Low-temperature liquid hydrogen pump and use thereof

A liquid hydrogen and low temperature technology, applied in the field of integrated low temperature liquid hydrogen pump, can solve the problems of large calorific value and small calorific value, and achieve the effect of avoiding safety problems and avoiding heat leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

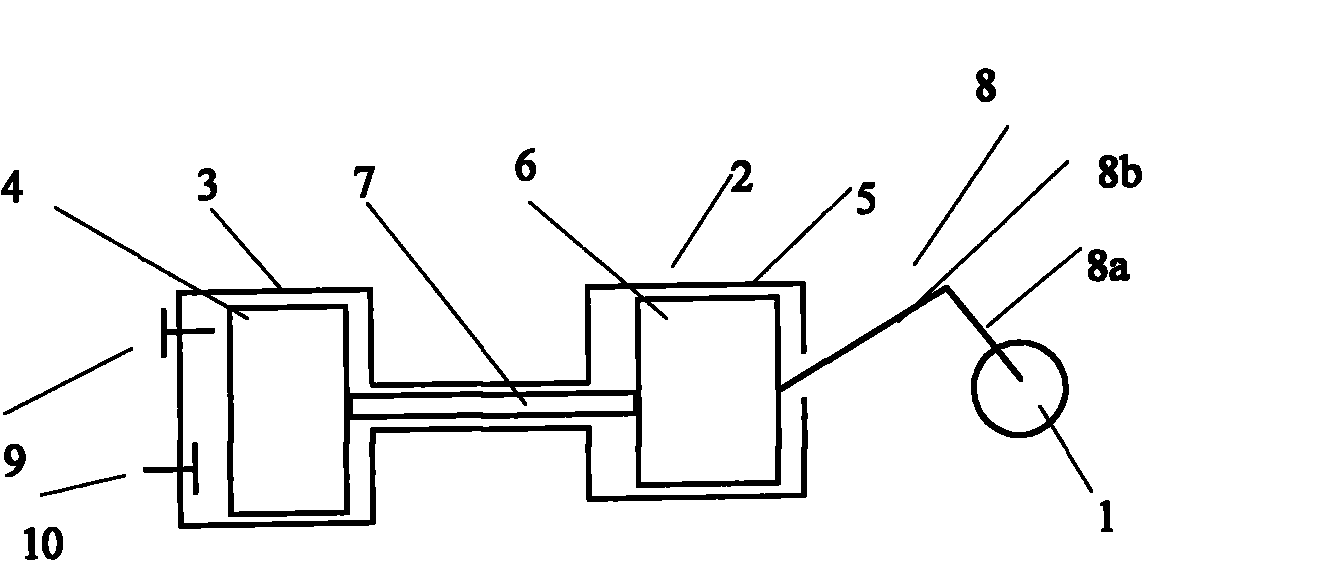

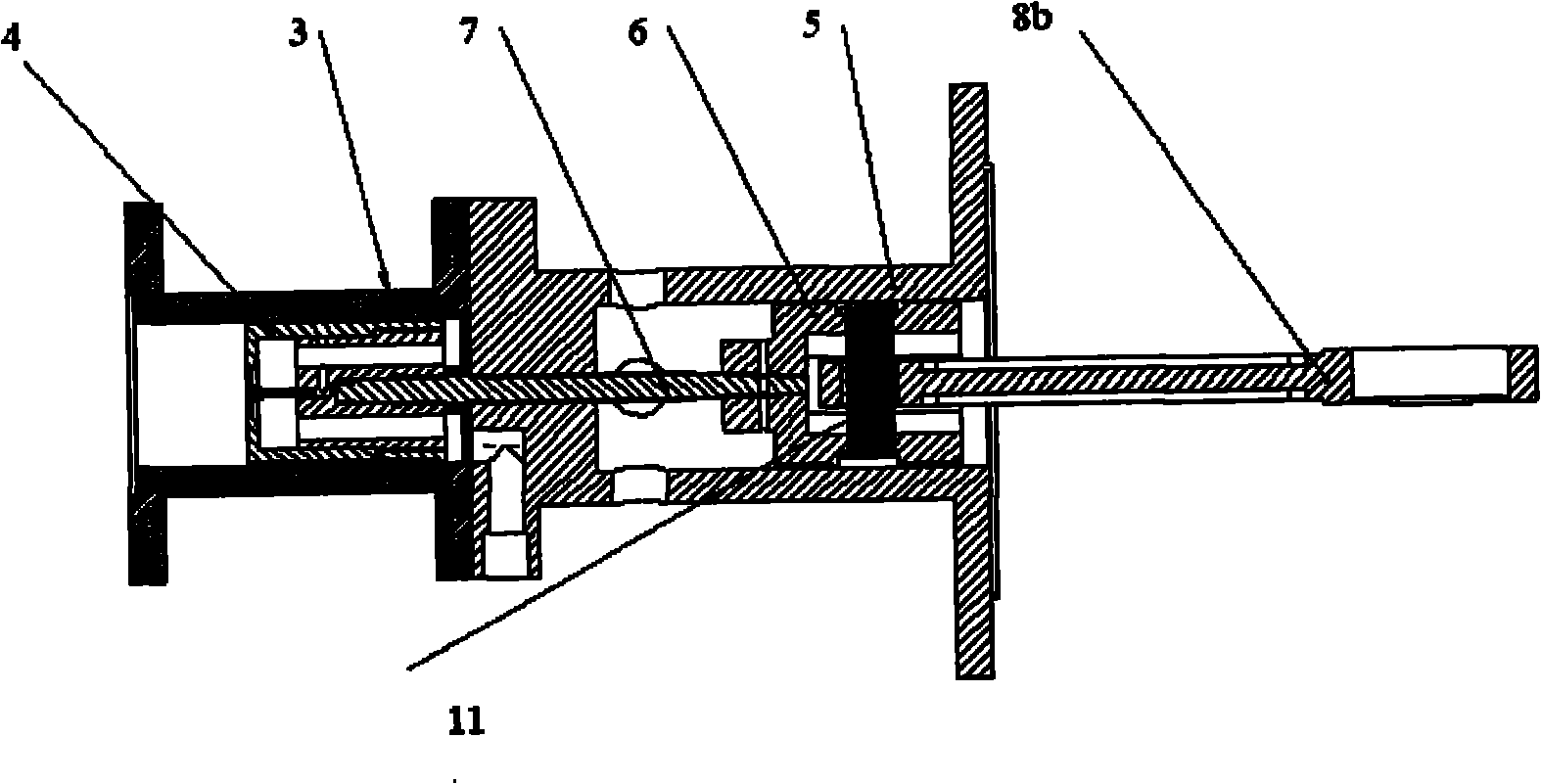

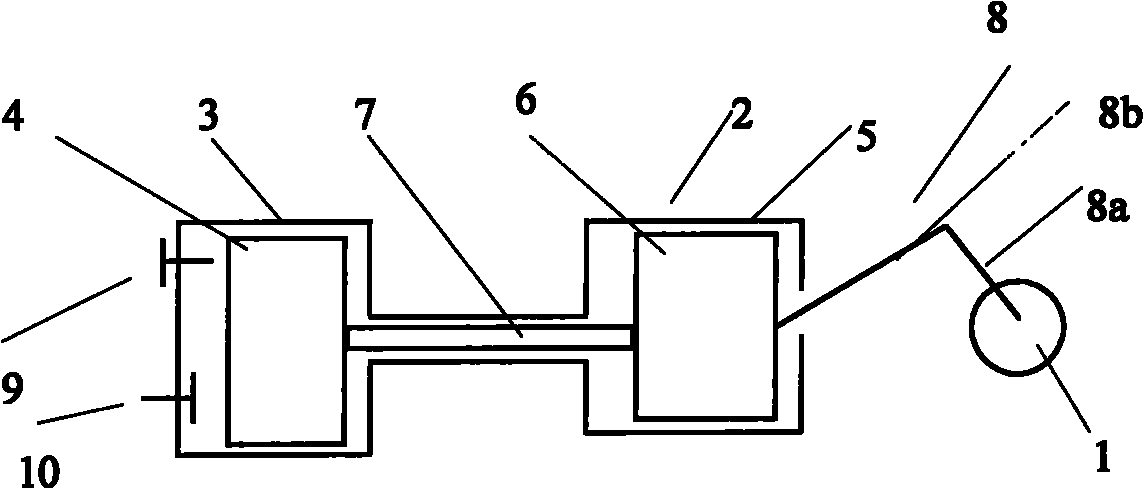

[0016] figure 1 It is an overall schematic diagram of a cryogenic liquid hydrogen pump according to an embodiment of the present invention. As can be seen from the figure, the cryogenic liquid hydrogen pump includes an electric motor 1, a working cylinder 3, and a guide cylinder 5 arranged between the two as a part of a transmission mechanism for example, and the working cylinder 3 and the guide cylinder 5 are respectively provided with a first A piston 4 and a second piston 6 are also provided with a piston rod 7 for connecting the two between the two pistons 4 and 6, wherein the motor 1 is connected to the second piston rod mechanism 8 by a crankshaft 8a and a connecting rod 8b. Two pistons 6 are connected. In addition, an outlet valve 9 and an inlet valve 10 are provided on the cylinder 3 .

[0017] Advantageously, in the present invention, the motor 1 used is an ironless motor. The biggest feature of this motor is that there is no ferromagnetic substance in the stator, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com