Capillary pump loop heat pipe with outer space working capacity and working method

A technology of working capacity and loop heat pipe, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as overheating, evaporator leakage, heat transfer deterioration, etc., and achieve the effect of optimizing start-up performance and smooth start-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

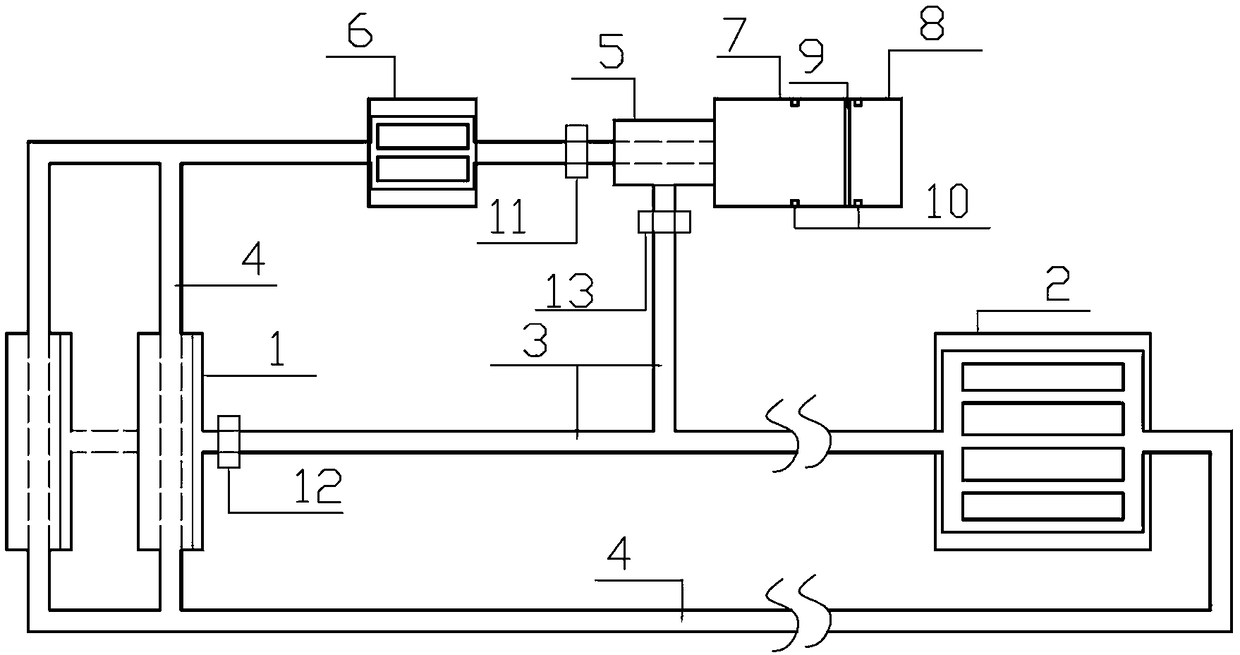

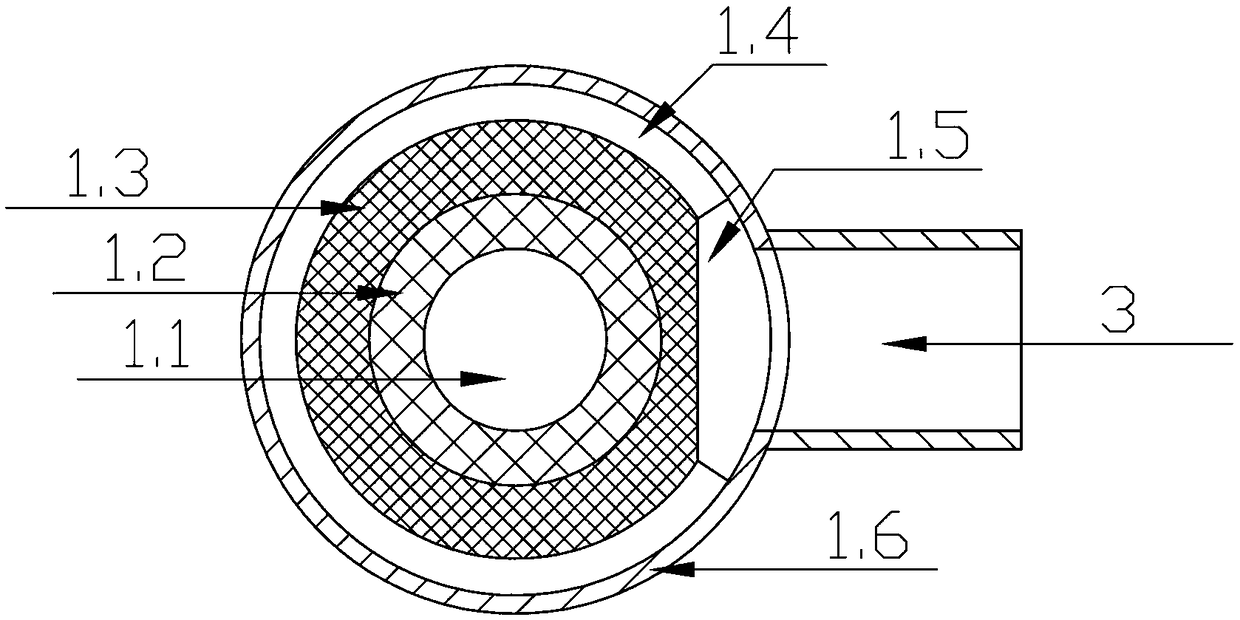

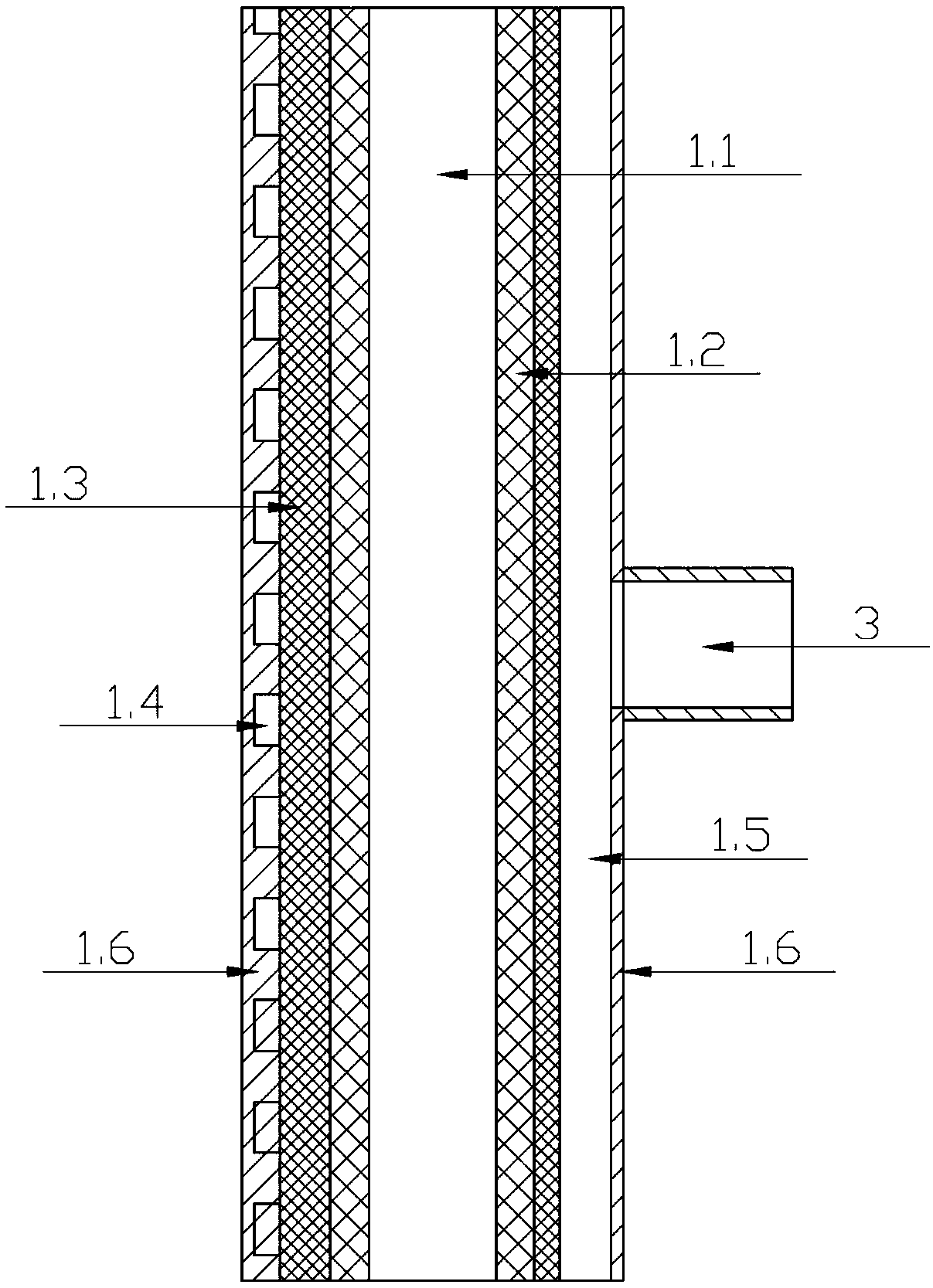

[0034] Such as figure 1 The overall structure diagram of the capillary pump circuit heat pipe shown; figure 2 A cross-sectional view perpendicular to the axial direction of the main evaporator shown, image 3 Axial sectional view of main evaporator shown.

[0035] exist figure 1 , the liquid-phase working medium enters the main evaporator 1 from the liquid-phase pipeline 1.1 of the main evaporator, most of the liquid-phase working medium is converted into steam and takes away a large amount of heat, and the steam gathers in the axial steam channel 1.5 through the circumferential steam channel 1.4, Finally, it enters the steam pipe 3 from the side of the main evaporator 1 . The steam reaches the main radiating heat sink 2 arranged in the outer space from the steam pipe 3, gradually condenses and releases the latent heat of vaporiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com