Tank for heat exchanger

a technology of heat exchanger and tank, which is applied in the direction of indirect heat exchangers, lighting and heating apparatus, stationary conduit assemblies, etc., can solve the problems of inability to detect the tank occurring at this face, the strength of the tank is greatly compromised, and the bypass leakage of heat exchange medium. achieve the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]The following is an explanation of preferred embodiments of the present invention, given in reference to the attached drawings.

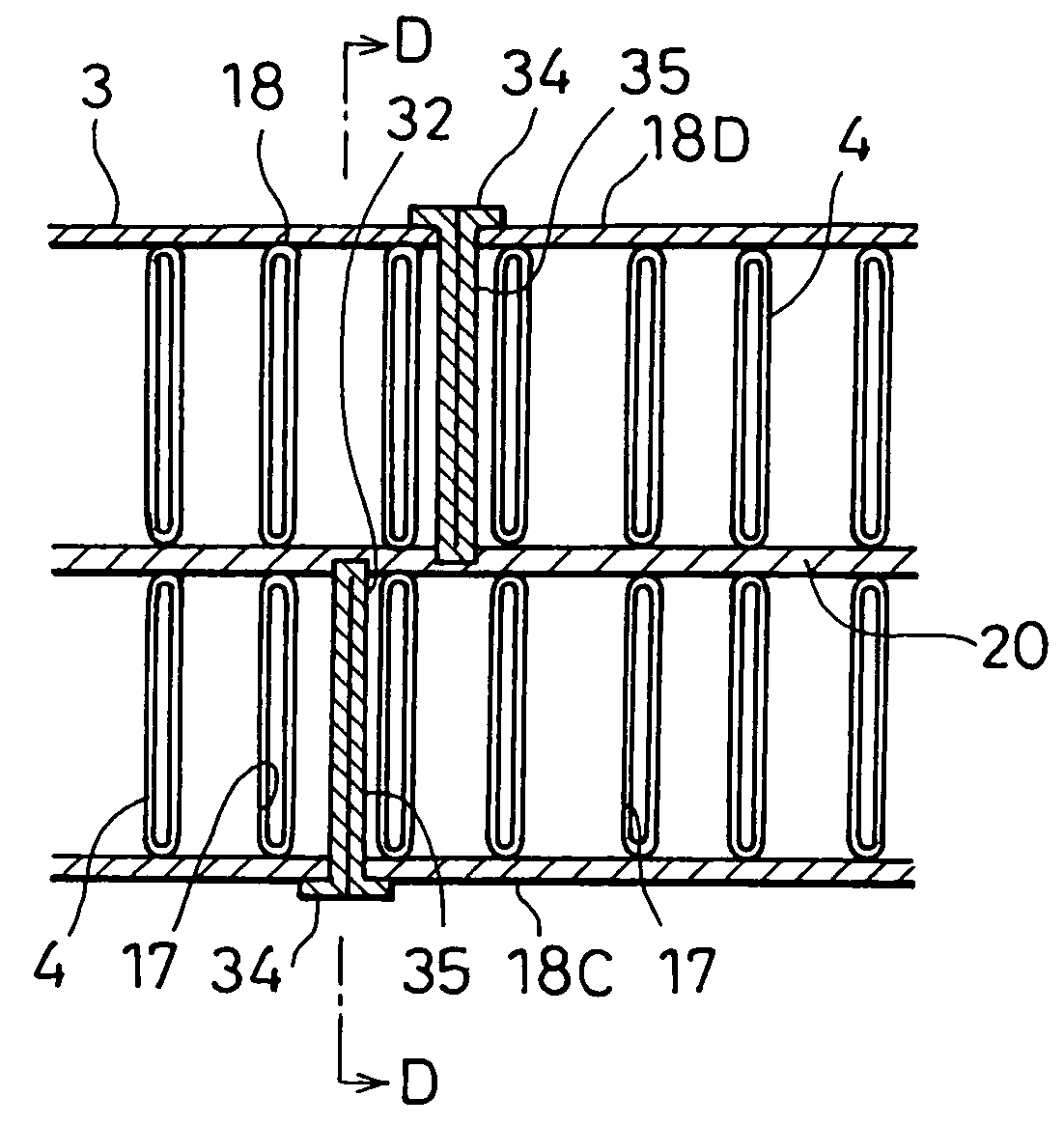

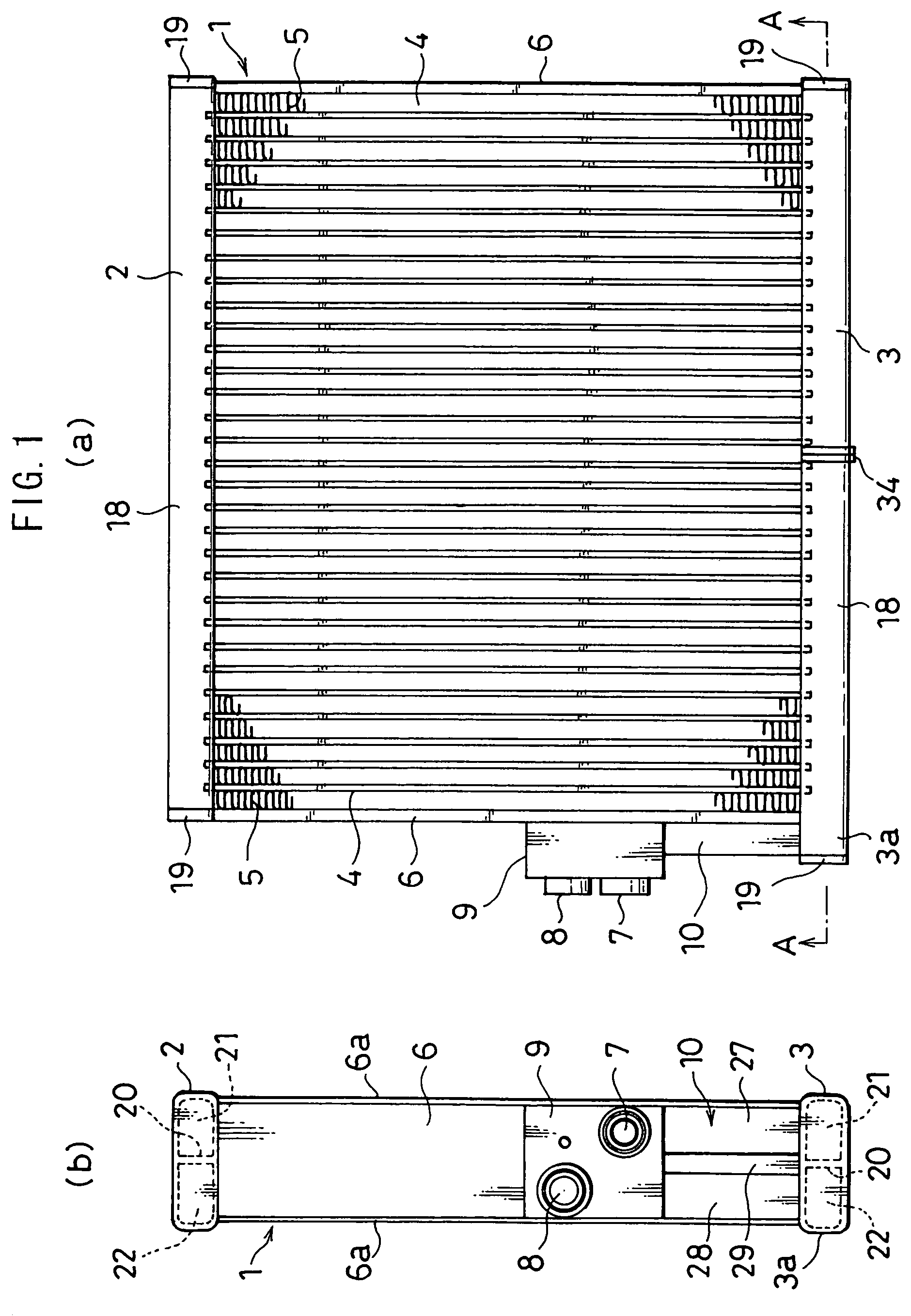

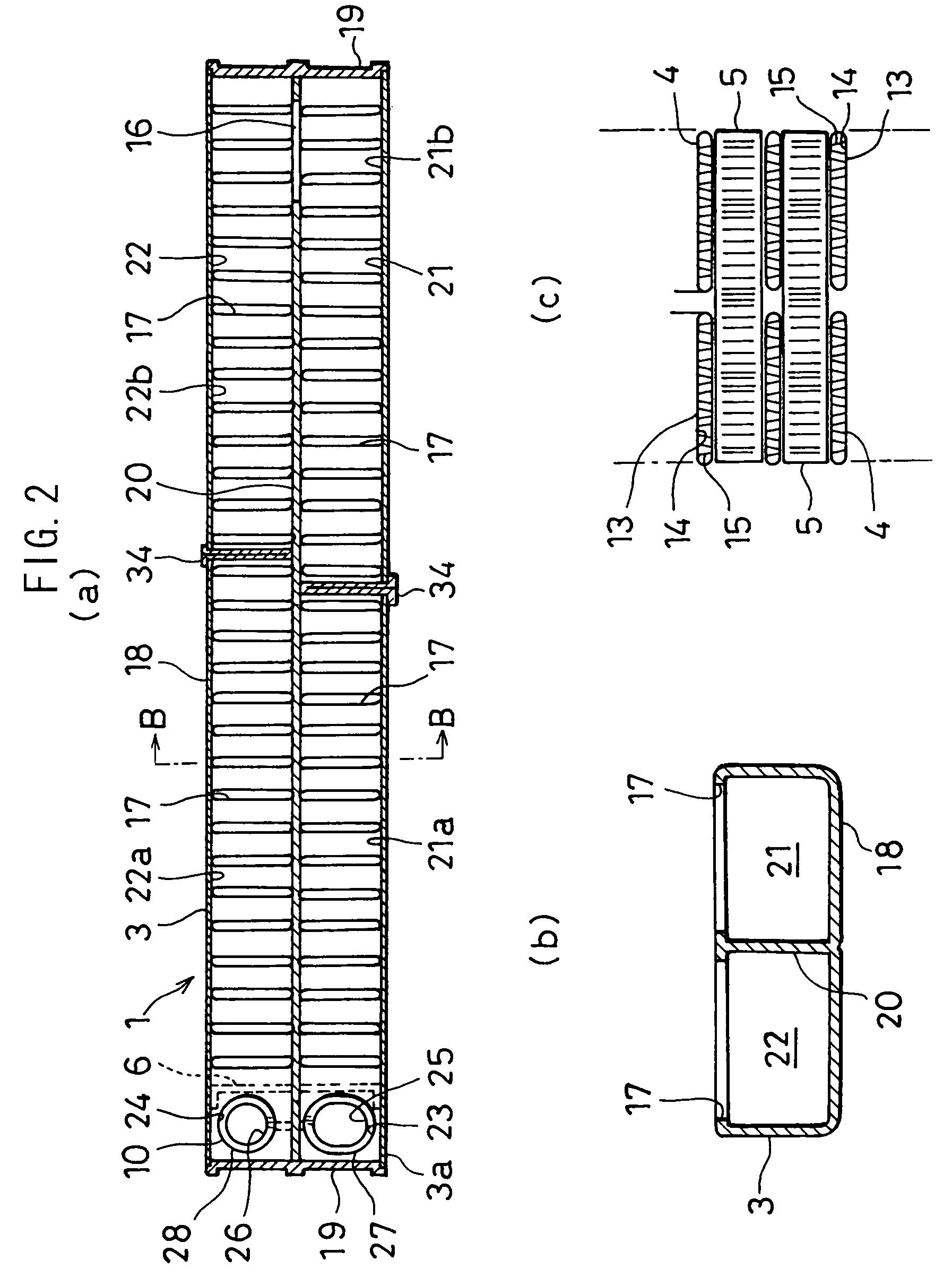

[0029]A heat exchanger 1 shown in FIGS. 1 and 2 may be used, for instance, as an evaporator constituting part of a freezing cycle of an on-vehicle air-conditioning system. The heat exchanger 1 comprises a pair of tanks 2 and 3, a plurality of heat exchanging tubes 4 communicating between the tanks 2 and 3, corrugated outer fins 5 inserted and bonded between the individual heat exchanging tubes 4, side plates 6 disposed at the two ends of the layered heat exchanging tube assembly and a side tank 10 at which a connector 9 having heat exchange medium intake / outlet portions 7 and 8 is mounted. The connector 9 is connected with an expansion valve (not shown). At the heat exchanger 1, a heat exchange medium supplied through the expansion valve (not shown) flows in via the side tank 10, the heat exchange medium then exchanges heat with the air passing between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com