipe comprises a main evaporator, a main radiation heat dissipation plate,a steam pipeline, a liquid phase pipeline, a liquid storage chamber, an adjusting chamber, an auxiliary evaporator, an auxiliary radiation heat dissipation plate, a main liquid phase pipeline valve,a main steam valve and an auxiliary steam valve; the main evaporator comprises a liquid phase channel area, a liquid absorption core area, a steam channel area an outer pipe wall and the like; the liquid absorption core comprises an evaporation liquid absorption core and a heat insulation liquid absorption core, wherein the evaporation liquid absorption core and the heat insulation liquid absorption core are provided with different materials and equivalent pore diameters; the starting of the auxiliary evaporator is optimized through the squeezing effect of the steam before starting, the auxiliary radiation heat dissipation plate and the auxiliary evaporator are used for leading out liquid-phase working medium with bubbles in the main evaporator and eliminating the bubbles, the problem of heat leakage in the stable operation stage is solved, so that the operation stability of the heat pipe is improved; the liquid storage chamber is used for separating the liquid storage area and the adjusting area, so that the adjusting sensitivity is improved, and the energy consumption is reduced; and the heat pipe structure has a wide practical prospect in the field of external space heat dissipation.

Owner:XI AN JIAOTONG UNIV

Novel industrial oven

InactiveCN104457148ASave internal spaceEvenly heatedDrying gas arrangementsDrying chambers/containersHeat leakEngineering

The invention discloses a novel industrial oven and relates to the field of machinery. The novel industrial oven comprises an oven body, an oven door, a circulating fan, electric heating components and a temperature controller, wherein the oven door is movably connected with the oven body, the circulating fan is arranged at the bottom of the oven body, the electric heating components are electrically connected with the temperature controller and are arranged on the inner wall of two sides of the oven body, the inner walls of two sides of the oven body are provided with airflow pipelines in the diameter of 1-2mm, and the oven door is provided with a two-point lock catch. The novel industrial oven can effectively transfer heat to materials to be heated uniformly, uniform heating of the materials can be ensured, and the oven door and the oven body are locked in a two-point locking way, so that the oven door and the oven body more firmly contact, and heat leak caused by deformation due to high temperature is avoided.

Owner:上海伟阳纸业有限公司

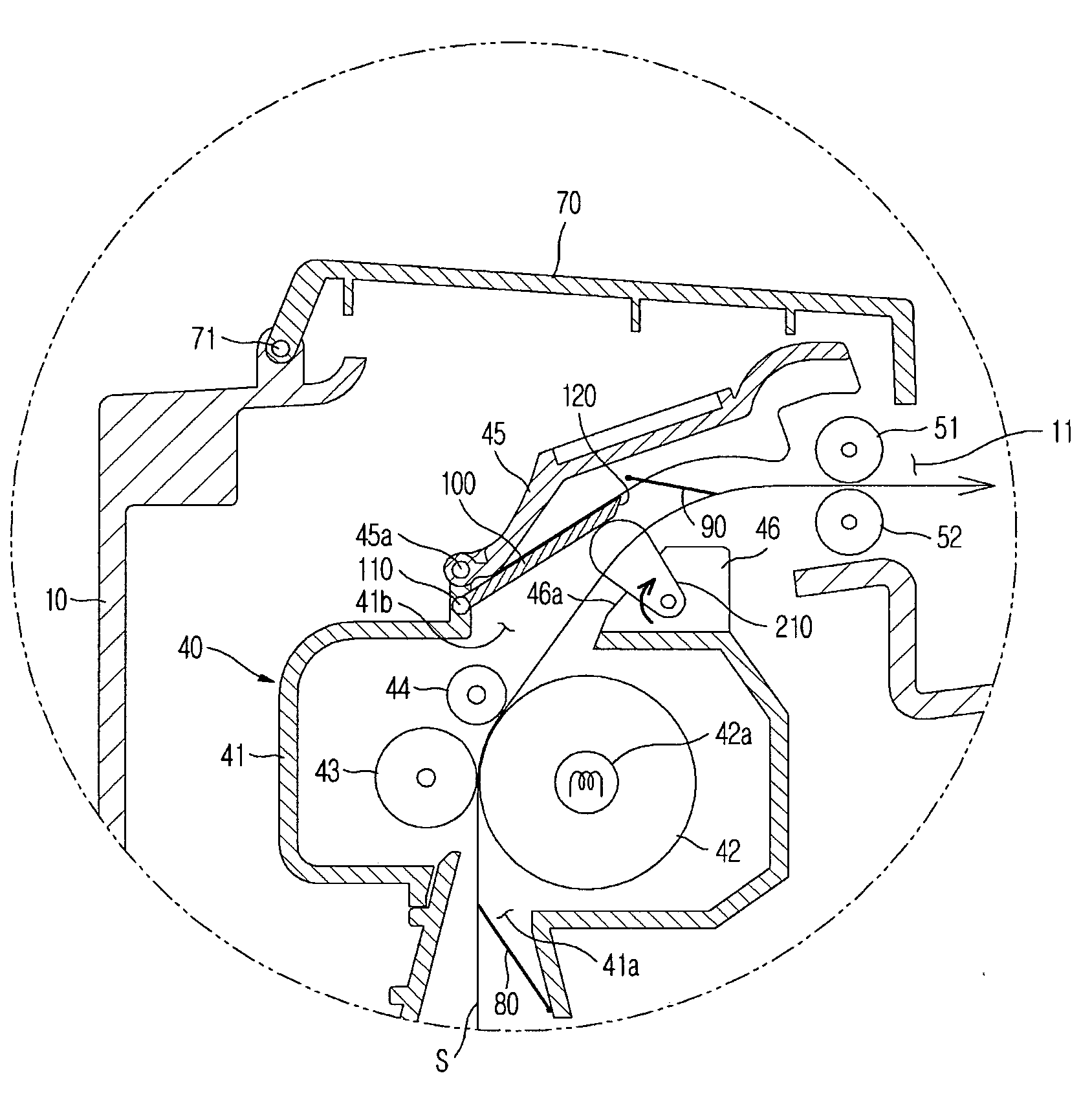

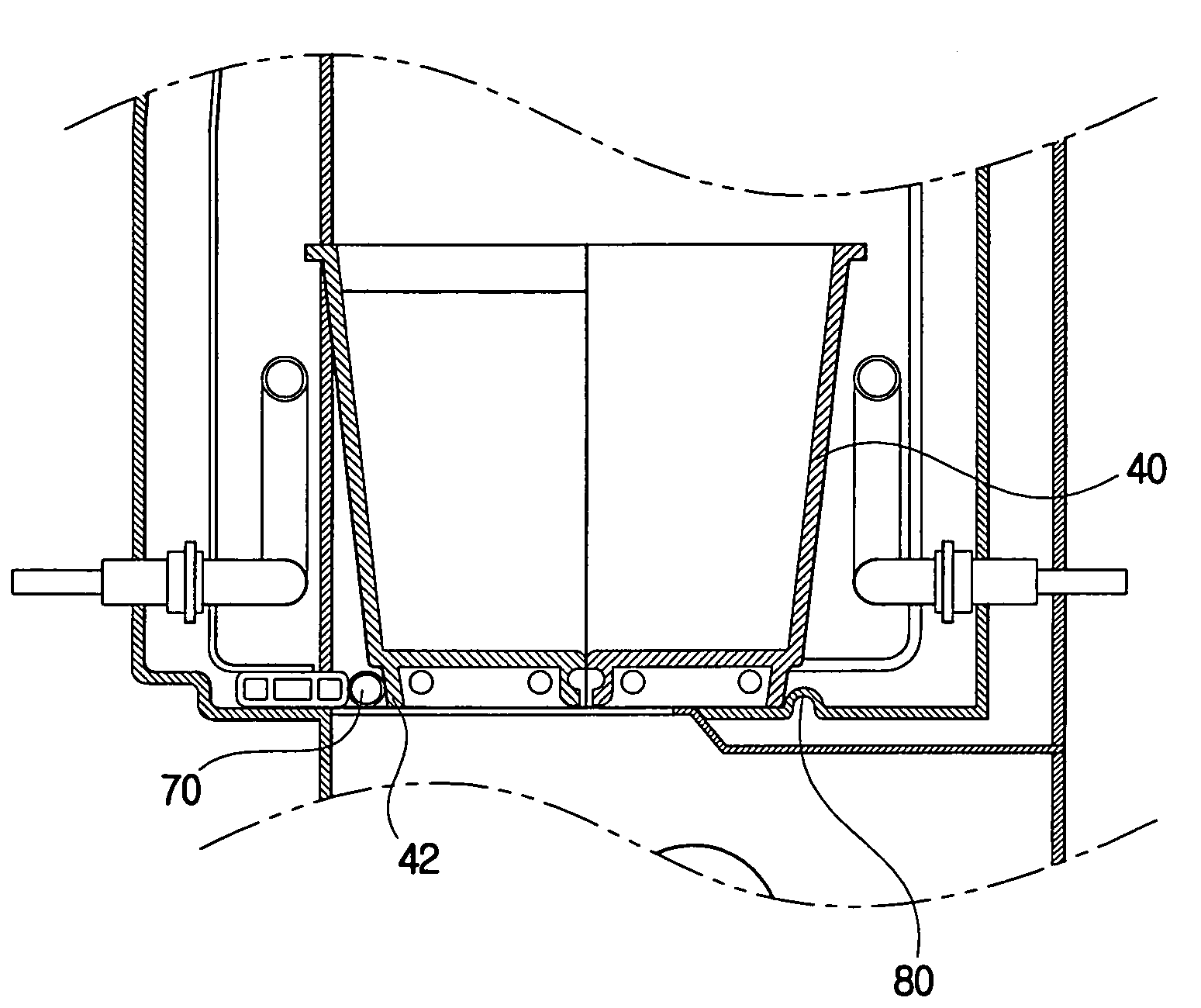

Image forming apparatus with opening/closing member

InactiveUS7792453B2Minimize temperature risePrevent heat dissipationElectrographic process apparatusImage formationCam

An image forming apparatus capable of minimizing a temperature rise of a cover by substantially preventing heat emission from a fusing device to an outside is disclosed. The image forming apparatus includes a main body, a fusing device mounted in the main body, the fusing device having an outlet to discharge paper, an opening / closing member opening and closing the outlet of the fusing device, a cam member moving the opening / closing member between a first position in which the opening / closing member closes the outlet to prevent heat in the fusing device from being emitted through the outlet and a second position in which the opening / closing member opens the outlet to permit the paper to pass through the outlet, a driving part rotating the cam member, and a control unit controlling the driving part to determine a rotational position of the cam member.

Owner:SAMSUNG ELECTRONICS CO LTD

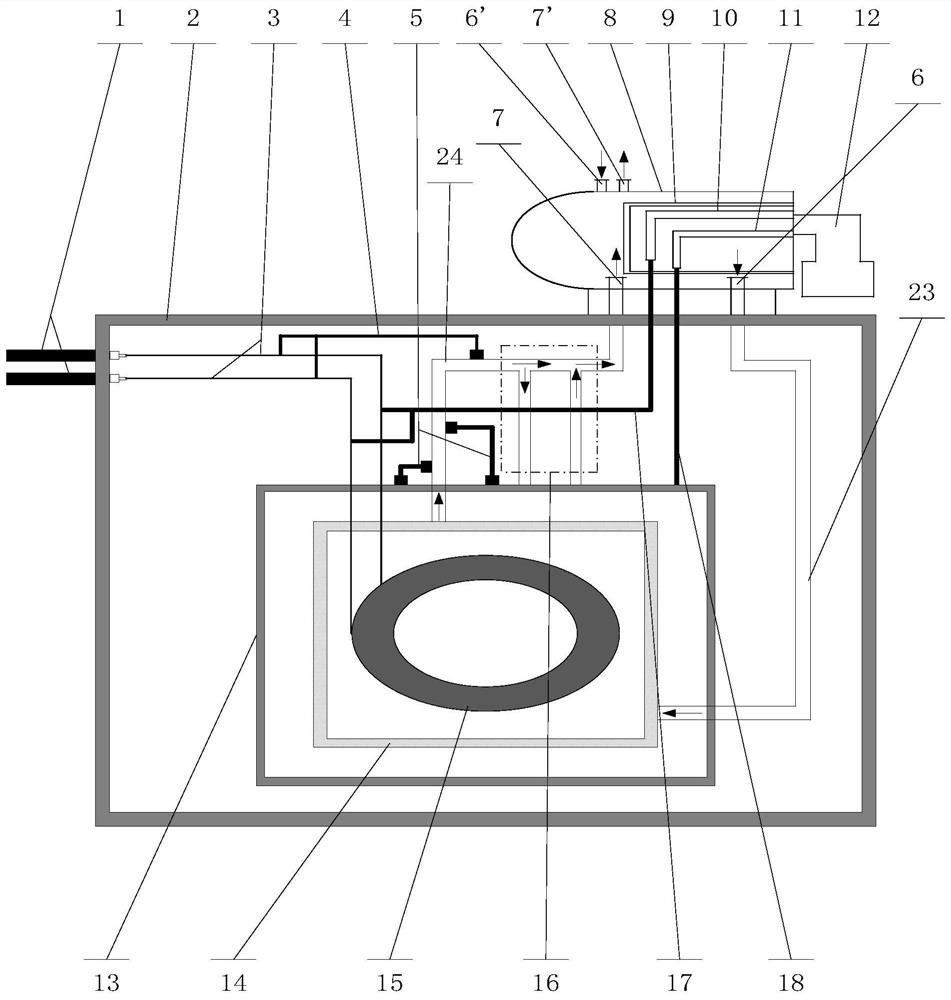

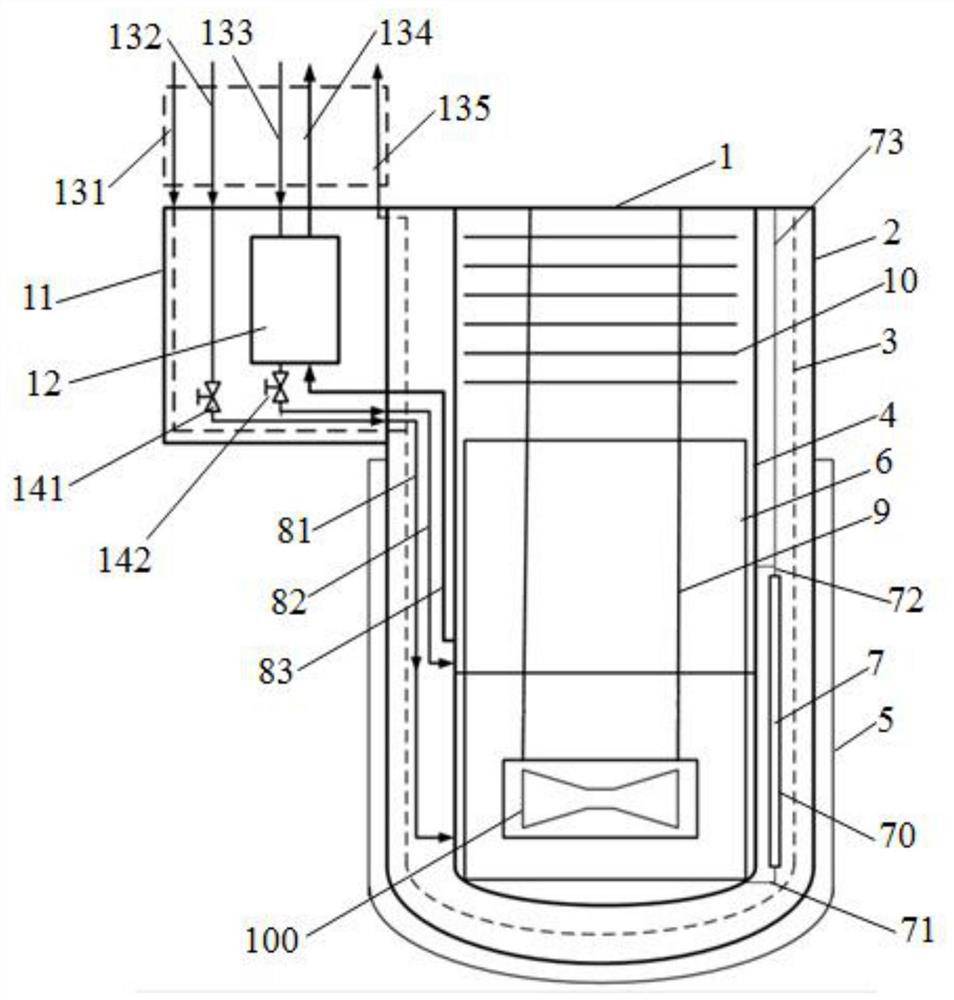

Superfluid helium Dewar low-temperature constant-temperature testing device

PendingCN111896578ASimplify Space UtilizationOptimize space utilizationMaterial heat developmentVacuum pressureEngineering

The invention discloses a superfluid helium Dewar low-temperature constant-temperature testing device. The device comprises a flange plate, an outer cylinder body, an inner cylinder body and a low-temperature pipeline system, the inner cylinder body is arranged in the outer cylinder body, an upper port of the outer cylinder body and an upper port of the inner cylinder body are connected in a sealed mode through the flange plate, four hanging rods are perpendicularly connected to the end cover face of the bottom of the flange plate, and a liquid nitrogen cold shield is arranged between the outer cylinder body and the inner cylinder body; the low-temperature pipeline system comprises a distribution valve box, a liquid nitrogen cold shield constant-temperature loop, a liquid helium inner barrel precooling cooling branch, a liquid helium inner barrel constant-temperature branch and a nitrogen vacuum pressure reduction branch. The superfluid helium Dewar testing device disclosed by the invention is good in space utilization rate and small in heat leakage, the heat leakage of the superconducting cavity during each test is reduced, the operation difficulty is simplified, and the testing efficiency is improved.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

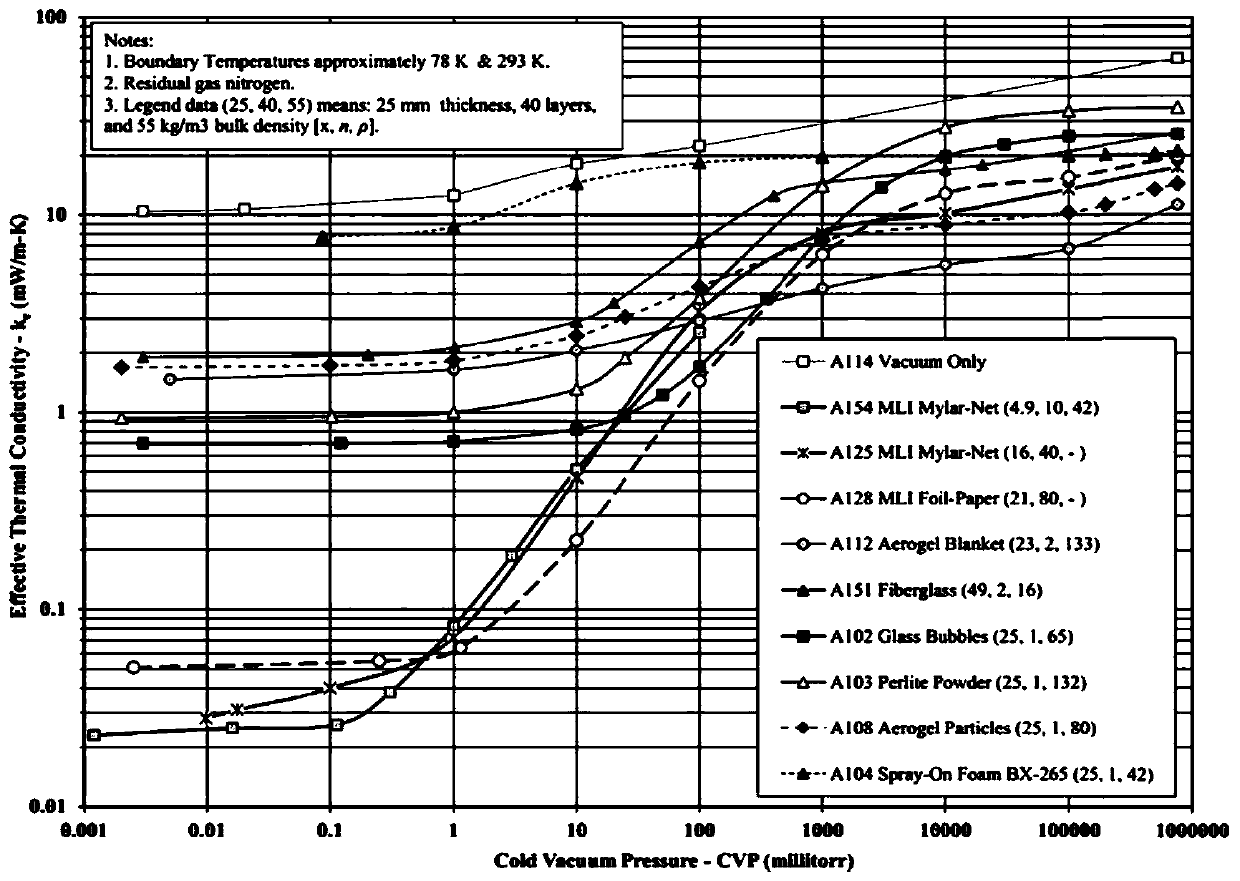

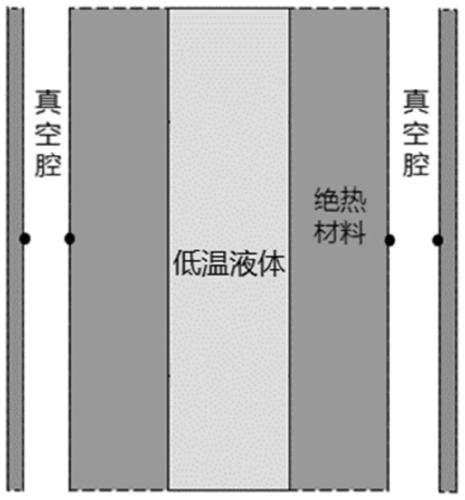

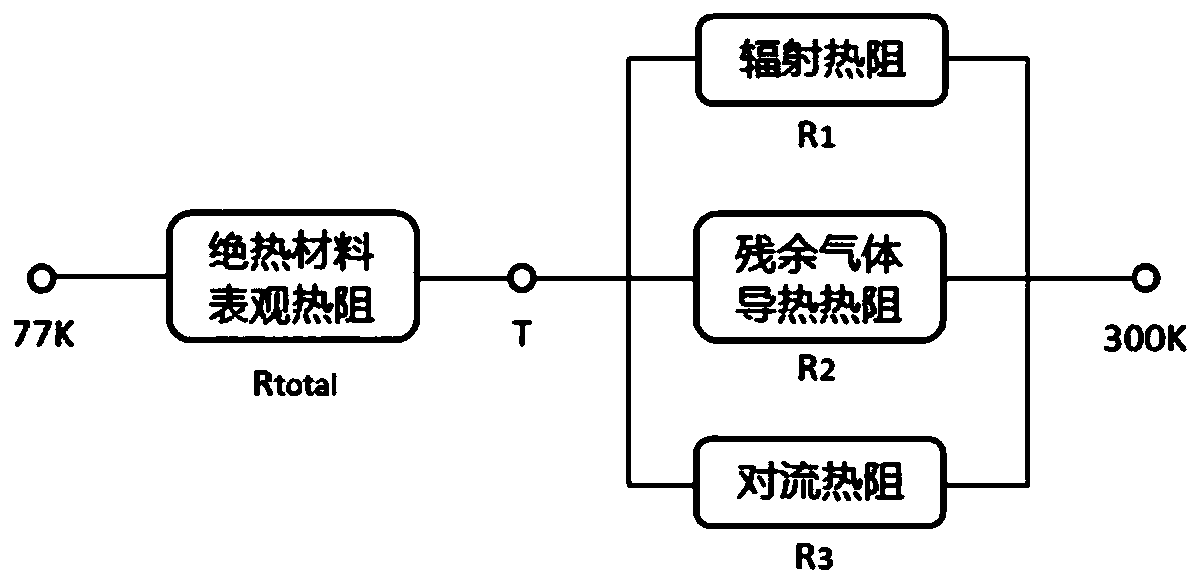

Vacuum degree detection method and device for vacuum insulated storage tank

ActiveCN111219598AHigh-precision detectionEasy to operateContainer filling methodsVacuum gauge using heat conductivity variationThermal thresholdMechanical engineering

The invention discloses a vacuum degree detection method for a vacuum insulated storage tank. The vacuum degree detection method for the vacuum insulated storage tank comprises the following steps that the temperature of the outer surface of a heat insulating material is detected; a vacuum degree numerical value in a vacuum interlayer of the vacuum insulated storage tank to be detected is obtainedaccording to the relationship between the temperature of the outer surface of the heat insulating material and the vacuum degree in the vacuum interlayer; or a temperature threshold is determined according to the relationship between the temperature of the outer surface of the heat insulating material and the vacuum degree in the vacuum interlayer, the obtained temperature is compared with the temperature threshold, and a result is output. The invention further discloses a vacuum degree detection device for the vacuum insulated storage tank. According to the vacuum degree detection method forthe vacuum insulated storage tank, the method that the temperature of the outer wall surface of the multi-layer heat insulating material in the insulated storage tank indirectly represents the vacuumdegree in the insulated storage tank is adopted so that the vacuum degree in the insulated storage tank can be conveniently and accurately detected; and the method is simple in operation, does not need to use an expensive vacuum gauge, avoids additional heat leakage caused by the installation of the vacuum gauge, and can realize remote monitoring at the same time.

Owner:ZHEJIANG UNIV +1

Manufacturing method of heat flux sensor and heat flow generation device for use in the manufacturing method

ActiveUS20180143087A1Short timeTemperature controlMaterial thermal conductivityPyrometry using electric radation detectorsHeat flowRadiation measurement

According to a manufacturing method of a heat flux sensor, the heat flux sensor is sandwiched between a heater plate and a cooling unit. The heater plate is disposed on the first surface of the heat flux sensor, and the cooling unit is disposed on the second surface of the same. A heat radiation measurement plate is disposed on a surface of the heater plate opposite to the surface on which the heat flux sensor is disposed. According to this configuration, the temperature of the heater plate is controlled in an inspection process such that the heater plate is kept at an ambient temperature. This makes it possible to stabilize the temperature of the heater plate in a short time.

Owner:DENSO CORP

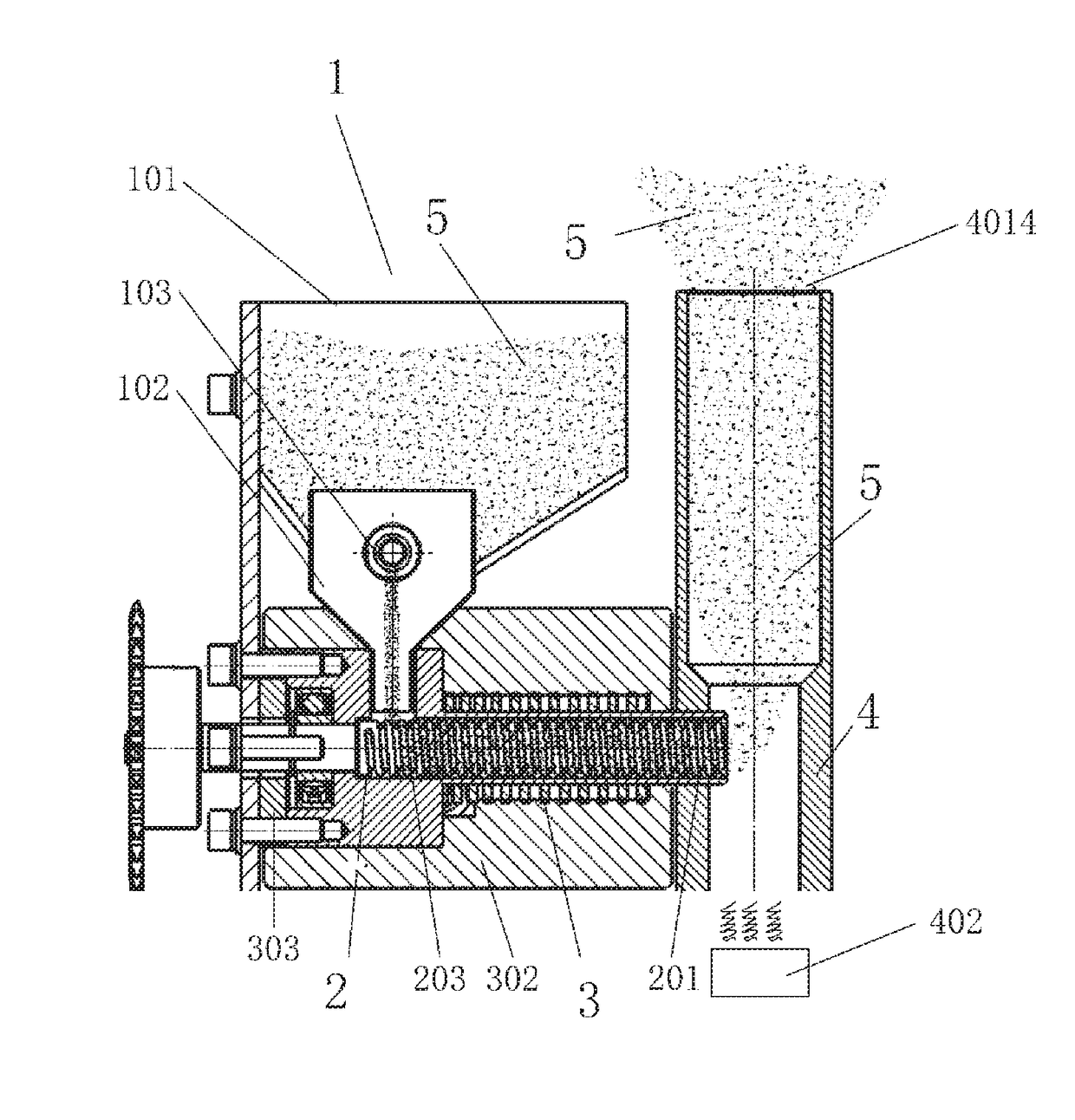

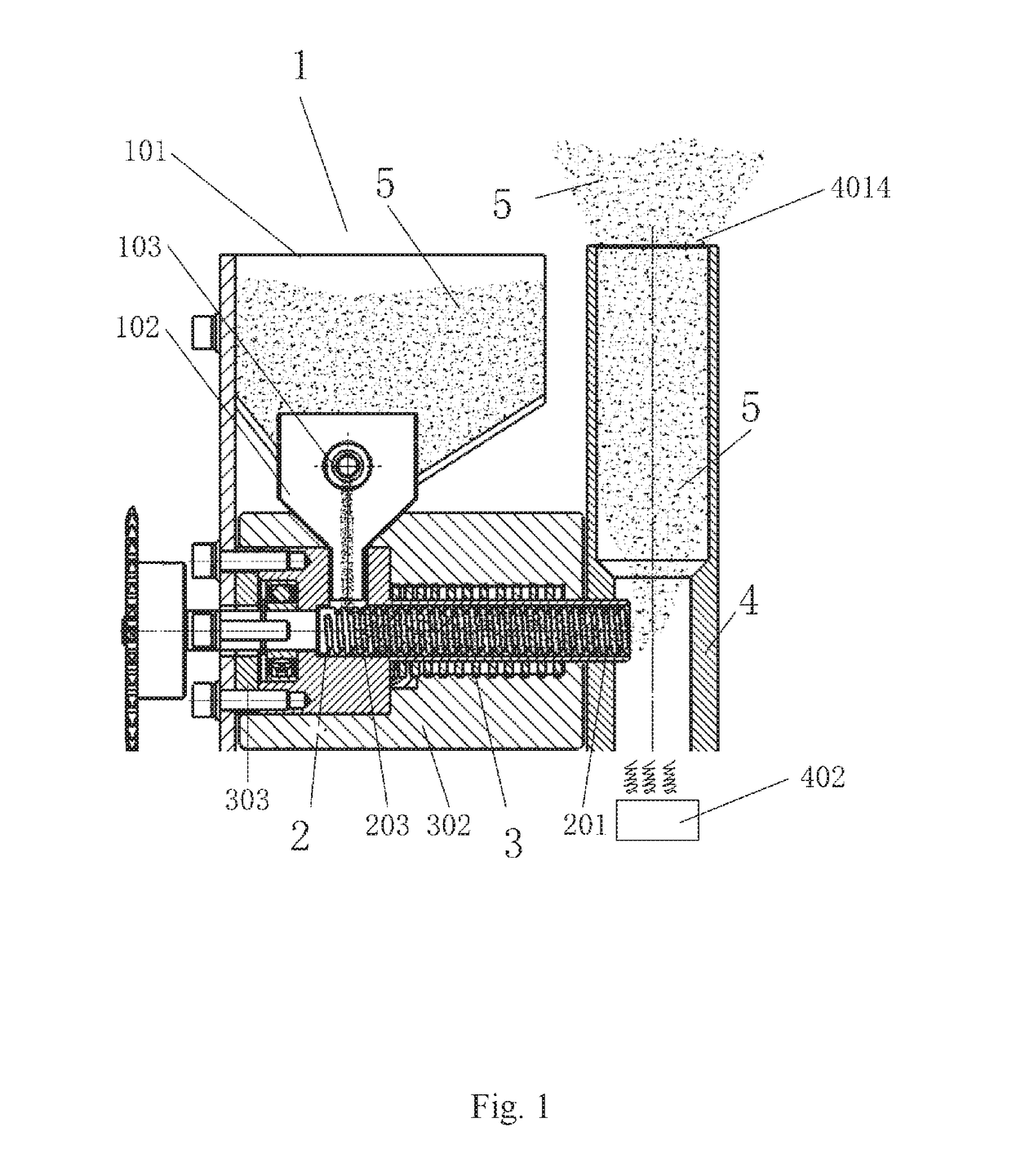

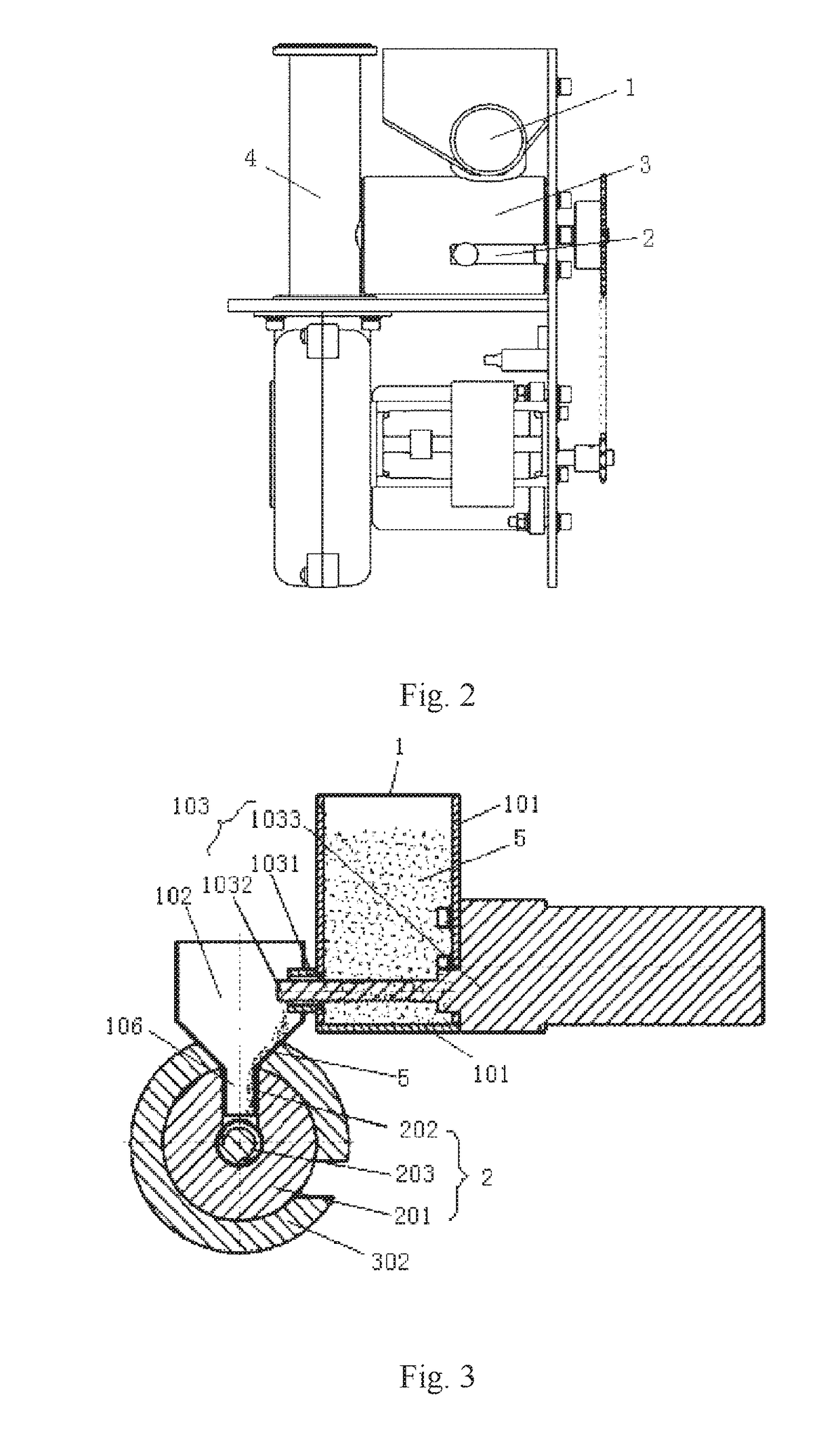

Cold firework spurting apparatus

ActiveUS20180238664A1Convenient and stableGood effectFirework simulationsFirework flares/torchesFireworksEngineering

The present disclosure provides a cold firework spurting apparatus, comprising: a feeding device; a conveying device; a heating mechanism; and a spurting device configured to ignite and spurt the metal powder heated by the heating mechanism, wherein an output end of the feeding device is open to the conveying device and an output end of the conveying device is open to the spurting device. Accordingly, the metal powder inside the conveying device is continuously heated by the heating mechanism attached to the conveying device during the conveying process such that the metal powder is constantly heated during the conveying process so as to form the metal powder ignited at high temperature. The ignited metal powder at high temperature is led and spurted outwards by means of an air flow formed by the spurting device so as to form a spurting effect of cold firework.

Owner:SHOWVEN TECH CO LTD

Multi tube-fins liquid-air heat exchanger and methods

InactiveUS20110042037A1Significant conservation of building space besides energyMany timesSemiconductor/solid-state device detailsSolid-state devicesShortest distanceEngineering

A secondary refrigerant fluid is cooled or heated in the operation of a multiple Tube-fins heat exchanger arranged in parallel for fins to conduct heat transfer with air being propelled by a multi-row bank of low profile brushless fans. Fluid is controlled to ascend the bank of tubes in unison rate for high efficiency heat transfer with air. Large temperature differential exists between air and fluid when conditioned fluid travels through the tubes for a relatively short distance. A system of components is so arranged that the fluid flow rate to every heat exchanger is preset and the “on” or “off” operation of any heat exchanger does not affect the flow rate destined for other heat exchangers. Fluid is not transported to a heat exchanger when it is not in operation saving energy. Each heat exchanger is controlled by an integrated thermostat so occupants can set the air conditioning operation individually independent of all other heat exchangers.

Owner:PUN JOHN YENKAI

Bread maker

InactiveUS7275479B2Simple sealing structureImprove productivityDoors for stoves/rangesDomestic stoves or rangesCooking & bakingEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com