Heat dissipation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

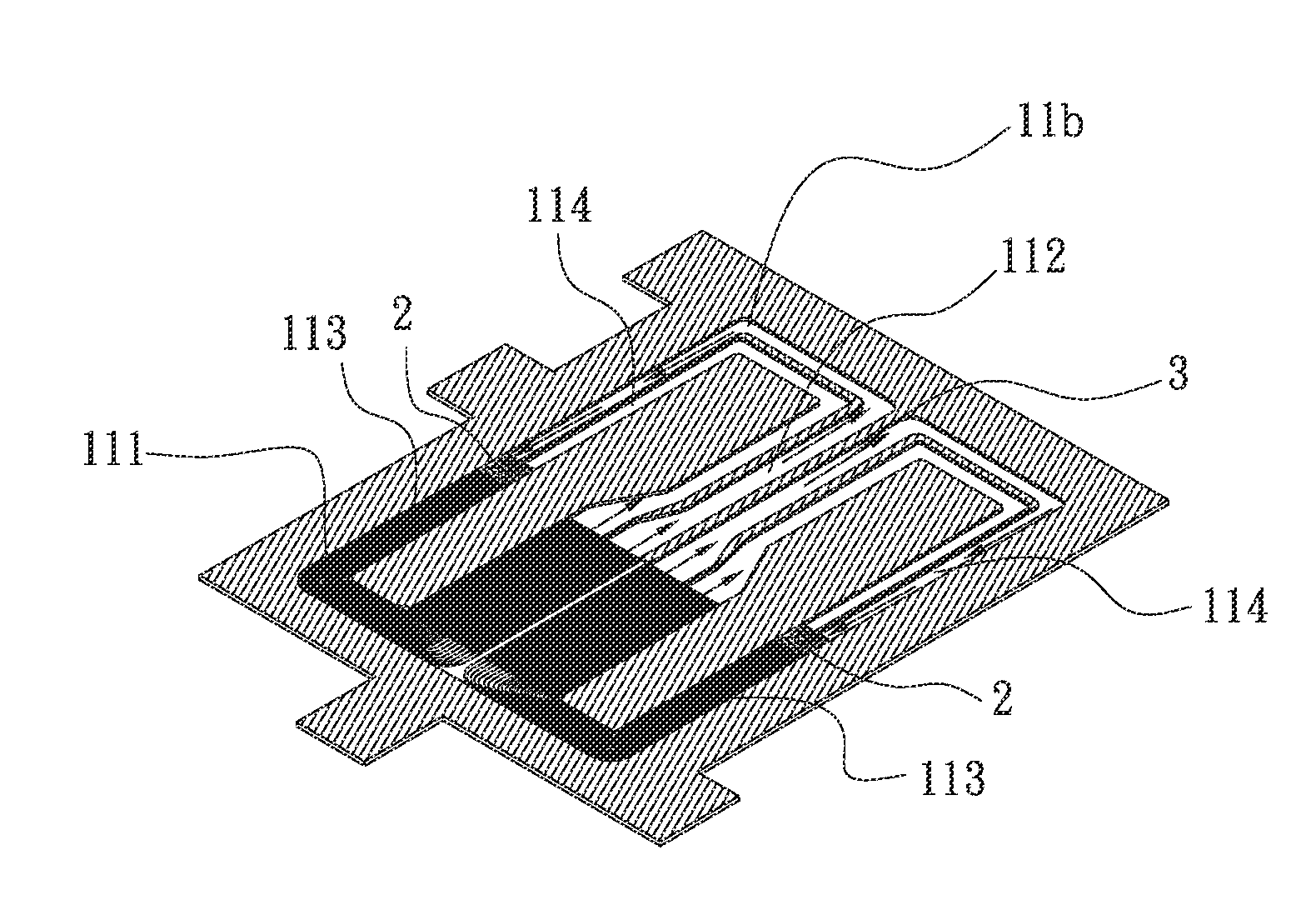

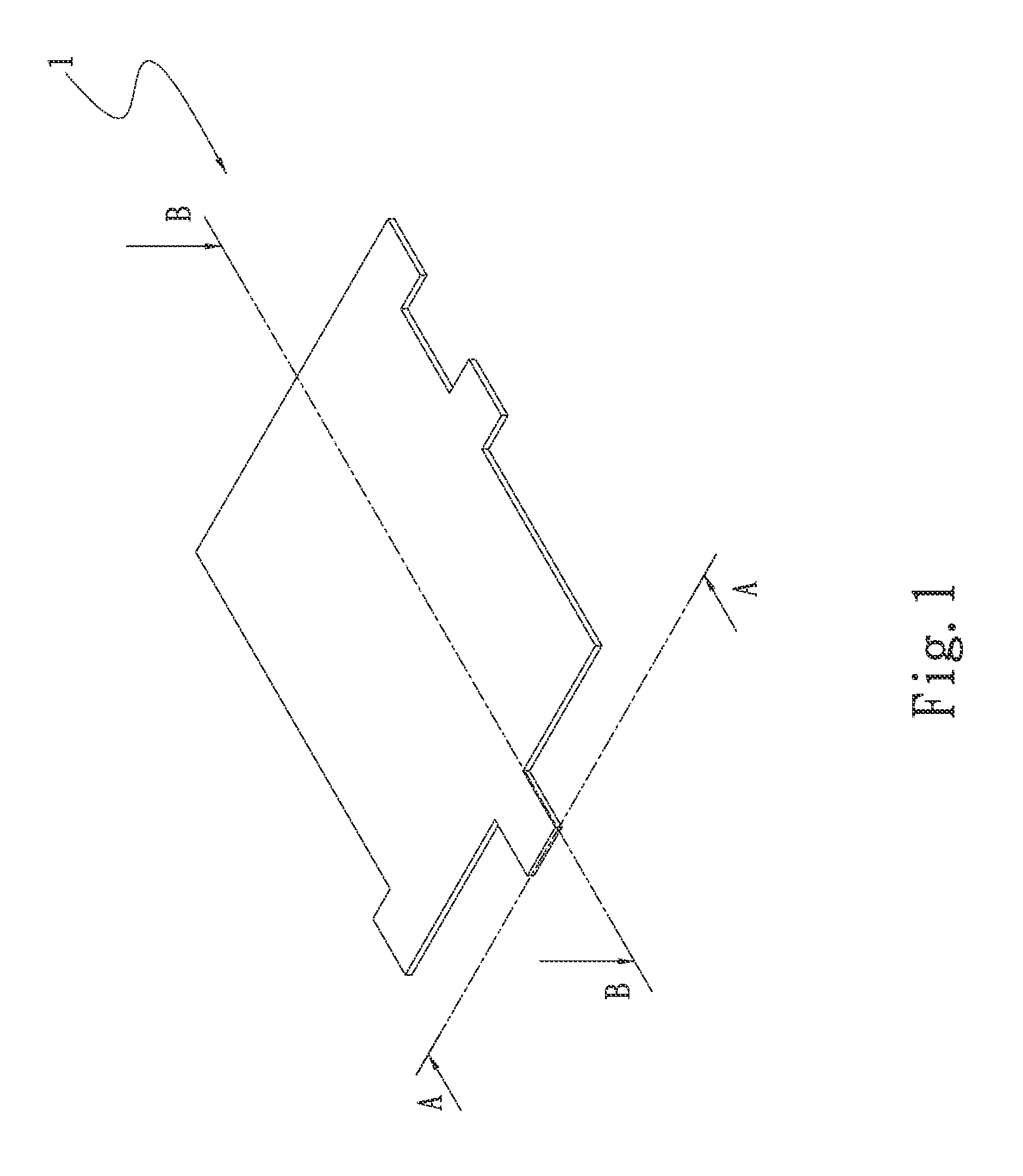

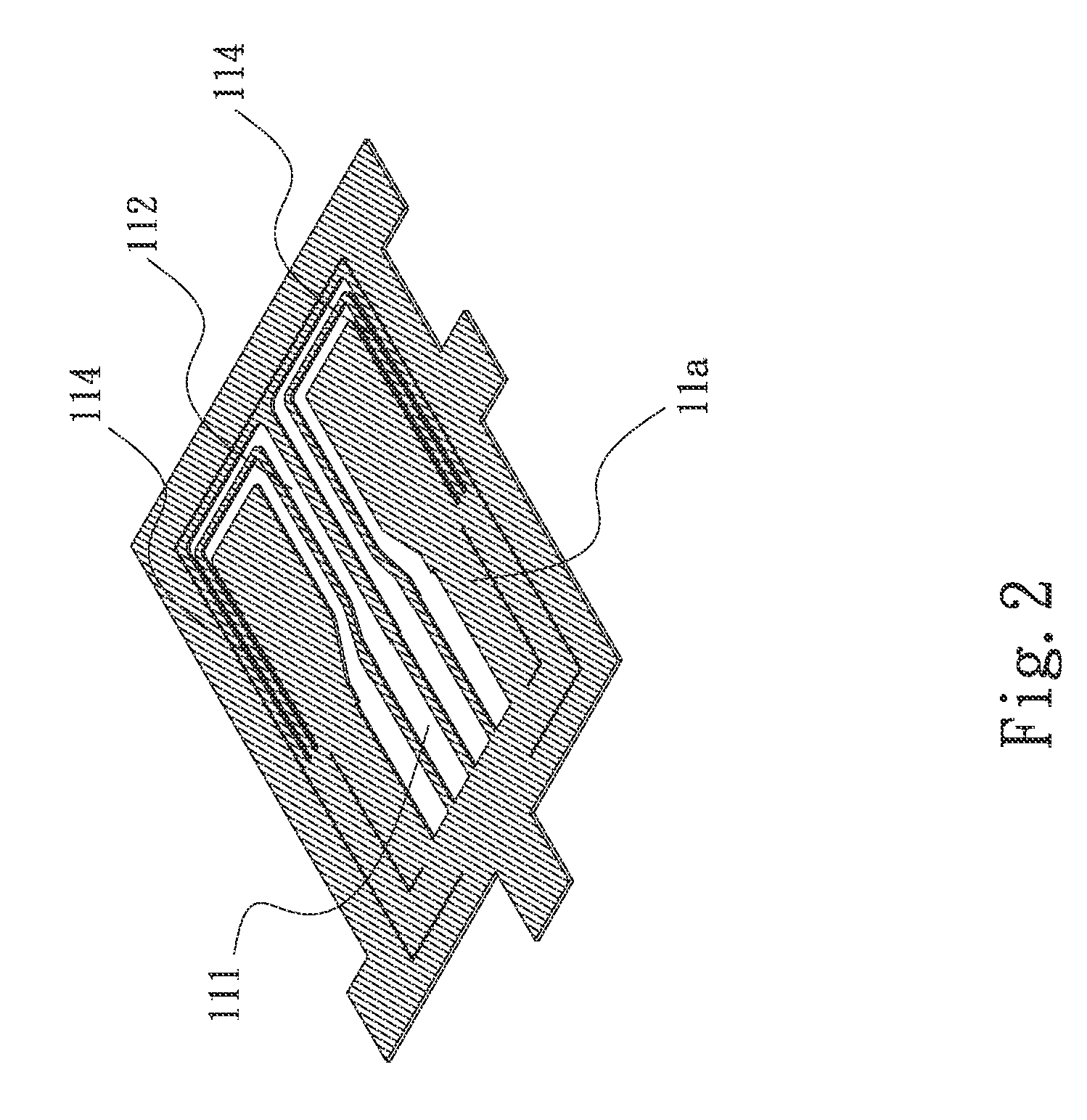

[0019]Please refer to FIGS. 1, 2, 3 and 4. FIG. 1 is a perspective view of a first embodiment of the heat dissipation structure of the present invention. FIG. 2 is a sectional view taken along line A-A of FIG. 1. FIG. 3 is a sectional view taken along line A-A of FIG. 1. FIG. 4 is a sectional view taken along line B-B of FIG. 1. According to the first embodiment, the heat dissipation structure of the present invention includes a main body 1.

[0020]The main body 1 has a chamber 11 having an evaporation section 111, a condensation section 112, a first backflow section 113 and a second backflow section 114. The evaporation section 111 and the condensation section 112 and the first and second backflow sections 113, 114 communicate with each other. A junction between the first and second backflow sections 113, 114 is coated with a heat insulation coating 2. A working fluid 3 is filled in the chamber 11.

[0021]To speak more specifically, the chamber 11 of the main body has a first side 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com