A superconduct magnet contactless power supply device

A non-contact power supply and superconducting magnet technology, applied in circuit devices, electrical components, etc., can solve the problems of reducing the efficiency of magnetic flux pump, magnetic flux leakage, limited application value, etc., so as to reduce the risk of quenching and improve the efficiency of energy transfer. , the effect of low output requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

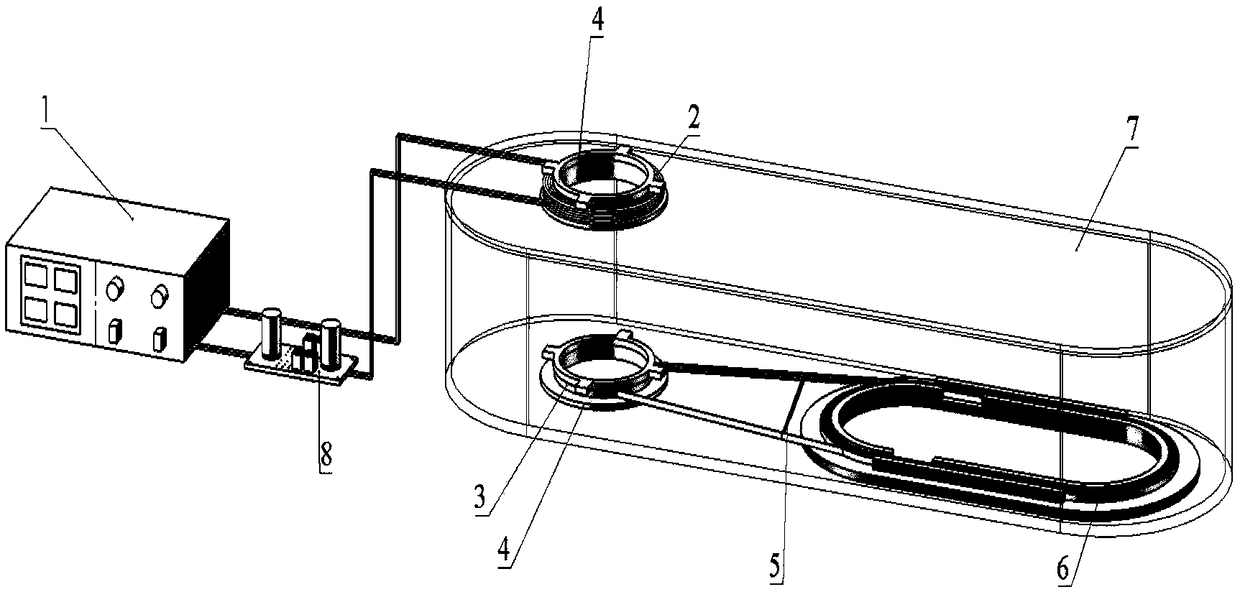

[0029] attached by figure 1 Shown, the specific embodiment of the present invention is:

[0030] The non-contact power supply device for superconducting magnets mainly consists of AC power supply 1, primary winding 2, secondary winding 3, coil frame 4, superconducting bridge 5, (power supply) superconducting magnet load 6, liquid nitrogen cryogenic container 7 and The compensation capacitor 8 is composed.

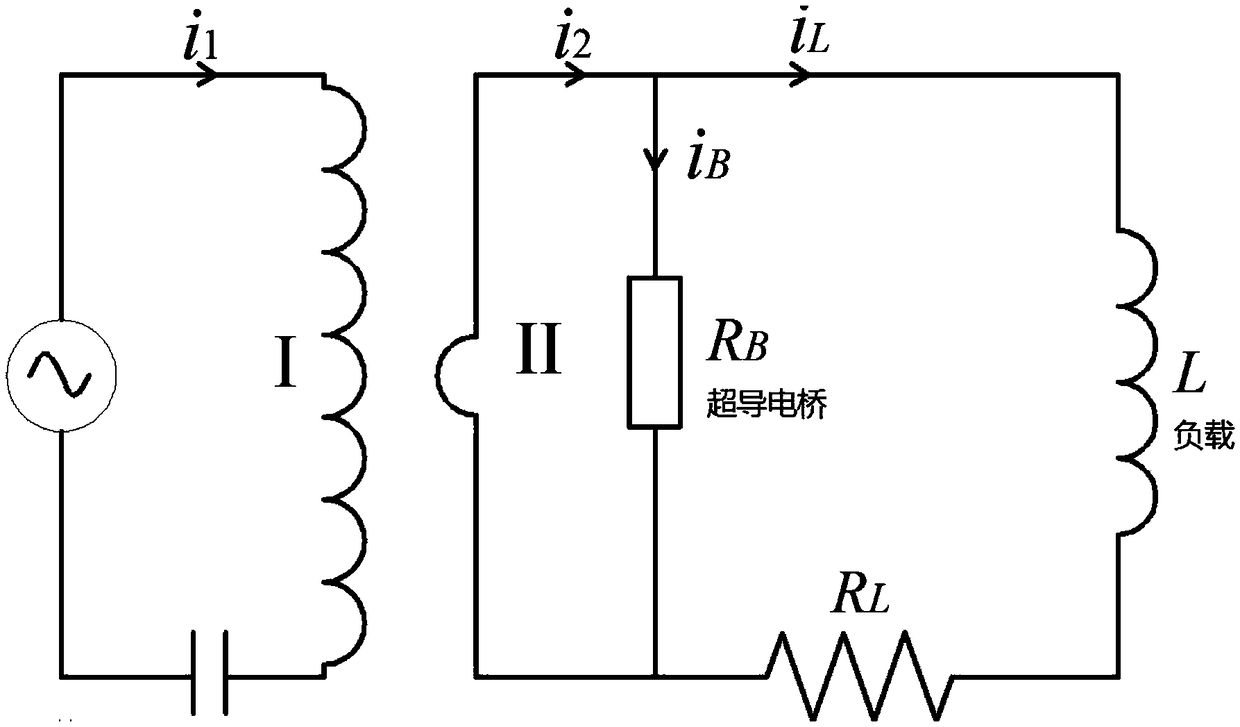

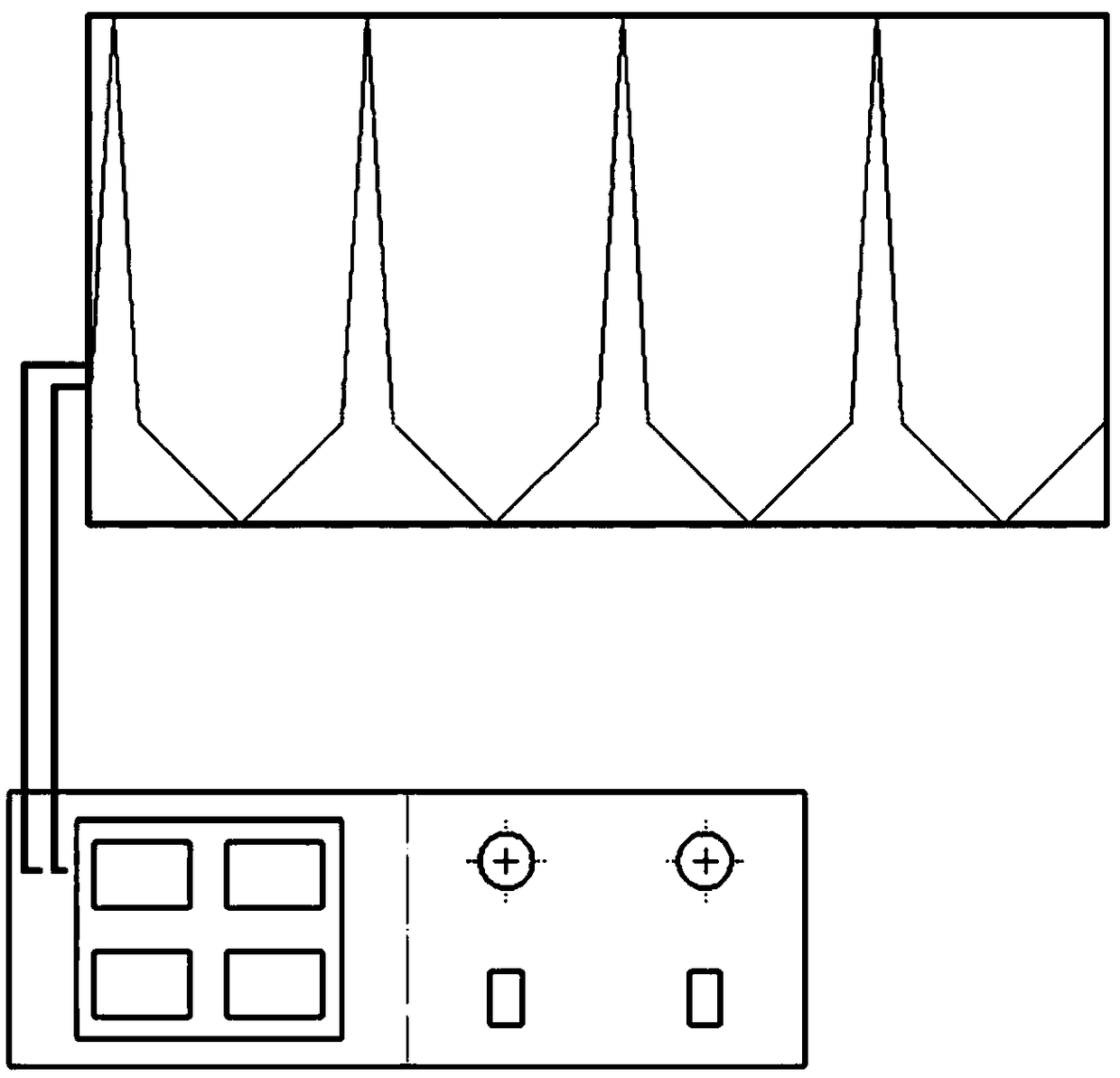

[0031] The AC power supply 1 is connected to the primary winding 2 through the compensation capacitor 8 to provide energy for the transmitter; the secondary winding 3 and the primary winding 2 perform energy transmission based on the principle of magnetic coupling induction, and the primary power is transmitted to the secondary in a non-contact manner. Winding 3; the secondary winding 3 is used as the power supply of the load 6 (superconducting magnet), and the asymmetrical triangular wave current signal is input by adjusting the AC power supply 1, and a large current is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com